Since the dawn of time, man has continually used his ingenuity to develop and perfect the tools needed to feed and clothe himself and those around him.

From soil-scratching sticks to the mechanization era in the mid-1800s to the chemistry era after World War II to today’s precision age that automatically guides high-powered tractors and combines, farm equipment has evolved through the ages to meet the food, fuel and clothing needs of the earth’s ever-growing population.

This timeline is a small excerpt of a much larger “Timeline of Ag Equipment Firsts” research conducted by Frank and Mike Lessiter and their staff over the last 15 years. Their larger timeline work spans from 5500 B.C. to the present, while the pages of this insert recap key innovations and industry developments over the last 55 years that Farm Equipment magazine has been published. A new generation of Farm Equipment subscribers do not know production agriculture without the use of GPS.

We’re aware that with each proclaimed “first” comes debate, and you’re welcome to engage in that debate. For comments, questions or discoveries, email mlessiter@lessitermedia.com. Special thanks to our “seasoned veterans” who reviewed the 2023 document, including retirees Paul Wallem, Randall Reeder and Lars Paulsson and B&G Equipment’s Tim Brannon and Exactrix’s Guy Swanson.

Click here for the complete Timeline of Ag Equipment ‘Firsts’

1969

- Kubota Corp. introduces its first tractor to the U.S. (L200 21-hp subcompact) to near-overnight success. Kubota Tractor Corp. is formed in 1972 to expand its penetration of the U.S. market.

- Rekord Sales of Atherstone, England, develops the first commercially successful straw chopper attachment for combines.

- Servis-Rhino patents the first 4-gearbox, flex-wing rotary cutter. The Flex 15 enables the wings to be raised without damaging the drivelines.

- Ace Pump Corp., Memphis, Tenn., introduces the first close-coupled hydraulic motor-driven spray pump.

- Oliver, Minneapolis-Moline and Cockshutt merge to form White Farm Equipment. In 1975, the 3 brands will be folded into the White brand.

- Avery Weigh-Tronix invents a weigh bar for the Art’s-Way grinder mixer. Patented in 1972, it revolutionized grinder technology, allowing a farmer to accurately weigh and dispense feed rations to different groups of livestock.

- The Loesch brothers of Kimball, Minn., develop a new approach to accurately plant any crop, regardless of seed size without having to change plates on each seed hopper. The air-assisted seed metering and central distribution design revolutionized planting and led to the introduction of the International Harvester (IH) Cyclo planter in 1971.

- Don Landoll, Landoll Corp., invents the first traveling axle trailer.

1970

- Melroe Manufacturing introduces the quick-attach system known as the “Bob-Tach” implement system.

- French-based Nodet introduces a vacuum planter that allows planting of virtually any crop with precision seed depth and spacing accuracy at speeds up to 8 mph.

- Specialized manufacturers like Hiniker and Year-A-Round build aftermarket cabs for all colors.

1972

- HDA Design and Chuck Pelly develop the Sound Gard cab, used in John Deere tractors from 1973 to 1994.

- Gleaner introduces the first electric-

over-hydraulic controls for combines. - The first plastic bag silage storage system is released in the U.S. by Ag-Bag Corp. Inventors Larry Inman, Ronald Garvin, Patrick Welch and Michael Koskela will receive a patent in 1995.

- Kuhn develops the disc mower hay cutting technology.

- Gary Vermeer designs and introduces a modern baler to produce “big” round hay bales. The first model formed a 6-foot wide by 7-foot diameter bale that weighed more than 2,000 pounds and would spur a manufacturing company in his name.

1973

- Ag-Chem Equipment Co. introduces the first 3-wheel applicator for fertilizer and other crop protection products. The TerraGator features high-flotation tires to minimize compaction.

- Telehandlers for use on farms are developed by Matbro in Horley, England, based on articulated cross-country forestry forklifts.

1974

- John Deere introduces its MaxEmerge plateless planter with finger-pickup seed metering, Tru-Vee openers and angled closing wheels.

- A.O. Smith Harvestore introduces the SlurryStore, an above-ground glass-fused-to-steel liquid manure tank containing pumps and agitation equipment. As the cost of chemical fertilizers rose, the nutrients in manure become even more valuable to the farmer.

- According to Charlie Glass, the U.S. has about 15,000 farm equipment dealers, each with an average customer base of 154 farmers. It is not uncommon to enter a county seat town and find 4 or 5 farm equipment dealers.

- Mort and Guy Swanson of Washington build a 29,000-pound no-till drill known as “Old Yeller.” A patent would be filed in 1975. Later, the Swansons team with Mike Johnson and Pete Thomason to build the Comfort King, the first successful no-till drill for the deep Palouse soils of Idaho, Oregon and Washington.

1975

- Kinze Manufacturing Inc., Willamsburg, Iowa, invents the rear-fold planter that led to acceptance of 12-36 row planters. The horizontally-folded planter leads to wider planters that farmers can move down narrow roads and bridges.

- Ohio no-tiller David Brandt imports a Moore seeder from Ireland, the first known no-till drill in the U.S.

- Valmont Industries develops center pivot irrigation equipment designed to cover corners, square and irregular-shaped fields.

- Dealers in the Red River Valley of Minnesota and the Dakotas report a shop rate of $17.50/hour with a reluctance to raise it. By 2023, most shop rates are in excess of $140/hour.

- New Holland is the first OEM to release a rotary combine (twin rotors) with its TR70.

1976

- Kinze introduces its 24-row, rear-fold planter frames, allowing farmers to double planting capacity. “John Deere was selling planters by the unit at the time, so farmers could put their own planting systems together,” recalls Ohio farmer Bill Richards, who credits the efficiency achieved from a 60-foot no-till planter for allowing him to expand to 8,000 acres in the ’80s.

- SprayTarget Co., Rosemount, Minn., develops the wet lime spreader.

- EPA approves Roundup, providing farmers with new non-soil disturbing options for weed control.

- Ag-Chem introduces a 5-wheel self-propelled ag chemical and fertilizer applicator, nearly twice the size of the original model to meet the needs of growers with larger acreages.

1977

- IH introduces its Axial-Flow (rotary) combine, which handles threshing and separation via a rotor and at significant productivity gains vs. the drum and straw-walker models. It was the first to be mass-produced.

- Valmont produces the first linear center pivot irrigation system.

- MacDon introduces the Hydro Mac self-propelled hydrostatic transmission windrower.

- Versatile introduces the Versatile 150, the world’s first bi-directional tractor. The first “push-pull” tractor is marketed as a “number of self-propelled machines in one.” The seat and console of the tractor swivels 180 degrees within the cab, full-time hydrostatic drive to all four wheels and articulated steering.

- Howard and Brian Dahl introduce small grain air seeding equipment with their Concord air drill, the first company to feature row-by-row packing and precision depth control. It’s the first air seeder to place fertilizer below the seed while planting, while changing seeding and fertilizer rates on the go.

1978

- Hesston introduces the industry’s first “large square” baler, offering significant efficiencies over smaller bale sizes.

- John Deere introduces its first commercially successful no-till planter, the 7000 series

- Cummins introduces the Constant Power Concept for 4WD tractors, giving farmers more tractive force under field conditions that run the engine below its rated operating speed.

- JCB introduces the Loadall telehandler.

- Orthman designs the disc stabilizer, a rigid disc with hydraulics that will pivot on command. This leads to the introduction of the Tracker, which was the industry’s first ground-engaging implement steering system.

1979

- Claas develops the first row-sensing, auto-pilot technology for combines produced for Ford. Fingers mounted on the header are directly connected to the combine steering system. The manufacturer also develops folding combine grain tank doors on equipment built for Ford.

- Raven’s sprayer controller developments bring precision to pesticide application. It accurately measures the flow of pesticides with the ability to shut off individual sprayer nozzles.

- Gleaner introduces the first 12 row 30-inch corn head.

1980

- A “perfect storm” commences for equipment dealers, with 21% interest rates, drop in farmland values and the grain embargo, recalls Paul Wallem. Sales of North American farm equipment fall 50% from 1979 as a result of the economic downturn, leading to a plummeting of dealerships over the next 6 years.

- Monosem (formerly Advanced Technical Implement) introduces vacuum planters, a new method to accurately place seeds at a higher, more uniform plant population than with mechanical or air pressure systems.

- Hydro Engineering is the first company to apply manure with a pumping unit to propel manure through a hose system for injection into the soil.

- John Deere produces a 4-row cotton picker, the first in the industry. The unit increases operator productivity by 85-95%.

- Washington’s Mort and Guy Swanson launch the Yielder No-Till drill, the first fertilizer placement drill with a paired row designed for no-till in the Palouse and Great Plains.

- The Alfa Laval Rationmaster Feeding System (with use of transponder for automatic data identification) allows dairymen to house cows as a group, yet feed them as individuals based on production, stage of lactation and body condition.

- Haybuster introduces the balebuster that allows operators to grind and more efficiently distribute hay bales. It automates range feeding, bunk feeding, bedding, erosion control and odor control on wastewater lagoons.

- Loral (AgChem) introduces Air Spread and AirMax boom-type, truck-mounted fertilizer spreaders with air-boom delivery as an option vs. spinner-type spreaders. The Air Spread was patented in 1984.

1981

- Kinze introduces its double frame planter for seeding corn or soybeans in 15-inch rows. By positioning planter tires between two toolbars, the front toolbar can be used for fertilizer while mounting side-by-side row units on the rear bar.

1982

- John Deere’s annual sales reach $3 billion under the leadership of William A. Hewitt, who took over in 1955 when the firms’ sales were $300 million.

1983

- Kinze introduces its “push-type” planter row unit mounted to the front of its double frame toolbar. Allowing growers to “split the rows,” the Interplant system offers a precision alternative to seeding soybeans with grain drills for narrower row soybeans. Growers can plant corn in 30-38-inch rows with this planter, then quickly switch to 15-19-inch soybean rows by engaging the “push” units.

1984

- North Dakota farmer, Ardon Herman, develops the Diamond disc blade to reduce breakage due to rocks. The diamond shape allows the unit to “float easily over rocks.” Summers Manufacturing, Maddock, N.D., manufactured the blade.

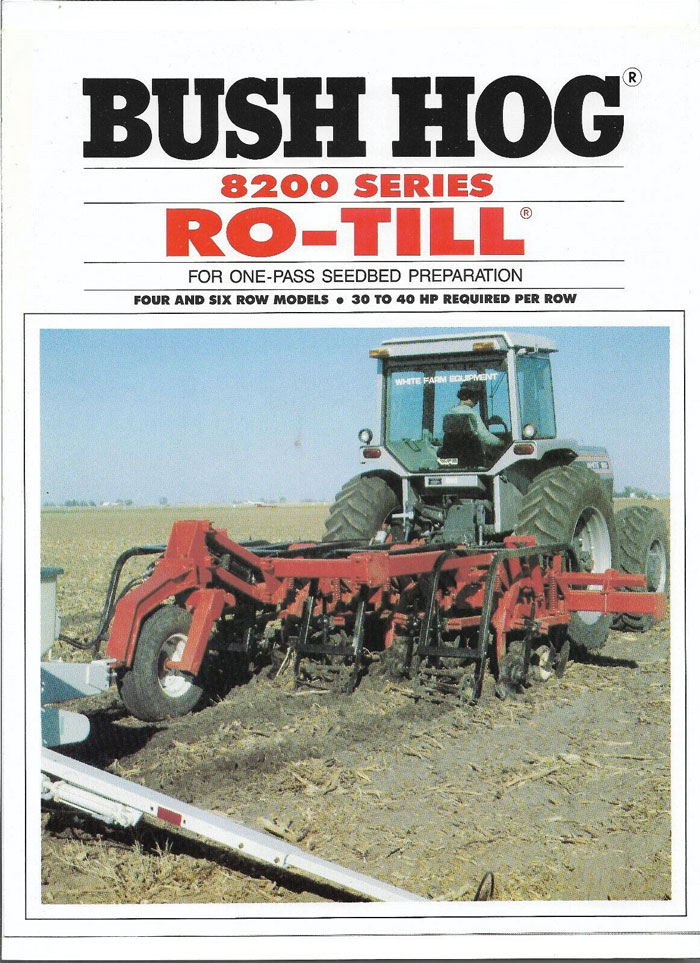

- The Bush Hog Ro-Till (developed by Leo and Jerril Hardin in the mid-1970s and marketed in the South under the name of Brown-Hardin) hits the market. Marketed as “Precision Applied Tillage (PAT), it will be considered the forerunner of strip-till rigs. The row-till unit deployed a coulter, a parabolic ripper with heavy limiters to hold down the big chunks, followed by discs and rolling baskets to form the ridge.

- Tenneco purchases IH’s agricultural equipment division.

1985

- Claas develops net wrap as an alternative to twine for round hay bales. It decreases hay losses and aids in retaining hay nutrition during storage.

- The prototype of the Willmar AirRide self-propelled sprayer is unveiled. The new model fits the need for a North American-built, high-capacity, self-propelled, high-clearance sprayer. The unit featured a 100-foot boom, 118-horsepower engine, 4-wheel hydrostatic drive, and a convertible chassis to accept a liquid or granular applicator.

- Case and IH merge to form Case IH.

- The Kinze Twin-Line planter allows raising and rotating of the planter frame into a lengthwise transport configuration as narrow as 11 feet, 2 inches from the tractor seat.

- Dealer business software becomes common and replaces the manually-intensive visi-record cards and similar practices. “Prior to then, parts managers worked late every night posting parts sales and stock order receipts on manual cards,” recalls Titan’s David Meyer.

1986

- Massey Ferguson introduces the first electronic lift control 3-point hitch as standard equipment on its tractors. It offers fast and precise control of height, draft sensing, rate of drop, as well as depth control to automatically maintain any pre-selected depth.

- Ford buys New Holland and forms Ford-New Holland Inc.

- Farm Equipment contributing editor Harold Halter notes that multiple-location dealerships in the U.S total about 2,750, and many are 3-5 dealer “chains.”

1987

- Caterpillar introduces the “Mobil-Trac” rubber track system with its Challenger tractor line, the first tractor to use rubber tracks. It allowed the travel of up to 18 mph without road damage and significantly reduced soil compaction.

- Howard Martin, Elkton, Ky., files a patent for the first ground-driven row cleaner for no-till.

1988

- Crary Air Reels are developed to evenly distribute grain at the combine head and improve harvesting efficiencies.

- Case IH introduces the Magnum tractor, the first new machine from the combined engineering of IH and Case.

- Hesston introduces the first fully automatic round baler.

1989

- Eugene Keeton of Trenton, Ky., files a patent for the brush meter for planters.

- Richard Follmer, owner of Progressive Farm Products in Hudson, Ill., invents the mid-mount, dual-placement strip-till toolbar, the first manufacturer to find commercial success in the strip-till sector.

1990

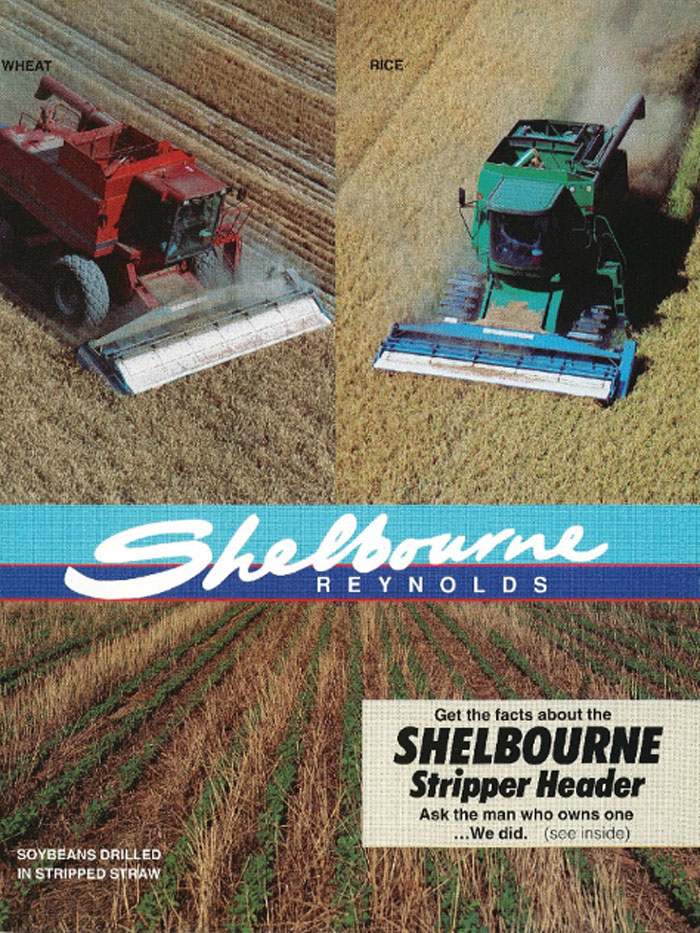

- Two years after the SRI stripper-header was developed in the U.K., Shelbourne-Reynolds sells its first U.S. unit to farmers in Kentucky. Within 5 years, adoption surges as Western wheat belt growers see the benefits of stripped straw in their no-till systems.

- AGCO is formed in the management buyout of Deutz-Allis from KHD, returning the manufacturing and distributing to the U.S. and offering equipment under the AGCO Allis and Gleaner brand names in North America. Dozens of manufacturers will be acquired as AGCO becomes the third largest producer of ag equipment.

1991

- JCB introduces its high road speed equal-size tire tractor named Fastrac in Great Britain. The world’s first tractor with a full suspension system, it handles road speeds up to 35 mph.

- Initial optical sensing research at Oklahoma State Univ. focuses on detecting and spraying weeds. At the same time, James Beck, a Northern California electronics engineer, develops the Patchen technology and in 1992 founds Patchen, a subsidiary of NTech. He then designs a spraying system integrating the technology. This integrated optical sensing becomes the basis for GreenSeeker variable rate fertilizer application system and WeedSeeker, which uses similar technology to selectively spot spray weeds.

1992

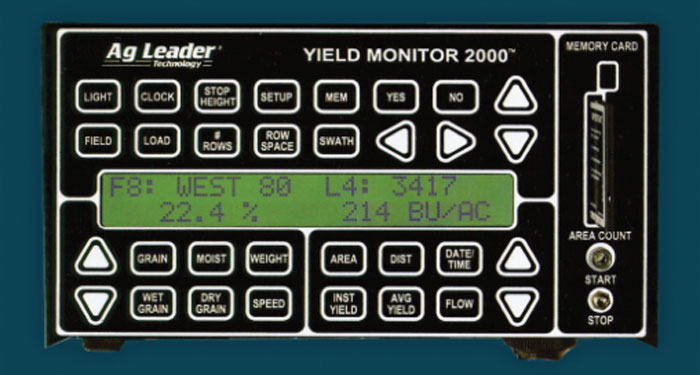

- Ag Leader founder Al Myers releases the Yield Monitor 2000, the first accurate combine yield monitor, which was a significant achievement in what would become known as precision farming.

- Satloc Inc. introduces the first GPS lightbar, initially designed for guidance in aerial applications. As the reliability of GPS receivers improved, the technology was adapted to ground-based applications.

- Trimble develops real-time kinematic (RTK) technology. By adding a correction signal to the signals coming from GPS satellites, RTK allows extremely accurate moment-by-moment location updates while on the move and becomes invaluable for high-accuracy guidance of construction and ag equipment.

1994

- Satellite technology is used in tracking and planning farming practices.

- Tenneco exits the farm and construction equipment businesses with a public offering of shares in the newly-named Case Corp., which switched from branding its machines as Case International to Case IH.

- Eugene Keeton files a patent for the Keeton Seed Firmer, an attachment to maintain effective seed-to-soil contact in no-till situations.

- Martin Industries produces its first floating row cleaner.

- Hesston introduces the first self propelled windrower using disc mower cutting technology.

- Pennsylvania no-tiller Steve Groff is the first N.A. farmer to build a cover-crop roller, emulating techniques learned from Brazilian no-tillers to reduce herbicide while using covers for weed control.

- The precision age begins as farmers use GPS receivers to determine which areas need specific quantities of water, fertilizer and pesticides. Farmers synthesize this data with yield information, weather forecasts and soil analysis in spreadsheets. “Precision farming is said to have moved ag mechanization forward more than prior advances,” says Paul Wallem, “and merged new technology of the information age within a mature industry.”

1995

- Fendt introduces the first continuously variable transmission, or CVT, tractor with its Vario launch. Developed by Fendt and Sauer-Sundstrand, the technology combines the infinite speeds of a hydrostatic transmission with the efficiency of a powershift by using a planetary gear set to split the engine output into a hydrostatic section and a mechanical section, eliminating traditional transmission gears.

- Marion Calmer of Calmer Corn Heads in Alpha, Ill., develops the first 15-inch narrow-row corn head.

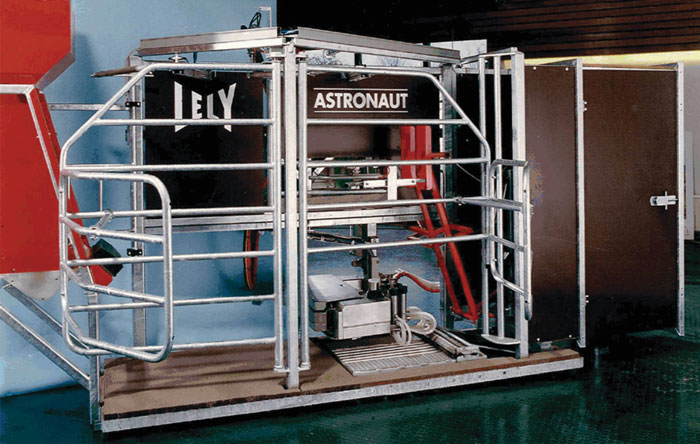

- Lely introduces the first version of the Lely Astronaut milking robot. It would be regarded by some as the most important invention of the 20th century for dairy farmers.

- Salford Farm Machinery Ltd., Ontario, Canada, introduces the “Wing Plow” to aid in soil conservation tillage.

- GMO seeds begin to be commercially introduced into U.S. agriculture, increasing yields, lowerng inputs and providing better results.

1996

- Monosem releases the first twin-row vacuum planter for peanuts. When it produced yield increases of 12-15% in Georgia, the company also develops twin-row cotton, corn and soybean planters. The twin-row configuration gives plants more room to grow, increasing yields and reducing inputs. The final design of the twin-row planter was patented in 2003.

1997

- Equipment Technologies introduces its mechanically-driven Apache self-propelled sprayer.

1998

- Developed by New Zealand ag engineers at Massey University, the Cross Slot planting system is introduced to the international market. Its no-till opener sows seeds into horizontal “inverted T” self-closing seed slots through virtually any amount of surface residue while avoiding hairpinning and allowing the banding of fertilizer without seed burn.

- Krone introduces the BiG M self-propelled mower conditioner in the U.S. It’s capable of cutting 30 feet of hay in one pass with a capacity of 40 acres per hour and merges the 30 feet into one windrow.

- Brillion Iron Works in Brillion, Wis., tests a vertical tillage implement. It began selling the “Zone Commander” in 2000, considered the “first” vertical tillage tool.

- Oxbo builds the first prototype double merger that led to “Hay-in-a-Day” and higher forage quality. Five years later, in 2003, Oxbo commercializes the first triple merger, branded as a MillerPro 310, that changed how alfalfa was windrowed for forage harvesting.

1999

- The AutoFarm Agricultural Division of Novariant launches the first commercially available automated steering system for farm equipment using GPS.

- CNH Global N.V. is formed following the merger of Case and New Holland. Following the divestiture of factories and product lines to gain approval from government authorities, a common platform manufacturing approach is followed but with the brands retaining their own identities and features.

2000

- Ingersoll becomes the first to manufacture and market boron alloy steel disc blades in North America. The steel provides longer life, less wear and improved performance in tillage equipment.

2001

- AutoFarm/Novariant announces the first successful implementation of sub-inch steering for a tractor with a front-mounted implement.

- Salford develops the Residue Tillage Specialist system for high-speed, no-till farming.

2002

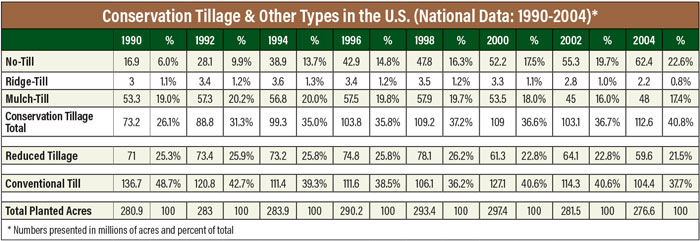

- With 55.3 million acres in the U.S., no-till surpasses mulch-till to become the predominant “conservation tillage” method, according to the CTIC. No-till and conservation tillage practices grow from 26.1% of planted acres to 40.7%, while conventional tillage falls from 48.7% to 37.7%.

- Jeff Moyer of the Rodale Institute designs the U.S.’ first U.S.-built cover crop roller-crimper. Several shortline manufacturers will release them to the market in the soil health trend.

2003

- Canada-based Montgomery Industries develops AutoBoom boom height control system to accurately control spray booms during high-speed spraying. Raven acquires Montgomery in 2005.

2004

- Claas introduces a 40-foot grain header for combines.

- Fendt introduces the Tractor Management System, an electronic software interface between the engine and transmission to control engine speed relative to ground speed. It maximizes power to the ground and fuel efficiency.

- Claas introduces its first self-propelled, large-scale mower for cutting a 45-foot swath in one pass.

2005

- Arizona’s John A. McClure is granted a patent for a guidance system for directing a towed implement behind a tractor using Differential Global Positioning Systems. Rights are assigned to CSI Wireless Inc. of Alberta, Canada.

- MacDon introduces the first flexible draper header, increasing combine productivity when harvesting soybeans.

2006

- In partnership with Orthman Manufacturing, AutoFarm introduces AFTracker, the first implement steering system based on RTK GPS.

- Richiger introduces the “Flexi-Grain Storage System” for loading and unloading grain stored in polyethylene bags.

- Case IH launches the Module Express 625, the first commercial cotton picker with the ability to build modules while harvesting for significant time, labor and capital savings.

- Australia’s David Trevilyan’s 120-foot Multiplanter no-till seeder seeds 2,337 acres in 24 hours for a world record. Four years later, his company will build a 212-foot frame.

- Iowa farmer Glen Dillman and sons add Air Clutch (2006) to their Acre Counter and Conser Clutch. The Air Clutch is the first on the market that controls every single row on a planter. The company will be acquired by Trimble in 2008.

2007

- Leica Geosystems introduces its Virtual Wrench service that provides customers with almost instantaneous remote trouble-shooting service via GPS satellite technology.

- Tier 3 engine requirements go into effect for tractors from 50-750 hp.

- The Krone Big X 1000 forage harvester with a 12-row corn header introduces the twin-engine concept. It’s propelled by 2 engines with a combined 1,020 hp.

2008

- Leica Geosystems debuts its Continuously Operating Reference Station network software that allows auto-steer system users to rely on signals from tower networks across the U.S. Many networks provide free RTK signal access through their state’s Dept. of Transportation.

- Valmont produces the first electronic control panel that will accept GPS directions for center-pivot irrigation.

- Precision Planting introduces the 20/20 Seed Sense monitor that pinpoints the percentages of seed singulation for each row, seed spacing, ground contact and down pressure, along with corn hybrid tracking and determines the economic loss per acre due to combined planting inaccuracies.

- Horsch introduces its high-speed compact disc (named the Joker) to North America. Neither vertical tillage nor a traditional tillage tool, it’s designed to break down residue while conserving moisture and preventing erosion.

- John Deere introduces the Intelligent Total Equipment Control Pro system that expands the use of the GreenStar system by automating tractor driving. When paired with AutoTrac, it takes over control as the tractor approaches a headland, allowing the operator to remain hands-free as it automatically decreases ground speed, lifts the implement, steers the tractor into the next area and then reengages the implement.

2009

- AGCO is the first ag equipment manufacturer to provide Selective Catalytic Reduction air-technology engines on tractors.

- New Holland introduces its hydrogen-powered tractor NH2 and the Independent Farm concept.

- Vermeer Corp. introduces its cob harvester to collect corn cobs expelled by combines for conversion into ethanol fuels.

- Precision Planting introduces the 20/20 AirForce system that allows growers in the tractor cab to control the amount of down pressure on individual planter row units

2011

- The Fendt/Trimble Guide Connect system features a driverless tractor that automatically follows another tractor running ahead in a field.

- All off-road diesel engines rated 174 hp and higher are required to comply with the EPA’s Tier 4i (interim) emissions regulations. The new rules called for cuts for a 90% reduction of particulate matter and a 50% drop in oxides of nitrogen vs. Tier 3. The changes drew an immediate rise in tractor prices by 5-9%.

2013

- AGCO launches Fuse Technologies to provide mixed-fleet-farming operations with improved connectivity to farm data.

- CNH Global N.V. and Fiat Industrial S.p.A. merge into CNH Industrial N.V.

- The Kinze autonomous grain cart demonstrates a driverless tractor. It showed autonomy in 4 models of operation: a grain cart following the combine through the field, unloading from the combine into the cart, return and park following unloading and stopping and awaiting further instruction from the farmer.

2015

- The “digital ag” era begins, allowing the collection, storage, analysis and sharing of electronic data information in ag, and higher personnel requirements of dealers. Concurrently, Right-to-Repair uproar begins as farmers seek access to codes needed for self-repair

2016

- After a successful alliance between Kubota and Great Plains’ Land Pride division, Kubota acquires 100% of Great Plains’ shares for a stock price of $430 million, significantly extending the new major’s line in seeding and tillage.

- The first integrated Harrington Seed Destructor is tested on Australian soil, where up to 99% of weed seeds were pulverized until no longer viable. It destroys weed seeds at harvest to reduce herbicide needs the following season.

- Case IH demonstrates the cabless Magnum tractor in its CNH Autonomy Project, which promotes autonomous seeding, planting and tillage for row-crop farming.

2017

- Vermeer introduces its ZR5 self-propelled baler that offers zero-turn capability, high speeds, automated baling sequence and faster bale chamber removal.

- Norbert Beaujot, the co-founder of SeedHawk, SeedMaster and Dot Technologies in Saskatchewan, introduces its diesel-powered U-shaped autonomous power unit. This driverless unit can be paired with a wide range of implements for tillage, seeding and harvesting. The concept is later sold to Raven, which was purchased by CNH in 2021.

2019

- Sabanto Ag builds its first autonomy kit and autonomously plants in 2020. The group also popularized custom farming with the use of its technology, or “farming as a service.”

2020

- Monarch Tractor introduces the world’s first fully electric, driver or driverless optional, smart tractor that is operated on a single electronic platform.

- Soletrac moves into the ag market with its battery-powered tractors. The equivalent of an 80-90 horsepower gas- or diesel-powered tractor, its eUT+ tractor is designed to fit between narrow rows in orchards and vineyards.

- Raven’s AutoCart allows a single operator to drive the harvester and call a tractor with the grain cart to come up alongside and receive the load.

2021

- John Deere introduces its See & Spray Select Technology that allows farmers to reduce non-residual, preemergence herbicide use by targeting and spraying only growing weeds in fallowed fields. Cameras mounted on the sprayer rapidly detect green plants and trigger a spot-spray herbicide application to these plants.

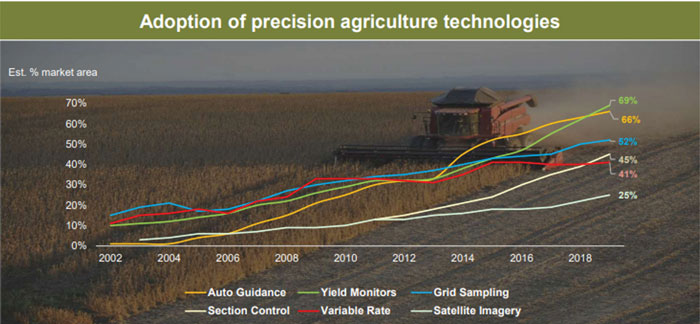

- The “Environmental Benefits of Precision Agriculture in the U.S.” study (AEM, ASA, CropLIfe and TFI) reports “the cultivation of 10.2 million acres of cropland was avoided via more efficient use of existing land”. The report states 15,000 tons of herbicide have been avoided due to adoption of precision ag technologies such as auto guidance, variable rate and section control

2022

- Case IH introduces the Trident 5550 fully autonomous self-propelled spreader for both liquid and dry fertilizer applications.

- John Deere announces that its fully autonomous tractor is production ready. The package combines Deere’s 8R tractor, TruSet-enabled chisel plow, GPS guidance and new advanced technologies.

2023

- New Holland is the first of the major-line ag OEMs to introduce an all-electric-powered tractor. Its T4 electric model is the equivalent of a 74-horsepower gas- or diesel-powered utility tractor while offering emission-free silent power.

- As consolidation rapidly continues, Farm Equipment releases a list of the 100 largest dealers (The Farm Equipment 100), which includes 1,940 ag stores, or nearly one-third of all ag equipment store rooftops in North America. The average Top 100 dealer operates 19.4 stores. Together, the top 100 dealers comprise an estimated $52.6 billion in annual revenues and employ more than 56,500.

Read Farm Equipment's 55 Years of History Coverage

Click here for the Farm Equipment History Video seriesClick here to read the "Looking Back" blog series