For 35 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The Products selected save producers time and reduce cost and labor, all while improving safety.

To be eligible for the award, each development — which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the entire industry, not to an individual company. Each year, an international panel of industry experts in technology, design and product development gather to evaluate the entries and select up to 50 products for recognition.

MacDon Industries M2 Series Windrowers & D2 Series Draper Headers

The M2 Series Windrower by MacDon is equipped with Harvest Touch display screens and is powered by Stage V Cummins turbo diesel engines with up to 280 horsepower, an increase of 20 horsepower over previous models, allowing for increased productivity in heavy conditions. The D2 Series Draper Header, as part of the windrower, uses a hydraulic cutting system for a 30% increase in speed over previous models and 25% more cutting surface. With an electronically timed double knife, vibration in the headers is reduced to improve durability and performance. It also has an increased draper size of 50 inches, correlating to a 20% increase in cutting capacity through heavy crops.

Compared to previous models, the increase in capacity through higher horsepower, larger header sizes, faster cutting speeds and improved user interface makes swathing at higher speeds feasible. This combined windrower and header is available in North America, Australia and New Zealand.

MacDon Industries, Winnipeg, Man.

Claas Xerion 12 Series

The Claas Xerion 12 series tractors are equipped with a 15.6 liter 6-cylinder engine, delivering up to 653 horsepower and 2,286 pounds of torque at 1,300 rpm. The CMATIC (CVT) transmission allows for minimal engine rpm use and intelligent transmission speed changes to achieve the most fuel efficiency.

With the choice between Terra Trac tracks that allow speeds up to 25 mph, or 800/70 R42 duals for up to 31 mph, there is minimal compaction of the soil and reduced slip for higher productivity.

The 4-point cab suspension offers better sound insulation, 21% more legroom than previous models and a Claas-exclusive CEMOS system that suggests optimal settings for ballast, tire pressures and engine droop settings. The CEMOS system has the ability to self-analyze and adjust settings when conditions change, making it more approachable for a novice operator.

Safety features include: 2-line hydraulic trailer brake lines, axles with overload prevention, seat presence switch that turns off any externally moving parts if no seat presence is detected, remote monitoring for preventative maintenance and a rigid frame design that increases stability at road speeds.

Designed for large-scale cash crop production, the 12 series can be used during cultivation, seeding and harvesting, with the power and control to operate heavy machinery.

Anderson Group, MergePro Hay Merger

With 6 rows of camless pickups, the Anderson MergePro 915 Hay Merger has a working width of 25 feet when configured for side delivery and 30 feet for central delivery, while the 1060 is 5 feet wider for both configurations. The curved tines and deflector above the pickup and belt ensure a constant flow of the crop from the field to the conveyor belt without damaging the crop. It also helps prevent debris such as rocks and dirt from being picked up and potentially damaging equipment. The MergePro can move 30 feet of high yield hay (up to 10 ton/ha) at a speed of 18 mph. Because of this high capacity, hydraulic adjustable suspension and large skids help minimize soil compaction.

Because the design is simplified and straightforward to operate without sacrificing performance, it’s easy to maintain and attach onto a farmer’s tractor.

Anderson Group, Chesterville, Que.

Claas CEMOS for Tractors

Claas Electronic Machine Optimization System (CEMOS) is a self-learning driver assistance system that uses software programming to monitor existing sensors on Claas tractor components to calculate optimal settings. It helps the driver adjust ballast, droop and tire pressure, increasing tractor area output by 16.3% and decreasing fuel consumption up to 16.8%. As the tractor is in use, CEMOS will continue to self-examine and suggest new, more efficient settings based on changing conditions.

Starting values for the engine, transmission and implements are automatically generated up front so that inexperienced drivers can maximize traction and field protection. This means that a larger, less skilled workforce can be employed to run Claas tractors at max performance throughout the day.

Originally developed for the Claas Arion line, CEMOS will be available for all Claas tractors in 2024.

Hagie Manufacturing Company, Hagie ExactDrop

The Hagie ExactDrop, designed to be added to Hagie STS sprayers with Hagie Hybrid booms from 2018 or later, is used for in-season ground application of nutrients or other crop protection products with full boom width productivity and precision, even in short application windows. It has a lightweight and flexible drop structure, which reduces strain on the sprayer and allows it to be used at widths up to 120 feet without compromising durability.

Additionally, switching from split application to broadcast application requires no tools and takes less than 15 minutes, allowing farmers to adjust to environmental conditions quickly.

The fiber composite structure was chosen to provide more flexibility in the fore/aft direction while maintaining stiffness in the lateral direction despite a 20% reduction in thickness.

Hagie Manufacturing, Clarion, Iowa

Art’s Way Manufacturing, CFB26

The CFB26 Forage Box by Art’s Way Manufacturing utilizes a hydraulic control system that allows the user to switch from front unload to rear unload without leaving the cab, increasing comfort and safety. Designed with a load sensing circuit on the front and rear unload directions, machine energy efficiency is optimized. Additionally, the front unload utilizes load sensing to automatically slow down the apron chain whe the cross conveyor or beaters are overloaded. The rear unload utilizes a 2-speed hydraulic motor design paired with a hydraulic manifold that senses load pressure to shift the motors from a high torque, low speed to low torque, high speed. The design gives the CGB26 faster rear unload time without sacrificing any load capacity. Depending on the output of the tractor, rear unload time can be as short as 45 seconds.

In-cab controls regulate the sequence of events in the operation of the front unloading system. Many systems require that the beaters are tied to the cross conveyor, while the CFB26 allows control of each system in sequence. This allows for smoother startup and reduced chance of jamming the system.

Art’s Way Manufacturing, Armstrong, Iowa

Agricultural Industry Electronics Foundation AEF e.V., Agricultural Industry Electronics Foundation

The Agricultural Industry Electronics Foundation (AEF), a global non-profit founded to improve cross-manufacturer compatibility in ag equipment, developed a cloud-based network called the Agricultural Interoperability Network (AgIN), which will give agribusinesses an improved way to exchange data through a standardized cloud connection. AEF members can join the AgIN network with their existing clouds and access each other’s services on a peer-to-peer basis through a secure network.

Everyone from seed and chemical companies to food processors, wholesalers and retailers handles massive amounts of data. AgIN use by agricultural equipment companies can help improve operational efficiency and enable better precision farming. Data exchange is indispensable to modern agriculture, and using data effectively is a competitive advantage, which drives the demand to simplify and improve data management. AgIN’s objective is to foster collaboration between members, partners and related initiatives to create an industry-wide solution that addresses common use cases, regulations and global data exchange requirements.

Agricultural Industry Electronics Foundation, Gütersloh, Germany

Raven Industries, Raven Cart Automation

Raven Cart Automation is a system that can be installed on both the tractor and combine that simplifies harvest operators’ ability to effectively run an unload-on-the-go operation by synchronizing the grain cart and combine’s heading and speed when the grain cart is within syncing range of the harvester. This sync window is 164 feet by 574 feet. It puts the combine driver in full control of bin positioning, which reduces operator stress and prevents spills, maximizing profits.

Using local radio communication, it syncs guidance and propulsion to align the tractor and harvester, which can be more reliable than WiFi.

Raven Industries, Sioux Falls, S.D.

Bobcat Company, Bobcat Premium Power Performance

Premium Power Performance by Bobcat is a power management system that distributes power more efficiently on Bobcat loaders equipped with high-flow (37 gpm) and super-flow (42 gpm) hydraulics. Used on compact track loaders and skid-steer loaders, it is currently available on the Bobcat T86 and S86 skid-steer loader. This system is designed to intelligently distribute hydraulic power where it’s needed, providing up to 13% more productivity. The hydrostatic and hydraulic pump work together by using pressure sensors to distribute power between the hydraulics and drivetrain. To maximize the system when operating auxiliaries, power is prioritized to the hydraulics to support attachment use. If no auxiliaries are in use, power is directed to the hydrostatic drive.

Bobcat Company, West Fargo, N.D.

Claas of America, Claas Disco 9700 RC Auto Swather

The Claas Disco 9700 RC Auto Swather is used for large-scale feed production of hay and forage for mowing, conditioning and merging of heavy crops in a single step. It is specifically designed to handle large forage volumes and high tonnage cereal crops such as rye or triticale; however, it can also handle delicate crops like legumes.

It has a working width of 31 feet, 2 inches, and its central swing arms deliver a side shifting of 27.5 inches. This allows for a larger overlap on side slopes and curvy headlands, ensuring a clean cut on every terrain.

The optional automatic slope control includes adjustment of ground pressure and belt speed based on conditions, countering risk of drift and stabilizing the machine. For example, at a slope of 10 degrees, a ground pressure of 100 bar at the lower mower and 120 bar at the upper mower unit will be automatically set.

The design of the merger belts allows for adjustable angular positioning, ensuring consistent crop flow in all conditions. The integrated lateral stability also ensures that the crop will not slow down until in the windrow.

RCI Engineering, T8088 Ag-Bagger

The T8088 Ag-Bagger by RCI Engineering has no backstop or cable braking system, making it a faster and simpler machine to operate. As a replacement, the Anchor Position Control uses internal anchors that pull through the forage as the machine progresses and fills the Ag-Bag.

The 2 internal anchors provide the extra resistance needed to increase the density of the forage without causing damage to the plastic of the Ag-Bag. The spring mechanism built in the Anchor Position Control removes any slack in the cable, keeping it aligned properly at all times. A lock-out mechanism is also provided, and a large cylinder provides sufficient force to retract the anchor back to the machine even in the densest Ag-Bagging conditions.

The T8088 features a 104-inch rotor for a 10-foot and 12-foot Ag-Bag. All other features of the T-Series are included such as sweeping tunnel cleanout, hydraulic lift and wider conveyor.

The T8088 is simpler since there is no backstop, safer because all cables are internal and more productive, as the time to change Ag-Bags is reduced to minutes rather than 1 hour. Additionally, the wide rotor allows for more throughput so that the T8088 can keep up with 1 large self-propelled forage harvester or 2 smaller harvesters.

RCI Engineering, Mayville, Wis.

Claas of America, Trion

The Claas Trion 740 and 740TT with Terra Trac tracks combine harvesters utilize a hybrid processor consisting of a tri-cylinder threshing system and a single axial separation rotor — each with its own variable speed control from the cab — designed to meet the class 7 combine requirements.

The drivetrain is designed to be easier to maintain and configure between crops, using a hydraulic valve to set threshing speed range while safely on the ground. Additionally, tensioning mechanisms and ground level grease banks for all in harvest interval grease points improve safety and operator efficiency.

Trion can operate with up to a 12-row chopping corn head and auger platform heads or draper heads up to 40 feet in working width. Additionally, the combine can be equipped with Claas’ CEMOS system and popular auto steering systems.

Compared to competitive class 7 combines, Trion uses up to 27% less fuel, requires 22% less time to re-configure between different crops and has a 33% faster uptime when completing daily maintenance.

Danfoss Power Solutions, EC-C1700B-420 Electric Converter

The EC-C1700B-420 Electric Converter by Danfoss is a heavy-duty DC/AC converter developed for electric or hybrid drivetrains in agricultural machinery such as sprayers, tractors, combine harvesters, specialty crop equipments, self-propelled feeder-mixers and other similar applications. It is capable of operating up to 690 VAC, which increases the power density of electric drive systems. The higher operating voltage and compact design allows manufacturers to reduce electric drivetrain size, weight and power losses. Software capabilities allow the hardware to control a wide variety of electric motors, connect to a local grid or create a microgrid.

The EC-C1700B-420 converter supports the transition to electric drivetrains by increasing power transmission capability and reducing system losses. Increasing the AC voltage from 450 VAC to 650 VAC increases power output by 44% with the same current. By increasing DC link voltage from 750 VDC to 1050 VDC, transmission power losses can be reduced by almost 50% while maintaining the same power throughput and conductor size.

For safety features, the converter includes hardware-based overcurrent and overvoltage protection, thermal protection and integrated insulation monitoring. It also supports high-voltage interlock loop (HVIL) monitoring.

Danfoss Power Solutions, Ames, Iowa

Unverferth Mfg., Equalizer SP Track Undercarriage

The Equalizer SP grain cart track system is designed for 2,000 and 2,500 bushel Brent and Unverferth grain carts with a 50-inch wide by 128-inch long track belt, providing a 20% greater footprint and less soil compaction. The design combines the cambering action of the end wheels with 20 degrees front-to-rear and 9 degrees side-to-side movements, with mid wheels that can pivot up to 16 degrees front-to-rear for maximizing ground contact over rough fields. Each track lays 44 square feet to travel over varying field and road contours to lower track belt heat and extend belt life.

Sealed pivot joints use chrome pins and self-lubricating bushings for reduced maintenance. Through the addition of urethane springs for suspension, vibration is minimized for less cart fatigue and greater operator comfort for meeting producers’ needs.

Unverferth Manufacturing, Kalida, Ohio

Claas of America, Claas Conditioner with Double Roller Drive

The double roller drive of the Claas 3600 F RC mower is designed for high yielding and heavy crops. It has an oil bath driven scissor gearbox to ensure reliability, and the pivoting design allows for maximum throughput of crops through the conditioning rolls. The double roller drive facilitates enhanced processing of heavy crops. During the conditioning process, the conditioner rolls have double as much power as previous models, ensuring a greatly improved crop flow, especially with large volumes of forage.

The gap of the rolls is adjustable with a wrench that comes with the mower, and a scale on the side of the unit shows the actual size of the roll gap. For further adaptability, the spring tension on the rolls is also adjustable.

Precision Planting, SymphonyNozzle

SymphonyNozzle by Precision Planting is a pulse width modulation system (PWM) with a 20|20 monitor that can be installed on existing self-propelled or pull-type sprayers, allowing for independent control of rate and pressure. It uses an easy-to-install point-to-point electronic architecture instead of a large harness on each half of the sprayer. The body does not require tools to disassemble for cleanout, and the check valve can also be moved to either side of the nozzle body without tools for easy installation.

The independent control of rate and pressure to drive a consistent droplet size also provides swath control and turn compensation, allowing a reduction in overapplication and potential drift.

Precision Planting, Tremont, Ill.

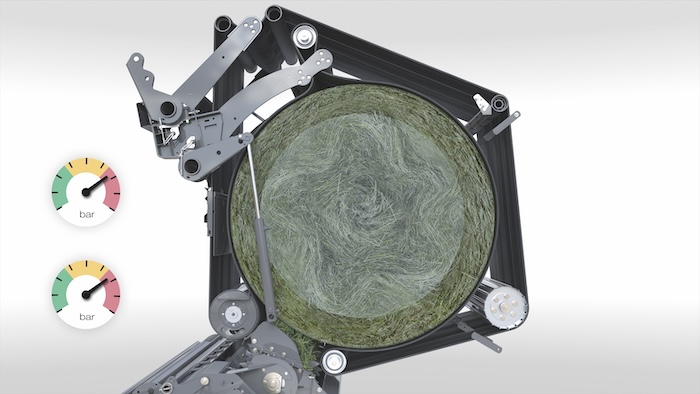

Claas of America, Claas Smart Density

Claas Smart Density density management system as part of the Variant 585 RC controls the baler’s 2 tensioning arms independently of one another, allowing the operator to switch between high bale density and a soft core bale from the comfort of the cab. While the exact density and size of the soft core can be adjusted — preventing damp hay from spoiling the bale by allowing ventilation — the outer shell of the bale is always firm and maintains its shape. The 2 independent tensioning arms with Claas software allows the baler to self-adjust and maintain set bale density parameters in all conditions and driving speeds.

With rotor knives engaged, the Smart Density system produces bales with 14% higher density while consuming 16% less fuel compared to balers in the same class.

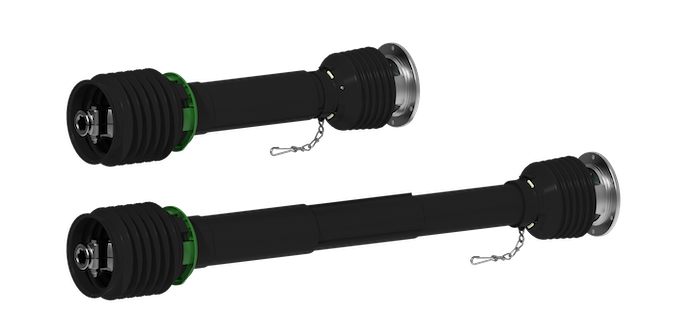

Walterscheid GmbH, a Comer Industries Corporation, WTS3 PTO Driveshaft

The WTS3 PTO Driveshaft by Walterscheid is a power transmission solution designed for applications where a large variable working range of the shaft is needed. Typical machines are mowers and rakes where the PTO driveshaft is compacted during transport and extending during the working phase.

The WTS3 shaft introduces a user-friendly guarding concept using 3 distinct lightweight telescoping members that ensures smooth running performance up to 1000 rpm. Additionally, the distribution of lubrication has been enhanced, increasing the lifetime of the shaft.

This is a highly customized product that will be sold directly to OEMs based on their specific requirements, making it unavailable for purchase on the Walterscheid website.

Walterscheid GmbH, Lohmar, Germany

Claas of America, Claas Net Wrap System on Variant 560 RF

The Claas net wrap system on the Variant 560 RF variable chamber round baler has an adjustable stretch and a braking system that works independently of the size of roll. The net wrap system runs at 9.8 feet per second, covering the edges of the bale and ensuring a proper stretch of all rolls of net wrap, regardless of quality or size. The net wrap sits on a roller so that dirt or crop residue can fall out without making it into the bale. Adjustable devices left and right of the roll make it easy to center the 48-inch net wrap in the 51-inch tying system to the middle of the bale chamber.

Depending on the net wrap used, the stretch can be manually adjusted by adjusting the speed of the drive pulley for the net brake roll. This increases efficiency and hay quality by maximizing the compression of the material and preventing tearing of the net wrap.

New Holland Agriculture, T6.180 Methane Power

The New Holland T6 is the world’s first methane powered tractor. The T6 delivers the performance of its diesel equivalent with the same power at 180 horsepower and 740 Nm torque, with the added advantage of up to 30% reduction in running costs. It also offers operators fuel flexibility and can run on either biomethane or compressed natural gas. When running biomethane, it can provide a 10%-15% reduction in carbon dioxide. A maintenance-free, 3-way catalyst is used for aftertreatment, eliminating the need for exhaust recirculation, selective catalytic reduction components and diesel exhaust fluid.

When used by livestock and dairy farmers, there is the opportunity to capture methane produced from animal waste to use as fuel. The T6 also reduces exhaust emissions with a 75% reduction in carbon dioxide, a 90% reduction in non-methane hydrocarbons, a 98% reduction in particulate matter and a 62% reduction in nitrogen oxides.

New Holland Agriculture, New Holland, Pa.

Spectrum Technologies, WatchDog Portable Wind Sensor

The WatchDog Portable Wind Sensor measures wind speed and direction and records them using the free WatchDog Wind smartphone app to provide geolocation and a date/time stamp as well as local temperature, humidity and barometric pressure. This innovation comes from concerns about wind drift-related damage to crops and the environment, which has led to corresponding government regulations.

Handheld wind speed meters are only as accurate as the operator’s ability to determine the precise direction that the wind comes from and the accuracy of handwritten information. WatchDog, however, provides accurate measurements which are automatically merged with other weather data and saved on a secure app.

The ultrasonic wind sensors require less power than other options, enabling the use of a rechargeable battery, making the WatchDog more portable and easy to use.

Spectrum Technologies, Aurora, Ill.

New Holland, T7 Long Wheelbase with PLM Intelligence

The T7 Long Wheelbase with PLM Intelligence by New Holland is compact enough for a livestock loader, has enough hydraulic capability and PTO power for large hay tool tasks and has the ability to deliver high drawbar pull through its large diameter tires with minimal soil disturbance.

Power increases come from the addition of an electronically controlled variable pitch turbocharger and a matching cooling package. This delivers 300 horsepower, and peak torque is maintained down to just 1,300 rpm.

To maximize uptime and improve long term product durability, the number of pipe connections in the hydraulic circuits was reduced by 30%. Additionally, multiple control valves were grouped into a mono block, eliminating multiple oil supply routes and reducing the chance of a fault. To speed up any fault finding, the driveline incorporates remote diagnostic pressure test ports. This gets rid of the need to dismantle components prior to fault finding.

New Holland Agriculture, New Holland, Pa.

CABA Tech, CABA DLI Detective

The CABA Tech DLI Detective is a free online software that allows users to analyze available daylight in any specific geographical location to determine the appropriate amount of daily supplemental lighting required to meet a set light integral target. Users are able to select pertinent variables, including greenhouse light transmission percentage, and are able to adjust those variables in real-time. The DLI Detective uses current data sets from NASA’s POWER Project rather than NOAA historical aggregate data, allowing users the most detailed analysis.

Providing a schedule of how much supplemental light to apply and when is critical to the global greenhouse grower’s community and is an aid to architects, growers, facility planners and utilities.

John Deere, 1 Series Round Baler

The John Deere 1 Series Round Balers, compatible with any generation of Deere tractor, help farmers ensure optimal moisture levels and bale weights by using new electrical architecture and touch screen G5e display for accurate data. The bale scale uses an innovative weight system that is accurate on both flat ground and hillsides, more accurate than traditional load cell measurement devices. Agronomic data can be stored and analyzed through the John Deere Operations Center post-harvest analysis. This also allows users to create variable rate fertilizing prescriptions based on yield removal rates.

The balers also reduce operator fatigue through integrated technology that automates gate cycle functions. This automatically opens and closes the gate at the right time, eliminating repetitive tasks, reducing operator error and minimizing downtime, helping farmers get the most bales as quickly as possible. The 1 Series also has a higher capacity feed system with 33% more capacity, net lift assist, net lighting, a larger MegaRoll, increased automation, improved diagnostics and integrated variable rate preservative system.

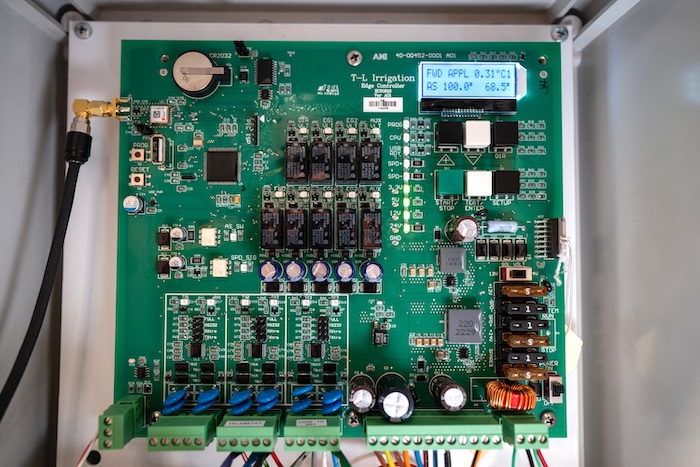

T-L Irrigation, Edge Controller

The Edge Controller by T-L Irrigation eliminates the traditional pivot point control panel found on mechanized center pivot irrigation systems and places the control directly at the end tower. Changing the controller location means all sensor input and control outputs are centralized to where the work takes place, at the end of the pivot. Along with cellular telemetry, the fully remote Edge Controller gives users the power to monitor and control pivot operations at any time with loT connectivity. Uniform water application is achieved by closed-loop speed control performed at the end tower and the continuous movement of T-L Irrigation hydrostatic drives.

GPS location, speed sensor input and water pressure input are constantly monitored by the Edge Controller, and electrohydraulic valves are utilized for speed, direction and end gun control. The hydraulic control valves also have a unique power saving function. The direction and end gun solenoid valve coils are energized with 24 VDC power to pull in the solenoids, and after 10 seconds the power is reduced to 12 VDC for hold in. This reduces power consumption by 50% for each solenoid in use.

T-L Irrigation, Hastings, Neb.

VeriGrain Sampling, AccuSample Ultra MT

The VeriGrain AccuSample Ultra MT is an automated grain sampler that also measures the moisture and temperature of the samples to determine spoilage risk and provides detailed information for optimizing blending. The Ultra MT mounts on grain handling equipment, such as swing augers, baggers and dryers and is controlled by the VeriGrain app via Bluetooth connection.

The hardware that mounts onto the grain handling equipment consists of a small auger inside a slotted tube, which is inserted into the grain flower. The auger transfers grain samples into a chamber where the moisture and temperature are measured, after which the sample is dropped into a proprietary bar-coded sample collection container.

Representative samples ensure spoilage and degradation risk analysis is accurate and provides the producer with information to get maximum value for their grain. Samples and stored grain information are easily shareable with buyers.

VeriGrain Sampling, Saskatoon, Sask.

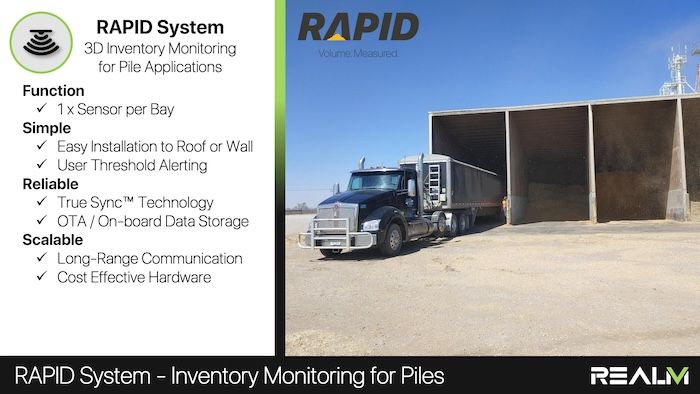

RealmFive, RAPID System

RAPID (Remote Access Pile Inventory Detection) by RealmFive is a system that combines a novel sensing solution with reliable connectivity and powerful software.

The sensing portion of the system measures the surface of commodity piles, transmits the data to R5 Cloud via RealmFive cellular connectivity and presents the inventory data to users through a cloud-based user interface. The system consists of a Lidar sensing assembly that enables automated remote measurement of the surface of a commodity pile. Backend software converts the measurements into volume, mass and number of truckloads. RAPID also includes time to empty projections and alerting. As a remote dry pile inventory monitoring solution, RAPID enables retailers to digitize their operations and better manage their remote inventories.

RAPID can be used for pile-based inventory monitoring applications as varied as feed, grain, sugar beets, timber, aggregates, etc. The sensing system scans a pile using an integrated Lidar sensor by rotating the sensor in 2 directions. This enables a 365-degree point cloud view of the installed structure on a frequency that can be set remotely. A device setup app enables the installer to measure dimensions of the dry bay and record it in the app, but users can enter their own bulk density values as well.

AGCO Corp, Fendt 200 Vario Gen3 Series

The 200 Vario Gen3 series is the smallest tractor in the Fendt family, while still combining all the same features the Fendt customers expect of its larger tractors. It is versatile and has lightweight maneuverability even in tough or unique crop conditions. The 200 Vario tractors are available in three models ranging from 94 to 114 rated horsepower and are available in either standard or 3-crop variant configurations. These tractors are powered by the AGCO Power 3.3 L engine and feature the Fendt Vario CVT.

The 200 series has a unique safety feature, in that it can easily switch the 2 filters with the push of a button on the display, so the operator may choose which will pull fresh air into the cabin. The CAT 4 (EN 15695) filtration protects from vapors and aerosols when applying pesticides or chemicals, and the CAT 2 filter protects against dust.

Case IH, Model Year 2024 Steiger 425-645

The Case IH Model Year 2024 Steiger 425-645 provides increased performance, improved serviceability and increased operator comfort with the new lineup of tractors. The 425, 475 and 525 models feature an updated Cursor 12.9L engine with a single electronically variable geometry turbo (eVGT) in place of the previous waste gate turbocharger for increased power and improved engine response to changes in load or throttle position. The 555, 595 and 645 feature a Cursor 12.9L engine 2 stage turbocharger engine with a larger, more robust low-pressure intercooler. The UVM mixer technology allows for improved mixing of the DEF with the exhaust stream, reducing the formation of urea deposits in the exhaust, especially in low-load conditions.

The engine fuel filter and crankcase ventilation (CCV) filter is relocated higher and forward on the right hand side of the engine compartment for improved serviceability. Hood support sub-structure has also changed from a one-piece to a bolted together design to aid in serviceability.

Alpha AgTech, Berry Impact Recorder

The Berry Impact Recorder by Alpha AgTech is an electronic sensor tailored for measuring mechanical impacts on berry fruits. The 1-inch sphere accurately records mechanical impacts up to 500 G-force with a maximum 4 KHz frequency, ensuring precise impact data capture. The recorder allows users to customize its capability, adapting its size and weight to match the requirements of their specific produce. Growers and distributors benefit from this data, optimizing their processes to ensure that customers receive the highest quality berries by preserving fruit integrity and reducing damage.

The Recorder provides quantitative measurements of mechanical impacts, allowing growers or equipment manufacturers to find the critical points that create high impacts and relate that to the actual bruising damage to fruits and vegetables.

The Blue Bird software used to configure the sensor and analyze its data is available on Windows, Mac and Android.

AGCO, Fendt 600 Vario DP Series Tractor

Fendt has launched the Fendt 600 Vario DP series tractor, designed for the 200-engine horsepower market. This series includes four models, ranging from 164 to 224 maximum horsepower, featuring the 4-cylinder, 5.0-lite AGCO Power Core 50 engine. The integration of the Fendt VarioDrive CVT transmission aims to optimize farm productivity through an efficient and user-friendly powertrain. All models are equipped with Dynamic Performance (DP) capabilities, allowing the release of up to 15 additional horsepower based on smart sensors that assess power demand. Unlike conventional constraints, the DP concept activates extra power in any operation when the system identifies the need for increased power.

In addition, the Fendt 600 series represents a fusion of new technology and improvements to existing machinery. It incorporates the FendtONE operators' station, enabling users to personalize their operating experience through various displays and configurable controls. The series also adopts the reliable VarioDrive CVT transmission from larger Fendt tractors, facilitating effective control with reduced slip through an automatic 4-wheel drive concept.

John Deere, ExactShot Liquid Fertilizer System

ExactShot — able to be added to Deere planters — doses starter fertilizer precisely onto seeds as they are planted vs. applying a continuous amount of fertilizer to the entire row of seeds, reducing the amount of fertilizer needed by up to 66% and allowing operators to plant 3 times as many acres between stops.

It uses sensors to spray the exact user-selected amount of starter fertilizer needed — from 0.1 to 0.6 mL at a prescribed length of 1 to 3 inches — onto individual seeds as they’re placed into the soil.

The development of ExactShot was possible through the use of software prototyping and video analysis of spray pattern and seed contact, allowing farmers to save on fertilizer costs and maintain healthier soils.

AGCO, Massey Ferguson 3 Series Specialty Tractor

The MF3 Series tractors, comprising 7 models in 3-dimensional versions and tailored for vineyards and orchards in the US and Canada, use Stage 5-compliant engines, transmissions with up to 30 speeds and a new operator interface. The series focuses on affordability and offers a range of power settings with unique dimensions. The MF 3VI.95 can be set to widths down to 39.4 inches, and the 3GE.95 and 3GE.105 have a minimal steering wheel height of 30.7 inches. These tractors employ existing technology for a new application, providing various alternatives based on specific dimensional needs.

The ability to complete the same tasks as standard configured machines but in a more narrow form is the most significant advantage of the technology present in narrow utility tractors. For example, an industry standard utility tractor of this general size has a width of 7.4 feet, which makes it difficult to maneuver in these tighter specialty settings without damaging trees and vines. But, a 3VI.95 can be set to 3.3 feet, which is less than 45% of the standard model’s width and makes farming tasks much less strenuous on both the crop and operators themselves.

Among the 7 models, the 3SP.75 and 3GE.75 closely resemble European counterparts but feature significant improvements. Models exceeding 75 HP offer enhanced transmission options with more gears, including an Eco Mode for fuel efficiency. The tractors also incorporate steel Bowden cables for transmission shifting efficiency and showcase a modern, content-rich instrument panel with a large high-definition display.

Case IH, Toolbar Lift System for Case IH Early Riser 2120 Rigid Trailing Split-Row Planter

The Toolbar Lift System for Case IH Early Riser 2120 Rigid Trailing Split-Row Planter offers improved ground clearance during transport for a Rigid Trailing Planter, easily accessible maintenance with access to planter row units and positive tongue weight for a more stable ride.

This system consists of 2 parallel link assemblies, actuated by 2 hydraulic cylinders through a range of positions including road transport where the carrying wheel tires are under the Toolbar, 2 storage positions with the carrying wheels in front of the Toolbar and a planting position with the tires further in front of the Toolbar. 4 radial tires offer increased floatation over traditional tire technology while avoiding running over any planted rows for increased yield potential.

Several safety features are in place on the Toolbar Lift System including 2 double pilot operated check valves, which hold the hydraulic lift cylinder pressure in a steady position even if there is a leak in the check valves. The hydraulic flow divider is used to ensure the Toolbar lifts and lowers level, despite when one side of the planter may be heavier than the other. Additionally, an optional rear-view camera allows easy view behind the planter using the operator’s tractor, making it easier to see equipment or obstacles when backing up to start a headland pass, backing up to a fertilizer tender, prior to raising or lowering the system or backing up for storage or maintenance.

AGCO, Massey Ferguson 9S Series Tractor

The Massey Ferguson 9S tractor is a new addition to the S Series, offering 285-425 horsepower. It features a 90-gallon-per-minute ECO pump for efficient planting at 1650 rpm, reducing fuel consumption and cabin noise levels, while increasing efficiency. The 9S also features an improved turning axle, providing a 10% improvement in turning radius for more efficient turning on headlands. The AGCO Power 8.4 Liter engine also enhances productivity with a longer service interval, lowering maintenance costs.

The Protect-U design of the cab creates a 9.4-inch gap between the cab and engine hood that reduces noise to 69 db. This design also changes where the engine intakes air onto the top of the hood, where the air is cleaner and cooler for enhanced engine performance. With 121 cubic feet of cabin space, 71 square feet of glass for increased visibility and an HVAC system that optimizes airflow, the operator enjoys a more comfortable working environment.

Case IH, AFS Furrow Command

Case IH’s AFS Furrow Command, available on the Precision Disk 550T, 550 and 500DS models, allows operators to make informed decisions on setting downforce via gauge wheel sensors that provide in-cab feedback. This means there’s no need to change hydraulic pressure settings for different field conditions to achieve consistent seed depth, the AFS Furrow Command will automatically change pressure on the go. This will improve overall seed and fertilizer depth control by automatically adjusting the hydraulic pressure for each frame section. It will also reduce component wear and tear by reducing excessive down pressure in conditions that don’t require it.

AFS Furrow Command is enabled by 3 major components: the downforce automation control valve, gauge wheel load sensors and software that makes the automated control possible. Within this, consumers have the option of a Drill or Section feature. The Drill feature controls the entire drill width with 1 hydraulic pressure controlling all frame sections. The Section feature controls each frame section independently for higher control resolution as each frame would have a unique hydraulic pressure, therefore achieving the highest level of seed depth control accuracy.

John Deere, See & Spray Premium Precision Upgrade

Designed for aftermarket installation on select John Deere sprayers, See & Spray allows the sprayer to see, target and kill in-season weeds using advanced cameras and machine learning that distinguishes crops from weeds and selectively target sprays only the weeds. To utilize this technology on existing machines, the design includes easy-to-install bundles that position multispectral cameras along the boom, secure ruggedized computers on the center-frame and wings and an update to the boom control system to make it more stable during operation.

The See & Spray Upgrade is designed to enable more efficient application of chemicals during in-season production of corn, soybeans, cotton or fallow ground weed control prior to the production of any crop, while providing data that allows growers to make better future agronomic decisions.

It is uniquely designed to completely integrate with each supported boom and machine in a retrofit capacity. Custom hardware and bracketry positions each camera so it maintains the appropriate overlap with neighboring cameras, while considering variables such as boom height, wing angles and in-season crop heights.

AGCO, Massey Ferguson 500R Series Sprayer

The Massey Ferguson 500R Sprayer by AGCO comes standard with LiquidLogic, which ensures constant circulation through the entire system. The 500R also offers Boom Clean Out, Product Recovery and No Spray Priming capabilities to reduce costs and waste.

Smart AWD with the transmission management system allows the machine to operate at a lower engine rpm and save fuel while maintaining pump pressure and spray pattern, ground speed and hydraulic flow.

The machine comes standard with a minimum of one camera and has nearly 360-degree visibility from the cab, offering the operator more visibility of their spraying application and the area around the sprayer.

The R Series Sprayer is an entry-level product geared towards a 1,000-2,000 acre grower operation.

Case IH, Steiger 715 Quadtrac

The Case IH Steiger 715 Quadtrac contains a Cursor 15.9 L engine, a fuel capacity of 520 gallons, 2 stage turbochargers that provide up to 778 horsepower and 2,401 pounds per foot of torque, providing operators with the increased productivity needed for tight harvesting and tillage windows or for accomplishing more work with a smaller labor force.

Other improvements include a larger drive wheel that engages 5 lugs at once compared to 4 on current Quadtrac track systems. The undercarriage main beam and roller beam are also lengthened to increase track footprint, with a total track length of 264 inches, minimizing soil compaction. An increased speed of 26.5 mph minimizes time spent traveling between fields, and with a total of 76,620 lumens, larger implements can be operated at night. A well-defined cable routing into the cab allows for easy mounting of secondary screens, displays and other devices for running implements.