A Farm Equipment Special Report: What Will Agriculture Look Like in 2021?

Wanted: farm help. Skilled operators need not apply.

That is, they need not apply for the jobs that require sitting behind the steering wheel of moving equipment. Experts predict machines of the future stand to be so independently intelligent that they will perform any number of functions without the operator's involvement. Some of these operations would be:

- Steering and operating implements automatically, including turning.

- Constantly scanning and sensing field conditions and adapting settings accordingly for precise and efficient field operations including tillage, spraying, planting, fertilizing and harvest.

- Delivering detailed reports wirelessly from the field to the appropriate farm consultants on everything from agronomic data to engine temperature.

- Self diagnosing error codes and contacting the equipment dealer or farm manager to schedule repair or maintenance.

- Predicting breakdowns and part failures before they happen, preventing field downtime as well as snowballing damages to other connected parts and systems.

- Allowing for a master operator to observe and, when necessary, dial in and take control remotely to adjust settings and resolve problems.

- Automatically adjusting energy output to match the task being performed for improved efficiency.

- Tracking entire fleets of equipment with telematics to identify efficiency problems, and directing equipment to where it needs to be when it needs to be there.

|

| Wireless communication between farm equipment, offices and dealerships will allow for seamless data flow and constant machine health monitoring. |

Systems such as John Deere's JDLink already allow machines to wirelessly report data such as fleet location, efficiencies, maintenance needs and diagnostic information from the field. A farm manager can log onto a web site to track the farm fleet and monitor efficiency.

"Producers harvesting grain can see if the truck is still in line at the elevator or if it's on its way back to the field. Or they can locate the service truck," says Jerry Roell, director of John Deere FarmSight. "As farms get larger, the need to know where vehicles are and what they're doing will become increasingly important."

Besides location, fuel use for various field operations can be noted and evaluated, helping producers determine the most fuel-efficient management strategies for their operations.

"We have the ability for remote service advisory. We can dial into the machine and look for diagnostic codes and monitor health of the machine," says Roell. "We can also help optimize the machine performance by monitoring fuel usage, idle time and how a machine is being used."

Horsepower also can be assessed. Knowing if operators need to be advised to throttle down or gear up to maximize horsepower utilization can help managers tighten operation efficiency even further.

When maintenance is needed or a diagnostic code is generated, a JDLink-equipped tractor can send alerts to the JDLink web site, text them to a cell phone or send them directly to the dealer. This ensures prompt response and minimizes downtime.

Predicting Breakdowns

In the next 10 years, companies like John Deere and Eaton plan to shrink downtime even further by having machines that can predict when they're likely to break down.

"We offer our construction customers a tool called Fleet Care that monitors oil analysis to predict what might be happening inside the engine," Roell says. "Our vision is to offer more prognostic services like this in agriculture in the future."

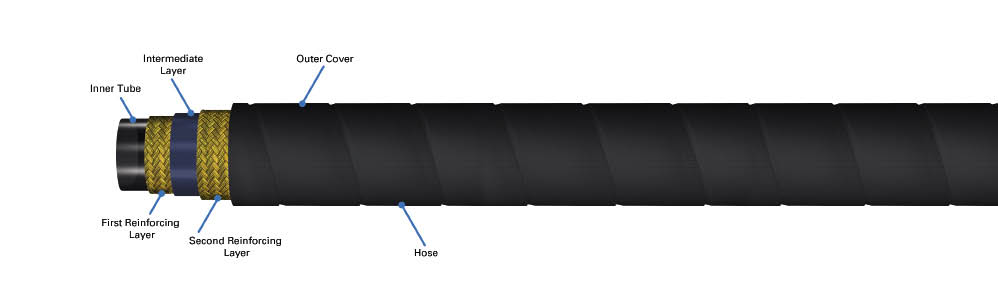

Last March, Eaton released Eaton LifeSense, a hydraulic hose condition monitoring technology.

"The hose knows when it's going to fail based on predictive measure, not by the number of hours it's been in use," says Jeff Schick of Eaton Corp. "It senses the integrity of the hose and can report within a certain percentage of error when it is likely to fail."

Managers can use this information to order a part before it fails, make sure the dealer has the part in stock, schedule repair and avoid sending a piece of equipment to the field that is about to fail. It also prevents costly and potentially environmentally harmful hydraulic fluid spills.

|

| Parts that can predict their own failure before it happens, such as this Eaton LifeSense hydraulic hose, will prevent snowballing repairs and costly downtime. |

The initial limited distribution of this technology wasn't in the ag sector, but Schick says it will be applicable in tractors, harvesters, sprayers and any other hydraulic-driven system in the ag market.

"This technology might be a bit ahead of its time today, but as we move ahead with autonomous vehicles it'll be more important to have a machine that's smart enough to know when it's going to fail," Schick says.

Plugging into a computer as part of a regular maintenance check is required for today's system, but Schick says remote, wireless reporting with an Onstar-type system is more likely in the future. Farm managers or dealers will receive an e-mail or text message notifying them of a pending malfunction.

Wireless, Seamless Data Transfer

No more pulling into the field 30 miles from home only to realize the memory card loaded with prescription maps is still sitting on the desk. In the future, data will be wirelessly shuffled between pieces of equipment; to farm, agronomist and equipment dealer locations — and to smart phones.

"Wireless connections will allow data collected from sprayers, fertilizer applicators, planters and harvesters to be easily accessible by farm managers and advisors. And there's never the risk that the memory card runs out of storage space, so all data makes it into the system," says Al Myers of Ag Leader Technology.

Prescription maps can be accessed from the field, which will greatly help producers and custom applicators alike, he says. This technology already is making headway in the market and in the next 10 years Myers says it should be available from every major equipment player.

"We see customers all the time that have yield maps on their office walls. They make great wall hangings, but they're not being utilized to their full potential," Roell says. "In the future, wireless data transmission will create a more open format for producers to collaborate with advisors. Making decisions based on that data will be easier and the result will be a greater adoption of variable rate technology."

Roell notes that there's a lot of interest in variable rate technology today, but the adoption hasn't matched the interest because it can be challenging to use and manage the data.

"GPS, GIS (geographical information systems) and variable rate technology will fill the gaps between farmers, equipment, technology and agronomy," says Robert Saik of Agri-Trend Group. "Geocoaches will mash the data together and provide the key information necessary to help producers make better decisions."

He says farmers of the future will either surround themselves with consultants or plug into an advisory network like that created by companies like the Agri-Trend Group.

"I surround myself with lawyers, accountants and marketing specialists to run my business. Why wouldn't farmers be any different?" he asks. "You can't be an expert in all areas."

Efficient, Electric Hybrid Equipment

Emission regulations have been driving engine design recently and, when paired with efficiency regulations, will continue to drive engine design in the future, Schick says.

More electric-hybrid powered vehicles along with electronic-controlled engine and transmission systems are likely in the next 10 years.

"Regulations have driven the need for electronic-controlled engines," says Schick. "When we tie together engine and transmission control into one system with electronics we can tune output to what function the machine is performing."

Engines can be put into modes depending on their current operation. An economy mode may be suitable when transporting between fields where a power mode could be kicked in when traction and maintaining field speed is essential, Schick says.

Electrification will be used in multiple ways in the future to reduce parasitic power losses.

"On the electric-drive concept vehicle, we removed the hydrostatic drives and replaced them with an electric generator that transfers electric power straight to motors on each wheel. Based on a 2,000-acre field test, the fuel efficiency improved by 25%," Godbole says.

Future options may include electrically driven fan drives and features such as air conditioning that is independent from the engine.

"Today, once the engine starts, all components also run. With electric drives we can shut those components off if they're not being used," Godbole says. "There's great potential to reduce auxiliary losses."

|

| More electric-hybrid vehicles like this AGCO electric drive concept vehicle will be used to improve fuel efficiency through electric power and electric control. |

He adds that electrification will likely be adapted to tractors that are used for multiple field operations.

"Tractors that use 40-50% of their load cycle and are constantly turning and changing their load cycle will benefit from managing energy intelligently with electricity," says Godbole. "Pure tillage tractors are likely not good candidates for electrification."

Systems should be able to self-adjust as field operations and conditions change.

"We can control engines electronically and we can take it to the next level by developing sensors for agriculture that go beyond agronomic function," Schick says. "There needs to, and will, be more sensor technology on the vehicles themselves to give feedback on performance and automatically control the machine correctly."

Bigger May Still Be Better

"For the last 50 years, the trend has been to create bigger tractors and I don't see that changing," says Mitch Kaiser, marketing manager for Steiger tractors. "In 2000, we had 440-horsepower engines, and today we have 600-horsepower engines. I don't see that trend disappearing in the next 10 years."

Strategically, Kaiser says a large tractor able to pull a 36-row planter will make 66% fewer passes than a lighter, lower horsepower tractor pulling a 12-row planter. Compaction, he reasons, occurs in a smaller area with the larger tractor. Benefits will also accrue from more efficient power use and covering more acres in a shorter time.

"I think we'll see engines that are more fuel efficient and that allow tractors to pull heavier, more complex machines faster and more efficiently than engine technologies of the past," Kaiser says.

To go bigger, Godbole says the future may see machinery with less steel and more engineered materials.

"We will find lighter materials with strength equal to steel," he says. "There will be higher costs associated with the materials, but if we can save 50% on weight it will still make sense."

The higher material costs would be offset by lower fuel costs and by reducing machine weights to comply with European road weight limits. This would keep foreign markets open to U.S. equipment. In all likelihood, road weight limits will also be regulated in North America, as well.

Back to September 2011 Issue Homepage