As scientists search for cleaner methods of producing nitrogen (N) fertilizer, they increasingly look to replace the century-old method of treating natural gas with high-pressure steam to produce anhydrous ammonia — the backbone of most forms of agricultural N products.

Lightning Nitrogen

One of the latest innovations comes from California startup Nitricity’s process of mimicking the effects of lightning on the atmosphere to produce nitrates to enrich irrigation water with plant-available N.

Lightning’s electrical energy is powerful enough to break the strong chemical bonds of atmospheric N’s two atoms, allowing them to quickly bond with oxygen in the air, forming nitrogen dioxide (NO2). Freshly formed NO2 quickly dissolves in nearby raindrops, creating nitric acid, which form nitrates. The nitrates fall to the ground in rain and seep into the soil.

“We’re harnessing the power of lightning,” says Nitricity CEO Nicolas Pinkowski, who says the process requires only electricity, water and air to produce one-step nitric acid. He says the system shows promise for decentralized, local N production that does not rely on fossil fuels.

“We’re harnessing the power of lightning…”

Nitricity isn’t “collecting lightning, ala Ben Franklin” but instead relies on battery power generated through solar collectors. Prototypes include 10-50 kW solar arrays connected to the Nitricity on-site system, which is housed in a shipping container. The company’s current mobile N “factories” can be located near irrigation systems to supply chemigation pumps.

“Our first test treated feed water of a commercial tomato production facility’s drip-irrigation system,” Pinkowski says. The company’s process produces calcium nitrate (a water-soluble nitrogen product). Since that time, Nitricity has worked with other irrigated specialty crops in the western U.S., including berries, nuts and stone fruits.

Ultimately, Pinkowski foresees scaled-up systems to service 50,000-100,000 acres so fertilizer could be produced within 50 miles of where it is being used. He says Nitricity’s one-step nitric acid system is an intentional departure from conventional fertilizer production to eliminate the reliance on fossil fuels.

GreenAmmonia

Another non-petroleum source of agricultural N lies in ammonia, chiefly ammonia produced by first splitting hydrogen from the H2O water molecule through electrolysis powered by electricity generated through renewable resources then treating it with catalysts to form anhydrous ammonia.

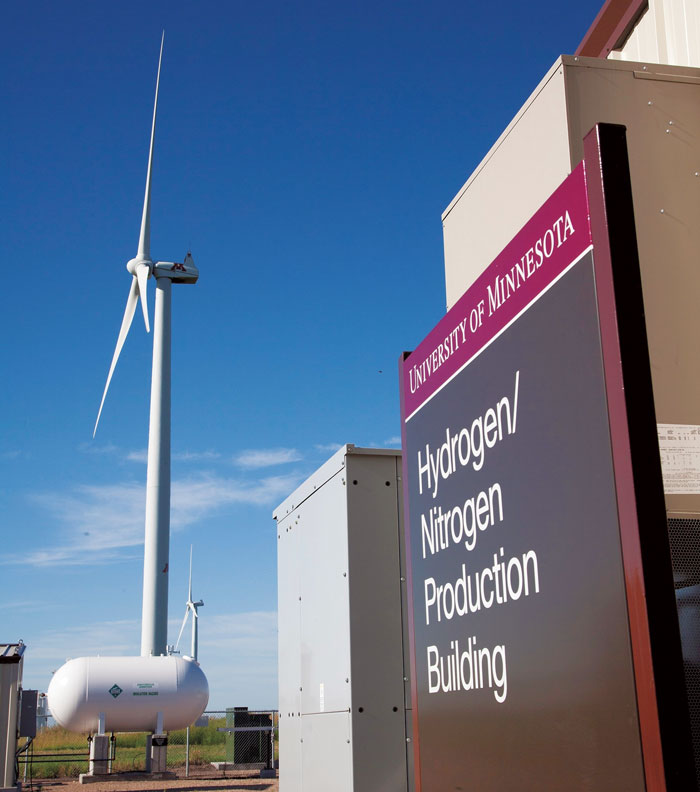

University of Minnesota researchers at the West Central Research and Outreach Center (WCROC) are working on wind-to-N fertilizer and are in the process of developing an intermediate pilot system to further prove scalability of the technology. Shortly after the WCROC was created in 2013, staff researchers built a laboratory system that produced 144 pounds of ammonia per 24 hours.

This wind turbine powers research developing wind for fertilizer systems producing green ammonia. Ammonia produced through renewably powered electrolysis can also be used for fuel in internal combustion engines. Photo: WCROC, University of Minnesota

Michael Reese, director of operations at the center, says the initial system proved the concept and helped scientists tweak the system for efficiency and work with the variables of wind energy, which was supplied by excess capacity of a nearby commercial wind turbine.

Concurrently, U of M mechanical engineers were proving they could successfully power a retrofitted John Deere tractor to run on a 50/50 blend of ammonia and diesel fuel. They also developed ammonia-fueled portable generators to power grain driers, which spike energy demands on local utilities across the Corn Belt during the fall. In both cases, the system provided an 85% reduction in fossil-fuel use. Internal combustion spark-ignited engines can be modified to burn 100% ammonia.

Ammonia, with a chemical content of 3 hydrogen molecules, provides triple the energy density compared to elemental hydrogen (compressed fuel-hydrogen). It’s also much easier to store and transport in existing steel tanks traditionally found in anhydrous ammonia infrastructure.

Those factors have the WCROC collaborating with the local rural electric cooperative to develop ammonia-fueled 150-250 kW portable generator sets to power areas of the cooperative’s grid that have periodic localized demand spikes known as disruptive loads.

“For about 6 weeks in the fall, grain drying and ventilation on area farms drive up demand, and portable gen-sets installed temporarily in grid nodes servicing those farmers can help the utility meet demand without building permanent and expensive substations to meet temporary demand,” Reese says.

Reese says wind-powered ammonia production offers a trifecta for farm country as technology of ag equipment and renewable energy continue to improve.

“Fuel needs, fertilizer and power-grid rationalization all will continue to grow in importance,” he says.