For 33 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The products selected save producers time and reduce cost and labor, all while improving user safety.

To be eligible for the award, each development —which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the entire industry, not to an individual company. Each year an international panel of industry experts in technology, design and product development gather to evaluate the entries and select up to 50 products for recognition.

Below is a selection of the 2021 AE50 Award winners.

Spectrum Technologies WatchDog 3000 Series Wireless Station

The WatchDog 3000 Series Wireless Station measures, records and communicates weather and environmental information. Its flexible configuration options for radio and sensors enables it to precisely meet the needs of any grower. With an LTE CAT-M1/NB-IoT cellular radio, the 3000 Series can monitor the widely dispersed fields of modern large farms. After an overnight rainfall, a farmer can see which fields can be worked without risking soil compaction and adjust field activities accordingly. With a mesh network radio, the varied microclimates of a vineyard, orchard or golf course are capably tracked, with localized disease pressure or frost warnings available. The all-in-one design with smartphone setup makes installation quick and easy for someone whose real job is not setting up weather stations.

Spectrum Technologies Inc., Aurora, Ill.

Farmation InjectorSentry

The InjectorSentry is a fertigation monitoring solution for use with center pivot and other irrigation systems. The InjectorSentry is designed to monitor fertilizer injection line flow and pressure, and if a problem is detected, alarm. The first question often encountered when starting a fertigation pump is, “What rate am I actually applying?” Then, after leaving the site, it becomes, “Is my pump still working as it was when I left it?” From plugged filters, to empty tanks, to mechanical problems, there are many reasons that cause fertigation applications to go amiss. When there is an issue, the next question is, “When did it happen?” The InjectorSentry answers these questions by showing how much product is being injected, monitoring the application and sounding an alarm if a problem occurs.

Farmation LLC, Hancock, Minn.

TeeJet Technologies AccuPulse TwinJet Flat Spray Tip

The AccuPulse TwinJet (APTJ) flat spray tip was designed specifically for use on sprayers equipped with pulse width modulation (PWM) spray tip controls. The unique nozzle design offers ultimate drift control without air induction, a method traditionally used to increase the droplet size of a spray. Patent pending pre-orifice and nozzle geometry re-circulates and slows the flow before atomization. The wide angle, twin spray design provides excellent leaf coverage and canopy penetration in broadcast spraying. APTJ is ideal for the application of systemic, post- emerge herbicides in terms of coverage and drift control near sensitive areas like susceptible plants, open water or residential areas. Every APTJ is individually tested prior to shipment to ensure precise flow rates and excellent distribution quality.

TeeJet Technologies, Wheaton, Ill.

LeafSpec

LeafSpec is an accurate, affordable and portable hyperspectral leaf imager. Within 5 seconds LeafSpec scans a leaf non-destructively and provides the measurement of a plant’s physiological features such as leaf moisture, chlorophyll content, nutrient level, diseases and so on. Innovated by the Plant Phenotyping Sensor Lab at Purdue University, the small handheld LeafSpec integrated advanced hardware and software technologies from existing hyperspectral imaging stations but provides even higher imaging quality. LeafSpec can be easily deployed at any location and generates hyperspectral leaf images with 0.5mm resolution. The cube image is immediately processed with an onboard microprocessor, and the measured plant features can be viewed in real-time with a smartphone app. Each measurement is geo-referenced and automatically viewable through the service of a digital ag cyber infrastructure.

LeafSpec LLC, West Lafayette, Ind.

www.sites.google.com/view/leafspecllc/home

Fendt IDEALdrive Steering System

The Fendt IDEALdrive Steering System from AGCO, eliminates the steering wheel and steering column on the Fendt IDEAL combine and gives the operator an unobstructed, end-to-end view of the combine header. The intelligent-control joystick located on the left side armrest requires 65% less muscle activity to operate than a steering wheel, reducing operator stress and fatigue during long hours of harvesting. A university ergonomics study comparing different steering technologies showed that joystick steering led to a 6% increase in productivity. Control is easy and precise in the field and on the road. IDEALdrive is an option from the factory on all IDEAL TrakRide combines (models 7T, 8T, 9T and 10T).

AGCO Corp., Duluth, Ga.

Intelligent Agricultural Solutions Engage SpreadControl

Engage SpreadControl is a quarter-boom section control upgrade for dry fertilizer applicators (“floaters”), and increases the swath control resolution from 35-17.5 feet per section on a TerraGator AirMax Precision (A & B series) applicator. This product reduces the amount of overlap per field by 3-5% or more. As stewards of the land, growers are always looking for effective ways to preserve the environment while maintaining a healthy farming operation. Increasing the precision of a floater allows the operator to apply product in the right place at the right rates while also affording them the ability to reduce application costs through saved fertilizer and longer equipment life.

Intelligent Agricultural Solutions, Fargo, N.D.

Agriculture Intelligence Agroview

By leveraging emerging areas of artificial intelligence (AI), machine learning, machine vision, cloud computing and automation, combined with elegant, user-centric solutions, Agroview provides critical data for growers and other stakeholders based on collected ground and aerial sensory inputs. Agroview’s patent pending AI utilizes deep learning algorithms to process, analyze and visualize data collected from smart ag technologies for precision production management, reducing data collection time and cost. Inputs include sprayers, satellite and UAV-based imagery. Agroview automates plant counting, plant gap detection and provides key plant data including plant height, canopy size and stress detection, while delivering full-field nutrient analysis and developing fertility maps compatible with variable rate technologies.

Agriculture Intelligence Inc., Gainesville, Fla.

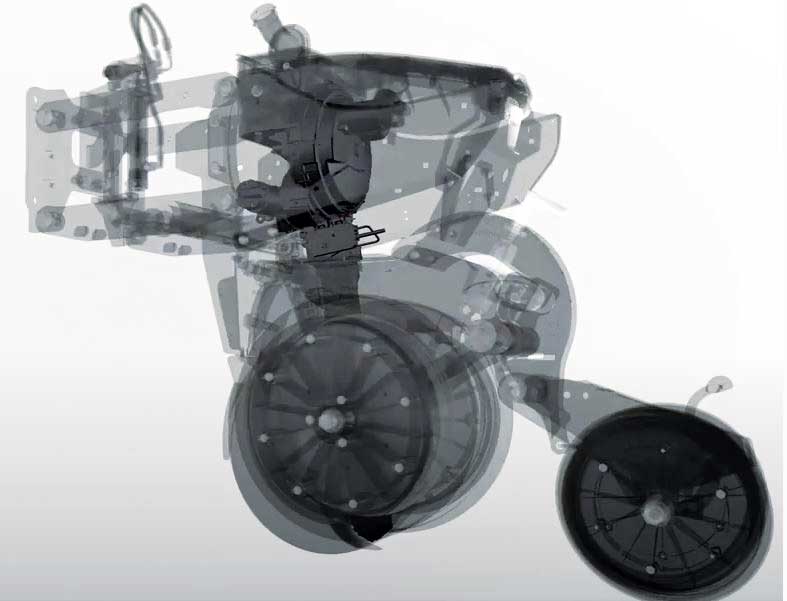

Danfoss Power Solutions MultiAxis-Steer

The new Danfoss MultiAxis-Steer electrohydraulic steering solution provides independent control of secondary steered axles on machines with multiple steerable axles to optimize safety, performance and operator comfort. Intelligent electronic control improves productivity by providing operators unparalleled maneuverability with minimal effort. MultiAxis-Steer allows safe and seamless changes between steering modes — including all-wheel steering and crab steering — during operation. It can also improve implement tracking and be applied to a theoretically unlimited number of axles. In addition, MultiAxis-Steer complies with the latest functional safety requirements. Control is accomplished by a new algorithm incorporated into the SIL2 TÜV certified failsafe PVED-CLS steering and safety controller integrated in the EHi steering valve. This results in less time required for OEMs to obtain functional safety certification for their machines.

Danfoss Power Solutions, Nordborg, Denmark

Kuhn VB 7100 i-Dense System

Available on the Kuhn VB7100 Series, the Kuhn i-Dense System is an intelligent density system, which independently controls the baler’s density settings based on crop conditions and moisture levels. This system has the ability to create extremely high-density bales. i-Dense pairs a twin tensioning arm system with measurements from a moisture sensor to automatically adapt the baling pressure according to different crops and crop conditions, without intervention from the driver. The system allows the driver to set the core density and the bale’s outer layer density independently of each other, and they will individually adapt to the new conditions. This results in the most economical use of the baler without compromising on performance. i-Dense allows a producer to create the best bales for their specific operation, and turn the crop into high quality feed.

Kuhn North America, Brodhead, Wis.

3Bar Biologics Bio-Yield

3Bar Biologics’ patented LiveMicrobe technology is a disposable, on-site fermentation system in which a beneficial microbe inoculum stabilized in dry formulation is released from a cap into a second chamber containing liquid, growth media and air to grow microbes exponentially to high population prior to use. By pushing the fermentation step on-site with the grower, this allows the freshest, most viable microbes to be consistently delivered to the crop, eliminating issues with microbe loss in the supply chain leading to less product variability and better overall performance in the field. Powered by the LiveMicrobe technology, Bio-Yield is a microbial biostimulant for improved corn production, enabling stronger early emergence along with improved plant growth and yield potential. As a platform technology, LiveMicrobe opens the door for many hard-to-stabilize beneficial microbes to be commercialized.

3Bar Biologics, Columbus, Ohio

Precision Planting FurrowForce

FurrowForce is an automated planter closing system with integrated sensing that manages soil density while fully closing the seed furrow. It uses two stages: one to aggressively close the furrow and a second to firm soil so that it maintains moisture for seed germination. Using a weight sensor that measures load on the second stage, FurrowForce automatically adjusts the force applied to the unit to maintain consistent firming force as the row unit encounters varying soil and field conditions.

Precision Planting, Tremont, Ill.

Autonomous Pivot

Autonomous Pivot turns center-pivot irrigation systems into robotic platforms for autonomous irrigation, fertigation and crop protection. The platform utilizes on-pivot ground penetrating radar for continuous noninvasive sensing of soil water content, 2 cameras, a wide field of view and a narrow field of view, a GPS and a rain gauge. These sensors’ data is uploaded to the cloud for analysis by an AI engine, namely the AI Agronomist. The ground penetrating radar is the first mobile soil moisture sensor that is available for farmers.

With deep learning and AI Agronomist technologies, the platform enables fully automatic symptom detection and autonomous treatment actions through Autonomous-Pivot’s app. Real-time data from the Autonomous Pivot platform allows farmers not only to make better use of essential resources to maximize yield, but also to reduce water, gas and other input costs. In the future, more sensors will be added to the platform, enabling fully autonomous farming of pivot-irrigated row crops.

Autonomous Pivot, Tel Aviv, Israel

Claas 6000 Series Straw Walker Combines

The Claas Lexion 6000 series is a new line of wide body straw walker combines comprised of 4 models: 466 horsepower class 8 6900 (wheels), 6900TT (Terra Trac), 402 horsepower class 7 6800 (wheels), and 6800TT (Terra Trac). The 6000 series processor features the APS Synflow threshing system with an integrated active separation cylinder and interchangeable and adjustable separation grate, and 6 four-step straw walkers for final separation. The 6000 series is equipped with the high-performance Jetstream cleaning system to provide leading crop cleaning and grain handling capacity. A 385-bushel grain tank is standard with an optional 425-bushel grain tank. Unload speeds reach up to 5.1 bushels per second and offer greater convenience for improved in-field logistics.

Claas of America, Omaha, Neb.

RealmFive Flex Max Long-Life Wireless Monitoring Device

Flex Max was developed to solve the problem of integrating brands and types of in-field and on-farm sensors. Flex Max builds upon RealmFive’s original Flex technology to add more inputs as well as an innovative combination of battery technologies that achieves a 5-year battery life, based upon a base data measurement and send frequency. Battery power allows installation in places and in applications where electrical grid power and even solar power are not options. Sensor input types include analog inputs, digital inputs and serial interfaces. Applications can be as diverse as level sensing, flow meters and soil moisture sensors. Other R5 Core standard features that are available include over-the-air configuration changes, firmware updates and TrueSync technology for reliably connecting to the cloud.

RealmFive, Lincoln, Neb.

Kondex Revolution Concaves

Kondex Revolution concaves are high-performance threshing components that feature a helical, half-width design to deliver greater set-up flexibility and crop condition adaptability than traditional concaves. Continuous rows of angled threshing or separating bars meet the crop head-on to improve threshing, thus reducing whitecaps in wheat and plugging in moist crop conditions. These concaves also reduce rotor power usage, and improve the combine’s overall productivity. Assemblies include MaxThresh — for optimal threshing — and MaxRound — for ultimate separation. Kondex Revolution concaves are available exclusively through John Deere.

Kondex Corp. & John Deere, Lomira, Wis.

Oxbo 6030 Vineyard Multifunction Machine

The Oxbo 6030 Multifunction Power Unit is an over-the-row vineyard product that is available with two different grape harvester attachments and a 3- or 4-row sprayer attachment. The 6030 steering system turns the front wheels up to 95 degrees, enabling the unit to turn in limited space. It features a simple attachment system for switching between sprayer and harvester. The harvester attachment is available with PremiumSort for removing up to 99.5% of material other than grapes. The sprayer is configured for 3 or 4 rows and uses a venturi nozzle system with up to 16 nozzles per row. The hydraulic variable speed fan for each row unit ensures precise delivery of product as well as adequate air flow for complete application of product. The machine utilizes a 4.4L CAT ACERT 174 horsepower engine with an integrated Eco-mode to reduce fuel consumption.

Oxbo International Corp., Lynden, Wash.

Kinze TrueSpeed, SureSpeed

TrueSpeed by Kinze Mfg. meets SureSpeed by Ag Leader for a high speed, high accuracy planting system developed to provide growers a planting solution that increases productivity and accuracy while providing efficient operation and low-cost ownership. This product was a collaborative development between Kinze for OEM application and Ag Leader aftermarket application. The system uses 24 volt brushless DC motors to power a new-design high-speed, high-efficiency vacuum seed meter and a mechanical seed transfer system, providing high accuracy seed placement at speeds from 3-12 mph. Developed primarily for row crop growers, the system uses a unique 2-stage brush type transfer system to accurately transfer seeds from the seed disc to a seed delivery mechanism that places seed into the seed furrow without the effects of gravity, hillsides or forward travel speed.

Kinze Mfg. & Ag Leader,

Williamsburg, Iowa & Ames, Iowa

www.Kinze.com and www.AgLeader.com

Dura Products Dura-ABV-B Auto-Batch Meter

The Dura-ABV-B Auto-Batch Meter, designed to connect with the Banjo EVX 100B Electric Valve, is suited to automate a venturi-driven chemical handling system. Simply join the factory installed electric connectors, plumb the valve to auto-batch, select the volume desired, press start, and the valve automatically opens and closes upon completion. Save up to five calibrations with measurements in gallons, liters and ounces. Female NPT and manifold flange connections offer plumbing options. Dura-ABV and Banjo EVX Valve remove the need for sophisticated wiring, PLC or plumbing. Operator error and herbicide exposure is eliminated.

Dura Products, Arcadia, Ind.

Amber Agriculture Ace Air

The no-cables way to monitor grain, the Ace Air system is the world’s first wireless, solar- powered CO2 analyzer for grain environments. The product kit includes two new hardware products forming an automation suite for on-farm and commercial grain bins. The headspace CO2 monitor snaps on to the roof of a storage structure and syncs with a wireless fan controller equipped to the aeration system of the grain environment. Both hardware pieces can be remote controlled from a mobile app. Aeration recommendations from advanced modeling are presented with click button controls to the end user.

Amber Agriculture, Chicago, Ill.

LR Gehm TridentPulsation

Using an integrated controller card, this pulsator enables consistent liner attach, gentle detach and continuous real-time pulsator monitoring. Cows milk at average peak flows of 20 pounds per minute with many cows achieving 25-35 pounds per minute resulting in average milking durations of 3.6 minutes. Reduced milking time reduces labor, permits more cows to be milked and enables cows to spend less time in the milking process. Several technologies incorporated into this pulsation product include the ability to hold a liner fully open during the attach and detach process to ensure full liner engagement and gentle removal. A positive pressure fresh air system ensures consistent liner action. An integrated sensor continuously monitors and verifies specified operation of the pulsator. A long-life feature is included.

LR Gehm, Lisle, N.Y.

Munsters Corp. CX24

Studies show the use of circulation fans can result in more stable house temperatures and better bird distribution while reducing litter moisture and ammonia. This leads to a reduction of up to 20% in paw lesions and lower feed conversion rates. The advanced design of the CX24 produces a higher centerline velocity, providing more control over the air movement in the barn. This precision creates ideal bird distribution leading to more even litter moisture levels for healthier paws. Munters’ unique chevron design is engineered to minimize specific frequencies generated by the fan blades, reducing noise of the fan in order to provide a comfortable environment for the livestock. Acoustic testing was performed in certified, a semi-anechoic chamber to isolate specific frequencies and optimize the design for maximum noise reduction.

Munters Corp., Lansing, Mich.

SGM Technologies Areca Dehusking & Processing Mill

The areca (or betel) nut is one of the major horticultural crops in the Indian costal region and has been dubbed the backbone of Indian costal economy. The Areca Dehusking and Processing Mill is designed to enhance the rate of production and eliminate the risk of injury involved in the traditional manual peeling process currently used. The machine, using an automated gear drive, will be easy to operate, and accommodate different sizes of either fresh or dry areca nut. The Areca Dehusking and Processing Mill requires only a single operator per day and functions in the voltage ranges (160 -240) available in rural areas where the power supply is unstable.

SGM Technologies, Shivamogga, Karnataka, India

Reinke Electronic Swing Arm Corner

ESAC increases water uniformity and eliminates under and over watering throughout the corners of a field through a unique and novel patent pending water application method. This increase in uniformity brings the swing arm corner to a higher standard in water use efficiency. ESAC provides growers with ways to increase additional acres under an irrigation system without buying additional ground. The innovation is in the application of the sequential zones, GPS positioning, electronic controls, and a patent pending water application method that provides the right amount of water-based system parameters, such as the unique coverage area in the field.

Reinke Manufacturing Co., Deshler, Neb.

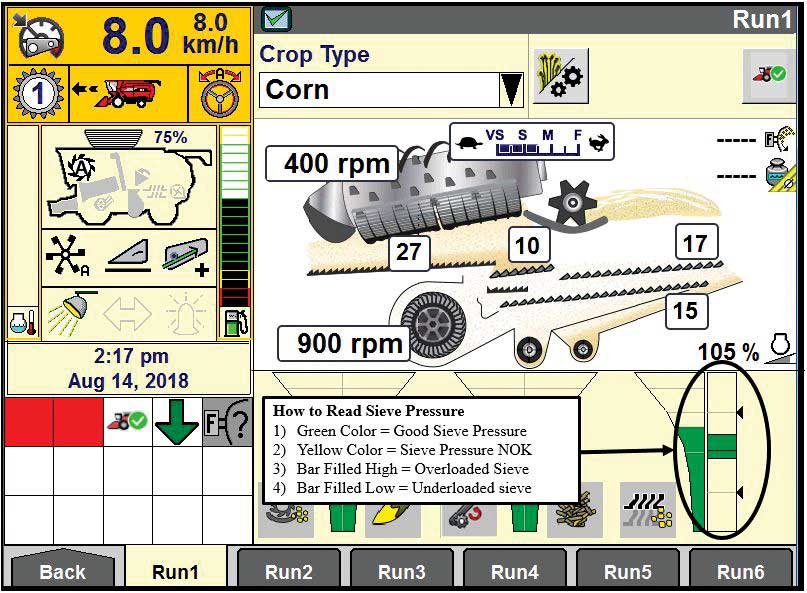

Case IH Sieve Pressure Visualization

With the launch of model year 21 Case IH provides instant cleaning system performance profile information via sieve pressure visualization for the Axial-Flow 250 Series Combine. Throughout the history of harvesting there has always been a risk of “making the wrong adjustment.” This is because although loss is sensed there is no way to understand what type of loss it is. Making any correction to the cleaning system without doing a kill stall was more or less a guess. When properly equipped with sieve pressure visualization, Case IH Axial-Flow 250 series customers will have the ability to define how the cleaning system needs adjusted thereby saving grain with the right adjustment.

Case IH Agriculture, Racine, Wis.

Haber Technologies DRI-Stack

Haber Technologies has developed a novel drying and aeration technology that directs airflow to specific locations within bins in a considerably more efficient manner than traditional plenum- based grain drying and aeration systems. The DRI-Stack System consists of a series of air tube stacks containing valves for directing airflow within the grain mass to specific locations in the bin. This system can be used to dry an entire bin of grain more efficiently and more consistently than either heated air or natural air systems. It can also be used to target specific hot spots within the bin. Tests in grain producers’ bins show that entire bins can be dried in less than one week, at a fraction of the price of traditional drying systems.

Haber Technologies, Ames, Iowa

Raven VSN Visual Guidance

VSN Visual Guidance system in full canopy utilizes a stereo vision camera and non-contact radar sensors to navigate the machine through emerged crops. VSN allows the operator to focus on other aspects of effective application control while eliminating crop damage and to cover more acres in a day. This provides easier machine operation, leading to a quick return on investment to maximize yield profitability. The operator covers 20% more acres due to increased speed and ease of use, and drastically reduces crop damage and misapplication in the field. This non-contact, multi-sensor approach maintains sub-inch accuracy through varying crop conditions at speeds up to 20 mph. VSN Visual Guidance works with a variety of Raven products, including the field computers Viper 4+, RS1 and SC1 and Slingshot telematics.

Raven, Sioux Falls, S.D.

Forest Concepts Hemp Dryer Model 1

The Forest Concepts Hemp Dryer Model 1 is a continuous incremental zoned dryer optimized for drying industrial hemp prior to storage and extraction. Raw harvested hemp is processed on screen-bottomed trays through the dryer and then sent to either to an extraction facility or for dry storage. A continuous line of bins advances through 6 drying zones and one cooling zone prior to exiting the dryer system. Semi-independent modules allow optimization along the drying curve and greatly reduces total energy consumption. Each of the 7 dryer zones have independent air handling fans, and heated zones have independent propane burners. The mechanical drying and cooling system is managed by an integrated PLC-based control system. The dryer is mounted on a highway-legal 48-foot flatbed trailer for mobility.

Forest Concepts, Auburn, Wash.

Case IH Fast Riser 6100 Front-Fold Planter

The Case IH Fast Riser 6100 Front-Fold Planter in a 61-row 45-centimeter row spacing configuration offers the most productive corn/soybean/cotton planting experience in Brazil, at 20 hectares (50 acres) per hour. This planting productivity allows more crop to be planted in the optimal window for increased yield potential, using a patent pending 5-section hydraulic wing down force system that includes in-cab adjustable settings to keep center section, inner wings, and outer wing agronomic designed Fast Riser row units at target depth, even at planting speeds up to 10 km per hour in challenging no-till conditions. Further enhancements to productivity come from approximately 100X less grease points than competition (7 vs. 650+) that reduce service times significantly. Large 5,440-liter seed capacity increases autonomy between seed tendering.

Case IH Agriculture, Racine, Wis.

Netafim NetBow

NetBow is an innovative, user friendly container irrigation multi-outlet dripper arc with high clogging resistance and superb water distribution. Placed on the substrate surface, NetBow ensures 100% uniform coverage of the substrate from top to bottom with no “blind spots” and might minimize drainage. With NetBow, roots develop in every square inch of the container including the top layer, where root development is critical, ensuring your crops reach their full growth potential. NetBow features eight of Netafim’s high clogging-resistant drippers to ensure uniform water distribution with a lower risk of clogging. NetBow is quick and easy to install and collect with little room for human errors saving labor and time. NetBow helps growers maximize nutrigation efficiency in containers.

Netafim, Tel Aviv, Israel

John Deere X9 Combine

The X9 machine brings together new levels of capacity, efficiency and technology. The industry’s widest body allows substantial increases in functional capacity that delivers more capacity throughout the harvest day and extending the hours of the harvesting day. The X9 1100 can harvest up to 7,200 bushels per hour in high-yielding corn and up to 30 acres per hour in wheat. The entire drives architecture is updated and a new propulsion system is in place to further improve efficiency. These changes, combined with the new 13.6L engine from John Deere Power Systems, provide significantly more capacity with a minimal increase in engine power in the X9 1000 and X9 1100 models, leading to an improvement in fuel economy.

John Deere, East Moline, Ill.

KMC 7406 Peanut Combine

The KMC 7406 Peanut Combine, a progressive pull-type peanut harvester, features a 20% higher capacity threshing system, four-tier cleaning system, and custom electronic control system that allows the combine to be adjusted from the tractor seat. The improved threshing system is designed to reduce vine wrapping, increase mass flow rates, and expand the operating parameters of the peanut combine to include less than ideal conditions experienced when crop moisture content is high and/or harvesting has been delayed beyond the ideal window. The four-tier cleaning system has multiple dirt release locations, innovative sizing rollers to remove clods and large debris, and a custom sieve to provide even air flow for the cleanest sample possible. Features include a swing away concave for easy cleaning, abrasion resistance, replaceable steel panels in the air conveyor, and easier access to all maintenance points.

Kelley Mfg., Tifton, Ga.

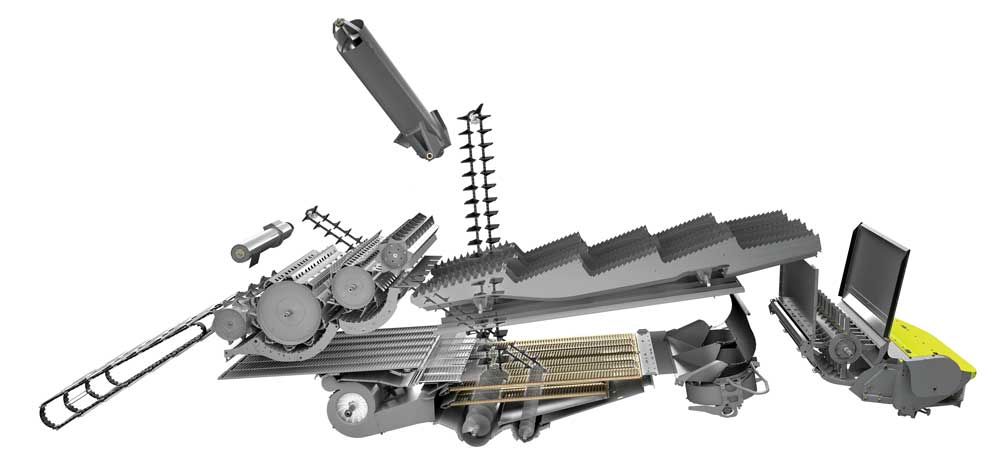

John Deere CF Folding Corn Head

New John Deere CF Folding Corn Heads allow customers to harvest up to 7,200 bushels per hour and 80,000 bushels per day in high-yielding corn by adding 16 and 18 row folding configurations. When transporting between fields, customers will appreciate improved visibility delivered by the enhanced frame design. Fold and unfold times have been reduced to save time moving between fields throughout the day. For harvesting leaning, down or flat crop, CF Folding Corn Heads can be equipped ready from the factory with Active End Fenders which pull more stalks into the head as the combine moves through the field. Active End Fenders are compatible with end fender extensions. Factory-installed Stalk Deflectors press corn stalk stubble to the ground to reduce tire and track damage.

John Deere, Bettendorf, Iowa

Schlot Live MkI Cane Loss Monitor

Scholt Live is a data-driven console that provides real time and quantifiable cane loss data to harvester operators, enabling fine tuning and maximization of harvesting performance. Incorporating Schlot Live into a harvesting program reduces cane losses by between 40-60% across normal operating conditions. Schlot Live addresses the considerable ‘invisible’ losses made up of cane reduced to non-recognizable matter by the extractor systems. This is achieved using proprietary algorithms that process 25 years of field research trial data against live harvesting data collected by an array of monitors installed at key locations on the harvester. Schlot Live brings immediate financial benefit to the sugar supply chain, with return on investment achieved in as little as 100 hours.

Schlot Pty, Cambridge, Tasmania, Australia

Raven Hawkeye 2 Nozzle Control System

Hawkeye 2 Nozzle Control is a pressure-based product control system that allows for precise sprayer application by dynamically controlling the rate and pressure in a variety of conditions. The nozzle control valve (NCV) builds upon the previous system: individual nozzle control reduces skips and overlaps; consistent rate and droplet size reduces drift and increases application quality; and turn compensation minimizes over and under application, achieving the ideal application rate across the boom. Each nozzle is controlled by its own pulsing NCV providing a consistent spray pattern across the boom as speed and conditions change ensuring precise droplet coverage. Hawkeye 2 can shut off flow by sections or individual nozzles. This technology saves on chemicals, reduces overlap and unnecessary application, and provides the most efficient coverage.

Raven, Sioux Falls, S.D.

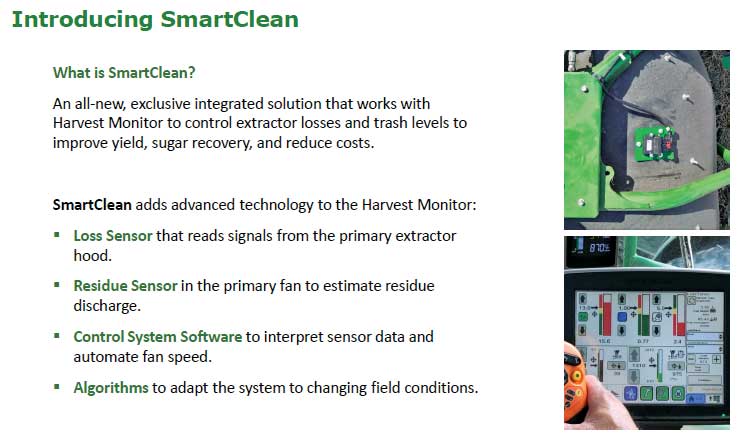

John Deere Harvest Monitor with SmartClean System Company

SmartClean is the controlled cleaning solution for mechanical cane harvesters that reduces operator decision making through a documentation system while delivering consistent customer defined product to mill. Agronomist, field managers or experienced operators set targeted results which are achieved through the sensors and control scheme. Coupled with integrated machine sensors, the control system minimizes cane losses, and manages residue ejection, and leaf trash sent to mill by managing primary cleaning fan speed settings. Agronomic information can be documented and recorded to provide live feedback on the vehicle and sent to the customer via the John Deere data and vehicle management system. The system uses a combination of sensors including accelerometer, stereo cameras, pressure, and speed sensors with an adaptive machine learning development algorithm, to generate correlations between fan speed and cleaning performance.

John Deere, Thibodaux, La.

Fendt 700 Gen 6

The new Fendt 700 Gen6 Series premium high-horsepower tractors deliver versatility, comfort and easy operation. AGCO engineers completely redesigned the operator station and the innovative new FendtONE operator interface provides a streamlined and highly efficient work environment. It features a 12-inch primary display on the armrest, an optional 12-inch pull-down display recessed into the roof liner and a 10-inch “digital dashboard” on the steering column. The 12-inch displays operate in unison, allowing the operator to choose and view up to 12 panels of information across the two screens. Navigation is easy and intuitive, like using a smartphone. The 700 Gen6 Series tractors can be adjusted to narrow and wide row spacings and are available in six models with engine horsepower ranging from 144 to 237.

AGCO Corp., Jackson, Minn.

Case IH MultiControl Armrest

Case IH upgraded the overall armrest ergonomic rating by 58% in customer focus groups by using innovative technologies like human positioning software, Case IH-developed human positioning optimization software, virtual reality simulators and 3-D printing. An iterative design and customer clinic process led to the optimization and delivery of the most comfortable armrest to the widest range of customers. Minor changes to our armrest design lead to major customer satisfaction and operator comfort sustainability improvements.

Case IH Agriculture, Burr Ridge, Ill.

New Holland Crossover Harvesting with TripleClean Cleaning System

The New Holland Crossover Harvesting system combines conventional drum threshing and Twin Rotor separation, with the TripleClean cleaning shoe to deliver enhanced capacity for midrange combines. This system significantly increases combine capacity, within the dimensions and engine power range of midrange combines, in classes 4 to 7. This Crossover Harvesting system ensures that a midrange combine delivers the capacity of a traditional rotary machine combined with the outstanding straw quality associated with a pure conventional system. The system is compatible with all combinable crops the world over, including, but not limited to soy beans, corn and rice in Latin-America to cereal crops, rapeseed and corn in Europe and CIS.

New Holland Agriculture, Zedelgem, Belgium

Case IH Category 3/4n 3-Point Hitch Quick Coupler

The Case IH Agriculture 3-point quick coupler carries the load of a 2-point or 3-point mounted implement while reducing the amount of material required and increasing durability. The design is driven by real-world customer application loading conditions, input through a design volume, then reduced via topology optimization to reveal the most ideal structural path. A two-software process is employed that passes the design from one to the other, developing it from a large volume of design space to a finalized casting that optimizes material usage. The new design improves the strength and life of the quick coupler while at the same time reducing the cost by both reducing weight and implementing a more common material, leading to a more sustainable design.

Case IH Agriculture, Burr Ridge, Ill.

New Holland BigBaler 340 High Density

The BigBaler 340 High Density produces bales that weigh up to 22% more than conventional large square balers. The patented SmartShift two speed gearbox provides easy driveline startup with full overload protection resulting in less wear on baler and tractor driveline components. Based upon the tractor’s torque, the gearbox automatically shifts up to the desired flywheel speed. An integrated oil-cooled brake stops the plunger at the ideal spot to ensure easy baler startup every time. A unique hydraulic axle suspension system yields improved ground following and ensures excellent weight distribution across all four wheels. The elimination of leaf springs allows for excellent accessibility underneath the baler. Combined with the high capacity 5 bar pickup and LoopMaster knotter, the BigBaler 340 High Density delivers greater producer profitability.

New Holland, New Holland, Pa.

John Deere ExactRate Liquid Fertilizer System

The ExactRate Liquid Fertilizer System utilizes existing ExactApply Sprayer technology in an innovative way as a planter applied fertilizer solution. The system uses pulse width modulation to enable features such as in-cab rate adjustments, variable rate prescriptions, individual row section control, and curve compensation. As the need for more precise input placement grows, ExactRate carries a lot of the features found in electric drive planters and delivers it to the liquid fertilizer side. The system provides an integrated solution for on-planter fertilizer delivery using familiar components and user interfaces, mitigating the need for growers to design and build their own system. The ExactRate Liquid Fertilizer System offers new capabilities to practice nutrient stewardship by applying the right source at the right rate during the right time in the right place.

John Deere, Moline, Ill.

Case IH 24-Row Air Pack System for Case IH Fertilizer Applicators & Air Carts

The new 24-Row Air Pack System provides a method to accurately deliver dry fertilizer products from a Case IH Precision Air 5-Series cart to a 60-foot 940 Nutri-Placer or 955 Nutri-Tiller fertilizer applicator. Featuring a series of unique 3-way splitters, this system can accurately and equally deliver product to 24 individual row units on 30-inch row spacing. This allows growers to make use of a highly productive 60-foot toolbar to cover acres quickly and efficiently. With growing emphasis on environmental impacts, fertilizer run-off can be minimized and plant up-take can be maximized by properly banding fertilizer in the root zone. The Case IH air carts and applicators properly deliver and place dry fertilizer products to lock in crop profit potential.

Case IH Agriculture, Normal, Ill.

Fendt 1100 Vario MT

The new Fendt 1100 Vario MT Series track tractors combine proven innovations from AGCO’s 30 years of experience in tracked tractors with newly engineered features that elevate operator comfort and in-field performance. The entirely new Fendt iD powertrain delivers a high-torque, low-engine speed concept through the use of the VarioDrive continuously variable transmission (CVT). All tractor functions, including CVT, PTO, cooling system and hydraulics, are geared to run at optimum levels with the engine speed in a working range of 1,100-1,500 rpm. These innovations lower fuel consumption, reduce engine and component wear and provide extra-quiet operation.

AGCO Corp., Jackson, Minn.

Case IH LB436 HD Large Square Baler

The LB436 HD delivers all-out efficiency by producing bales that weigh up to 22% more than standard series of large square balers. The exclusive two speed gearbox provides easy driveline startup with full overload protection resulting in less wear on both baler and tractor driveline components. Based upon the tractor’s torque, the gearbox automatically shifts up to the desired flywheel speed. An integrated oil-cooled brake stops the plunger at the ideal spot to ensure easy baler startup every time. A unique hydraulic axle suspension system yields improved ground following and ensures excellent weight distribution across all four wheels. The elimination of leaf springs allows for excellent accessibility underneath the baler. Combined with the high capacity five bar pickup and TwinePro knotter, the LB436 HD delivers greater productivity to the producer.

Case IH Agriculture, Racine, Wis.

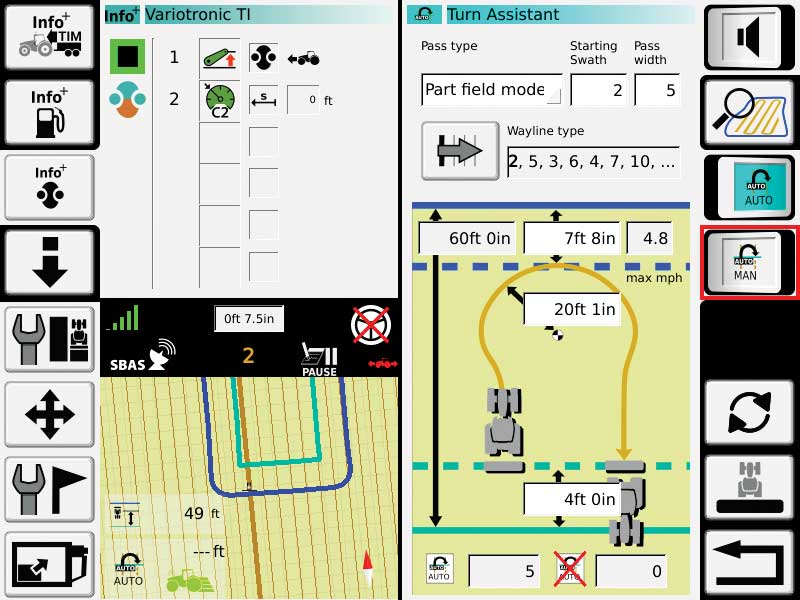

Fendt Turn Assistant

The smart technology of the Fendt Turn Assistant manages all the steps for precise and efficient hands-free turning of a tractor and implement at the field edge. Unlike other systems, it self-adjusts within the parameters set for that field and it includes a field overview map, allowing the operator to see each turn. The system has two modes. Traditional U-Turn mode completes headland turns, and Part Field mode completes turns in areas of the field that require a specific pattern, such as skip rows during a deep tillage operation. Both modes make the operator’s job easier, save time, reduce fuel use and result in smoother turns, causing less impact on the soil.

AGCO Corp., Jackson, Minn.

John Deere CH950 Sugar Cane Harvester

With the new CH950, John Deere presents to the industry a more sustainable sugar cane production system that allows controlled traffic on all the operations from planting to harvesting, reducing compaction by 60% for increased yield and crop longevity while using 30% less fuel. This 2-row harvester, doubles productivity, decreases losses by 60% and requires 28% less infield transport equipment and 33% fewer operators resulting in 22% less harvesting cost

John Deere, Thibodaux, La.

AGCO 9350 DynaFlex Draper Header with AutoDock Header Docking System

The 9350 DynaFlex Draper Header with AutoDock Header Docking System is a 50-foot flexible header with the industry’s first automatic system for attaching all mechanical, electrical and hydraulic connections of the header to the Fendt IDEAL Combine. The combine operator pulls up to the header, lifts it from the ground or trailer, and pushes a button in the cab. AutoDock uses guide pins and hydraulic actuators to connect the drives on both sides of the header and connect all systems with a single-point coupler while mechanically latching the header – all in 5 seconds. The 9350 Header with AutoDock improves harvest productivity for a number of crops with its width and ground-hugging flexibility.

AGCO Corp., Duluth, Ga.

Case IH AFS Connect Steiger

The Case IH AFS Connect Steiger provides new operating and connectivity features which build on proven reliability and efficient power. The AFS Pro 1200 display allows for operation of all tractor and implement applications and controls at the operator’s finger tips and in one convenient location. Built-in 4G connectivity with remote display viewing, remote service tool support and Firmware Over The Air (FOTA) allows faster and more efficient support of tractors in the field. The redesigned cab interior provides ample storage space and power outlets allowing the operator to stay connected with personal electronic devices. All of these and many other features combine to make the new Case IH AFS Connect Steiger a comfortable and productive high horsepower tractor.

Case IH Agriculture, Fargo, N.D.

John Deere HDR Rigid Cutterbar Draper

John Deere HDR Drapers bring innovations that enhance the performance, efficiency, and ease of use of John Deere’s grain harvesting solution. A new hinged frame provides nearly two times the vertical wing range compared to competitive machines, while delivering more consistent cut height in uneven and rolling terrain. Integrated cab controls allow the combine operator to quickly change cut height or float pressure on-the-fly from the cab. Grain Saver Draper Belts reduce canola loss up to 25% compared to traditional smooth draper belts. Optional fingered top augers improve feeding performance in bushy crop and help reduce grain loss, while higher feed drum torque and wider center-feed system enable higher throughput. HDR drapers are available in cutting widths from 35-50 feet

John Deere, Bettendorf, Iowa

Fendt Momentum Planter

The Fendt Momentum Planter is a high-capacity, high-speed planter that addresses planter soil compaction while setting a new standard for seed placement accuracy on contours and in challenging planting conditions. The in-line tandem transport wheels with very-high flexion tires combine with the optional Load Logic system to eliminate planter pinch rows. Weight is hydraulically transferred across the planter constantly to maintain either a load balance or controlled traffic mode. Tire inflatio n pressure is automatically regulated to minimize yield-robbing compaction. Momentum’s dual-toolbar SmartFrame innovations include a vertical contouring toolbar with row unit travel up to 68 inches to maintain ground contact and uniform planting depth, even over terraces, for even emergence and optimum yields.

AGCO Corp., Duluth, Ga.