The new Perkins 2600 Series engine platform unveiled in mid-September at a product launch in London is a further refinement of highly efficient, emissions-compliant power plants designed by the global engine maker for heavy-duty, off-highway applications — specifically those found in agriculture.

“As the off-highway industry moves toward a lower-carbon future, equipment manufacturers still face expectations for long-term productivity and reliability in the world’s most demanding work environments,” says Jaz Gill, Perkins vice president of global sales, marketing, service and parts. “To date, our engineers have completed more than 20,000 hours of design validation on the 2600 Series as they prepare it for dozens of applications in agricultural tractors, harvesters, sprayers, wheel and track loaders, heavy-lift trucks and other material handling equipment.”

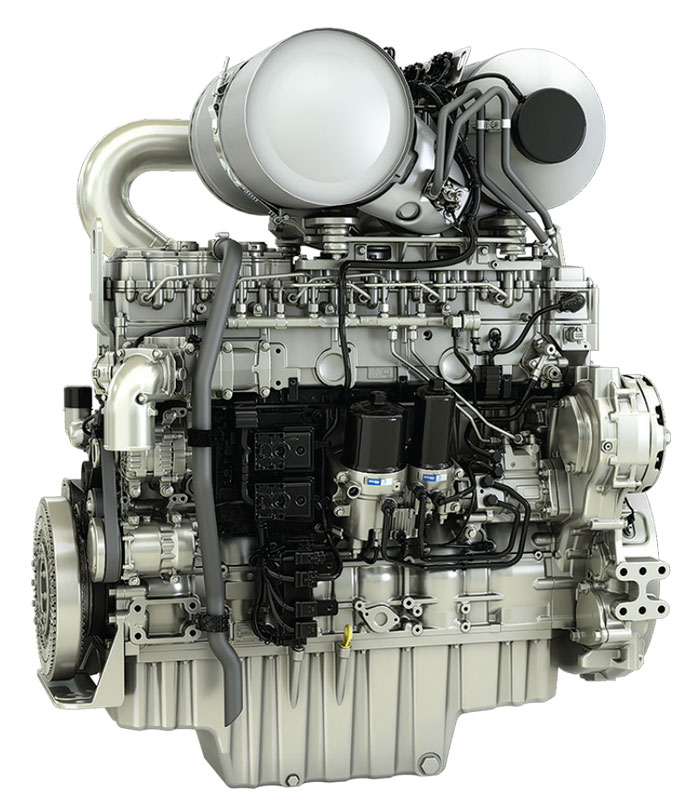

The new Perkins 2600 Series diesel engine family offers OEMs a choice of power ranges for agricultural and off-road equipment markets, renewable fuel compatibility and the capacity to meet future emissions standards. Photo by: Perkins Engine Co.

With 82 specific patents, the 12.9-liter, inline 6-cylinder diesel is packaged in 8 power ratings ranging from 456 to 690 horsepower, with up to 2,360 lb.-ft. of torque on tap at an operating speed of 1,300 rpm. Across the power range, the 2600 Series is designed to operate at elevations up to 12,000 feet and in temperatures ranging from -40 degrees F. (with cold-weather aids) to 140 degrees F.

Perkins is offering the common-rail, direct-injected engine for OEM pilot models in 2025 as complete units configured at the factory with on-board exhaust aftertreatment and cooling systems.

Gill says the factory-packaged units offer “space protected” designs to accommodate configuration adjustments anticipated for future tiers of emission standards in the U.S. and EU without relocating OEM customer connection points. Also, because the new engine family shares many components on a common core engine, OEMs can reduce their inventory and integration costs.

The 2600 Series is specifically designed to meet EU Stage V emission standards as well as U.S. EPA Tier 4 Final, China Non-road IV, Korea Stage V and Japan 2014, and it will also be available in versions aimed at lesser-regulated countries.

“Our engineers have completed more than 20,000 hours of design validation on the 2600 Series as they prepare it for dozens of applications in agricultural tractors, harvesters, sprayers, wheel and track loaders, heavy-lift trucks and other material handling equipment…”

The new engine family is compatible with renewable liquid fuels such as 100% hydrotreated vegetable oils, B100 distilled biodiesel and up to B100 standard biodiesel, depending upon customer demands and fuel supply availability. Also, Perkins engineers designed the engine to support future development of spark-ignited natural gas and hydrogen fuel capabilities — ensuring the line is competitive with similar future-oriented multi-fuel designs such as those recently introduced by Cummins.

The 2600 Series features maximized integration of common parts across its various models, and Perkins officials say the design emphasizes simplification elements such as elimination of all loose washers as well as nearly half of the usual number of “leak joints” found in traditional powerplant designs.

In addition, the valve train of the new engine features service-free hydraulic lash adjustment, no-maintenance integrated open crankcase ventilation filtration and a 5,000-hour diesel particulate filter service interval.

The upgraded design results in lower fluid consumption, and it extends oil and fuel service intervals to 1,000 hours to reduce downtime and operating costs.

Takeaways

- Perkins 2600 Series diesels will likely be operating on farms near you.

- The engine family is designed to reduce parts inventory.

- Future emissions compliance and renewable fuel capability are built-in.