What do you get when the son of the local New Holland dealer marries the daughter of the local Case IH dealer? While this sounds like the start to a bad joke, it’s actually the foundation of the Ellens Equipment ownership team, a couple who knows a thing or two about running a successful dealership and who treats the business like another one of their children (including knowing when it’s time to let them spread their wings). Don and Linda Ellens, now with their son Luke, have built a top-notch single-store New Holland dealership that each of them have breathed new life into as they’ve stepped into management and ownership roles. “They’re a hardworking family, rock solid in a very small community,” says Bill Bohmer, who leads the Spader 20 Group Ellens is a part of.

“For somebody who’s got the kind of experience and know-how Don’s got, he is very willing to listen. And to me, that’s what sets him apart. He doesn’t always have to be right and it doesn’t always have to be his way,” Bohmer says. “His customers love him. And I don’t want to understate the fact that Linda and Don are a pretty good team.”

And Bohmer says Linda is a very important part of that team. “It’s just not Linda, would you answer the phone? That isn’t it at all. Linda is a driver. When a dealership, a single location dealership like this grows, somebody has to be the glue behind all the activity and can sense problems in the troops before they become real problems. And she’s pretty savvy in that particular way,” he says.

Don’s father, June Ellens, started the business in 1954 when he purchased the Allis-Chalmers dealership from Vander Woude Motor Sales, which had been selling cars along with Allis-Chalmers equipment. The dealership initially operated out of the back of the McBain Hardware Store. In the 1960s, June took on the New Holland line and moved into a building dedicated to the dealership. “In 1972, the local Ford dealer passed away and he [June] took on Ford. So we had Allis, Ford and New Holland basically until the big deal with AGCO [buying Allis-Chalmers],” says Don. “We tapered off on that and focused on New Holland and Ford. When Fiat bought New Holland, that was really good for us and we dropped the Allis-Chalmers line and picked up a lot of shortlines along the way.”

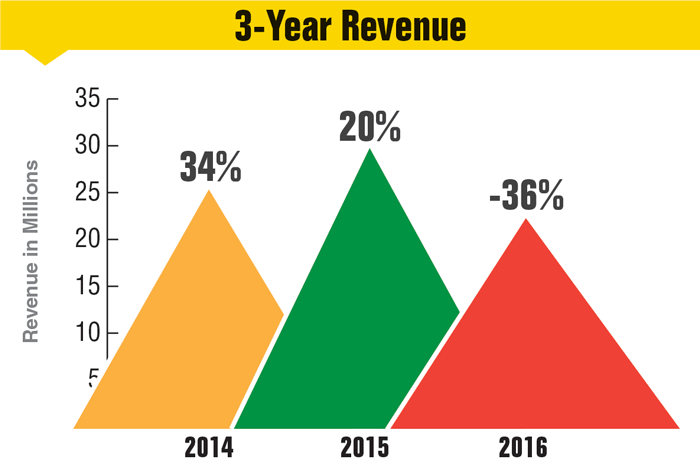

Ellens Equipment had been seeing strong revenue growth, but with a heavy reliance on dairy customers sales dropped off in 2016 when the dairy market hit a slump.

The dealership has come a long way since 1954 and, while still a single-store dealership, has grown considerably. “One item that impressed the judges is that they generated $964,800 per employee with only 24 employees,” the Dealership of the Year judges noted. “This is an impressive number and was the best of all dealers in 2017, both large and small. They have a strong market share, second highest ROA of all 2017 entrees, and just built a brand new facility to help their operation.”

Agents of Change

The management team agrees that the defining moments for the dealership came when each of them — Don, Linda and Luke — stepped into larger roles at Ellens Equipment.

In 1993, Don, who had been the service manager and working in the shop for 15 years, moved into sales and management when the retirement of a salesman left an opening. While June didn’t retire immediately, he handed the day-to-day management of the business over to Don. “That’s when we started to grow,” says Don. “I’m not sure if we were stagnate because of the culture or if it was the sales team we had then, but I stepped in and it was a breath of fresh air. We added quite a lot in volume and sales and grew every year for some time.”

The Ellens Equipment management team includes (l to r) Luke Ellens, sales; Linda Ellens, controller and office manager; Don Ellens, owner; Brent Whetstone, service manager; and Bryan Stoll, parts manager.

For one thing, when Don stepped into a management role, Ellens started to do more marketing and advertising. Don also increased the dealership’s inventories, something June hadn’t been comfortable doing, Linda says. She adds that much of the growth had a lot to with Don’s personality. “He’s a people person and outgoing, and that was a draw to people.”

Ellens Equipment,

McBain, Mich.

Founded: 1954

Employees: 24

Owners: Don, Linda & Luke Ellens

2016 Revenues: $23,155,212

2016 Market Share: 47%

Major Line: New Holland

Shortlines: Mahindra, Bobcat, Meyer, Kinze, Woods, Kuhn Knight, Killbros, Alo Quicke, Poettinger, Degelman, Remlinger, Berlon, Unverferth, Hagedorn, Mensch Manufacturing, Landoll, Brillion, Scag, Oxbo, Grouser Products and Trimble

When Don’s mother Mic, who had been the bookkeeper, began having health problems, Linda started helping out on the financial side of the business. Prior to coming on board full time in 2000, Linda had been a nurse. Today, she serves as the controller and office manager. Linda’s ability to relate to the employees and her focus on HR helped change the culture at Ellens, she says. “It helped Don as a leader, having me supporting him behind the scenes,” she says. “And then when Luke came, it was just another shot of momentum. When Don took over, he had such a passion for service it really helped us grow. And I think when Luke came, he had such a passion for his product and confidence in his product that the excitement and love of it was just contagious.”

Luke returned to Ellens Equipment 6 years ago after spending about 5 years with New Holland, where he was a regional service manager, a hay and forage representative and most recently the self-propelled forage harvester product specialist. “When he came back, it was a huge boost because he had a lot of business and product knowledge and was very, very confident in the product,” says Don. “About the time Luke came back, the self-propelleds were coming in. There were a lot of customers who were buying used ones. There were some dealerships close by that were selling used stuff. It wasn’t going over real well because the equipment was used and it wasn’t take care of. Luke came back and our new sales exploded.”

Luke’s homecoming impacted more than just equipment sales for the dealership, though. Through his work with New Holland, Luke had been inside many successful dealerships and was able to bring their best practices to Ellens Equipment. “Luke brought back insight on how other businesses were run, and that helped us look outside the box a little and start doing things differently,” Linda says.

One of the key changes Luke implemented was formalized meetings, which have greatly enhanced communication and employee engagement.

Improving Communications

Per Luke’s suggestion, Ellens Equipment started holding regular meetings about 5 years ago, at first just with the managers. After moving into a newly built facility in February 2016, the addition of a conference room improved the quality of the meetings. Today, Brent Whetstone, service and warranty manager, meets with the service technicians every morning to review the schedule and the day ahead. The parts manager, Bryan Stoll, also meets regularly with his team and there is a weekly sales meeting. The leadership team — Don, Linda and Luke — which Ellens refers to as “Triple E” meet weekly as well.

“Having regular departmental meetings has really helped with communication,” says Linda. “I think everyone feels more a part of the team because they know what’s going on before it’s happening.”

"We sell on service, not on sympathy..."

— Linda Ellens, Co-owner & Controller

Luke says the move has helped make the dealership’s culture stronger and grow the “team” mentality. “We had a good culture before, but now the whole team has input. We do value their opinion — and always have — but now they feel like they can suggest something and see we’re listening and making changes,” he says.

The improvements weren’t immediate, of course, as not everyone was initially comfortable with leading a meeting. For example, it took some time — and some intervention on Linda’s part — to get the parts department meetings really rolling to be effective. “We asked Bryan to start holding the parts meetings, and he is a very soft-spoken, gentle man. When we went to the first couple parts meeting, there was just nothing there,” Linda says. “I’m not a parts person, but somebody had to facilitate the meetings, so I started doing it. Then one day I left a meeting a little frustrated and said to Luke, ‘There’s no camaraderie, there’s no talking, nothing is happening.’ He set me straight and suggested I come up with an agenda for Bryan so that every week he can say, ‘How many lost sales did we have? Does anybody have any customers issues that we need to discuss, etc.?’ We gave him some guidelines on how to run the meeting.”

Exclusively Online

A little guidance was all it took. Linda says that over the course of just a couple of weeks the meetings totally transformed. “Sometimes he has a lot to say, sometimes he doesn’t. And it’s just been interesting to see him grow into a team leader and all he needed was the little bit of direction,” she says.

It’s also helped spur suggestions from the parts employees. “We didn’t get a lot of input from the other parts guys until that happened,” Don says. “Once you have a topic of conversation, then we started getting ideas from the other guys.”

The sales meetings have become more structured and focused as well, as the team and dealership have grown. When the sales team was just Don and two or three sales guys, they’d just gather in an office at the old facility. Now with 5 salespeople and a dedicated meeting space, the meetings are more formal. Don recognized he was doing a poor job at running the meetings, so Linda took over facilitating them with the goal of keeping the team on task. “Because they’re so service oriented, pretty soon they’re answering their phones and then they run out [to help a customer]. There was nobody to keep them focused,” Linda says. “I’m more detail oriented, so throughout the week when one of the guys comes to me with a problem or the service manager comes with an issue, I keep track of all those things. Then I have an agenda for all departments and when I come into the meeting, I help communication between all the departments.”

In 2016, Ellens Equipment moved into its new building. The management team of Don, Linda and Luke Ellens consulted with a number of other dealers on the design of the building, incorporating many of their ideas.

The dealership recently took another step to improve communications. Starting in June, Ellens began including “The Insider,” a company newsletter with each employees’ pay stub. “We realized we were keeping in touch with the personnel in the front offices, but we were losing touch with our techs and yard guys. So each week, we now include with their stub a newsletter of sorts,” Linda says. “We mention upcoming vacations, birthdays, new developments or improvements, absorption rates for the month prior, upcoming company lunches, etc. We are getting good feedback from our staff on this already.”

With the improved communication has come a better informed staff. The entire Ellens team now has a better understanding of the key metrics guiding the business.

Watching the Numbers

The top metrics management keeps a close eye on include gross profit margin, expenses, absorption rate and aged inventory. The dealership’s 2016 absorption rate was 66%, but their goal is at least 85% and the entire team is focused on that target.

“Right now, we’re challenging our teams on absorption rates. We set up a bonus program for goals on absorption,” says Don. “We had to start with explaining to all of them what absorption is and how it can benefit the dealership. It’s been a learning lesson for everybody.”

Timeline: The Evolution of Ellens Equipment

1954: June Ellens purchases the Allis-Chalmers equipment dealership from Vander Woude Motor Sales and founds Ellens Equipment and operates the business from the rear of the McBain Hardware store.

1968: Ellens Equipment moves into its first building on M-66.

1972: The dealership takes on the Ford tractor line when the local Ford dealer passed away.

2010: Ellens adds New Holland self-propelled forage harvesters to its lineup.

2012: The dealership starts offering T9 4WD New Holland tractor.

2015: Bobcat products are added to the equipment lineup including sales, parts and service, expanding Ellens’ ag and construction product coverage.

Summer 2015: Ground breaking for the new facility east of McBain.

2016: Ellens Equipment moves in to a new facility, which is about 3 times the size of the old store in town.

Ellens started educating the entire team on absorption in the fall of 2016, but didn’t start incentivizing the team until January 2017. Linda says they showed them the formula (total gross profit margin from parts and service divided by total dealership expenses) and then explained what gross margin is for both departments. “A lot of them had never really thought about it or understood it, but then we explained it to them and showed them all the expenses at the dealership and just how the absorption equation works,” she says. “Then I ran through some scenarios with them to help them understand how they play a part in it. So, if we increase sales in parts, this is what it does to our absorption rate, and if we increase our margin this is what happens. If we decrease our expenses, this is what happens.”

To help keep everyone focused on improving the dealerships absorption rate, the company replaced the yearly incentive with a quarterly one. Now, each quarter if they achieve 85% absorption, all employees get a bonus. The amount of the bonus goes up as their absorption rate goes up, so “if we get 100% absorption, then it’s a really significant bonus,” Linda says.

“Now that they understand it, they’re thinking all the time that ‘this is money in my pocket’ if we can get our absorption up here,” Don says. “They’ll come to us and say, ‘Maybe we don’t need this. Maybe we can get this cheaper.’ Everybody started thinking about it because everyone’s invested in it now.”

Linda provides a monthly update on their absorption to provide the teams with an idea of their progress and what they can do in the month ahead to make strides.

Parts returns previously had been a problem area for the dealership. With 12 different vendors, and 12 different timelines for parts returns, Ellens Equipment was often missing deadlines for returns. Frustrated that they kept missing the returns, Linda called each of the vendors and found out the specs and time frame for their returns and set them all up in a program.

"To be proactive, you need to have extra people who have time to think about doing things a different way …"

— Linda Ellens, Co-owner & Controller

Each vendor is entered on the calendar now and a month before the deadline for the returns a reminder will automatically pop up. Seems simple enough, but it’s made a big impact. “Last year, we did more parts returns than we ever had done. We maxed out every vendor. Now we have a parts return plan with timelines to follow,” she says. “It was a good winter for us. I was a little worried with the dairy market down with how cash was going to flow. And by doing all these parts returns, it created a lot of cashflow that we didn’t really plan on. Plus we reduced inventory.”

Another number that Don watches closely is their used equipment inventory turns. It’s an area the dealership has been paying particularly close attention to over the last few years. He’s found that being part of a 20 group has really helped. “One thing that is really good for me, is our 20 group, they hold us accountable. We now have a mentality that when that equipment’s one-year birthday comes around, it’s time for it to go. It’s money that we don’t have, that we can’t spend,” he says.

Don oversees all of the trades and sets the prices for the used equipment, and he says he’s gotten a lot more conservative with it over the last year because of market conditions. While he says there are some used pieces they like to keep on hand for rentals and backups, when used units reach the 12-month mark, they move them. “We use Auction Time a lot, but prior to that we try to discount the unit and advertise it as a special to get it moved so we don’t have to send it to auction,” he says.

Ellens Equipment Video Interviews

Visit www.FarmDealerOfTheYear.com to watch exclusive videos with Ellens Equipment. Filmed on Location by Farm Equipment editors, these videos are sponsored by CDK Global Heavy Equipment.

Ellens has some contacts in the construction market that one of the salesmen brought with him when he joined the dealership; they have proved to be useful sources to tap to help move some of its older skid loader inventory.

Don says they also work hard at getting items presold before taking the trade. “Some of the [construction] market has been really difficult to move used equipment in. And customers are aware of the challenges. The market is tight. They know it. They don’t want to admit it, but we make them aware of what our situation is and when you have a good product and you have good service, then the business comes along,” he says.

Growing & Diversifying

Over the last several years Ellens Equipment has grown and diversified its product offerings and customer base. The introduction of the self-propelled forage harvester line helped expand the dealerships regional reach. The relationship’s developed based on the choppers has helped open the door for tractors, Oxbo and Pottinger products as well, Linda says. “Our industry has grown and our coverage has grown — all the way [north] to the [Mackinac] Bridge and then 2.5 hours south. We’ve really expanded our forage harvester market. Our service team is the best in the business and they are the reason customers are calling us from all over the state. They want us, our service, and they want our product,” says Luke.

A significant reason for growth is the addition of after-hours service and parts availability. Ellens’ team members are available 24/7 to keep customers up and running. Their dedication to the dealership and vision of Ellens Equipment sets them apart from other dealers in the area, the Ellens say.

On the dealership’s ability to grow their market, Bohmer says, “McBain is a very small town in north central Michigan, and they went west quite a ways. And because of their expertise, were able to sell both the product and the service. And they’ve taken a certain amount of market share from both in-line and other color manufacturers.”

Ellens has also put an increased focus on the construction market in recent years. In addition to New Holland construction equipment, the dealership also carries Bobcat. “That’s been really nice for us. The construction industry is going strong right now, so that helps us when dairy’s down like it is now,” Linda says.

Ellens Equipment’s new facility allowed them to triple the amount of parts storage available, including additional storage on a mezzanine level. Built on 20 acres of land just outside of town, there is plenty of room for future expansion.

The Bobcat line, along with 2 salespeople with construction backgrounds, are opening up a new customer base for Ellens Equipment. “One of them came to us from a Bobcat dealership full of prior knowledge, and that really helped us hit the ground running and he’s done a very good job,” Don says.

In late May, Ellens Equipment signed on as a Mahindra dealership to help supplement their offerings in the subcompact and compact tractor market. The dealership needed to fill holes in New Holland’s product offering and decided it was time to look elsewhere. The Ellens were impressed by the Mahindra organization and were looking for a product that wasn’t already represented in the area. “I’m very confident in fact that with our sales and service support, our products — whatever we sell — will sell. It’s just a matter of getting something out there that can be differentiated from another product. That was a huge part of why we went with Mahindra,” says Don.

This growth means that today Ellens Equipment is doing the business of 2.5 stores out of a single location, says Bohmer. With that in mind, the management team is focused on the dealership’s future and is currently working on their succession plan, and has an eye on possibly expanding.

Planning the Future

With the increased volume, Don says they are looking to hire another service manager to work under Whetstone. They’ll then divide the product linesups, with Whetstone managing one group of products and the new hire managing the other. “We had to sit down and realize that we’re doing this much business and we look at our peers and they’re doing half as much,” Don says.

Historically the dealership has had a lean staff, but they found that meant they were always functioning reactively. Over the last 5 years, Linda says they’ve been trying to transition from being a less reactive dealership to a more proactive one. “To be proactive, you need to have extra people who have time to think about doing things a different way … and it’s a total change in our mindset,” she says.

What the Judges Say

“The item that impressed the judges is they generated $964,800 per employee with only 24 employees. This is an impressive number and was the best of all the dealers in 2017, both large and small. They had extremely high revenue growth in 2014 and 2015 but were down in 2016 due to the market slump in ag equipment.”

Part of that has been cross training. For instance, everyone on the administration side of the dealership is trained to enter invoices, receivables and more than one person knows how to do payroll, Linda says. “It’s the same thing with ordering parts. If Bryan, our parts manager, is sick, we have another guy who steps right in. We are protecting ourselves by having someone who can step up in case of an injury or whatever. But it also gives that person peace of mind if they want to go away for a week or they get ill. They’re not just going to come back and have it piled up,” she says.

Don says the cross training adds continuity to the dealership and the customers, too. “Somebody steps in and it might not be the same person the customer is used to working with but the job gets done,” he says.

That wasn’t the case just 5 years ago. “We had gotten ourselves into a position where we were thinking, ‘Oh my goodness, we can’t have this guy quit. If he quits, we’re in trouble,’ says Linda. “We learned and are trying to prepare for the future, no matter what tomorrow brings.”

While the dealership has been very successful as a single-store operation, the Ellens — and New Holland — see it growing in the future. And while Don is excited to grow, he knows the addition of another location will change how they operate. “We know how to deal out of one dealership. The second one …” Linda finishes his thought saying, “They say the second one is the hardest, the third is easy. But time will tell.”

“We want to learn from dealers that have been through it. Being part of that 20-group has been good for us. It’s a learning process, moving into that stage. Not only that, you take us out of this role here and we have to have somebody set up to manage that store — we’re trying to position ourselves for that,” Don says.

"Luke was not afraid, just like me, if something has to be done we get our hands dirty and get in there and pitch in. That’s a huge part of it, just being a part of the team..."

— Don Ellens, Co-owner

One thing that is certain in Ellens Equipment’s future is that Luke will eventually take over ownership. “We started working on the succession plan 3 years ago. But then this building came along and occupied a lot of our time, and we just said, ‘OK, let’s sit back. Let’s get through this. Let’s see how that all works out,’” Don says. “Now it’s time, we’re going back into transitioning some of the stock over to Luke.”

While there’s no set timeline at this point for Don and Linda’s departure, Linda says she’d like to at least step back a little in the next 5 years. However, there’s more to succession planning than just transferring the ownership, and that’s something that tugs at Linda. “One of the things that I struggle with, if I’m completely honest, is Luke is such a strong asset to the business in that he is very good with people, he is so confident in his product. And there’s something charismatic about him when he’s with the customer that he’s gained us a much larger customer base than we ever dreamed we would have. When we take him out of that position, is the dealership ready for that?

“I think we have to find the right person to take Luke’s place before we can transition him. Or maybe we have to look at it differently. Maybe there’s a store manager and Luke continues to do what he does. So how does Ellens Equipment look 5 years from now to maintain the momentum our team has created? And also, how do we start transitioning both Don and I out as we’re very key people here. How do we transition that to Luke? The three of us are very strong together. And when the time comes for two of the three of us to step out, it’s going to be a change for the dealership.”

READ ABOUT VALLEY TRUCK & TRACTOR

DEALERSHIP OF THE YEAR ALUMNI GROUP

Nominate a dealer for The 2018 Dealership of the Year

July/August 2017 Issue Contents