Sievers Equipment Co.

Established: 1971 |

Maintaining good business records is required of all enterprises. Actually “keeping” them safe and secure, though, is a completely different story. For Sievers Equipment Co., keeping good records and being diligent with their system backups proved to be more than a good business practice — it helped them pick up the pieces when disaster struck.

Walter and Ruth Sievers, along with their sons Gary and Jim, opened the Case IH dealership in 1971 in Edwardsville, Ill., as an Allis Chalmers store. After 4 years the company outgrew its space and built a new facility in Hamel, Ill., which remains the dealership’s home base. At that same time, Sievers Equipment took on the Steiger tractor line.

Today, Gary and Jim, along with their sons Brian, Greg, Mark and Tim, run the six-store dealership.

“It’s kind of funny to look at it because it [the Edwardsville facility] could fit inside of this one about 10 times or more. It’s amazing where the equipment’s gone and where we’ve gone as a company in that timeframe,” says Brian Sievers.

A Growing Company

In the early 1980s, the Sievers added New Holland hay tools to their lineup and began their expansion, opening a second store in Litchfield, Ill. “We picked up Case IH in the 1987-88 timeframe when the Magnum tractors first came out. We got in right at that time, and then picked up the Ford tractor line with New Holland in 1989,” Brian says.

After acquiring the territory of Voils Bros. International in 1993, Sievers Equipment built a new facility in Hillsboro, Ill., and closed the Litchfield location. The acquisitions kept on coming with the addition of the Greenfield facility in 1999. Eleven years later the company grew again, acquiring 2 stores — Auburn and Carlinville — just a month apart.

“We had contact with Keith Beatty at the Auburn store prior to him being ready to sell out, and we just told him whenever he was ready that we were interested in talking with him,” Brian says. “It was August of 2009 when he called us and said he was ready. We started talking with him, and then within about two weeks the Konneker’s from Carlinville came down and said they were selling and wanted to know if we were interested in purchasing that store also.

“Two at a time was a little bit of a challenge, but geographically the Carlinville store is located right in the middle of all of our other ones. We sure didn’t want somebody else right in between our other locations, so we did them both that year. We closed on Auburn in March 2010 and Carlinville in April.”

Before these latest expansions, however, the dealership and the Sievers family would be dealt a large blow.

Tragedy Strikes

On the afternoon of February 9, 2007, a fire broke out above the parts department of the Hamel store. The fire spread quickly and by the time employees were able to react it was already too late. It took only minutes for the flames to engulf the entire building and spread to the attached repair shop.

Three key members of the staff — Gary, Jim and Brian — were out of town when the fire broke out. They were in Orlando for the Case IH business meeting. “If I’ve ever had a frog in my throat making a phone call, I remember standing on our front lawn here — I don’t think the fire department was here yet — calling and leaving my dad a message that ‘you need to call me back, our building’s on fire.’ I hope I don’t ever have to do that again,” Mark says.

The three cut their trip short and got flights back and watched the St. Louis news coverage of the fire on a laptop in the Orlando airport. “It was just sickening because you can’t do anything about it,” Brian says.

“For me the hardest part, was obviously not being there, but also having to watch. There was Grandpa on TV being interviewed, knowing that he had to stand there and watch 35 years of his life burn up in front of him. That was the toughest part for me. The building you can rebuild and all that kind of stuff, but it was hard to watch that,” Brian says.

Gary and Jim Sievers (center) opened Sievers Equipment Co., along with their parents, in 1971 in Edwardsville, Ill. Today, their sons — (l to r) Greg, Brian, Tim and Mark — are also involved in the 6-store dealership’s operations. |

When Gary, Jim and Brian finally made it back to Hamel around 10:30 p.m., there was nothing left of the main building. Two shops behind the main building survived the fire, though. “We would have really been in trouble without those shops,” Brian says. “We had about 40 people working at that time. The other two locations couldn’t have absorbed all those people; we would have had nowhere to go.”

Sievers Opens Construction Store

In June, Sievers Equipment opened a construction equipment-only store in St. Peters, Mo. While the other stores handle construction equipment in addition to ag equipment, this will be the first store dedicated to JCB equipment. It is also the dealership’s first location in Missouri. “It’s not a whole new business because we’ve been in it for a while, but we’re trying to get our construction brand firmly established and we’re doing that in the new market in the new facility,” explains Mark Sievers, who handles the JCB side of the business. Sievers picked up the JCB construction line in 2005 to complement the tractor/scraper sales. “We were involved in construction through those sales, but we didn’t have backhoes, we didn’t have excavators and that kind of equipment and we were looking for something to complement the tractor/scraper business and JCB seemed like a fit,” says Brian Sievers. Prior to opening the St. Peters location, construction only made up about 10-15% of Sievers business. “We’re hoping to change that. In the future, we hope what we’ve done with our Case IH brand, we’ll be able to do with JCB,” says Brian.

While there was no sort of emergency plan in place, Brian says the employees who were onsite that day did an incredible job of getting everything they could out of the building.

In June, Sievers Equipment Co., expanded to include a construction equipment only store located in St. Peters, Mo. |

“The employees here did a really good job of limiting the damage. If they hadn’t been on their toes as much as they were, it could have been a lot worse. They cleaned as much as they could have cleaned out of the shop before it burned and moved vehicles away from the building,” says Brian. “They really did a good job of making sure that at least the damage was contained to the main building and not our other two shops.”

In addition, everyone got out of the building safely and no one was injured.

System Back Up

The company was prepared in one sense though. Their business system automatically backs up regularly, and when all was said and done Sievers Equipment only lost about half a day worth of business.

“Friday morning’s business records are what we lost, we had to recreate that from memory. But our computer system vendor, DIS, had us up and going by the following Tuesday. We had our system back up, we had our inventory back, we had our accounts receivables back, payables, all that, and we were able to give a list to the insurance company as to ‘here’s the parts we lost down to the penny.’ We knew exactly what we lost. The insurance company was fantastic; we’ve got no complaints about them whatsoever. They were ready to write us a check before we were ready to tell them what we needed. They were there and offered support for continuing business.”

The dealership didn’t waste anytime getting back up and running, in part thanks to a comment Walt made to the news. “When they asked him when we were going to rebuild, he said ‘We’ll be open Monday,’” says Gary. “There was no lag time, we just kept rolling along. With the help of family and the good employees, we just moved right on.”

When Sievers Equipment Co. rebuilt its Hamel, Ill., location following the fire, a mezzaine over the showroom was included to allow for future office expansion. |

By Monday morning they had moved into a setup shop and got the telephones set up, and within the first day or so they had a new business server ordered. “They got it to us quickly, so we could communicate again with our vendors and the other stores. It was chaotic there for awhile,” Jim says.

Back to Business

“Those few days afterward I don’t know that anybody knew if what we were doing was necessarily right or wrong,” Brian says. “I think our primary focus was to be able to get back to some sort of level where we could support our customers again.”

In order to get back to serving customers, Sievers Equipment set up a temporary parts warehouse and started working with its vendors to get parts ordered and back on the shelf, all while sifting through the pile left by the fire, Brian explains. “But our primary focus was the customers because it was 6 weeks before spring planting season. We knew we had to be functional in order to support our customers,” he says.

Jim Sievers says taking care of the customer is at the core of their mission statement, and it was no different following the fire. “The building part of that was in the background, which is why it took a little while to get up and going on the rebuilding.”

Through radio and advertisements the dealership kept its customers abreast of developments and directed them to the two other stores in Greenfield and Hillsboro, Ill. “We wanted to make sure we didn’t lose our customers,” Brian says.

Jim says this worked because the business system is set up so all of the stores are tied together working as one system. Within a week, the Hamel location was back to actively ordering parts and filling orders. “Obviously we didn’t have anything left on the shelf, but we were able to order everything, and we did have 15,000 square feet of shop space we were able to use. So we carried on without really missing too much at all,” Brian says.

A temporary computer system was setup by the Tuesday following the fire. “I was on the phone with our computer vendor while I was still in Florida before we even left the hotel, getting the backup machine on the way. We sent them our backup tape on Saturday and had that box powered back up on Tuesday,” Brian says. “Our stores were all integrated together, and that’s a little bit of a double-edged sword because when that system was down — and it was crispy, the physical box was burned up at the store here — Greenfield and Hillsboro didn’t have access to their inventory either because that was all in that one box.

“So they worked for us to get that back up and going as soon as possible and with the help of DIS we were able to do that really quick. Within 5 days we were up and going.”

Building Anew

With just scraps left of the original building, there was no other choice than to completely rebuild. Sievers Equipment’s new facility is 63,000 square feet, nearly twice the size of the old facility. “Honestly, if given the choice, if somebody said you’re going to have a fire, whether it be here or at my home, the way it happened here where it burned to the ground is the better way. There was no question about saving any part of it. There was no choice, we pushed it into a pile and hauled it away.

“That was the easy part of it because you didn’t have to think about it. Then it was just a matter of how are we going to rebuild, how big did we want the new store,” Brian says.

The footings for the new facility were in place in January and the Sievers moved back in by that September. “We were fortunate because harvest was late that year so we were in right before that started and it worked out well,” Brian says.

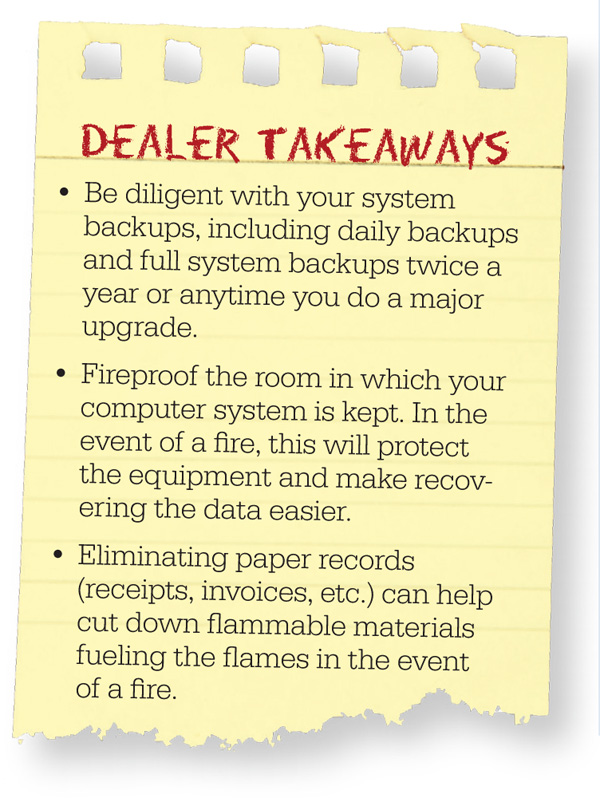

One of the main features of the new building is something most people never even see. The room where the computer system is housed is completely fire proof. “That was one of the things we requested when they built the new place. We wanted to do whatever we could to build in some fire protection to that room in case something bad happens again,” says Brian.

“One recommendation to other dealers would be if they don’t have their computer really isolated and fireproofed, they ought to get it that way,” Brian says.

System Backups

While Sievers Equipment was good with system backups before the fire, the dealership group has become even more diligent at it since the fire. Each day the system is backed up, covering all the inventory records, accounting, etc. Then, the backup media is taken off site until the next day. The dealership rotates out a different media every day, Brian explains. In addition, twice a year a complete system backup is performed. Complete system backups are also performed whenever there’s a major update to the system. “It seems redundant, but it’s only redundant until you need it and then you’re stuck,” Brian says.

He adds: “So that is very important to have a very rigid and a very thorough backup plan as far as your data is concerned.”The dealership is also trying to cut down on the amount of paper they keep around. “We’re a lot more technically advanced than we were back then because we found out after the fire that you maybe don’t need to keep all the papers, so we’ve gotten pretty close to being paperless,” Brian says.

To eliminate much of the paper, Sievers started using Easy File. “What that allows us to do is we scan in all of our important documents like wholegood invoices, packing lists and the like,” Brian explains. “They get scanned into our business system and are archived there and then backed up every night as part of our backup schedule. Had we done that prior to the fire, we would have had a lot more information left over.”

Moving Forward

This past summer Sievers Equipment opened up its first store that’s dedicated solely to construction equipment in St. Peters, Mo., that carries JCB equipment . While there is an immediate focus on growing the construction end of things, the Sievers aren’t settling down on the ag side of the business. “We are still interested in growing our ag business. If another facility or territory would become available, our long-range plan is to keep growing the business with more dealerships,” Brian says.