For 31 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The products selected save producers time and reduce cost and labor, all while improving user safety.

To be eligible for the award, each development —which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the entire industry, not to an individual company. Each year an international panel of industry experts in technology, design and product development gather to evaluate the entries and select up to 50 products for recognition.

New this year to the AE50 Award is “The Davidson Prize,” in honor of Dr. J. Brownlee Davidson, founder and first president of ASABE, which will recognize the top innovations among the AE50 winners. The Davidson Prize winners will be announced during Commodity Classic in Anaheim, Calif., in February.

In reviewing this year’s winners, Maury Salz, president-elect of ASABE and president of Claas Omaha, says a clear trend continues to be the move toward data and electronic control systems. “You see more and more work being done on sensors and delivery of data to the users. The future is more sensors, more data, more knowledge, more transparency and more efficiencies being gained out of that,” he says.

Kuhn Merge Maxx MM 1100 Hay Merger

With 36 feet of continuous merging capability in a single pass, the Merge Maxx MM 1100 hay merger is the largest and most efficient merger on the market. ISOBUS compatibility allows for improved operator ergonomics and reduced fatigue. Designed for commercial operations, the MM 1100 incorporates proven 6-tine bar cam pickups with tine-arm wear guards and anti-wrapping rings. The floating windguard ensures the operator lays down smooth and even windrows to make the forage harvester more efficient. The crop netting improves leaf retention into the windrow for optimum feed quality. Folding the machine is done in one simple operation to make it faster and more efficient when transporting from field to field.

With 36 feet of continuous merging capability in a single pass, the Merge Maxx MM 1100 hay merger is the largest and most efficient merger on the market. ISOBUS compatibility allows for improved operator ergonomics and reduced fatigue. Designed for commercial operations, the MM 1100 incorporates proven 6-tine bar cam pickups with tine-arm wear guards and anti-wrapping rings. The floating windguard ensures the operator lays down smooth and even windrows to make the forage harvester more efficient. The crop netting improves leaf retention into the windrow for optimum feed quality. Folding the machine is done in one simple operation to make it faster and more efficient when transporting from field to field.

Kuhn North America Inc., Brodhead, Wis.

Class Jaguar 900 Series (Type 498) Forage Harvester

The Claas Jaguar 900 Series has added many new innovative features to the new Type 498 forage harvesters. The feeder house has been redesigned for better feeding and offers an optional hydraulic header drive that allows the operator to adjust header speed from the cab for changing conditions. A new heavy duty axle with optional differential lock improves traction in wet conditions and hilly areas. The drivetrain has been redesigned for improved efficiency, less fuel consumption and up to 13.6 mph in first gear. Duals can now be ordered from factory for even greater stability on hilly or soft ground. The automatic adjustment of the shearbar now also adjusts the lower drum concave for improved cut quality and performance in silage blowing in the field.

The Claas Jaguar 900 Series has added many new innovative features to the new Type 498 forage harvesters. The feeder house has been redesigned for better feeding and offers an optional hydraulic header drive that allows the operator to adjust header speed from the cab for changing conditions. A new heavy duty axle with optional differential lock improves traction in wet conditions and hilly areas. The drivetrain has been redesigned for improved efficiency, less fuel consumption and up to 13.6 mph in first gear. Duals can now be ordered from factory for even greater stability on hilly or soft ground. The automatic adjustment of the shearbar now also adjusts the lower drum concave for improved cut quality and performance in silage blowing in the field.

Claas of American Inc., Omaha, Neb.

Kelley Mfg. Co. KMC 2100 Double Fold Field Cultivator

The KMC 2100 Double Fold Field Cultivator is an economical 3-point lift implement that creates a smooth seedbed. It has up to 41 feet working width, improved transport dimensions and a better center of gravity location. The shortened overall length is the result of repositioning the gauge wheels, tines and toolbar. The wings flex to keep a consistent operating depth (2-6 inches) on uneven ground. Transport safety is improved by reducing the width (17 feet, 10 inches) and height (13 feet), while maintaining excellent rear visibility from the tractor cab. Operators can cover more acres per day due to the 47% increase in operating width over the previous model. The spring-loaded rear finishing section can be equipped with various options depending on the soil type and desired condition of the seedbed.

The KMC 2100 Double Fold Field Cultivator is an economical 3-point lift implement that creates a smooth seedbed. It has up to 41 feet working width, improved transport dimensions and a better center of gravity location. The shortened overall length is the result of repositioning the gauge wheels, tines and toolbar. The wings flex to keep a consistent operating depth (2-6 inches) on uneven ground. Transport safety is improved by reducing the width (17 feet, 10 inches) and height (13 feet), while maintaining excellent rear visibility from the tractor cab. Operators can cover more acres per day due to the 47% increase in operating width over the previous model. The spring-loaded rear finishing section can be equipped with various options depending on the soil type and desired condition of the seedbed.

Kelley Mfg. Co., Tifton, Ga.

Hardi Rubicon Self-Propelled Sprayer

The new Rubicon introduced by Hardi is the largest production self-propelled sprayer made. It provides the ability to cover more ground, in less time, minimizing labor, fuel and depreciation, while maximizing the available days per year to apply chemicals to your crops, and allowing the savings in labor and fuel. The large cab is the new certified “class 4” clean environment, setting it apart in the industry. With a 2,200-gallon product tank, and up to 160 feet Aluforce boom, a powerful and efficient 380 horsepower Cummins FT4 engine, all new incredibly stable boom suspension system and pneumatic ride.

The new Rubicon introduced by Hardi is the largest production self-propelled sprayer made. It provides the ability to cover more ground, in less time, minimizing labor, fuel and depreciation, while maximizing the available days per year to apply chemicals to your crops, and allowing the savings in labor and fuel. The large cab is the new certified “class 4” clean environment, setting it apart in the industry. With a 2,200-gallon product tank, and up to 160 feet Aluforce boom, a powerful and efficient 380 horsepower Cummins FT4 engine, all new incredibly stable boom suspension system and pneumatic ride.

Hardi North American Inc., Davenport, Iowa

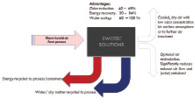

Graintec Hot Air Drying

Hot air drying is one of the most widespread drying methods within the extruded aqua feed industry. The exhaust air from hot air dryers are malodorous, humid and warm. Traditional processing invokes the use of separate process steps to allow reduction of odor emission, in order to obey local legislation and keep a positive relation with nearby neighbors. The new solution brings a promising alternative to the existing technology pool, promising an eco-efficient and sustainable technology to simultaneously reduce odor, increase process energy efficiency and safeguard fresh water resources for future generations.

Hot air drying is one of the most widespread drying methods within the extruded aqua feed industry. The exhaust air from hot air dryers are malodorous, humid and warm. Traditional processing invokes the use of separate process steps to allow reduction of odor emission, in order to obey local legislation and keep a positive relation with nearby neighbors. The new solution brings a promising alternative to the existing technology pool, promising an eco-efficient and sustainable technology to simultaneously reduce odor, increase process energy efficiency and safeguard fresh water resources for future generations.

Graintec Inc., Kansas City, Mo.

Innoquest SpotOn Digital Soil Compaction Meter

The SpotOn Digital Soil Compaction Meter from Innoquest is a handheld meter for quickly and accurately quantifying areas or layers of compacted soil in production agriculture and turf markets. This electronic meter features high sensitivity and automatic peak compaction capture previously lacking in analog type meters sold to the same markets. A large digital display includes a color-coded bar graph for easy interpretation of compaction readings by farmers and growers. The meter’s electronic loadcell design allows all types of soil to be accurately measured without the need for changing tip sizes.

Innoquest Inc., Woodstock, Ill.

Valley Irrigation Valley X-Tec Center Drive

The new Valley X-Tec advanced DC drive motor with FastPass technology delivers top performing speed for quick irrigation cycles and dynamic power to take on the toughest terrains. It operates at up to twice the speed of a standard, high speed AC center drive motor. The advanced DC drive can move at speeds as low as 1 rpm — just 1% of maximum motor speed — or ramp up to a fast 136 rpm. Valley X-Tec can do more than move twice as fast as standard AC motors. It can also move at full torque at any speed to handle rough terrain with ease. Technology operates up to twice the speed of a standard, high speed AC center drive motor. The motor design provides constant torque at any speed, providing growers with control and additional options to maximize crop yields.

The new Valley X-Tec advanced DC drive motor with FastPass technology delivers top performing speed for quick irrigation cycles and dynamic power to take on the toughest terrains. It operates at up to twice the speed of a standard, high speed AC center drive motor. The advanced DC drive can move at speeds as low as 1 rpm — just 1% of maximum motor speed — or ramp up to a fast 136 rpm. Valley X-Tec can do more than move twice as fast as standard AC motors. It can also move at full torque at any speed to handle rough terrain with ease. Technology operates up to twice the speed of a standard, high speed AC center drive motor. The motor design provides constant torque at any speed, providing growers with control and additional options to maximize crop yields.

Valley Irrigation, Valley, Neb.

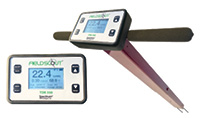

Spectrum Technologies Field Scout TDR 350 Soil Moisture Meter

The FieldScout TDR 350 Soil Moisture Meter provides growers, researchers and turf managers with a portable tool for measuring three important parameters in the soil: moisture, salinity and temperature. The TDR 350 adds electrical conductivity (EC) and temperature sensors to improve water content accuracy in a wider range of soil conditions and at grower-selectable depths through its use of replaceable rods in multiple lengths. An optional infrared temperature sensor provides instantaneous surface temperature readings, bypassing the latency of contact sensors. The integral GPS receiver records the location of every measurement. The TDR 350 will help growers better manage irrigation, fertilization, near-surface salt accumulation and disease pressure.

The FieldScout TDR 350 Soil Moisture Meter provides growers, researchers and turf managers with a portable tool for measuring three important parameters in the soil: moisture, salinity and temperature. The TDR 350 adds electrical conductivity (EC) and temperature sensors to improve water content accuracy in a wider range of soil conditions and at grower-selectable depths through its use of replaceable rods in multiple lengths. An optional infrared temperature sensor provides instantaneous surface temperature readings, bypassing the latency of contact sensors. The integral GPS receiver records the location of every measurement. The TDR 350 will help growers better manage irrigation, fertilization, near-surface salt accumulation and disease pressure.

Spectrum Technologies Inc., Aurora, Ill.

Sukup Mfg. Co. Sweep Wheel Grain Reclaimer

The Sweep Wheel Grain Reclaimer is an assembly that reduces the amount of grain left behind the drive wheel of a bin sweep. It consists of a slanted plate that fits over the drive wheel gearbox and directs grain inward toward the sweep auger, and a reclaim shield that fits behind the drive wheel. It captures grain so the sweep wheel can lift it onto the slanted plate, where it flows by gravity into the path of the sweep auger. This patent-pending assembly reduces the amount of grain left behind by more than 80%. Besides reducing manual labor to remove grain after the sweep has been turned off, traction of the sweep’s drive wheel is significantly improved.

The Sweep Wheel Grain Reclaimer is an assembly that reduces the amount of grain left behind the drive wheel of a bin sweep. It consists of a slanted plate that fits over the drive wheel gearbox and directs grain inward toward the sweep auger, and a reclaim shield that fits behind the drive wheel. It captures grain so the sweep wheel can lift it onto the slanted plate, where it flows by gravity into the path of the sweep auger. This patent-pending assembly reduces the amount of grain left behind by more than 80%. Besides reducing manual labor to remove grain after the sweep has been turned off, traction of the sweep’s drive wheel is significantly improved.

Sukup Mfg. Co., Sheffeld, Iowa

Case IH Agriculture CVXDrive for Steiger & Quadtrac Tractors

The CVXDrive in the Case IH Steiger, Rowtrac and Quadtrac series tractors is the industry’s first continuously variable transmission for an articulated tractor. At 605 peak horsepower, it is the highest horsepower agriculture tractor with a continuously variable transmission available today. The intuitive CVXDrive delivers constant variable speed and uninterrupted power to the ground from 3 feet per minute to 25 mph. The four mechanical speed ranges in the continuously variable transmission ensure peak mechanical efficiency, especially in the lower operating speeds where power and torque are required for the intended use of a 4WD tractor. Once the operator sets the desired operating target (working speed or engine rpm), the CVXDrive automatically selects the most efficient transmission range, turning novice drivers into experienced operators.

The CVXDrive in the Case IH Steiger, Rowtrac and Quadtrac series tractors is the industry’s first continuously variable transmission for an articulated tractor. At 605 peak horsepower, it is the highest horsepower agriculture tractor with a continuously variable transmission available today. The intuitive CVXDrive delivers constant variable speed and uninterrupted power to the ground from 3 feet per minute to 25 mph. The four mechanical speed ranges in the continuously variable transmission ensure peak mechanical efficiency, especially in the lower operating speeds where power and torque are required for the intended use of a 4WD tractor. Once the operator sets the desired operating target (working speed or engine rpm), the CVXDrive automatically selects the most efficient transmission range, turning novice drivers into experienced operators.

Case IH, Racine, Wis.

Kondex Corp. Straw Claw Chopper Blades

Kondex Corp.’s Straw Claw chopper blades feature a patented, self-serrating design that uses a laser cladding additive on a through-hardened blade to control product wear and maintain blade sharpness longer. By controlling the wear pattern, Straw Claw blades have a reduction in chipping and blade damage, which better maintains rotor balance and minimizes maintenance. Their stay-sharp design creates a more efficient cut time after time, while delivering smaller, more consistent straw particles than traditional blades. Having smaller particles produces a thinner, more evenly distributed crop mat that maximizes ground contact for the fastest microbial breakdown.

Kondex Corp.’s Straw Claw chopper blades feature a patented, self-serrating design that uses a laser cladding additive on a through-hardened blade to control product wear and maintain blade sharpness longer. By controlling the wear pattern, Straw Claw blades have a reduction in chipping and blade damage, which better maintains rotor balance and minimizes maintenance. Their stay-sharp design creates a more efficient cut time after time, while delivering smaller, more consistent straw particles than traditional blades. Having smaller particles produces a thinner, more evenly distributed crop mat that maximizes ground contact for the fastest microbial breakdown.

Kondex Corp., Lomira, Wis.

Kuhn Krause Interceptor 8050 High Speed Tillage

The Kuhn Krause Interceptor is a high speed tillage system utilizing rotary soil engaging components, combined with a single row of heavy duty, adjustable, 30 inch tines that maintain full contact with the soil surface, which force “airborne” soil and residue from the front row of blades downward, for further sizing and leveling. Two parallel rows 32 flute Excalibur CT shallow concavity blades, configured in a tandem vs. offset design, are mounted onto individual, compound angle bearing arms providing a clean cut that removes young weed growth and creates a uniform seedbed floor for today’s high speed planting demands. Two active hydraulic down pressure circuits maintain uniform operational depth across the machine and consistent contact of the Star Wheel rotary treaders.

The Kuhn Krause Interceptor is a high speed tillage system utilizing rotary soil engaging components, combined with a single row of heavy duty, adjustable, 30 inch tines that maintain full contact with the soil surface, which force “airborne” soil and residue from the front row of blades downward, for further sizing and leveling. Two parallel rows 32 flute Excalibur CT shallow concavity blades, configured in a tandem vs. offset design, are mounted onto individual, compound angle bearing arms providing a clean cut that removes young weed growth and creates a uniform seedbed floor for today’s high speed planting demands. Two active hydraulic down pressure circuits maintain uniform operational depth across the machine and consistent contact of the Star Wheel rotary treaders.

Kuhn Krause Inc., Hutchinson, Kan.

New Leader NL5000 G5 Dry Nutrient Applicator

The NL5000 G5 is a high output, variable-rate, dry nutrient applicator with 16 section swath width control. The patented technology dynamically and simultaneously adjusts the spinner assembly left/right and fore/aft to give the operator a highly responsive and reliable method to apply the right amount of nutrients in the right place. The G5 section control gives increased accuracy for point rows and irregular shaped areas, and provides last pass control to significantly reduce overlap when finishing a field with less than a full swath. A new advanced hydraulics system supports the spinner control, fast and exact conveyor control and an automatic chain tensioner.

The NL5000 G5 is a high output, variable-rate, dry nutrient applicator with 16 section swath width control. The patented technology dynamically and simultaneously adjusts the spinner assembly left/right and fore/aft to give the operator a highly responsive and reliable method to apply the right amount of nutrients in the right place. The G5 section control gives increased accuracy for point rows and irregular shaped areas, and provides last pass control to significantly reduce overlap when finishing a field with less than a full swath. A new advanced hydraulics system supports the spinner control, fast and exact conveyor control and an automatic chain tensioner.

New Leader, Cedar Rapids, Iowa

Praxidyn Mixmate

Mixmate is a fully automated chemical blending and record keeping system with modular options for portable or stationary installations and measurement by weight or volume. The patent pending jug process drains, weighs, rinses, records and reconciles the data from a jug in about 12 seconds. It can simultaneously measure multiple products for fast mixing speeds. The typical time to fill a large sprayer is 4-8 minutes. The Android app controls the system and captures the records automatically. The app synchronizes with Praxidyn Intersect cloud service to backup data and provides access from the office. Intersect has CSV and API data access for easy data transfer with other record keeping systems. Intersect and Mixmate can automate data processing to save time and reduce errors in the office and the field.

Mixmate is a fully automated chemical blending and record keeping system with modular options for portable or stationary installations and measurement by weight or volume. The patent pending jug process drains, weighs, rinses, records and reconciles the data from a jug in about 12 seconds. It can simultaneously measure multiple products for fast mixing speeds. The typical time to fill a large sprayer is 4-8 minutes. The Android app controls the system and captures the records automatically. The app synchronizes with Praxidyn Intersect cloud service to backup data and provides access from the office. Intersect has CSV and API data access for easy data transfer with other record keeping systems. Intersect and Mixmate can automate data processing to save time and reduce errors in the office and the field.

Praxidyn, Oakland, Iowa

Lindsay Corp. FieldNET Pivot Control Lite

Pivot Control Lite from FieldNET by Lindsay is an easy-to-install, economical remote monitor and control product for agriculture that adds on to any brand of electric center pivot irrigation system, converting them into a highly efficient management solution. Pivot Control Lite gives farmers the tool to properly place irrigation water in the right spot to avoid over-watering, which can decrease unnecessary pumping costs, use water more effectively and reduce labor cost and time. Pivot Control Lite includes an integrated cellular modem and on-board GPS. Additionally, Pivot Control Lite will monitor the electrical cable and detect tampering and alert the proper people to a potential theft of the copper wire.

Pivot Control Lite from FieldNET by Lindsay is an easy-to-install, economical remote monitor and control product for agriculture that adds on to any brand of electric center pivot irrigation system, converting them into a highly efficient management solution. Pivot Control Lite gives farmers the tool to properly place irrigation water in the right spot to avoid over-watering, which can decrease unnecessary pumping costs, use water more effectively and reduce labor cost and time. Pivot Control Lite includes an integrated cellular modem and on-board GPS. Additionally, Pivot Control Lite will monitor the electrical cable and detect tampering and alert the proper people to a potential theft of the copper wire.

Lindsay Corp., Omaha, Neb.

F Poulsen Engineering Robovator Weeding Machine

The Robovator Mechanical weeding machine removes weeds growing near the plant. A camera above each row controls a hydraulically operated tool that moves in and out of the row at the correct time with respect to the passing plants. The cameras record and detect the position of the individual plants. The software calculates the correct timing from plant to plant. The software and the side shift mechanism lock the position of the machine on to the row. In this way it is possible to remove weeds close to the plants.

The Robovator Mechanical weeding machine removes weeds growing near the plant. A camera above each row controls a hydraulically operated tool that moves in and out of the row at the correct time with respect to the passing plants. The cameras record and detect the position of the individual plants. The software calculates the correct timing from plant to plant. The software and the side shift mechanism lock the position of the machine on to the row. In this way it is possible to remove weeds close to the plants.

F Poulsen Engineering, Hvalsø, Denmark

Hesston 2370 Ultra High Density Baler

The Hesston by Massey Ferguson 2370 Ultra High Density (UHD) baler redefines the capacity, capability and performance of high-density large square balers. A faster, more powerful plunger, extended-length bale chamber, newly designed pickup assembly, heavy duty chassis, redesigned driveline and new gearbox are the key features that will allow this baler to create bales with 20% greater density than those of Hesston’s current extra density model, the 2270XD. The 2370 was designed specifically for producing heavy, dense bales in grass hay and hard-to-bale crop residue.

The Hesston by Massey Ferguson 2370 Ultra High Density (UHD) baler redefines the capacity, capability and performance of high-density large square balers. A faster, more powerful plunger, extended-length bale chamber, newly designed pickup assembly, heavy duty chassis, redesigned driveline and new gearbox are the key features that will allow this baler to create bales with 20% greater density than those of Hesston’s current extra density model, the 2270XD. The 2370 was designed specifically for producing heavy, dense bales in grass hay and hard-to-bale crop residue.

AGCO Corp., Duluth, Ga.

GVM Double Duty Twin Chain

GVM’s Double Duty Twin Chain spreader offers up to four section swath width control with simplicity and precision. It features two bar chains with individual shutoff and air-actuated funnel control to precisely direct product placement. After product is placed onto the spinner discs, the patented five blade spinner discs reverse-rotate to spread product farther and flatter than a traditional spreader. Offering up to a 120 foot spread width, the Double Duty Twin Chain offers on-the-go adjustability, perfect for waterways, point rows and boundary spreading.

GVM’s Double Duty Twin Chain spreader offers up to four section swath width control with simplicity and precision. It features two bar chains with individual shutoff and air-actuated funnel control to precisely direct product placement. After product is placed onto the spinner discs, the patented five blade spinner discs reverse-rotate to spread product farther and flatter than a traditional spreader. Offering up to a 120 foot spread width, the Double Duty Twin Chain offers on-the-go adjustability, perfect for waterways, point rows and boundary spreading.

GVM Inc., East Berlin, Pa.

New Holland CustomSteer

The CustomSteer system from New Holland allows operators to choose their own steering ratio, reducing to just one rotation if desired. Aimed at reducing operator input while carrying out repetitive maneuvers such as with a front-end loader, turning at the field end or while reversing trailers. Uniquely, a different ratio can be set for forward and reverse and switching ratios can be programmed into the automated end of row system, Headland Turn Sequencer II. Precise steering control is maintained and safety ensured as the custom ratio gradually returns to the standard ratio as travel speed increases.

New Holland, New Holland, Pa.

AGCO Challenger RoGator C Series Applicator

The RoGator C Series with the LiquidLogic application system from AGCO defines responsible, productive and agronomically focused application. Automation, recirculation and streamlined flow paths focus on accuracy and crop safety for applying nutrients and crop protection products while preventing residue accumulation. Product cleanout processes evacuate over 90% of residual volume while on-screen prompts guide the operator. Operator interface improvements and automation reduce workloads in areas such as agitation, load management and the elimination of repetitive tasks. Drive system, hydraulic and engine management are controlled automatically to deliver peak performance at lower rpm and with a fuel savings of 11-15%.

AGCO Corp., Duluth, Ga.

John Deere ExactApply Nozzle Control System

John Deere ExactApply intelligent nozzle control system provides sprayer operators a comprehensive solution that improves their quality of spray. ExactApply customers will have improved coverage due to an industry exclusive 30-hertz pulsing and more flexibility from the cab with automatic nozzle switching. The system will also offer operators turn compensation, individual nozzle on/off, LED lights in each nozzle body and smart diagnostics.

John Deere, Ankey, Iowa

AGCO Challenger MT700 Series Track Tractor

The all-new Challenger MT700 Series Track Tractors are designed with maximum productivity and operator comfort in mind. At the center of this innovative new tractor is the entirely new AccuDrive Powertrain, which delivers a high-torque, low-engine-speed concept. With a maximum operating speed of 1,790 rpm and a working range of 1,200-1,600 rpm, all tractor functions, including the CVT, PTO, cooling system and even hydraulics, are geared to run at optimum levels at this ultra-low engine speed. This delivers lower fuel consumption, reduced engine and component wear and extra quiet operation. The system is comprised of a redesigned oscillating midwheel system, all new primary hardbar suspension and an advanced cab suspension.

AGCO Corp., Jackson, Minn.

New Holland Guardian SP310F Front Boom Sprayer

The New Holland Guardian SP310F high clearance front boom sprayer covers ground faster, maximizes acres sprayed per hour and allows for applications later into the growing season. The sprayer features a new active suspension that provides a variable height adjustment for an industry leading 72-78 inches of crop clearance. Additionally, the machine has 20 inches of wheel travel and the suspension adjusts to apply an equal load to all four wheels in the most demanding of terrains reducing soil compaction and maintaining traction. This equates to higher spray speed, more acres per hour, less fatigue to the operator and less stress on the machine. Additional major enhancements include a new cab, designed specifically for a front boom sprayer, and a redesigned center section and lift arms.

New Holland, St. Nazianz, Wis.

Case IH Nutri-Placer 930 HSLD Fertilizer Applicator

The new Case IH Nutri-Placer 930 HSLD fertilizer applicator sets the bar for productivity for anhydrous ammonia fertilizer applicators of its size, while minimizing soil erosion. Achieving speeds up to 11 mph, the Nutri-Placer 930 fertilizer applicator with new High-Speed Low Disturbance (HSLD) coulters helps growers cover acres fast and efficiently, achieving up to 57% greater productivity than a traditional shank-style fertilizer applicator. The HSLD coulters provide better residue cover and a more level surface finish than other coulter-style applicators available — properly sealing nutrients to lock in each crop’s profit potential. The heavy-duty Nutri-Placer 930 frame provides the strength and stability needed for high-speed operation, while the stubble-resistant radial tires prevent costly downtime due to tire failures and reduce soil compaction.

Case IH, Racine, Wis.

Case IH Trident 5550 Liquid/Dry Combination Applicator

The Case IH Trident 5550 liquid/dry combination applicator is the industry’s fastest converting combination applicator on a row-crop chassis. This 390 horsepower machine is engineered from the ground up to be changed from a 1,400 gallon liquid system to a 10 ton dry applicator and back again throughout three seasons of use with an industry leading changeover time of 42 minutes by using the Case IH Aerial Lift Device, along with an appropriate lifting machine. It is also the first applicator to feature optional factory-available duals in row crop tire sizes to make wet fields more accessible and reduce soil compaction.

Case IH, Benson, Minn.

Claas Easy on board App

The new Claas Easy on board app enables farmers to use an Apple iPad as an ISOBUS terminal. A wireless interface adapter is connected to the ISOBUS plug in the tractor’s cab and creates a wi-fi network. The iPad connects to the Wi-Fi network and establishes a save link between wireless interface and tablet. By creating a save link, it is not possible for other devices to connect to the same implement at the same time. The Easy on board app is available through the Apple iTunes app store. As soon as the app gets started, it is loading the ISOBUS information from the implement. The implement can be controlled from inside or outside the cab. In addition, it includes a task management menu that can record jobs like bale count or worked acres.

Claas of American Inc., Omaha, Neb.

John Deere 5R Series Utility Tractor

The John Deere 5R series utility tractors are a ground up design that brings large tractor performance, capability and comfort into a utility tractor package. The new 5R tractor design is a compact design (smallest wheelbase in its power class) with electro-hydraulic partial power-shift transmission, pressure flow compensated hydraulics (up to 114 liters per minute flow), up to 125 horsepower and several best in class features: fuel efficiency, max allowable payload and ballast, turning radius, forward visibility and comfort. The newly designed transmission provides two operating modes: manual mode operation and controls to allow the operator to easily shift to desired settings and automatic mode to allow the operator to set the desired tractor speed. Tractor efficiency was a focus in the design and provides 3% better fuel and 7% better fluid consumption compared to the closest competitor in its class. In addition, loader integration was a focus and will provide the customer with increased productivity.

John Deere, Moline, Ill.

Enginuity Worldwide LLC AgriCapture Cube

The AgriCapture Cube is a soil remediation cube that includes a dose of partially carbonized agricultural waste and/or anaerobic digestate (AD) material and improves overall soil health while controlling the mobility of minerals and nitrogenous wastes associated with waste products. It provides an effective solution to the management and disposal of agricultural/AD wastes. The effective management of waste steams is paramount for the clean air and clean water for the next generations. The AgriCapture Cube increases carbon sequestration of soils, increases soil health and efficacy, and provides a safe and effective means to stabilize nitrogenous compounds on the field to avoid leaching into surrounding waters.

Enginuity Worldwide LLC., Centralia, Mo.

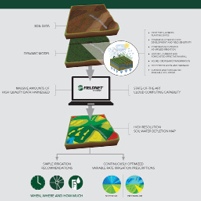

151 Research Inc. GrainViz

GrainViz is a way of monitoring stored grain through 3-D electromagnetic imaging. Using a series of antennas on the outer wall of the bin, it creates a highly-detailed 3-D image of the moisture content of the entire bin contents, allowing producers to closely monitor and condition the grain. Producers view their data through a website on any web-connected device. GrainViz sees the bin in its entirety, ensuring no hotspots are present at any point during conditioning or storage. It can detect the pre-conditions for hotspots and also allows for fine-grained control of the grain conditioning process, allowing producers to maximize the quality and price of their crop.

151 Research Inc., Winnipeg, Man.

Meter Group Atmos 41 Compact Weather Station

The Atmos 41 Compact Weather Station is designed for continuous monitoring of environmental variables, including all standard weather measurements. All sensors are integrated into a single unit, requiring minimal installation effort. Ultra-low power consumption and a robust, no moving parts design that prevents errors because of wear or fouling. The weather station packages 12 weather sensors into a single, compact device for atmospheric conditions. The data are transmitted over a single wire, so only one port on a data logger is needed. The Atmos 41 measures air temperature, relative humidity, vapor pressure, barometric pressure, wind speed, wind gust, wind direction, solar radiation, precipitation, lightning strike and distance, compass direction and tilt.

Meter Group Inc., Pullman, Wash.

John Deere S700 Combine

The introduction of the next generation of John Deere Crop Harvesting Solutions brings innovation to machine optimization, harvest information and cab and control technology. A suite of seven technologies collectively called “Combine Advisor” helps set, optimize and automate the combine. The system uses ActiveVision camera analysis of clean grain samples and tailings along with loss sensor information to determine combine performance and adjust rotor speed, concave clearance, fan speed, chaffer and sieve clearance to maintain operator-set performance as conditions change. The S700 Cab and Controls include the intuitive Gen4 CommandCenter display, customizable CommandArm, redesigned ergonomic multi-function control lever with customizable buttons, and industry-exclusive swivel seat for improved in operator control and comfort.

John Deere, Moline, Ill.

Capstan Ag Systems Individual Nozzle Boundary Control for PinPoint II

By invoking sub meter precision algorithms coupled with location information gathered from both the user’s GPS and satellite mapping, the Individual Nozzle Boundary Control from Capstan Ag System provides applicators with an exact spray application down to the field’s edges. The Individual Nozzle Boundary Control feature is designed to allow the applicator to save time, money and dramatically reduce the environmental risk associated with spraying field boundaries and waterways with Capstan’s PinPoint II precision spraying system. Productivity benefits stem from not needing to boarder field features such as waterways, field boarders, trees or other mid-field obstacles, which saves time and chemical. Environmental benefits include reducing overspray or overlap of chemicals into areas that are desirable or protected areas such as waterways, lakes, streams, rivers and neighboring fields or zones where off target application could be detrimental.

Capstan Ag Systems, Topeka, Kan.

New Holland Optispread Plus Residue Management

The Optispread Plus residue management system for New Holland CR Combines gives combine operators an improved residue spreading system that delivers an excellent chopping performance and equal spreading of the chopped material over the whole width of current and future headers. The patented system relies on three principles: airflow based MOG spreader, active spreader with V shaped paddles, Mixed MOG / straw spreader flow with air draft support. On top of this, the complete system uses 3% less power. This benefits in lower fuel consumption, lower CO2 emissions and increased throughput with the same available engine power.

New Holland, West Flanders, Belgium

ACGO Datatronic 5 Tractor Terminal

Massey Ferguson’s, new Datatronic 5 system puts complete tractor and precision farming control at the operator’s fingertips. The system and in-cab terminal combine all functions needed by a modern tractor such as tractor functionality, implement control, guidance and precision data into an ISOBUS-compatible tablet-based user interface, which is straightforward, intuitive and efficient. Today’s tractor operators have become well adept to using consumer-based tablets, they are intuitive in functionality as well as powerful, fast and responsive. The goal of the Datatronic 5 terminal was to mimic those same characteristics of the consumer-based tablet interface.

AGCO Corp., Duluth, Ga.

New Holland IntelliTurn

The IntelliTurn system from New Holland is an automatic end of the row turn system that utilizes knowledge gained from the NH Drive Autonomous Concept Tractor Project. It allows the operator to improve machine efficiency by intelligently and automatically plotting and executing the most efficient turn path at the headland. The system automatically ensures that the implement re-enters the infield work area in line with the desired path without the need for intervention, reducing operator fatigue and increasing work rates. The system dynamically modifies its path planning based on vehicle speed when approaching the turn, recommends speed reductions where necessary, all allowing for an optimized vehicle turn.

New Holland, New Holland, Pa.

Case IH In-Cab Split-Row Lift System for Early Riser 2140 Pivot Transport Planter

The In-Cab Split-Row Lift System for Case IH Early Riser 2140 Pivot Transport Planter represents an industry-first, in-cab split-row lift solution for all soybean row units on a planter. This system eliminates special tools and operator physical exertion traditionally required to manually raise or lower all, or center section, soybean row units when changing between 30 inch (corn) and 15 inch (soybean) row spacing. The operator can now raise or lower all soybean row units from the comfort of the tractor cab by simply interfacing with the planter’s touch screen display and a single tractor electro-hydraulic remote, saving time and increasing productivity during row spacing changeover.

Case IH, Racine, Wis.

Hesston WR9900 Series Self-Propelled Windrower

Led by the new WR9980 self-propelled windrower, the re-designed Hesston by Massey Ferguson WR9900 series self-propelled windrowers has power, capacity and comfort. At 256 horsepower, the new WR9980 provides more capability with less parasitic loss, lower field compaction and no reduction in maneuverability, all without increasing overall dimensions. The improved hydraulic system delivers a 20% increase in available header power on 16 feet disc headers for higher throughput and performance in the most difficult crops and conditions. The new, larger, higher-visibility VisionCab delivers a 50% increase in AC cooling capacity and a new user interface for more intuitive monitoring and control.

AGCO Corp., Duluth, Ga.

Claas Grain Quality Camera

The Grain Quality Camera is a high definition color camera that monitors the quality of grain in the clean grain elevator. High quality pictures of the grain flow are taken every second and then processed to calculate the real-time amount of foreign matter and broken kernels traveling into the grain tank. The feedback from the camera is then displayed to the operator in a picture and/or bar graph so he can actively see the quality of grain entering the grain tank and can modify combine settings according to the camera’s feedback. Picture refresh rates can be adjusted for optimal viewing, as well as active audible and visual alerts inform the operator when the amount of foreign matter and/or broken kernels exceed threshold.

Claas of American Inc., Omaha, Neb.

Hardi Alpha Evo Self-Propelled Sprayer

Hardi North America introduces advancement in its self-propelled sprayer the Alpha evo with a new three post class 4 cab and a new 120 feet Twin spray boom option. The Twin spraying system option has also been enhanced to be able to reach an all-new distance of 120 feet of crop coverage per pass. The combination of these new items along with a pneumatic ride and exceptionally strong yet lightweight design to minimize any potential compaction, and the Twin’s ability to place chemical applications in a uniquely precise fashion to minimize or eliminate drift.

Hardi North American Inc., Davenport, Iowa

John Deere Connected Support – Expert Alerts

John Deere Connected Support – Expert Alerts utilizes telematics machine connectivity and data analytics to predict component failure, reduce diagnostic time and minimize downtime. This all results in higher levels of machine availability, improved machine performance and lower costs for machine operation. Unexpected machine downtime during critical usage times is a crucial risk for farmers and contractors especially as machine and field/farm sizes continue to grow. Due to this technological innovation, cost savings can be achieved at customer and dealer levels while improving the operational efficiency and on-time execution of critical field tasks. Smart proactive repair is less costly and more effective than reacting after the failure.

John Deere, Moline, Ill.

Lindsay Corp. FieldNET Advisor

FieldNET Advisor is an irrigation management support solution designed to provide growers with simple, science- and data-based irrigation recommendations to enable faster, better-informed irrigation management decisions that help to maximize yield potential, while reducing unnecessary input costs and waste. FieldNET Advisor combines more than 40 years of crop and irrigation research into FieldNET’s technology platform, leveraging volumes of big data, cloud computing and remote sensing capabilities, and machine learning to deliver growers field- and crop-specific irrigation recommendations relating to when, where and how much to irrigate. FieldNET Advisor simplifies irrigation decisions for growers by dynamically tracking crop development, seamlessly retrieving irrigation application data and performing computationally intensive soil water depletion calculations, all within the FieldNET platform.

Lindsay Corp., Omaha, Neb.

Venntis Technologies TotalGrow Pure Flowering 200 Lamp

The TotalGrow Pure Flowering 200 Lamp is efficient, reliable and effective photoperiodic lighting for greenhouse growers to control the timing of flowering in long day plants. No other light produces such a targeted light spectrum to trigger long day perception in any plant, and it does so with very minimal power consumption, installation effort and investment cost. This new generation of photoperiodic light bulb eliminates all unnecessary wavelengths and bulb components while utilizing the latest LED advancements in unique configurations to control flowering with unmatched reliability and cost effectiveness for growers.

Venntis Technologies LLC, Holland, Mich.

GK Machine Lettuce Harvester

The GK Lettuce Harvester is a double sided, shaded, stainless steel framed harvest platform designed with a unique track undercarriage, alternator/inverter system with extensions on both sides and it folds up for trucking. The unique feature of the platform is its ability to be driven either direction, one side is for boxed lettuce, the other is for heat sealed bag products. Picking and processing tables fold down on either side specific to the process type. The platform rotates for steering and to maintain alignment with the field, allowing 360 degree direction of travel independent of the platform orientation.

GK Machine Inc., Donald, Ore.

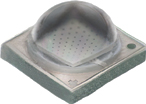

Cree XLamp XP-G3 Royal Blue LED

Optimized for horticulture lighting applications, Cree XLamp XP-G3 Royal Blue LED is the industry’s highest performing Royal Blue LED. The new XP-G3 Royal Blue LED doubles the maximum light output of similar size competing LEDs and delivers breakthrough wall-plug efficiency of up to 81% enabling horticulture lighting manufacturers to deliver higher performance products, reduce luminaire size and lower system cost. At its 2A maximum current and 85C junction temperature, the Cree XLamp XP-G3 Royal Blue LED delivers up to 3402 mW radiant flux, which corresponds to 13 µmol/s PPF in the 450nm peak wavelength light that falls within the peak absorption spectrum of chlorophyll b.

Cree Inc., Durham, N.C.

New Holland Dynamic Command Transmission

The Dynamic Command transmission system is a completely new design of the 8 Step 3 Range Semi Powershift utilizing the dual clutch concept similar to that used with the automobile industry. This is the first transmission of this type within this horsepower segment and provides the customer with the most all around solution in terms of efficiency and productivity. The Dynamic Command transmission is a combination of both new and existing technology. It uses the dual clutch concept from the Auto Command CVT transmission with the electro hydraulic engagement and disengagement of the range and individual gear synchronizers logic from the Electro Command.

New Holland, New Holland, Pa.

John Deere Plus2 Round Bale Accumulator

This new accumulator design is the industry’s first integrated round bale accumulator, it attaches to John Deere 7, 8, 9 and 0 series 6 foot tall round balers. This accumulator allows the operator to carry 2 bales while making the third, and can dump 1, 2 or all 3 bales in one strategic location. This design incorporates a hydraulic system that will transfer the bale from the chamber to the cart and slide the bale to the side with one single hydraulic outlet. The integrated design provides superior maneuverability and handling. The Plus2 accumulator saves operators time and money and reduces regrowth damage.

John Deere, Moline, Ill.

John Deere BalerAssist

BalerAssist is a John Deere 1-Series Large Square Baler that gives the operator the ability to hydraulically control the drivetrain. This revolutionary new drivetrain system is able to operate at two different reduced operating speeds in both forward and reverse directions as well as parking at any given position. This option reduces the time to remove plugs that can occur in the pickup or rotor by engaging BalerAssist from the monitor to back out the plug, meaning operators can spend more time baling and less time dealing with plugs. BalerAssist can also be controlled with a wireless remote, which makes performing maintenance and adjustments, including knotter troubleshooting, a one-person job.

John Deere, Ottumwa, Iowa

John Deere Precision Cotton Harvesting Technology for CP690 & CS690 Cotton Harvesters

The John Deere CP690 and CS690 cotton harvesters offer industry exclusive integrated precision cotton harvesting technology. Onboard moisture sensing and round module weighing technologies are factory integrated into a cotton harvester to provide real time data to a customer that corresponds to cotton quality. Round module moisture sensing uses capacitance technology to provide the most accurate moisture readings. Round module weighing allow producers to easily calibrate their yield monitor in field based off of field and seed variety. Moisture and round module weight can then be tracked and managed by Harvest Identification, Cotton Pro and John Deere Operations Center Field Analyzer application to optimize the cotton production system. These four technologies combined provide a precision farming package that enables a producer and/or farm manager to preserve cotton lint and seed quality and to optimize the overall production system to maximize profitability.

John Deere, Ankey, Iowa

John Deere XUV835 Gas and XUV865 Diesel Gator Utility Vehicles

The new XUV835 Gas and XUV865 Diesel Gator utility vehicles offer the ultimate experience in power, comfort and conveniences. The factory-installed cab on the R-spec model has heating and air conditioning, room for three passengers, dash-mounted controls, tilt steering and a fully-adjustable operator’s seat. It is also the quietest cab in the Gator utility vehicle lineup — quiet enough to have conversations at a more comfortable volume. Models are available in E-, M- and R-trim levels, similar to John Deere tractors, which allows operators to match the right specifications to best meet their needs.

John Deere, Moline, lll.

John Deere AirRinse Sprayer Rinsing System

John Deere AirRinse is an advancement in field crop sprayer rinsing that automatically utilizes water and air to enhance dilution factors, reduce chemical cross contamination risk and reduce the environmental impact of rinsing sprayers. The R Rinse system first applies more of the remaining spray liquid to the field and then better dilutes and recovers the residual liquid compared to traditional rinse methods. Dilution is improved by a 16x factor using the same volume of rinse water. Two convenient and automatic modes allow efficient rinsing in the field or the farmyard to give operators peace of mind the sprayer is effectively rinsed before the next spray application, while also reducing the sprayer’s environmental impact.

John Deere, Ankey, Iowa

Post a comment

Report Abusive Comment