Overseas Journal #1. Farm Equipment ‘Falls In’ on Embedded Tour Assignment to Germany & France

Editor’s Note: When our team started first started conceiving of our plans for the “Ag Equipment Entrepreneurs: How We Did It” podcast series that we released to our audience last year, Helmut Claas and Cathrina Claas-Mühlhäuser (the second and third generation owner-operators of German-based harvesting equipment manufacturer Claas) was on the short-list. A few previous efforts to arrange the meeting (including a previous attempted trip to Germany) had not worked out.

But just as we were about to turn the page on that podcast series and move onto our next plans for our collection of nearly 30 interviews and 45 hours of video footage, a creative idea emerged from Claas’ North American office in Omaha. John Schofield North American Marketing Coordinator John Schofield relayed their suggestion -- to throw me in with a private delegation of 120 during a weeklong visit European manufacturing operations, do the Ag Entrepreneurs interview in Germany and gain some time at the once every 2-years Agritechnica Show in Hanover, Germany.

By the way, Agritechnica is a behemoth of a farm machinery show (world’s largest) that I’d attended twice previously but not since 2007. With ample notice to break in the shoe leather, I was eager to get back. The event’s size (2,820 exhibitors across a 23-building expo ground) and international influence (attracting 450,000 visitors) only continues to grow.

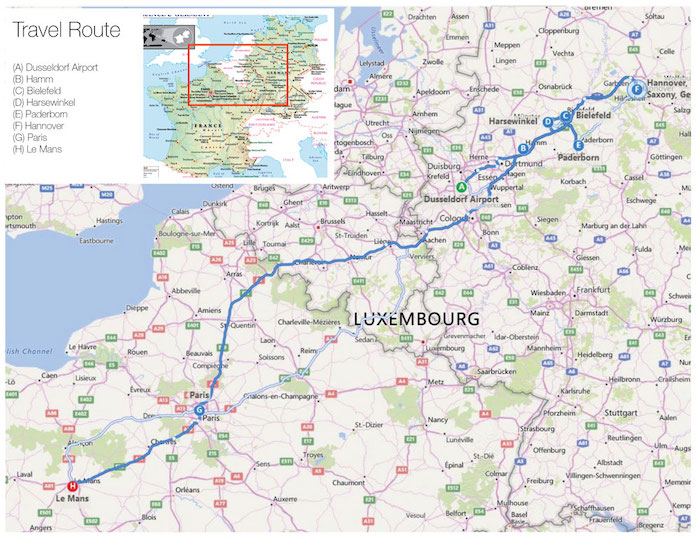

So after much planning, the buses that arrived at the Dusseldorf, Germany airport picked up Claas’ 120-person group, which included VIP customers and prospects (farmers and custom harvesters), Claas America employees, a handful of Claas machinery dealers and just one outlier (an ag equipment business journalist).

I jumped at the chance for this embedded assignment as a peacetime "Ernie Pyle" opportunity to better connect with these different corners of farming, especially in the huge fleet operations in the custom cutting world, many of whom were my bus-mates between plant tours. Plus, it was a rare chance to more deeply understand a $5 billion (U.S. dollars) company that appears ready for serious dealer recruitment and development as it adds the long-awaited tractor purchased from Renault in 2003 to its hay, forage and grain harvesting offering.

The Claas North America people like to use the term “long line” (not short or specialty line) but it’s clear to me that is merely semantics. Their “long-game” intent is to be seen by their dealer partners as a major-enough supplier in which dealers can sustain themselves on Claas business.

Other than a few minor disruptions and bus switches and an extra flight (and deviation from the group’s schedule and an extra flight to interview Cathrina, and tour the Harsewinkel headquarters with a Nebraska trade delegation with Gov. Pete Ricketts), and interviews and photo shoots I conducted while standing in the bathroom stairwell of the coach bus, the group appeared interested in what I was doing, open to share and also wanted to hear our vantage point on the equipment manufacturing, distribution and sales/service back home.

After coming back with full notebooks and multiple recorders and cameras, I’m going to share my week with you in this “journal entry” blog series. We’ll be releasing another “journal entry” every couple of days chronicling the experience in Germany and France in mid-November 2019.

Overseas Journal #2. Düsseldorf to Paderborn, Germany: Claas’ Industrial Technologies (CIT) Operations

Editor’s Note: Farm Equipment Editor/Publisher Mike Lessiter was part of a 120-person tour arranged by Claas North America to tour the manufacturer’s various European manufacturing operations and visit the Agritechnica 2019 trade fair in Hanover, Germany. This installment is part of an ongoing “Journal Series” of that trip, which spanned 11,653 miles in 7 days from November 10-17, 2019.

I’d mentioned in my last journal entry that I was the sole journalist on the Claas Agritechnica trip. Being in the event business (and knowing what it takes to “herd” dealers, farmers and, of course, staff), I’d made a deal with myself to keep things easy on my Claas contact John Schofield and Erin Atkins oversaw hundreds (thousands?) of details on this trip. You see, I learned my presence and chairperson interview request required a change of schedules from the group, as well as a rental car and extra flight (Düsseldorf to Paris to catch up with the rest of the group) for John and me.

Yet my working to finalize an article and a business proposal in the Delta Sky Club in Atlanta on Sunday night (Nov. 10) prompted a check-in call from Schofield to make sure I’d arrived. By the time I packed up my laptop and got to the gate, Schofield was the only passenger there, and with just one ID badge and itinerary left to hand out. Oops. John’s a good sport and I promised him I wouldn’t be “that guy” on this trip. You’ll have to come back later for the rest of the story.

For the 8-hour flight, I was seated next to Marketing Specialist Alan Osterhaus, who’d joined Claas after graduating last spring in Dairy Science and Ag Business from the Univ. of Wisconsin Platteville. I’d spend a lot of time throughout the week with Alan, John and Daryl Theis, who joined Claas of America in December 2018 as head of marketing.

Alan and I killed some time talking about his adopted state of Wisconsin (he’s from a northern Illinois farm family) and his experience that landed him at Claas’ Omaha operations and multiple trips in just a few months on the job. No sleep was in the cards for either of us. I did work my way through inflight movies. My highlights from the trip were Yesterday, The Quiet One (documentary about the Rolling Stones’ Bill Wyman), and 30 for 30’s Survive & Advance (the remarkable NCAA championship story of Jim Valvano and NC State.)

German-style sustenance, the first of many great meals.

We arrived on time at the Düsseldorf Airport at mid-morning on Monday, Nov. 11. Coach buses were waiting to carry us to Claas’ Paderborn facility (107 miles northwest of Düsseldorf), passing through some beautiful farm country. We first stopped for schnitzel, pommes frittes (fries), soup and bier at Deutsches Haus in Paderborn city center -- one of my favorite meals of the trip. I sat with Tucker and Tyson Poling, part of the family custom cutting operation (see below) that had numerous employees on the trip. Both helped me raise a glass of Pils to my German mother-in-law, back in the states on her 76th birthday.

After an efficient but energizing meal, we were off for the Paderborn factory, officially known as Claas Industrial Technologies (CIT).

About CLAAS Industrial Technologies (CIT), Paderborn, Germany

Claas’ facility in Paderborn is focused on drive technologies and hydraulic systems. The campus is 110,000 square meters, employs 600 people over 3 shifts and does the equivalent of $228 million U.S. in revenue. More than once it was mentioned that the Paderborn operation is the “heart of Claas;” that the pre-production of wheels, drive axles and gearboxes was the very basis of the manufacturer’s driving technology.

The Paderborn operation was founded in 1956 when Helmut Claas couldn’t find enough people for his growing capacity needs in the tiny hamlet of Harsewinkel. The much larger burg of Paderborn offered more labor, so Class put his operating investment into Paderborn, about an hour’s drive south from the Harsewinkel headquarters.

Claas Industrial Technologies (CIT) Offices.

By 1975, Claas had come with a revolutionary automatic steering system for forage harvesters, which the CIT started making available to other manufacturers as well. That industry leadership continues to this day, with Claas supplying the likes of Amazone, CNH, Horsch, John Deere, Lemken, MacDon, Oxbo, Same Deutz Fahr, and Vermeer as well as other manufacturers, including municipalities and automakers. Along the way, the CIT became a full system supplier through independent bench and vehicle tests

Following a detailed presentation on the facility, we broke off into 2 groups for a 90-minute or so tour.

Of high interest to our tour was the Terra Trac undercarriages produced at the CIT. Regarded by the company (via the new Claas book, Sowing Ideas: Harvesting the Future) as Innovation #16, the Terra Trac (introduced in 1988) represents the intersecting interests of high road speeds and excellent mobility in the field with high load capacity. According to the presentation we heard, CIT is reinvesting 5.6% of sales annually to continually develop its chassis concept and other competencies at the plant. Because my company (Lessiter Media Inc.), also publishes No-Till Farmer, it was noteworthy to see the system promoted for no-till and its soil protection and compaction-reducing benefits.

The CIT had the most variety of the first of many tours on the Claas trip. And while the plants’ physical buildings showed their age, they were well-lit, orderly and clearly demonstrated a great deal of modernization for a metals machining business (including Kuka robots), with numerous examples of intricate final-machining and hardened parts, as well as a modern paint system. With the number of custom cutters on the trip, a fair amount of time (even a return-tour) was spent examining the corn cracking and shelling components machined at the facility.

3. Claas Terra Trac undercarriage system

Back on the bus, I got the chance to meet Todd and his wife Honey Poling, co-owners of PMS & Harvesting in Clayton, N.M., whose holdings include a large-scale custom harvesting business covering the Texas panhandle, New Mexico and Oklahoma. I would learn more about the Polings throughout the bus trip, but I quickly grasped that this was not just a typical custom cutting operation, evidenced by the number of representatives and wives on the bus for a first-hand look at the manufacturing operations and equipment. The number of acres harvested and the company’s fleet size (choppers and tractors) remains too big for me to get my head around.

I learned that the PMS harvesting business took off in large part when the Faria family (based in Arizona and California) moved its new dairy operations into the Texas panhandle, which included a then record-setting 106-cow rotary milking system to support 7,100 cows. Poling who credited his early exposure to Claas as part of his growth, also clearly gained from earning the opportunity to be the Farias family’s harvester of choice. The Faria family continued to move more cows into the region and a needed the efficient, reliable source of feed that PMS would cut for them.

We arrived at the Legere Hotel in Bielefeld, Germany (our home base for the next 3 nights) just in time to drop the bags and walk to the Brauhaus Johann Albrecht near the town square. Over a great buffet of German cuisine and free-flowing pitchers of bier, I met two farmers from Colorado and their wives, and a newly engaged farm couple from Iowa who had lots of work ahead of them to harvest upon their return.

I got to back to the room at 9:30 or so that night and found myself nodding off (with multiple file folders on the bed) as I prepared for the “Ag Entrepreneurs” series interview with Cathrina Claas-Mühlhäuser the following morning. For those of us unable to sleep on the plane (and smart enough not to fall asleep on the bus), it was a long day, at 25 hours awake. I had no problems sleeping that night -- a good thing as the giant (almost overwhelming) Agritechnica experience would come fast the following day.

Be sure to return to www.farm-equipment.com/acrossthepond19 for the next entry.

Coming Next ... Overseas Journal #3. Interview with Cathrina Claas-Mühlhäuser (Claas Corporate Chair), Eric Raby (North America President and General Manager -- Sales) and Day 1 at Agritechnica

For More Information ... Other Recent Claas North American content from the editors of Farm Equipment

- John Deere, Claas, CNH Industrial and 365FarmNet Form ‘DataConnect’

- Royal Reesink Buys into Manitoba Claas Dealerships

- [Video] Presenting the New Axion 800 & 900 from CLAAS North America

- [Video] Introducing the New 8600 Lexion from CLAAS North America

- [Video] CLAAS at the 2019 Dealership Minds Summit

- Claas Announces Plans to Grow North American Market, ‘Be Brighter’ Branding Campaign

- Claas of America Breaks Ground on New On-Site Training Facility

- Thomas Böck Named Claas' First CEO