|

Clair Urbain, Contributing Writer

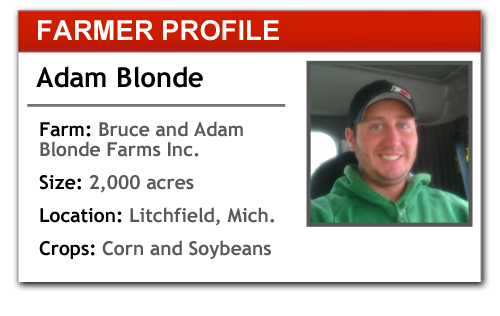

Bruce and Adam Blonde are adopting precision farming systems one step at a time on their 2,000 acres of corn and soybeans near Litchfield, Mich. Three years ago, the father-son farming team started with a Trimble EZ-Steer assisted steering system, first using it for chisel plowing, then adapting it for spraying and planting.

This year, they continued upgrading by adding a Trimble 750 controller to the tractor that pulls their Case IH 1250 16-row planter with auto row shut-off controlled by a Case IH AFS 700 monitor. The Blonde’s also upgraded to a Trimble EZ-Pilot assisted steering system that compensates for pitch in addition to roll and yaw for even more accurate steering.

They have a similar unit in their Case IH Maxxum 125 tractor that pulls the fertilizer spreader and sprayer. “This is the first year that we have used the unit to apply variable-rate fertilizer,” Adam says.

“We like it tremendously because we have many odd-shaped fields. The variable-rate fertilizer application and auto row shut-off on the planter really helps us lower our seed and fertilizer costs.”

Point of Pain: Calibration Conscious

The key to putting all the pieces of the precision puzzle together is making sure the products are updated and properly functioning once the Blonde’s hit the field. The key to putting all the pieces of the precision puzzle together is making sure the products are updated and properly functioning once the Blonde’s hit the field.

Adam can’t stress enough, the importance of calibration across all pieces of their precision farming equipment. To get the job done thoroughly, they’ve had to rely on multiple dealers.

This year, the Blonde’s needed to enlist the help of a regional independent precision farming dealer to back up the assistance of their local Case IH dealer.

“Our local dealer didn’t have any experience with installing or calibrating the EZ-Pilot system, so we had to reach out to a dealer in Fort Wayne, Ind., to get the unit installed correctly, then calibrated,” Adam says. “It took us most of one day to get the system calibrated, but that extra work has gotten us higher in-field accuracy.”

The system uses Wide Area Augmentation System (WAAS), which claims a 4- to 8-inch accuracy. But through proper calibration, Adam says he’s confident they are within 2- to 4-inch accuracy.

The Blonde’s take similar care in calibrating the systems used to control the dry fertilizer spreader as well as the Hardi 90-foot Commander sprayer.

“The learning curve for my father was a bit steeper than for me,” Adam says. “He does all of the spraying, and although the system is easy to operate, it took him awhile to really believe the unit was following a straight line.

“You just have to trust it. You will swear there is no way it is going straight, but almost always, it’s right on track.”

|