For 100 years, some combination of Riechmann brothers has been serving Okawville, Ill., and the surrounding communities. Today, the third and fourth generations are working in the business and make up the dealership’s board.

The original Riechmann brothers — Hugo and Walter — purchased the business in 1922 from C.H. Erke. Hugo ran the dealership while Walter worked on the family farm. The next generation of brothers — Bill and Loyd — were thrust into the business when Hugo passed away, and they were just 21 and 15 years old, respectively. Since then, the dealership has expanded beyond Okawville through acquisitions. In 1988, the Breese, Ill., store was added, and Centralia was acquired 10 years later. Most recently, in 2017, the Farina store was added.

In 2010, with the business expanding, the family decided it was time to form a board. “We saw need to have a board and have monthly meetings just to strategize and plan,” says Keith Riechmann.

Today the board includes Bill Riechmann Jr., CEO; Keith Riechmann, Okawville store manager and sales; Matt Riechmann, Okawville service manager and sales; Kirk Riechmann, Integrated Solutions manager; Lance Rabenort, Controller; Kevin Riechmann, Breese store manager and sales; Mark Riechmann, transportation coordinator; Trey Riechmann, Okawville service writer; and Mike Riechmann, Centralia store manager and sales.

Founded: 1922

Employees: 96

Ownership Group: Trey Riechmann, Matt Riechmann, Mark Riechmann, Mike Riechmann, Bill Riechmann, Keith Riechmann, Kevin Riechmann, Lance Rabenort and Kirk Riechmann

Locations: 4

2021 Revenue: $120,609,610

2021 Market Share: 71%

Return on Assets: 15.76%

2021 Parts & Service Absorption Rate: 90.96%

Major Line: John Deere

Shortlines: Golden Bell, Horst, J&M, Killbros, Pik Rite, Remlinger

“Everybody goes to the board meeting, and nobody has more say than anybody else. It’s a true family run business,” says Bill.

“I’d say our strongest asset is everybody grew up in this business — literally from the time they could walk they worked in this business. We’ve all done parts, we’ve all done service, we’ve all done sales, and now we’re all managing,” says Keith. “We understand every part of the business. I don’t think there’s any other dealer or organization that has the amount of knowledge our board has with just a 4-store organization.”

Competitive Landscape

Riechmann’s AOR covers a diverse customer base. Washington County, where the Okawville store is located, is the No. 1 wheat county in Illinois.

“When you have wheat, it’s a lot more hours on the equipment. The wheat is double cropped, so they’re running the sprayer, the planter and the combine over the same acres twice in one year,” says Bill.

Okawville is a town of about 14,000 people, and it has 4 dealerships, an indication of just how agriculturally driven the community is, Bill says.

The next county north, Clinton County, is the No. 1 dairy county in the state and is served by the Breese store. Those customers have a lot of livestock. That store is a self-propelled chopper dealer and also sells a lot of hay equipment and loader tractors. Finally, the Farina store is farther north and serves a much more traditional Illinois ag customer — a lot of corn and soybeans, Bill says.

Keith says their biggest competition is inline, with large multi-store operations surrounding Riechmann Bros. They are surrounded by a 27-store Deere dealer to the south and west and a 22-store Deere dealer to the north. “We’re a small dealership between 2 huge groups. That’s our main competition,” he says.

“We’re a small dealership between 2 huge groups. That’s our main competition,” he says.

Most of the competitive dealers are single-store operations, but the Riechmanns note that is changing. Sievers, a 7-store Case IH dealer based out of Hamel, Ill., recently acquired a store in the area. Whether larger operations or single stores, the Riechmanns say all the dealerships have been over 50 years and are well established.

“As long as we keep improving some processes in the day-to-day, I think we’ll get to 100% in the next few years…” – Lance Rabenort, Controller

While the neighboring larger Deere dealers limit Riechmann Bros. ability to expand, Bill says it hasn’t been a concern to the group.

“We’re in such a good location with the livestock and the wheat and have very financially set customers. We’re pretty content here. For the people in this room, we’ve got enough work.”

Bringing Absorption Back into Focus

While Riechmann Bros.’s absorption rate is an impressive 90.96%, Rabenort says they have spent the last 7-8 years working on it. When he first started working in the business, the absorption rate was showing somewhere around 130%.

“I started to look into how and why, and it wasn’t 130%,” he explains.

After digging around, Rabenort discovered they weren’t reporting what was going on at the department levels by location properly.

Keeping Used Equipment Under Roof

When driving down the highway, it’s not uncommon to see used equipment lining the road in front of farm equipment dealerships across the country. You won’t find that at any of Riechmann Bros.’s 4 John Deere stores, however.

All the dealership’s stores have a building to store their used inventory — particularly combines, which CEO Bill Riechmann says helps eliminate lot-rot.

“You can keep it for 2 years and still sell that. Now, if it sits outside for 2 years, that’s a whole different deal,” he says.

While it doesn’t come without added expense — all those buildings get taxed — the Riechmanns think the benefits outweigh that cost. “We’ve got a better product to sell. It makes it easier to sell if you have a better product.”

“My grandfather and his brother (Bill Sr. and Loyd) were very much in the business and getting things done. Even when we had 3 locations, the books looked as if we had one,” he says.

Once Rabenort started breaking metrics down by location and by parts and service department, putting expenses in the right place, the dealership’s absorption rate dropped down to the upper 70s.

“We started making improvements then on how we were doing some things in our aftermarket, and it’s been a steady climb back to our goal of 100%. We’re still doing a lot of things that I think will help get us there in the next couple of years. We have great people. They work incredibly hard and efficiently. As long as we keep improving some processes in the day-to-day, I think we’ll get to 100% in the next few years,” Rabenort says.

Beyond absorption, one of the primary metrics the dealership monitors is customer satisfaction. The dealership’s customer satisfaction score is 99% based on the John Deere customer surveys, well above the North American average of 85% for John Deere dealers.

“We expect to be in the top 25% of dealers…” – Bill Riechmann, CEO, on Deere’s Dealer of Tomorrow Scorecard

“Our general mindset is if that stays above 95%, we’re going to have good years,” says Rabenort.

The Riechmanns emphasize customer satisfaction to their staff.

“Our employees have that same mindset that I have to take care of the customer better than anybody else. If our technician or parts man does a better job than anybody else, the customer is going to come back. It’s pretty simple,” Bill says.

To help the team provide the best service, management has given the technicians free rein to have one-on-one conversations with the customers, says Keith.

“They don’t necessarily have to go through our shop foreman. They’ve been around; Frank’s been here 30 years and Mark’s been here 25 years. Some of our best techs will go directly to that customer. They know who to take care of and how to take care of them quickly. That says a lot about our employees. A lot of them micromanage themselves,” he says.

Group Texts Keep Techs Up to Date

Because Riechmann Bros. is a relatively small dealership group in comparison to some of the much larger organizations out there, the technicians across the 4 stores know each other well and are comfortable calling each other.

“All of our service people call each other to ask, ‘Have you seen this?’ And if they figure something out, they immediately send a group text out that lets the others know about something that’s happening on a new piece of equipment and to be prepared for it,” says Matt Riechmann, service manager at the Okawville, Ill., store.

“A lot of our customers, we feel, can’t afford to do business anywhere else because we keep them going. Our motto is we don’t want a customer to be down more than a day. We don’t care how serious the breakdown is. We want to take care of them, get them up and going within a day’s time.”

While the dealership watches technician productivity and efficiency, Rabenort says they don’t have a set number they want the technicians to hit.

“There’s a knowledge of who’s doing what and how efficiently, and that takes care of itself if the customers are being taken care of. That’s just the honest answer,” he says.

In the parts department, the dealership values having the right part when the customer needs it over a high parts inventory turnover.

“Having the right part when they need it, that’s the key,” says Keith. “It’s not how many parts you have on hand, it’s having the right parts on hand. With all the experience we have and our parts guys have, we understand that. We know what we need in the bin to take care of our customers, and we’re not afraid to put it in the bin to take care of them.”

Bill adds, “Our parts managers have free rein to stock whatever they think we need to stock. If they feel that part needs to be on hand for the customer, put it in the bin. They don’t ask us, they just stock it. But you’ve got to have the right people who know what they’re doing to do that, and we’ve got the right people.”

As a result, Riechmann Bros.’s first pass rate is over 90%.

Inventory Challenges

High demand and supply chain delays have created some of the lowest new equipment inventories for farm equipment dealers in years. Bill says, “It’s been one of the biggest challenges we’ve face in our careers, I believe. We can’t get parts, and we can’t get wholegoods.”

“Over the years, if you couldn’t find something, you’d find ways to make that happen. We just think outside the box. We have to get that part, we have to get that machine. How are we going to do it? We just don’t say, ‘Can’t get it, sorry.’ We’re going to figure out a way, if it’s at all possible, to keep our customers running.”

Riechmann Bros. recently opened a new facility in Breese, Ill., that replaced its old store closer to town. The Riechmanns bought 15 acres of land and began planning back in 2016. However, then the opportunity to buy the Farina, Ill., location came up, CEO Bill Riechmann says, so they shelved the project to help conserve some capital reserves. They finally moved into the new Breese store in January 2022, but in May were still waiting on fixtures held up by supply chain delays. The new store is 34,000 square feet, significantly larger than the old facility that sat on just 3 acres of land. Features of the new store include a much larger parts storage area, an indoor wash bay, a training room and an IT room.

That might be using an aftermarket part if they can’t get it from Deere. Or, Keith says, they may run someone up to Iowa to get a part.

However, because of the supply chain constraints, he says the dealership is being allocated on the amount of equipment they can sell.

“It’s a real struggle. Do you cherry pick to get the slots? Like every other dealer, we have our MUD customers, naturally they get priority, but that’s a tough conversation to have with our other customers,” he says.

While the Riechmanns say they haven’t seen a major shift in new customer to used customer — Bill says because of the increasingly high price for new equipment — it’s a change that he thinks they’ll see in the future.

Keith adds, “We’ve got good, solid customers who would like to buy new, but they buy 1- or 2-year-old equipment because it’s, No. 1, financially beneficial, and No. 2, they understand where we’re at. We can’t sell new to everybody. Somebody has to buy used.”

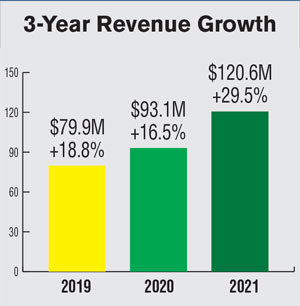

Business Growth

Over the last 3 years, Riechmann Bros. has seen strong revenue growth. Last year’s revenue of $120 million was a 29.5% increase over 2020, and that followed 16.5% growth and 18.8% growth over the 2 preceding years.

“The farm economy was getting stronger, and I think we are really as good a dealership as we’ve ever been as far as taking care of the customer. And I think everything just came together where we’d picked up the final location, and the market share of that location was really low when we got it. And we’ve expanded that really quickly,” says Matt Riechmann.

“We’re not done yet, and we’ve got some work to do, but the parts sales are off the chart from where they were when we moved in there. The biggest key in the future is finding more people like we have. That’s going to be our biggest challenge — finding more people who care about the business. Our employees care about our business as much as the board, and that’s the key.”

Riechmann Auctions Helps Build Relationships for Dealership

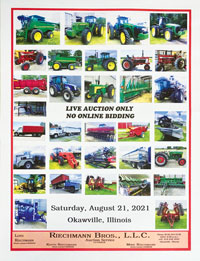

In addition to operating Riechmann Bros. for 100 years, the Riechmann family has been in the auction business for over 60 years. While the two businesses are separate entities, the auction company, Riechmann Auction Services, is also run by family members — Loyd, Keith and Mike Riechmann — who are all involved in the dealership.

The auction company does not sell any of the dealership’s used equipment and is nearly all estate sales. In the early years, Loyd Riechmann would run small farm sales every Saturday of February, March and April. By 1987, advertising was getting expensive, and it was getting hard to attract people out to the small sales in the spring. At that point, they shifted to one large auction the third Saturday in March that is held in Okawville, Ill.

The auction draws a crowd of about 3,000 people from at least 12 states, as well as South America.

The auction business helps give the Riechmanns a feel for the used equipment market and helps them get to know the people in the used equipment business.

“We get to know a lot of the used equipment jockeys and make acquaintances and know who buys what. It’s been a very good deal for our company,” says Bill.

The board meets officially on a monthly basis and reviews many of the metrics included in Deere’s “Dealer of Tomorrow” scorecard. The scorecard includes all the departments and shows how the dealership ranked vs. its peers. Metrics are marked in “green, yellow and red. If we have a red area, we’re concerned about that. That means we’re in the bottom 25%,” explains Bill. “If we’re in yellow, we need to make it better. Green is where we expect to be. We expect to be in the top 25% of dealers.”

Looking ahead for continued growth, Bill says right now they are working on improving their day-to-day processes.

“Process is one thing that we did lack before Lance started us down that road, we just did our thing. You know, we knew our business well enough and it worked, but we are working on getting processes in place and we’re still developing them and trying to get them the same through the 4 stores. This will help us get more efficient all the time. Because again, you have to get better at what you do,” he says.

One area in particular that the dealership is focused on improving processes is centralized parts ordering. Recently, the dealership has started keeping track of best practices and making notes on how daily stock orders are done, how personnel work, how work orders are completed and the like. The next step will be figuring out how to show the staff that these processes aren’t going to make their day harder — in fact they will make things easier in the long run, Rabenort says.

Matt describes the dealership’s relationship with Deere as strong. “It has to be. We need them and they need us.”

Dealership of the Year Video Series

Visit www.FarmDealerOfTheYear.com to watch exclusive video interviews with members of the Riechmann Bros. board. Filmed on location by Farm Equipment editors, topics include:

- Improving Absorption Rate

- How Riechmann Auctions Helps the Dealership Business

- Finding Success as a 4-Store Dealer Surrounded by Larger Dealers

- Riechmann Bros. Celebrates 100 Years in Business

The last few years have seen some turnover in people at Deere, but Matt says the new people who have come in have been very supportive of Riechmann Bros.

“I feel very confident when I pick up the phone that I’m going to get an honest answer, and that’s all we ask because we know that they can’t get us everything we need,” Matt says. “But I know they will try to get us everything they can. And you got to have faith in the people that you’re working with, whether it’s the employees or the company. If you’ve lost that, your business will suffer.”

As a 4-store Deere operation surrounded by large organizations, it could seem like Riechmann Bros.’s time is limited. But after 100 years, they firmly believe they are in a good spot.

“Deere is pretty honest with us,” Bill says. “If we keep our market share where they like it … I don’t think Deere is concerned at all. And I don’t think we are either. We think we can be viable as a 4-store dealership. We like the 4-store dealership. We’re confident we can handle the 4 stores. We do a good job at it, and we enjoy it. It’s our life.”