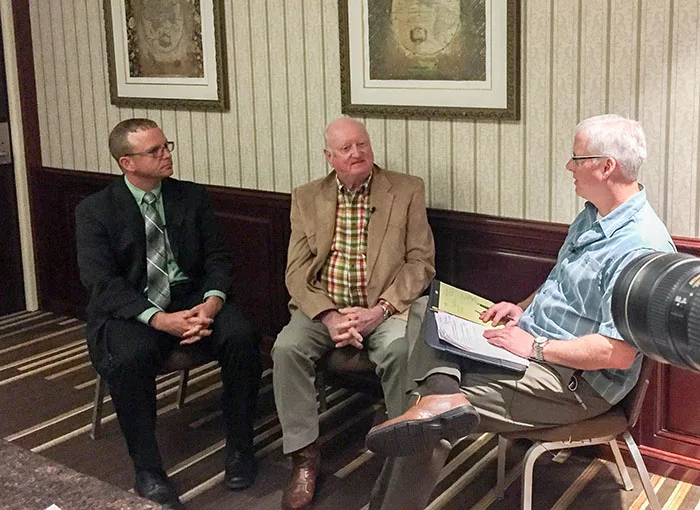

The following is the full interview between Farm Equipment editor Mike Lessiter and Tom and Tim Burenga of Worksaver. They detail the company’s origin story, their early memories and the differences between yesterday and today’s farmer.

Tom Burenga: There were 3 gentlemen in Litchfield, Ill., that formed the old Wikomi Company and one of those gentleman was J. O. Hinken, and he ended up with that company after a year and he ran it up until 1974, the end of 1974. And then he sold that company to Phil Sams. Phil Sams operated the company, he had a manager there that ran it and then Phil, I met Phil in 1978 and in the end of ’79 he asked me to come down and try and operate the company and help them straighten it out. I had run the manufacturing operations of Tractor Supply prior to that. So anyway, I came down and started in December of ’79. We had some very tough times, the ag economy was down considerably, and it stayed down through the early 80s. We had a lot of rebuilding to do. The old Wikomi Company of course was in very bad shape. The widow of Mr. Hinken had foreclosed on us on Wikomi and so we formed a new company called Worksaver Incorporated and that officially came about in April of 1980. Had a lot of challenging times. We had many, many things that were wrong, and the worst of it was the ag economy and I had by spending 10 years with Tractor Supply I had met a lot of people and a lot of them had left Tractor Supply and gone into the farm store business and so that was the one market opportunity that I saw and so we developed a lot of our new equipment and some of the old, we adapted it to the farm store market and that’s what helped us stay alive. So that’s how we at least got to a breakeven point anyway.

Mike Lessiter: Tim, go over the scope of the products that you have.

Tim Burenga: We have a vast array of different products that we have for the market. Basically any type of attachment for a 3-point front loader or skid steer is mainly what we build. And we have a lot of different product lines. We have Land Management products where we have debris removal, material handling products such as pallet forks, grapple rakes, rotary brooms. We have snow removal products, blades and pushers. We have fencing products, post drivers, posthole diggers. And another product line we just got into a few years ago was adapter brackets where we take tractor manufacturers older connection styles and convert them over to either skid steer or euro global attach. So anyway, with all that said, we have over 500 whole goods that we offer to the market.

Mike Lessiter: And a mix of both your own label product as well as making product for other manufacturers?

Tim Burenga: Yeah.

Mike Lessiter: Who are some of the OEMs that you supply?

Tom Burenga: Well in 2003 we were asked to build some products for John Deere’s Frontier division and we accepted that and we started building I think 7 or 8 different products at that time, and then that’s now expanded.

Tim Burenga: We’re at 38.

Tom Burenga: And so that’s the biggest part of our company, but we’re also looking for other contract work to do and we build stuff for Buhler up in Canada and we do a little bit for Woods and Alamo, and for Bush Hog, CE attachments — which is a division of Gehl.

Mike Lessiter: And the Worksaver product line goes through a 2-step distribution?

Tom Burenga: Everywhere except Illinois. Yes, in Illinois we are direct to the dealer, but everywhere else in North America we do go through wholesale distribution. And primarily the way our business is as of right now, it’s 50% Worksaver, 50% contract manufacturing.

Mike Lessiter: I’ve had the pleasure of getting to your place, but for our listeners here, describe the type of machines and type of manufacturing that you do down there in Litchfield.

Tom Burenga: Well, years ago we were building mainly product line for the farm stores. And the competition we had were down south and they paid a lower wage and so they could produce their equipment more economically or for less cost than ours. And I knew at that time we had to do something to change it. So we started back in say 1990 to try and modernize and add computer-operated equipment and become more productive. And I’ve told the men that work for us, we didn’t necessarily need to work harder, we had to work smarter. We had to produce more product per hour per day to compete against the southern competition that we had at that time. And that we have kept that philosophy and so now today we have 5 welding robots, we have a laser operated cutting machine, we have plasma cutting machines, got CNC operated lathes and machining centers, we have a CNC operated press brake. We still have some of the old equipment, big old presses and stuff like that, but we definitely tried to modernize and also become more sophisticated in our manufacturing with our fixturing and tooling and stuff.

Tim Burenga: Yeah, that’s one thing that’s made us successful, Mike, is that we’ve never sat still and just said, “hey this is good, we’ll just ride the wave.” We’re always developing our processes, investing in new technology, changing past practices to the most efficient way. And that’s what you got to do today to be in business. You always have to change and don’t be afraid of it.

Mike Lessiter: And you had a project here in the last year or so that you were pretty proud of.

Tim Burenga: The opportunity came around for us to install a solar field to help provide some of our energy requirements. And a long story short, when we were all done we got 340 kw solar field, and that provides about 45% of our power. And with the programs that are out there today, it made sense for us to do the project and probably the biggest benefit that we’ve received from it is we’re not in an industrial area so we suffered a lot on low voltage and brown outs, which would fry motors and computer boards and things of that nature. By having the solar field there, it actually has a capacitor and we’re not seeing those low voltages anymore. We’re still susceptible to spikes, but the brown outs we don’t see anymore. So it’s been a good project.

Tom Burenga: Yeah, it’s been very, very good for us.

Mike Lessiter: What’s the size square footage of your operation?

Tim Burenga: Well we just did an expansion this year and we’re now at 152,000.

Mike Lessiter: Tom, you come from very much a manufacturing background. Is that fair to say?

Tom Burenga: Yeah, I’ve always been connected with it. I was an engineer for FMC Corporation at one time and then from there I went with Tractor Supply and they had a couple of different manufacturing facilities, one in California that made cotton picker parts and another one, a larger one up in Richland Center, Wisc., and they made engine parts, and then we expanded that and they made air compressors and pumps and manifolds. And then eventually we got into some shortline farm equipment.

Mike Lessiter: You were working out of the Richland Center at one time.

Tom Burenga: Yeah, I started in Chicago and spent about 4 ½ years in the Chicago office, but then we expanded the factory up in Richland Center, I was spending more time up there so I relocated up there and then just made trips to Chicago to coordinate the activities that we were doing with what the Tractor Supply wanted to do.

Mike Lessiter: Tell me about the job that you were hired to do down there what eventually became Worksaver, what that climate was like and what you were tasked with at the time.

Tom Burenga: The company had been sadly mismanaged. The people that Phil Sams had thought could manage it were not doing a good job. And when I walked in the door we had machinery that was bad, the buildings were bad, they leaked like a sieve, sadly we had quite a few employees that were not good, drug addicts and alcoholics were part of the problem, and obviously the quality of the equipment had gone down. So one of the immediate challenges was to straighten all that out. There were no safety rules and no work rules. The accident rate was so bad the only insurance they could buy was through the state of Illinois, which was very, very expensive. So I didn’t do anything fancy, just put in common sense work rules and safety rules and called a meeting and told everybody, :okay everybody’s got a clean slate, but from now on here’s what we go by.” Interestingly we lowered the accident rate 96% that first year, just common sense stuff. And that helped a lot. Then had to get rid of some of the bad employees and that was a tough job but it had to be done, and that cleaned it up. Then we also worked redesign on some of the equipment. One of the deals there was basically no drawings at that time. They made sample parts and hung them on a nail in the factory and sometimes there would be slight differences between the parts, so some of the nails had 4 to 5 parts, all the same part but with slight differences. And there was a very fine gentleman that ran the metal fabrication department and he knew which one of those was the master. Well, I was there 3 months and the poor guy got sick and died. So we had – I had an immediate challenge going through all those parts and then making drawings and finding out which one was the right one.

Mike Lessiter: So how long were you there before things took another turn and you ended up leaving the company?

Tom Burenga: I was optimistic that I could turn it around in a year or two, and with the farm economy being down and all the other unknown problems there that I ran into, it took over 4 or 5 years before we got into a breakeven point. So that was a very tough period. But then we started doing other things and we started being able to buy used equipment that was in better shape than what we had and become a little bit more productive. And we built the farm store business up to it was over 50% of our business for quite some time. Everything we stayed on that course and did modernize and become better at it, but then in the early 2000s, about 2008, 9, we saw that the farm store industry was not an industry we wanted to remain in. Other people had gotten into it and the profit margins had always been slim, they became even less so and sometimes non-existent. So we knew Mike Kloster had joined me at that time as a sales manager and we basically we worked our way out of the farm store business and started doing more contract work and concentrating more on products that our distributors could sell. And that took several years to do, but it was like walking away when you walk away from over 50% of your business, today it’s about 5%, we still do a little bit.

Mike Lessiter: It takes some courage to do that.

Tom Burenga: It was challenging. And then Mike, Mike has always been very good in sales and marketing. We started doing more contract work. I mentioned John Deere, we started building product for them in 2004 and that was good, too, because they’re demanding and we had to change a few of our processes, especially our painting and quality control to meet their standards. And then we used those same things to our other products and we improved theirs also. Then as we improved of course we were also looking for other contract work, which I mentioned earlier, we’ve done some of that. So we finally have expanded and also kept all the modernization and this is where we got to with the other CNC equipment. We’ve added onto the buildings and tried to make improvements all around, and I think that’s what’s helped us out enormously. We’ve got some good people now. Mike Kloster is now our president. He’s been our president of the company for 11 years.

And then Tim joined us and when Tim got out of college he took over the shipping department and was able to make a big contribution there. And then the plant manager I had at that time told me he was going to retire. So we had Tim work with him and take over the plant manager job and Tim did a good job there and also was able to make improvements and help us out considerably from that standpoint. And then as we moved on, I knew that Tim eventually would like to take over the company but we – Mike and Tim and I bought the company from Phil Sams in basically January of 2016. And we’ve got a good working relationship. We work together on it and work on a lot of the problems and of course we identify the problems and then figure out a plan on how to solve it, or try to go a new direction. And it’s worked out quite well. And we’ll keep trying to move forward.

Mike Lessiter: So today the company is owned by the 3 of you. Did you have ownership starting in the 1980s?

Tom Burenga: The arrangement I had with Phil Sams, part of the reward for saving the company and turning it around was I got 25% of the company, and that took some time. Of course in the beginning years it was 25% of a net worth, but it did eventually work out.

Mike Lessiter: What do you remember when you were telling Paulette, your wife, about this move you were going to make down to Illinois, what was that like?

Tom Burenga: Of course I already mentioned that in ’79 and 1980 the farm economy was in bad shape anyway, and Tractor Supply had sold the factory up in Wisconsin to another gentleman and I tried to stay on with him and that did not work out. And of course then Tim, Tim had just been born, and so when we moved to Litchfield, Ill., Tim was only 5 months old. So having 3 children and a wife and then walking into a business that had all kinds of problems, it was a real big challenge. And I tell you, my wife was a very strong supporter and helped me through those trying times, very much so. But at the same time I put a lot of time in at the factory, so she had the bigger responsibility of raising the children.

Mike Lessiter: What’s your earliest memory of Worksaver?

Tim Burenga: The factory also dubbed as a babysitter sometimes, so I’d always get in trouble and get dirty running around the place and usually Dad would scold me a little bit on that. But I don’t know, probably about 6 or 7 we were old enough to do some manual labor. We would just – had a little wheelbarrow and we’d walk up and down the street and pick trash out of the ditches. If a post needed painted around the facility we would do that. When I got older I’d do lawnmowing and janitorial work and things of that nature. But as I kept getting older and developing, Dad let me work with the team leaders and the shop supervisors and they were able to teach me the trades of machining and welding and running CNC equipment. So anyway it was a very good education and Dad was a strong believer in having us kids come from the bottom up. And the other thing he instilled in us was to make sure we never asked anybody to do a job that we haven’t done ourself, and that was a good thing to learn.

Tom Burenga: I also took my children to some of the farm shows and after they’d worked or been around a show or two, then we let them help, they could hand out literature. And then as they acquired some knowledge they could even talk to some of the people that came up to our booth. And I always think that that was a valuable part of their education. Sometimes when I wrote a notice to the schools that they were going to be out of school for 3 or 4 days, the school didn’t see it quite that way but I felt that they would learn more at the farm show than they would those 3 or 4 days in school. I think it gave all my children the ability to talk to strangers and try and answer their questions and help them out and look them in the eye when they’re talking to them. I think it was another valuable – and they also, I had some very good sales people and they worked with them and I would tell all 3 of my children, pay attention to this fella, you’re going to learn something if you just watch how he talks to people and his sales technique.

Tim Burenga: Yeah, I was eleven and sold my first piece of equipment at the Louisville Farm Show, so that was a pretty memorable moment for me.

Mike Lessiter: What was it?

Tim Burenga: A bale spear, a bucket bale spear.

Mike Lessiter: So did Dad give you the commission on that?

Tim Burenga: No, I didn’t see that. I think it’s still in escrow somewhere.

Mike Lessiter: Tim, did you always know that you wanted to do this as a career?

Tim Burenga: For the most part, yes. I mean Dad and I have always been able to have that working relationship and we like working together and we expect each other’s traits. Right out of college I was planning on going to work for somebody else for a while, but through some situations that happened it just – the timing was right. They had a need for me to come back and run the shipping department, so I started with that and then like I said took over the production facility and then went on to sales after that. It just all fell in place. Yeah, it would have been nice to get some more outside experience, but it just worked out to start right after college.

Mike Lessiter: Sounds like you’re getting an extremely well rounded perspective since you’ve been there in the plant management and purchasing and sales and marketing. You’re seeing every aspect of the business and getting your hands dirty.

Tim Burenga: Yes, we’re very fortunate to have Mike Kloster on our team and Mike has said he’d like to work at least another 10 years. And that’s great with me because we work very well together, as well, and then when he’s ready to retire then I’m hoping to take over the whole company.

Mike Lessiter: That’s a story that’s coming up in these interviews is the grit of your dad’s generation and my dad’s generation that I’m not sure exists as much today, the risk taking, the boot strapping, jumping in and all that. So, that’s a story that I’m intrigued about as we’re getting into these things.

Tim Burenga: I tell you something that’s very important in our working relationship is that we don’t take it personal. You know, work is work and we’re able to separate that from the family life. And we see a lot of other peers that can’t do that and usually that’s not successful, but for us we are fortunate enough we’re able to keep it separate. But I was kind of lucky in the early years, I was only a little baby so I don’t remember the early years, so I was kind of fortunate because Dad he worked ungodly hours and not only was he our chief engineer, he was our sales manager. He was the safety man. I mean he had to run the whole place. He did have a plant manager but there was a lot of hours and a lot of time that he spent at the factory.

Mike Lessiter: Was there a time, and most of the people I’ve talked to can identify a couple times, was there a time that things were very touch and go and you weren’t sure you were going to make it?

Tom Burenga: I can tell you a couple Saturdays that we’ve had to go to the post office and get the mail and hope there was enough checks there to cover what we had handed out the Friday before. Yeah, had several times. We did that – but there was always other – you had to identify different opportunities or ways to try and combat the problem. And with some of the early farm store people you could put a deal together and make things happen. There was a company out of Iowa, Central Tractor, and they were a good company to work with. I did a lot of work with them. And Elliot Brody was the owner of the company and he was tough and demanding, but he was also very fair. And he had several other people that were working for him that had been with Tractor Supply and that was how I knew them. But we ended up building rear blades. Like one time we were desperate. It was back in the early years and I’d got the company to a breakeven, but we would make money the first 6 months and then lose it the last 6 months and come out about even. And the problem was we were not manufacturing enough product in the last 6 months to cover the overhead. And so I knew that Central Tractor sold a lot of rear blades, so we went to them and put a very, very sharp deal together that…anyway, we built the rear blades for them, and we’re talking 10,000 rear blades. The other part of the deal was you had to start shipping the blades in September and you didn’t get paid for them until January. So I also had to go to our suppliers and tell them that I had this opportunity but I needed them to work with me and they all did. So tough time, but when January came we got the check, we paid everybody and as a result we ended up making some money because we were able to instead of having to use the profit we had made in the first 6 months to subsidize and cover the overhead of the last 6 months, we were covering the overhead and so therefore we could keep some of the profit.

Mike Lessiter: That’s a dividend of trust and relationships from years prior, right?

Tim Burenga: You know, Mike, one that comes to mind is that same farm store group got merged and consolidated and ended up being a big company called Quality Farm Stores. And anyway, I graduated college in 2001 and that’s when I joined Dad and Mike. Anyway, I think it was a week or 2 weeks after I got out of school they filed bankruptcy and liquidated the company and at that time they were 35% of our business approximately, and you talk about a huge hit. And then to top it all off our labor union went on strike and so they were standing on the street. So here we are fresh out of college and we’re doing production work, working ungodly hours, just trying to get equipment out the door and service our customers. Luckily it didn’t last very long, it only lasted 3 weeks on the labor dispute, but the ramifications of that customer going bankrupt took us about 3 years to recover from. Anyway, that was a real quick wakeup, “hey, you’re in the real world now, make a go of it.”

Mike Lessiter: You stepped right in the fire.

Tim Burenga: Exactly.

Tom Burenga: Yeah, that bankruptcy was a bad deal. It was an orchestrated bankruptcy. An east coast financing company had bought the farm stores, at what it had been previously 5 separate customers for us, Central Tractor got bought out – or the owner had retired and he got bought out and then he bought Country General, which was out of Grand Island, Neb. And then they bought Big Bear which was out of St. Cloud, Minn., And so they cut it down. Well then this other finance company they bought Quality Stores out of Muskegon, Mich., and then they bought the Central Tractor and then they ended up buying Fisco, which was a small farm store group out of California. So what had been 5 separate customers for us, with nothing on our part, became one giant 35% of our business. And what they did was they immediately pulled money out of the company and then operated it on the supplier’s money. And they kept demanding and wanting longer terms. So anyway, it was quite a time. When we first found – when Mike and I found out about it that they were in that bad a shape, it was I think May of 2001 and they owed us about $1.2 million. And by calling other suppliers to them, we found out if you stop shipping, they’d quit paying. So we couldn’t afford that so we, what you call “played the game.” We kept shipping and then Mike would call them one week and ask for money and I would call them the next week and ask them for money. And we did that. Now the downside of that is in October when they did go bankrupt, then anything that they had paid you the 90 days prior was subject to be returned to them as preferential payment. But however that’s negotiable. And so then we had to go hire a bankruptcy attorney. So we got a very expensive education in that line.

It was out of our control. I guess what has always amazed me that the attorney, the bankruptcy attorneys ended up controlling the money, the money that got paid back and other funds and then they would sit back and study those funds at $300 an hour and then over the next 5 years dole out $20,000 or something back to the companies that they owed it to. I made the comment to the bankruptcy attorney that we had hired and I said you know this is like a license to steal. He said yeah, isn’t it wonderful? I didn’t quite share that opinion.

We survived it, which is amazing. I mean by the time we got all done it cost us well over $800,000, between what we lost and the attorney fees and all that. It was serious and very significant. But at the same time in the early years it wasn’t that kind of money but we were teetering on whether or not you’re going to keep the doors open.

Tim Burenga: The other one he wasn’t running to the bank on Saturday to cover payroll, but it was still a major hit. Yeah, I’d say the early years were definitely the most challenging for Dad. You know, another opposite end of the spectrum, in 2004 we exploded in growth and that’s when we first started doing a lot of contract manufacturing for a couple of companies. And that was my first year that I took over the plant in the purchasing. And in April of 2004 raw material prices sky rocketed and in a 3 month time period they doubled from what they were. So here we are trying to grow fast, and our input cost doubled. And I learned a very valuable lesson later that summer. I ran the company out of cash, and you talk about struggles. And so it took us about 45 days to get back in line and get some cash flowing again, but that was a very valuable lesson, too, is don’t run out of cash. Very hard to operate.

Mike Lessiter: Interesting, one of the interviews we did we talked about the A’s and there was people weren’t – there was nothing back them up. They persevered because it was the only way to get through it. And talked to a 2nd generation who said the problem 25 years later was that not only were business conditions very challenging and dire in some cases, but now there was something to lose on top of it. His father didn’t have anything to lose in the first place.

Tom Burenga: That’s true. When there’s nothing there to begin with you’re not going to lose a whole lot. But on the other hand, in the early years I had 3 children at home and a wife and so I just had to make it work. I mean when you find yourself in a corner, there’s only one way out and it’s a lot of hard work. You better get it done.

Mike Lessiter: What have you learned, you’ve been working alongside your father your entire life. What are some of the tenants, the core principles that you’re going to pass on to your children that you’ve received from your dad?

Tim Burenga: Well the first one is just don’t be afraid to work. You know, get in there, get dirty, get the job done and learn how to show somebody else how to do it, too, and develop those leadership skills. But probably one of the most important lessons I learned from my father was always look at different situations, there’s never just one solution. Come up with multiple solutions for a problem and then evaluate them and then pick the best course of action. And yeah, it takes a little bit more time to do that, but any time I was doing design work back in engineering school, Dad would look at something I did and said okay, do it another way, and forced me to take the time to think of a different solution and that’s been very valuable going forward is just to always look at different ways to solve a problem.

Mike Lessiter: What is your biggest success? Specific, whether it was a deal, a specific period of time, the positive defining moment in the company’s history?

Tom Burenga: We’ve had several. The first one was putting that 10,000 rear blade order with Central Tractor. I mean I basically was selling the blades at cost, but we ended up making money and it was because we had covered the overhead we were able to save the money we made in the early part of the year. Not a huge amount, but at least it was a positive amount. The others, oh, we’ve had several. We’ve also developed new products and there’s been several times we’ve had new products take off and do quite well.

Mike Lessiter: What were some of those specific products?

Tom Burenga: Well we were early on in developing a grapple rake and it was kind of funny the way that worked out. I have a farm in southern Missouri which some people would not call it a farm, it’s pretty rough, very rough. And we were down there clearing some land and Tim was down helping me and he was using a frontend loader with a pallet fork to pick up larger pieces of wood, unburned wood out of an old burn pile. And I was down on the ground picking up the small stuff. And he got done and came down alongside of me and he was working beside me and all of a sudden I saw him jerk his hand back, a copperhead snake had struck at him.

Tim Burenga: Missed.

Mike Lessiter: Good reflex.

Tom Burenga: We killed the snake and the snake did not bite him, but both of us agreed that we didn’t like working down there with the snakes. So we came back and built the first grapple rake. Took it down there and tried it and on the first model I had the hydraulic cylinders were on the rear and on the outside. Tim was using it on the tractor to push a big tree into a burn pile and another tree spun around and hit the hydraulic cylinder and bent it, so that kind of put us out of commission. So anyway we took it back to the factory and had it sitting there, waiting until we had time to make a new hydraulic cylinder. And my salesman at that time came to me and he said you know we can sell those. And I said well really. I said how many can you sell? Oh, he said, I can sell 80 or 100. And so oh, okay, and we needed the sales. So anyway I had an engineer working for me at that time and I already knew some changes that wanted to be made and I told him what to make. He did that and we went into production and that first year we sold 400 of them. So that was kind of a…

Tim Burenga: Yeah, a neat, good product.

Mike Lessiter: Came off a need on the old farm.

Tim Burenga: A lot of products that we’ve developed came out of necessity, whether it be at his farm or my farm. So anyway we’ll see something that we can improve or make better and it’s just one of the avenues to get ideas from.

And then something else that’s made us successful is Dad and I test it to what we designed it to do, or what the engineer designed it to if it’s one of our engineers. But then we go destroy it and that way we learn where’s the weak points, how can people hurt the piece of machinery and that’s made us very successful because be able to hedge off a lot of potential failures in the field.

Tom Burenga: But we do have even though I may design a piece of equipment or Tim, whatever, then we build a prototype and then we get other people involved, including production people and the other sales people and we ask for their inputs and criticism. And several times we’d make changes out of that meeting before we actually put it on the marketplace.

Tim Burenga: I’d say one of our big success stories that we have as a team is our team of employees. We’ve got a great staff of people and a lot of longevity and tenure. If it wasn’t for them we wouldn’t be here.

Tom Burenga: And everybody works together. Tim’s right, we have an excellent team now and they’re all good people, good folks, and they’re in there trying to make the company successful, whether it’s from order entry to trying to ship it properly out the back door and package it right. Yeah, very, very good.

Mike Lessiter: How did you achieve that culture of teamwork and hard work. I mean that’s where a lot of companies ultimately struggle, right?

Tim Burenga: I think just because we’re not afraid to jump right in with them. You know, when growing up and Dad’s always been out in the shop and we got 2 types of machinery at our place, those that are being moved and those that will be moved because we’re always changing the way we produce. And the fact that we jump right in, we work with the employees, goes a long way with them.

Mike Lessiter: Yeah I see you busting your rear end.

Tom Burenga: Yeah, and then we’ve tried to do things to make it better for the employees. When I walked in here the buildings were very old and we were confined, space was a premium. Here a few years ago we wanted to build a new lunchroom for the employees and we built a nice one. It’s in an old building but we built a nice air conditioned lunchroom, made it big enough that we can even hold plant meetings and safety meetings. And I think the employees liked that, the fact that on breaks, especially in the summer like you come to an air conditioned spot and cool off, have their snacks or whatever and go from there.

Tim Burenga: And then the other reason, or how we were able to build our team was just keeping them involved. We don’t really run a dictatorship where we tell them what to do all the time, we actually invest in their thoughts and ideas and they get to help in the process. And they get to take ownership of what we’re doing.

Mike Lessiter: What you guys accomplished in your company. It must be far more difficult to do what you did back then.

Tom Burenga: Well everything has become so much more expensive. I mean go back to the early years, the first machine I bought was an iron worker, a very simple $10,000 iron worker. But at that time it was such an improvement over the old piece of junk that was there running, it was a huge step forward for us, but for $10,000. Here early this year, the beginning of the year, we identified that we have a problem or had a problem in our paint area that even though we have 2 paint booths and we were operating them 2 shifts, we couldn’t paint fast enough to get all the product painted. And so Tim basically took the project on of adding on to our paint building and adding a third paint line. That was upwards around $600,000. Anything new we want to do today is so expensive. We have other situations that we know how to correct, but we’re talking a couple million dollars to fix them.

Mike Lessiter: Very capital intensive.

Tim Burenga: Yeah. You know in the old days we could save money by laying employees off. Today our factory overhead with our machinery is so high that that doesn’t do any good for us, that we have to keep the tons running through the factory. So it makes us a little bit more due diligent and a little bit better at long term planning and putting our customers together to where we can sustain that amount of volume that we have to push through.

Tom Burenga: That’s the other lesson we’ve learned that all this computer operated equipment is very nice and when it works it’s fantastic. But when things slow down, the cost of just having that equipment there will just eat you alive. So if you buy that equipment, you have to keep it busy. So you better figure out things you’re going to do or how you’re going to keep that equipment working. Whether you make any money or not it becomes immaterial. It’s just the fact that you can cover the cost of having that machinery there.

Mike Lessiter: We toured some dealers, some farmers, got some combine time in yesterday while we were down here, and they were all asking about the group that we were here for. And I said it’s the manufacturer of shortline manufacturers. Got me thinking that the farmer who doesn’t think about, he likes his short line equipment but doesn’t think about the challenges that must go into short line machinery still having a place in the world and what they’re working on. What do you think the farmer perhaps doesn’t realize about the technology coming to his operation if it were not for the short line manufacturer?

Tom Burenga: Well here again, the farmer today is more knowledgeable than definitely the farmers of 30, 40 years ago. And the big contributing factor there is the internet. So what that enables different farmer people to do, our potential customers, they can actually go on their computer and see our piece of equipment handling hay, handling materials with a grapple or digging a posthole or driving a post with post driver, and they can see the equipment operate. And so they’ve got better questions, more intense questions as far – or more specific question than what it used to be. Also — inventory is always a problem at dealers. And of course the majors, they want the dealer to have their inventory. So a lot of dealers basically don’t stock very much short line stuff and so sometimes the only time they can see our product is at shows. Well, the internet has evened that out that they can – they don’t have to necessarily go to a show to see it, although some of them do. They can go on the internet and see the product. And so to me I think they’re better equipped and more educated and I think they’re also more knowledgeable about some of the short line equipment than what they were in the past.

Tim Burenga: Yeah, I think the farmer would just be amazed at how difficult it is to get product to market. And the old channels still work quite well, but with the implementation of social media and YouTube and the internet it’s definitely a different market place and that’s starting to become more interesting with the foreign competition on the more simpler products. So the amount of time and resources that companies have to invest and how do they get their product in front of the customer is quite immense.