Inventory management has become extremely important for larger dealer groups with tens of millions of dollars in inventory and millions of dollars at risk. But even for smaller dealerships where the dollars at stake are smaller, inventory management is still vital. And it all starts with the sale of new equipment. The best way to manage both your inventory is with a washout cycle.

New equipment market share is important for a number of reasons, and future used machine population helps fuel the parts and service “machine,” which is an essential revenue source for any dealership. Without strong absorption rates, dealerships are relying on wholegoods sales. And during a downturn, wholegoods sales suffer and margin dollars become thinner and thinner.

The Ask the Expert: Used Equipment series allows dealers to regularly ask questions and get them answered in real time. It is brought to you courtesy of Iron Solutions.

At Iron Solutions, we provide used equipment valuations, market intelligence and a suite of integrated, cloud-based business systems custom-tailored for the equipment industry. Our proprietary model is built on actual dealer sales transaction data. Learn more…

How does washout tie into all of this? Simply, all of the aforementioned dialogue is 100% tied to your ability to sell the used equipment generated from the sale of new equipment. The dealership has to have an understanding of the volume of used equipment it can digest in a given amount of time. It also must understand how this will affect cashflow, used equipment inventory turns and return on assets.

With all of this being said, I am not suggesting you stop or even slow the sale of new. Instead, I want you to understand what you are getting yourself into. How does the sale of new equipment affect current used inventory as well as future used inventory? How does the generation of used equipment inventory affect ratios and metrics at your dealership? Last but not least, what are the contingency plans in place to control these predictive outcomes?

Washout cycles are the best way I’ve found to control used inventory. I use this method when I look at used equipment inventory, both current and future. For the sake of this article I will use combines as an example.

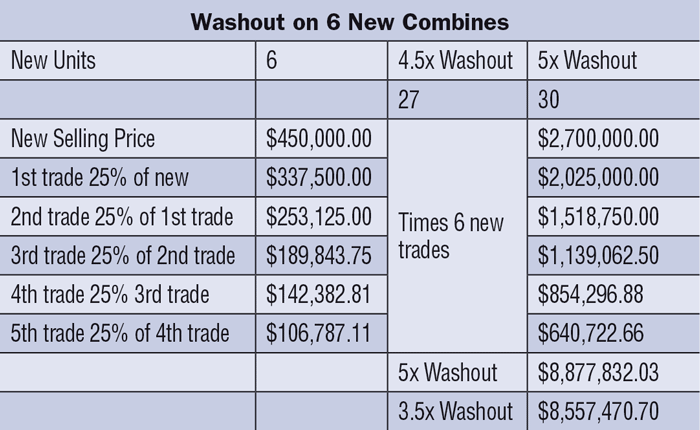

For easy math, let’s assume in a year we sell 25 new combines and, on average, sell 125 used combines. We will assume there is a 4.5–5 unit washout to get to the best three words in the equipment business — cash no trade! This means if you sell 25 new combines, then you will generate 113–125 used units. Why is this important? This helps me understand the effects this segment of used inventory has on the overall cashflow, used inventory turns and return on assets.

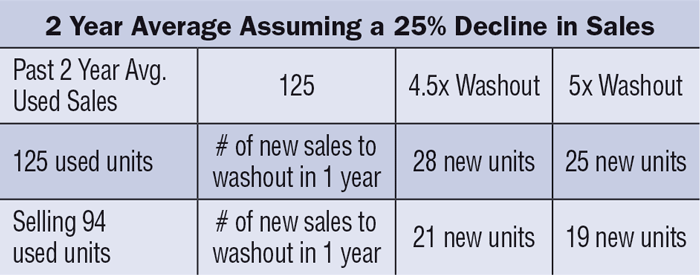

I like to take a 2-year average of used combines sales to set a baseline. Once the baseline is established, then I make adjustments based on where the market is year-over-year. For example, if the average used units sold is 125 and sales have softened by 25%, I adjust my expectations of used combine sales by 25%. This means the expectation of 125 used units will drop to 94.

What happens if you sell 25 new combines and the used combine market falls off by 25%? It’s only 6 more new combines, right? What’s the big deal?

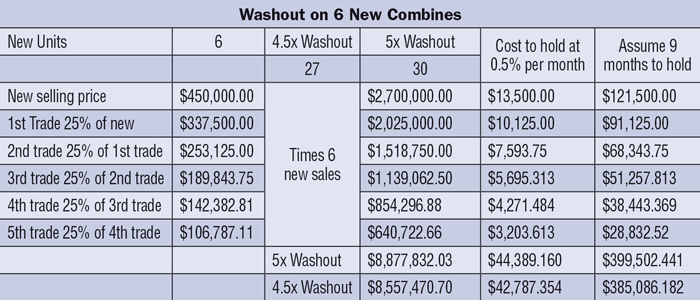

It sounds sweet and innocent, but it’s a bigger problem than it appears. These combines have the potential to sit in your inventory for a prolonged amount of time. These are the combines salespeople call about asking what they can sell them for since they have been in inventory for so long. If you don’t believe me, take a look at your inventories. I am as guilty as the next guy. The next question I ask is what do the effects of these 27-30 combines have on cashflow, used equipment turns and return on assets.

Unfortunately, in this business an overwhelming amount of dealership cash is tied up in used equipment. Now, I know that’s not a shocking revelation to anyone reading this, but what does this cost? Depending on the floorplan amount, these combines could be costing the dealership $1,000 per month in interest alone. This does not account for any depreciation or the infamous “lot rot.”

By looking at these machines, it is easier to assess the risk associated with selling new when you know and understand the washout cycles for equipment segments. It allows for planning the worst case scenario and the effects the outcome will have on used equipment turns, margins and return on assets. This is risk management and this is what remarketing managers do — manage risk!

I will leave you with one last thought. No matter the emotional attachment to a deal or “How good of property” a machine will be, it is an inanimate object. It doesn’t understand the time, value of money, margin, equipment turn or assets return. It doesn’t care! Have a plan and move forward. Even when it hurts, you will feel better in the long run.

Related Content

-

The Washout Cycle — A Better Way to Manage & Sell Used Equipment

Casey Seymour swears by this strategy for managing used — and new — inventory for the best cashflow.