Machine autonomy has tremendous potential throughout the agriculture industry. But when it comes to leveraging a fully autonomous solution, few market segments present as much immediate potential as sod farms.

“Due to the extremely high acre travel involved with sod farming, we view it as the best market opportunity for autonomy right now,” says Mike Burdick, sales director at Sabanto, a developer of autonomous retrofit kits for tractors.

A dealer down South helped bring the opportunity to light.

Takeaways

- Sod farmers are generally receptive to automation due to the high acreage travel their machines accrue over the course of a year.

- Sod farms that are struggling to find labor are especially receptive to automation.

- The choice between a tractor retrofit kit and standalone machine largely comes down to how much a sod farm needs to mow, and which other field work it would like to automate.

- Semi-autonomous equipment such as sod harvesters can also help reduce labor needs.

“When I’d first met with Sabanto, I told them I didn’t want to immediately go to the row-crop space,” says Brian Kelley, founder and executive vice president of Ag Technologies in Cordele, Ga., a precision ag dealer and technology solutions consultant. “I told them I was taking their retrofit kit to the sod market because it makes the most sense. The nice thing was that the leadership at Sabanto had the humility to make the pivot toward sod.”

That pivot has paid off. Ag Technologies has sold dozens of Sabanto retrofit kits to several southern sod farms over the past year or so.

A manufacturer of autonomous electric tractors has also seen the opportunity in the sod market. Monarch Tractor has been emphasizing the dairy industry due to the repetitive work and high tractor utilization associated with that type of operation. The same can be said of sod farming.

“In a third of the country, sod farms are mowing almost 11 months out of the year,” says John Isaacson, lead test technician at Monarch Tractor. “As you move north, that only scales back by a month or two. Within that window, a mower is typically mowing all day, several days a week. That is a lot of machine time, and it’s repetitive work. That’s a big pain point growers are hoping autonomy can help solve.”

Unobstructed Utilization

Burdick puts a sod farm’s autonomy opportunity into context. A corn/bean grower managing 1,000 acres might make 8-10 trips across their fields over the course of a year. That’s upward of 10,000 acres of travel. Now take a 1,000-acre sod farmer. If they’re mowing 3 times a week for 40-50 weeks, that’s upward of 150,000 acres of travel.

“The economics of autonomy and the efficiency of ‘mowing with the internet’ are through the roof,” Burdick says.

Kelley agrees, adding that at least 85% of his sod farm customers are solely looking to automate the mowing aspect of their operation. That said, some customers are looking to automate other tasks, such as fertilizing and spraying, and perhaps even rolling and aerating. With retrofit kits like Sabanto’s, growers can automate all of those different implements and functions.

AMP Mowers from FireFly Automatix provide a 100”W cut and are available in both reel and rotary mower configurations. Pictured here is the AMP L-100 reel mower that’s well-suited to grass types that are maintained shorter. All AMP mowers utilize an advanced sensor known as LiDAR. Unlike radar which uses radio waves, LiDAR (light detection and ranging) uses light in the form of a pulsed laser to measure distances to objects. It’s known for being extremely precise, which enables something like an autonomous mower to do a really good job at detecting obstacles. FireFly Automatix

“The more field work you can do, the better the ROI,” Burdick says.

Along with acreage travel and tractor utilization, there are other reasons why autonomy really lends itself to a sod farm. A big reason is the consistent, relatively unobstructed environment the equipment operates in.

“You’re generally dealing with a crop that is fairly uniform and low to the ground,” says Steve Aposhian, principal founder and chief technology officer at FireFly Automatix, a manufacturer of fully autonomous mowers and semi-autonomous turf harvesters. “It’s also a more open space that makes it easier to see obstacles. That’s not as easy to do when you’re mowing something like alfalfa.”

Options for Full Tractor Autonomy

Sod farmers essentially have 2 ways to go when looking to automate aspects of their operation:

- purchase a retrofit kit to automate an existing tractor and implements

- purchase a dedicated autonomous machine that’s designed to perform a certain task(s)

Which way to go will largely come down to what the sod farm’s existing equipment fleet looks like, how much and how often they want to mow, which other tasks they want to automate and how much they are willing to invest.

“If a grower has to invest $250,000 just to automate a single task, it might not make financial sense unless they have a lot of acres to manage and are really struggling to find labor,” Burdick says.

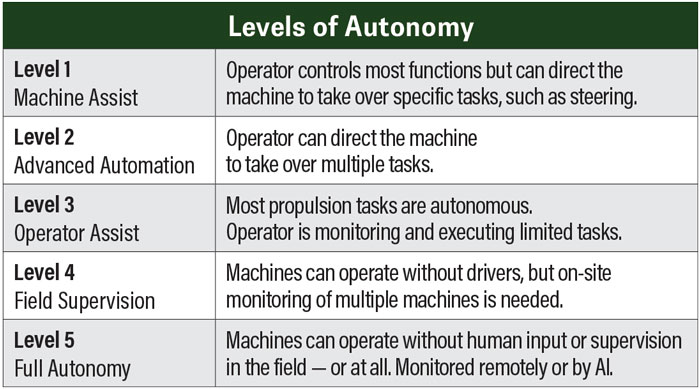

There are varying degrees of machine autonomy, and each can have a positive impact on different aspects of a sod farming operation. Fully self-driving tractors and mowers, for instance, represent full Level 5 autonomy. But even semi-autonomous equipment can drive productivity through the roof.

For a sod farm that fits that criteria, Aposhian says other factors will also contribute to a relatively quick ROI on a fully autonomous, dedicated mowing machine.

“In the world of automation, simpler is better,” Aposhian says. “A fully electric autonomous mower is simpler than a combustion machine.”

In the case of FireFly Automatix, two styles of autonomous mowers are offered. One is a diesel-electric hybrid with a 251-inch cut width. The other is a smaller, fully electric machine with a 100-inch cut. Aposhian says the smaller model is what’s really catching on with sod farms.

“There is no fuel, hydraulic oil, engine oil or coolant,” says Aposhian, who happened to grow up on a family sod farm alongside his father and brothers. “When you look at it, making a machine drive autonomously is actually pretty easy. The complications arise when you think about the other things an operator does. For example, an operator could detect when a machine is leaking hydraulic oil all over a field. That can be very difficult to detect with sensors.”

Monarch’s Isaacson says another potential challenge with autonomy — regardless if you’re talking about an EV or diesel-powered solution — relates to runtime. He says Monarch’s fully electric tractor generally provides a 4- to 4.5-hour runtime, which is on par with the runtime of the typical diesel-powered tractor used to mow sod farms. In either case, a human being must intervene to refuel the mower, whether that means plugging it in to recharge or adding diesel to the fuel tank.

In the case of FireFly Automatix, Aposhian says their 100”W electric mower is capable of mowing 20-25 acres on a single charge, and can recharge in roughly 2.5-11 hours depending on which charger the customer is using. A human must retrieve the mower and drive it back to wherever the charging station is.

Another potential challenge relates to communication with the implement. According to Isaacson, it’s hard for an autonomous tractor to know when a belt or blade breaks on the mower trailing behind it, if a roller bearing went out, etc., — unless that implement is tied into the central neural system of the tractor, i.e. the CAN bus on a traditional farm tractor.

Monarch Tractor’s MK-V electric tractor is data-driven and driver-optional. It offers a runtime of up to 14 hours, and can recharge in 6 hours with an 80-amp charger. It’s equipped with a Cat I/II 3-point hitch, hydraulic top and side links, enabling integration with a range of compatible implements ranging from mowers and sprayers to tillers and weeders. Monarch Tractor

Sabanto’s solution, referred to as Steward, is currently designed to work on roughly 20 tractor models across 3 brands: Fendt, John Deere and Kubota. The retrofit kit includes several familiar “off the shelf” components. For instance, the GNSS positioning system runs off the Trimble RTX network, so the kit includes a Trimble receiver. The steering system also comes from Trimble.

“There is no need to reinvent the wheel on some of these things,” Burdick says. “The proprietary software comes into play when you’re talking about starting, stopping and maintaining the tractor, along with the overall field operation. That’s all in what we call the brain box, or the main control box.”

Installing the Sabanto retrofit kit on a compatible tractor generally takes about a day for 2 technicians, according to Burdick. “Once installed, it can pull a mower, roller, sprayer, spreader and Agri-vator,” Burdick says. “It is truly a multi-faceted autonomous tool that can do 90% of what a human operator can do.”

Opportunities for Semi-Autonomous Machines

Self-driving tractors help reduce labor needs by allowing a single operator to remotely control several machines at once. It’s a concept known as “swarming,” and you’ll typically hear talk about swarming 3-5 machines in a mowing-type application.

It should be noted, however, that a fully autonomous machine like a self-driving tractor is not the only opportunity for automation on a sod farm. Machines with specialized aspects of autonomy can also help increase productivity.

Case in point, FireFly Automatix has offered semi-autonomous sod harvesters for a decade now. “They fit somewhere around Level 2 or 3 on the autonomy scale,” Aposhian says. That means the equipment still requires an operator, but the operator is there to monitor certain automated tasks.

In the case of FireFly’s ProSlab sod harvesters, the process of taking sod slabs off the conveyor and stacking them on a pallet is automated. Additionally, the machine utilizes electro servo motors, as opposed to relying on hydraulics. Aposhian says that provides fast, smooth and reliable movements. That helps speed productivity while reducing machine wear and fuel consumption. Most importantly, it helps reduce labor needs.

“The desire is to mow 3 times per week during peak season. An autonomous solution allows these farms to take a 10- to 12-hour workday & potentially extend it to as much as 16-24 hours…”

“We’re doing a lot more with less, and in a much shorter period of time,” says Lindy Murff, vice president of Murff Turf Farm in Crosby, Texas. He bought his first FireFly semi-autonomous ProSlab sod harvester in 2014. Today he’s running 11 machines across his 4,500-acre operation.

“With the harvesting operation we have, I would need around 45 people to harvest the old-fashioned, manual way,” Murff relates. “By using these automated machines, we’re doing it with 22 people.”

Since the slab-stacking process is automated, Murff has been able to reduce headcount from 3 to 1 on a single machine. When harvesting the old-fashioned way, 2 people were needed per machine just to manually transfer the slabs from the machine’s conveyor to a pallet.

“Just the process of putting a new, empty pallet on the machine took about a minute,” Murff relates. “When you do that 100 times a day, that’s over 1.5 hours wasted. Not anymore. We could not produce at the level we are if not for these semi-automated harvesters.”

More Benefits than Just Labor Savings

If it’s not already obvious, the big ROI factor on autonomous equipment is labor savings. But as Kelley points out, there’s a “product quality” component that also factors in. More frequent mowing promotes better root development. That enables sod farmers to produce a premium-quality product.

“Every sod farmer I’ve ever talked to said they’ve always wanted to mow more frequently,” Kelley says. “But they were always a little behind because of labor. With autonomous mowing, they can keep their mowing regimen on task. Our customers tell us that a better sod product is as valuable as the labor savings.”

A FireFly Automatix semi-autonomous ProSlab sod harvester has become standard equipment at Murff Turf Farm in Texas. They currently run 11 machines across their 4,500-acre operation. Murff Turf Farm

Burdick couldn’t agree more. “Historically, the typical sod farm could get across its acres 1.5-2 times per week,” he says. “From what I hear, the desire is to mow 3 times per week during peak season. An autonomous solution like ours allows these farms to take a 10- to 12-hour workday and potentially extend it to as much as 16-24 hours.”

Additionally, the more Agri-vating a sod farm can do, the better. That’s a method of aerating that’s specific to sod farms. Burdick says an Agri-vator is one of those implements that doesn’t even get pulled out of the shed because the sod farm just can’t get around to it. By automating the field work, Agri-vating once per week is entirely possible.

Nonetheless, mowing is the main activity. In addition to more frequent mowing, more precise mowing is also something dealers can talk about when pitching autonomy to sod farms.

In the case of FireFly Automatix, their 100”W mowers are offered in either a reel or rotary mower configuration. Reel mowers are better for grass species that are kept shorter. Additionally, Aposhian says a patented steering and drive system features 4 independent motors, 1 for each wheel. That enables gentler and more precise turning, which is beneficial when sod is soft or wet and prone to scuffing.

Retrofit kits bring autonomy to not only the tractors they are installed on, but also the implements those tractors pull. Pictured here is an Agri-vator on a John Deere tractor retrofitted with Sabanto’s autonomy solution. Agri-vating is an important post-harvest activity to help relieve compaction on a sod farm. Sabanto

Overlap is another thing to think about, which speaks to both cut quality and efficiency. Burdick says the sod industry average is 10-12% overlap. That might equate to a foot or more depending on how wide the mower implement is.

“The Sabanto system can dial the overlap down to an inch or less,” Burdick says. “That allows the tractor to mow more sod each day.”

Machine wear and maintenance are other important factors to consider with respect to total cost of ownership (TCO) and ROI.

Sabanto’s system is designed to have a minimum turn radius associated with the tractor and mower it’s pulling. That’s so it doesn’t turn too quickly, which is how some operators end up snapping a PTO shaft.

“The operator tells our system how they want it to turn, and it will make that same sweeping turn every single time,” Burdick says. “That reduces wear on both the tractor and the implement. Plus, well-designed autonomous tractors don’t ride the clutch or ram into things.”

Given all of these benefits that translate directly to a sod farm’s bottom line, it’s fairly easy to see why automation companies like FireFly Automatix and Sabanto have placed so much emphasis on the sod market. Even for those sod farms that aren’t having a difficult time finding labor, the potential benefits of autonomy seem to hit home.

“The general ROI timeframe is in the window of a year to maybe 2-2.5 years,” Aposhian says. “But there are also intangible benefits that really seem to connect with sod growers. We always hear about things like reduced stress, the owner’s quality of life improving, and gaining the ability to get more done and expand the operation. All of those factors play into things, and it’s hard to put a number on things like that.”

Sabanto’s Steward Retrofit Autonomy Kit is currently compatible with roughly 20 tractor models across the Fendt, John Deere and Kubota brands. The kit includes a proprietary main control unit, CAN bus monitoring interface, cellular antennas and a receiver. The system’s advanced cameras, obstacle detection sensors, GNSS systems and robotics pair with mobile and desktop applications, allowing for complete control and field monitoring. Sabanto

Dealers should tread cautiously when talking about ROI anyway, according to Burdick. The pie-in-the-sky payback numbers some marketers touted with respect to previous innovations have left some growers a bit skeptical. Dealers should be realistic when discussing ROI expectations. Sabanto actually provides a template so growers can plug in their own equipment and wage information to get a personalized ROI projection. That said, in most instances where a sod farmer is able to bolt a Sabanto retrofit kit onto an existing tractor, payback is in the 1- to 1.5-year range. If the customer has to go out and buy a compatible tractor, the ROI window often extends out to 1.5-2 years.

“Keep in mind that this number becomes exponential when an operation becomes larger,” Burdick points out.

Say a sod farm is running 5 mowers. Being able repurpose 3 of those operators to other aspects of the operation increases productivity. The other 2 operators can remotely operate the 5 autonomous tractors, and could likely operate up to 10 tractors if the operation wanted to expand.

“That’s when things become exponential with autonomy,” Burdick says. “In that type of scenario, the payback could happen in something like 6 months.”

Nothing will happen if a sod farm isn’t prepared to make the shift to autonomy. There’s more to it than just buying autonomous equipment or retrofit kits. According to Kelley, training tractor operators to remotely control autonomous machinery is actually the easier part of the transition.

“Change management can be a tough thing,” Kelley says. “Leadership at the sod farm needs to have a clear vision for why and how they want to use autonomy. They also need to realize that they’ll need to change some of their core processes. They’ll also need clear metrics to help measure performance and success. Just like when implementing a new software, autonomy is only going to work as well as the time and effort users put into it.”