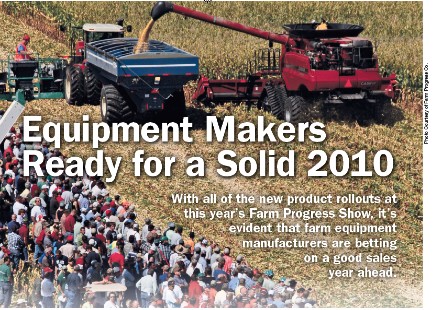

A Farm Equipment Staff Report

While most crystal balls are somewhat cloudy about prospects for ag equipment sales in the coming year, last month, Farm Equipment editors found a surprisingly high level of optimism from the exhibitors at the 2009 Farm Progress Show in Decatur, Ill. “We’ve seen no slowdown at all, so we’re coming out with new products for next year,” said Paul Kaeb, CEO of KSI Conveyors.

“We’ve seen nothing but growth this year and expect more of the same next year. It’s exciting. We have new dealers, and growers are coming to us for options,” added Greg Sauder of Precision Planting.

Equipment makers say they continue to see a significant level of interest from farmers in improving efficiency and productivity of their operations, and that gives them confidence about their demand for tools that will help improve their bottom line.

“There was huge interest in application efficiency when we saw record high fertilizer prices last year,” says Matt Wolters of SureFire Ag Systems. “While we’ve come off those highs, we’ve also had a corresponding drop in commodity prices, so farmers are still in the position of needing to be very efficient.”

Some exhibitors, like Jim Williams of Hagie, expressed genuine surprise at the level of interest he’s seeing from farmers. “I’ve gone to several farm shows and field day events recently and, even though commodity prices aren’t where they’d like them to be, I’m amazed at the interest we’re seeing from farmers. They’re still comfortable and interested in looking at equipment.”

Dave King of Ag Leader is also encouraged by the expanding use of precision ag tools. “No farm is too small for precision. We’re seeing more small farmers get into guidance first. If they farm 500 acres, they want the basics. We’re seeing more precision on corn acres and into the cotton market.”

In this annual report, Farm Equipment editors again this year scoured the Farm Progress Show for the latest innovations in ag machinery and technology. The following report reveals what we found. More of the newest developments will appear in the annual SHOWCASE issue in January.

FERTILIZER APPLICATION

YETTER MFG. introduced its new 2968 Row-Unit Mount, In-Between Fertilizer Opener that uniquely installs behind the gauge wheel for off-the-row placement of starter or nitrogen fertilizer. The design helps eliminate fertilizer buildup on row unit gauge wheels. “It will fit on a White, John Deere or Kinze planter,” says Andy Thompson, territory manager for Yetter. “You just unbolt your closing wheels and bolt in the framework. That moves your closing wheels back about 12-14 in. You mount the fertilizer disc between the gauge and closing wheels.” The 2968 fertilizer opener utilizes a 10-in. disc for easier penetration.“

ANH3 has devised the Liquimatic vapor separator system that replaces typical heat exchangers for improved distribution of anhydrous ammonia. The system retains the ammonia on a completely liquid state until it has been divided among the injectors. Orifices precisely control the flow to each injector. “We don’t have vapor lines anymore and we are not using ammonia to cool ammonia. We’re actually just separating vapor and bleeding the gas off, plus it’s more of a clear gas that has no nitrogen value to it at all,” says Randy Litterly, president of aNH3.

Nick Jensen says the new BLU-JET Legacy commercial class fertilizer applicator was being shown for the first time at Farm Progress. It can work 15-21 rows on 30-in. centers. With an oscillating rocker, it’s built on a 6 x 6 frame with a 9 degree up and down flex. It also features 6 high-flotation tires to minimize soil compaction. Jensen expects the new unit to be available in time for spring planting.

MOWING & SHREDDING

Buhler featured the FARM KING 1520 Flex-Wing Mower. The 15-ft. mower features heavy-duty gearboxes and is ideal for cutting corn stalks and trees 2-3 in. in diameter. A 6.5-in. blade overlap optimizes cutting performance, says Jordan Parmer. Production began in September and the unit will be available soon through dealers.

SCHULTE showed off its new FX-180 15-foot Flex- Wing rotary cutter, which features 6.5-in. blade overlap, a single-domed, 7-gauge continuously welded deck and a 4-gearbox driveline with independent slip clutches. The FX-180 is designed to be a “long-lasting economy cutter,” says Wayne Kalthoff.

HINIKER displayed its AR-2000 high-capacity flail shredder, designed for thorough shredding of tough residue from BT crops while offering maximum productivity. The firm also highlighted its 5630 flail windrower that shreds and windrows in one pass.

SPRAYING

TEEJET is manufacturing a new compact ball valve platform ideal for small- and medium-sized sprayers, as well as larger sprayers with high section counts. These come with the flow-back valve feature currently used by 20 OEMs in North America. “As applicators are using automatic boom section more and more, they want greater resolution across the boom, so they go to more valves,” says Pat Maney. “When you go to more valves, you can go to smaller valves. It has a compact footprint and an electric motor-driven ball valve, which makes it a little different from other small valves.”

Philip Beasley says GVM’s 6215 Predator is their most rugged mechanically friendly machine. It’s has 2WD and a drive train with an airshaft differential. It comes standard with a 115-gal. fuel tank, differential lock-up, power brakes, and a standard 50 in. clearance. An optional 120-ft. boom gives the 6215 high-production capabilities.

MILLER–ST. NAZIANZ unveiled the new SmartDrive front-wheel assist drive system for its Condor sprayers. The Condor G Series features are a newly redesigned frame and hood, as well as the optional SmartDrive system when more traction is required in deep mud. Because it’s an on-demand system, operators only use it when they need it.

Kevin Schultz of FAST says that while the model 9600 sprayer is designed for 1,000-1,500 acre farm, it’s loaded with features. These include a new hydraulic retractable telescoping hitch, 80- to 100- ft. booms, and the stainless steel wet boom comes standard. This model is available in 1,050- and 1,300-gal., compact Stealth Tank with a low center of gravity. They also come equipped with a Raven 450 auto rate controller and 60-gpm flow meter.

FARM KING displayed its new model 1200 highclearance pull-type sprayer, released to the market in August, says Jordan Parmer. Meant for pre- and post-emergent field applications, the sprayer features a sloped tank design, 3 tank sizes, patented Henschen boom suspension and adjustable axle width.

ALLIANCE unveiled its new 400-600 gal.-capacity 3-point sprayer. The front-fold model transports easily and has “one of the heavier booms in the 3-point market,” says Blake Rule. The sprayers feature a 90-ft. front-fold boom, powder-coated frame and standard 100-gal. rinse tank.

BESTWAY announced it’s offering the V-Ride Boom Suspension Adjustment that allows operators to adjust the boom ride to varying conditions — “It’s the only sprayer on the market where you can do that,” says Dave Benson. Growers are picking up an additional 2-3 mph because of the smooth ride, he says.

TILLAGE

YETTER MFG. displayed a new strip-till row unit that features gauge wheels that allow depth settings. The unit also utilizes the Shark Tooth residue managers. “We’ve opened up the area around the knives so that if you are going into heavy corn stalks, they will flow through the unit much better,” says Andy Thompson, territory manager for Yetter. “The disc sealers are a big change for us. They are independent of each other, and they can be locked rigid or run them independently. There is complete infinite adjustment on the discs. “

The new TerraStar soil imprinting system from MAY WES has been designed to consolidate soil, manage water flow and reduce erosion while increasing soil surface area and water infiltration. MayWes has also incorporated the TerraStar into a universal tool bar that enables it to be used during both fall tillage and spring planting seasons.

M&W (member of the Alamo Group) had its first showing of the Earthmaster Series 10 primary tillage line. An upgrade of earlier tools, the four-model series is designed to break through the compaction layer to allow roots to get down to the rich soil below the layer.

SALFORD introduced a series of improvements to its Residue Tillage Specialist (RTS). The RTS NH3 allows growers to equip their unit with application tools like NH3 shanks for use with today’s high residue and vertical-tillage farming methods. Benefits include quicker application with less fuel and horsepower, the ability to put anhydrous shanks on 15- or 30-in. spacings, and a quick switch to residue management and seedbed preparation. Describing the rapid growth of the company, Jim Boak notes that the manufacturer has increased its number of dealers five-fold since 2001 (to 150) and has 12 times higher revenue.

WIL-RICH unveiled its 614 NT Disc Harrow, a primary tillage disc that offers 311-348 lb. per blade and comes in sizes of 14 ft., 4 in. to 36 ft., 4 in. “Corn stalks are getting heavier and there’s more of them. This machine will answer that,” says Gordon Nyquist. The 614NT includes a level linkage system and Wil-Flex bearing stand to reduce breakage in rocky conditions.

KRAUSE exhibited its first precision tillage tool, the Gladiator, which features a fixed-frame toolbar and patented ST-PRO row units that cut through tough residue and provide consistent tillage depth control, says Curt Davis. The Gladiator also includes the patented STRIK’R soil conditioner with chain reel technology to firm soil without destroying the berm. “Customers told us they wanted something that is wrench-free and easy to adjust,” which led to features like the self-lubricating pivot points and toolless shank depth adjustment. Available in 12- and 16-row models, the Gladiator will be available in January in the High Plains, and the rest of the U.S. in fall 2010. The company also unveiled its 8300 Class III Tandem Disc Harrows for primary tillage.

AGCO unveiled its new 7600 series Sunflower striptill system, featuring 8- and 12-row models. “We see growth from both the no-tillers and those doing conventional tillage who see the economics, but want the advantage of warming the soil and managing the residue,” says Tom Draper. Designed with a heavy construction for reliability and durability, he says that AGCO’s message would be on “selling the system, not the iron.”

BRILLION exhibited its Folding Soil Builder II. It has the same design as the Soil Builder II but with folding 17- and 21-shank models for use with higher horsepower tractors, says Gary Wallander. The implement will be available to producers for the 2009-10 tilling season. The folding shanks increase working width up to 26 ft., and the transport profile is 15 ft., 4 in. wide and 23 ft., 4 in. long. The Folding Soil Builder II has 25 in. front coulter blades spaced at 7.5 in., 15-in. shank spacing and a single-point depth control valve for working depths of 8-12 in.

ENVIRONMENTAL TILLAGE SYSTEMS (ETS) highlighted its new SeedWarrior, designed with a compact folding toolbar, central-fill system, high seed (7,500 lb.) and fertilizer capacity (1,250 gal.), active downpressure on wings and hydraulic seed meter drive. “It’s also precision-enabled and brings steerable cart technology to the planter industry,” he says. The firm also promoted its Soil Warrior and Mini Warrior units.

SUMMERS MFG. showed its new DiskChisel at the show, providing another more-aggressive choice to its CoulterChisel for managing heavy residues and mixing them with the soil. Other new innovations at Summers’ exhibit was a new Hydraulic Fold Rolling Chopper (featuring C-shank chopper mounting springs), designed for busting stalks with the soil, and a larger version of the SuperCoulter, now available in 50-ft. widths.

PRECISION AG

PRECISION PLANTING introduced its new 20/20 RowFlow system. It works with the 20/20 SeedSense monitor to provide farmers with a simplified, cost-effective option for automatic control of variable rate drive systems and swath control. RowFlow and SeedSense work together to provide prescription control of variable rate and swath control without the need for additional monitors and without paying software unlock fees. Both hardware and software, 20/20 RowFlow can be installed on variable rate monitors and control existing row clutches.

TRIMBLE announced the improved AgGPS FmX integrated display version 2.0. The new version of the touch screen controller with built-in global navigation satellite system receivers adds functionality for use with the AgGPS TrueGuide implement guidance system, the EZ-Steer assisted steering system and the LB25 lightbar. “The addition of GLONASS (Russian equivalent of GPS) means producers can hit off of 10-12 satellites per day compared to 6-9 per day with GPS alone,” says Matt Hesse. “That means increased hours of operation, greater vertical accuracy and better coverage even in fields where dense foliage would otherwise interfere.”

RAVEN exhibited its mechanical drive Smart Steer assisted-steering system that can interface with Viper Pro, EnVizio Pro and Cruizer precision ag systems. The assisted-steering system corrects for roll, pitch and yaw through 3D terrain compensation. SmartSteer’s near-silent direct mechanical gear drive eliminates slippage and delivers more accurate steering through the field from start to finish, says Paul Welbig.

FARM WORKS announced that formula-based prescription map writing is now available for its Pro software, which was introduced in January to enhance customers’ abilities for yield averaging and profit/loss mapping. “Growers want to know if they’re being profitable,” says Brian Stark.

LOUP ELECTRONICS unveiled its ISOBUS planter interface module and virtual terminal. The module will read data from smart sensors on any virtual terminal that is ISOBUS compatible, says Jesse Farmer.

DICKEY-JOHN showed its Vigilense high-rate blocking sensor for air seeders and grain drills. The system detects all sizes of seeds, granular fertilizers and pesticides. Even a small amount of seed blockage is costly and the sensor can prevent that, says Thomas R. Elmore.

TRACTORS

MAHINDRA featured its new 4035 tractor this year. With a product lineup dominated by 2WD tractors, the 4035 is unique for Mahindra and was introduced specifically to meet the 4WD demands of the U.S. market. The 4035 is available only in a 40 hp but the company anticipates having both 45- and 50-hp models available in the coming months.

NEW HOLLAND unveiled a host of new entries to the market this year including the Boomer 3050 compact cab tractor. According to William Frederick, the 3050 features the same quality features of other models in the Boomer line with a factory installed cab that offers the widest opening and threshold on the market. The cab also features a high-visibility roof panel that allows the user to see the loader through its entire range of operation. Indicate

KUBOTA highlighted several new products at the show, including the M126X Power Krawler for vegetable and specialty crops, the M series utility tractors and M100X series diesel tractors.

JOHN DEERE touted its new lineup of high-powered row-crop tractors with the introduction of its 8R Series. The line includes 6-wheeled models that range from 225-345 engine hp and 3 track models that range from 295-345 engine hp. What sets it apart, says Eric Hodson, is the tractor’s next-generation CommandViewII cab. It features a roomier work environment that’s equipped with integrated, easy-to-use monitors and controls, with visibility enhanced in all directions.

For its first appearance at the Farm Progress Show, TYM showcased the T433 model tractor. According to Andy Robson, the T433 is big on economy and big on performance. It features an ergonomic design, wet-disc brakes for real stopping power, and hydrostatic power steering for ease of handling.

UTILITY VEHICLES

KAWASAKI’S Mule 610 4 x 4 is a year-round vehicle that offers big muscle in a smaller package, according to Mark Hosbach. It offers a centrally positioned gearshift, easy access under-hood storage, and a fuel-efficient engine that still provides the power to be the workhorse of the farm.

NEW HOLLAND has made its way in to the UTV market with the new line of Rustler Utility Terrain Vehicles. In both 2-seat and 4 passenger units, and either gas or diesel engines, buyers can customize and accessorize to fit their specific wants and needs. Bill Frederick says the UTV is available in blue, camouflage or stallion and there are over 180 available options.

GENERAL FARMSTEAD

DK PRECISION TRENCHERS showed off its DK-628 chain trencher for tractors, which is designed to install 4-12 in. tiles. “This offers versatility. A lot of guys already have the tractor. We get calls from farmers wanting to get their work done, and with this machine they don’t have to use up their shed space,” says Joe Kirian. The trencher is for tractors 185-275 hp and offers 0-6 ft. trenching depths and 9-24 in. trenching widths.

Scott Luden demonstrated the features of the new Post Puller and Pounder from KOYKER. Luden says you can pull or pound a post without leaving the tractor seat or touching the post by hand. Oneperson operation leads to improved efficiency and safety and the puller and pounder can be used on anything from 1-in. diameter post to railroad ties.

WESTENDORF’S Freedom Mount system has a heavy-duty boxed design, yet is lightweight. The unit features low-profile, box I-beam construction, contractor- grade bucket with remote couplers to change attachments with the push of a button. Other features include protected hydraulic lines and lineless cylinders, extended lift height, and clean dump and water holding rollback angles. It also offers a standless dismount design with an automatic lock-on feature.

New from HCC and SHAVER is a professionalgrade post driver. These post drivers deliver up to 100,000 pounds of impact and drive everything from steel to wood posts. According to Ron Roglis, it will even drive a railroad tie into the ground. Available in either skid-steer or tractor mounted models, these units are capable of driving a 4- or 5-in. post in 10-15 seconds.

DANUSER MACHINE unveiled its EP Auger Series, designed to be a smaller, more affordable hydraulic product to compete with PTO-driven models in the hobby farm market, says Glenn Danuser. It’s designed with a one-piece forged output and carrier assembly, and one-piece, forged steel output housing. The EP6, EP10 and EP 15 have hydraulic flow of 6-30 gpm and have a maximum hydraulic pressure of 3,000 psi.

DEGELMAN’S Speedblade snow blade allows the user to control the snow better because of a unique design that changes the blade’s width on the fly. Derek Molnar says the ability to hydraulically put the wings at any angle lets the user change the width depending upon snow conditions or the job size. Speedblade was also designed with a low profile so the operator can have the highest profile possible.

BOBCAT exhibited its M Series of skid-steer loaders that offer improved operator comfort and easier-touse controls, says Jarrod Steck. The loaders feature a new cab-forward design, 10% more cab space and 18% stronger hydraulics for improved attachment performance. The S630 and S650 model loaders have 74-hp turbo diesel engines, operating capacities of 2,180-2,690 lb. and a lift height of 121-124 in.

LIVESTOCK & FORAGE

Allin Butcher with ROTO-MIX showed off the company’s remodeled 532-16 truck. Now with metal sides, a bed liner and a 34,000-lb. net load capacity, Butcher says this truck offers a consistent flow until empty and delivers an excellent spread pattern.

In addition to its series of hay bale accumulators, KUHNS MFG. unveiled its new Tie-Grabber with twin wrapper. According to Kenny Kuhns, the unit creates tighter bale bundles, stabilizes loads for transport and creates freestanding stacks. Kuhns, which is actively seeking dealers, says that sales have doubled each year since 2004 when the company was formed.

KUHN NORTH AMERICA is extending its line of hay tools with the introduction of a large square baler. The aggressive design of the integral rotor provides maximum efficiency with high-performance throughput in all crop conditions. The main intake functions are protected by a series of clutches instead of shear bolts. The baler also utilizes the simple Twin-Step knotting system. Four models are available that can produce bales sizes of 2 x 3, 3 x 3, 2 x 4 and 3 x 4.

IRRIGATION

The mobile design of the T-L IRRIGATION Quick- Tow System mounts the power source, hydraulic pump and fuel tank on the pivot point that keeps towing preparation to a minimum. Daniel Glenn says timing is critical when moving from location to location, and T-L’s system scissor jack design utilizes hydraulics to lift the towers, enabling tire rotation in minutes.

REINKE’S OnTrac advanced satellite technology allows users to control their irrigation system via cell phone, smart phone, secure Internet website or a combination of all. In addition, users can receive alerts and status updates on any of the devices. Neil Lundsman says as the theft of copper wire is on the rise. The OnTrac has also been a very effective theft deterrent by immediately informing users when there’s any disruption to their irrigation system.

GRAIN HANDLING

Russ Kiefer from AGRI-COVER showed off the company’s newest tarping systems for the agriculture industry. The AutoLock Dual Drive system has a Kevlar driveline that works together with a 3-in. aluminum roll tube to provide a powerful front- and rear-drive system. Kiefer says, “It’s a system you can count on to cover heaped loads even in windy conditions.”

Ron Braun showed off the new MK Flex auger in the WESTFIELD booth. This new unit allows users to unload double-hopper trailers without moving the truck. The MK Flex offers hydraulic handle bar controls, outriggers for stability, and the hydraulic drive that make for easy positioning of the hopper.

DEMCO’s model 1350 grain cart has inline wheels to minimize soil scuffing and a hydraulic orbit motor that allows the company to keep its corner placed auger. The cart has a 1,350-bu. capacity and a 22-in.-diameter, computer-balanced discharge auger with Posi-Drive connection. “Grain carts are getting bigger and bigger to keep the combines going,” says Mike Sievers of Maurer Manufacturing.

Mike Ellerbrock says UNVERFETH’S X-TREME model grain carts have the greatest outward, upward and forward auger reach of any front-folding grain cart. With capacities of 1,300, 1,100 and 1,000 bu., the carts also have computer balancing that virtually eliminates any vibration of the lower and upper augers.

KONGSKILDE displayed its new SUC 1000 DTR self-contained, diesel-powered grain vacuum for ethanol plants and commercial applications. “We were asked by an ethanol producer to make one that could suck up grain and clean up debris and dust in the factory,” says Steve Schroeder. The machine has a 140-hp John Deere power unit, 70-gal. fuel tank, a rack for easy storage of hoses and heads, and a specially designed trailer.

BRANDT unveiled its 5200EX GrainVac, a highcapacity machine that can process up to 5,800 bu. an hour, says Jason Bouchard. With a 10-in. auger and more than 160 in. of lateral and vertical reach, the 5200EX features a new dual-blade, wear-resistant fan that increases fan life by 100% compared to the 5000EX model. The 1-1.5 ratio gearbox allows use of larger drive sprockets, which increases the life of the chain drive, as well. Brandt also featured its new 13X110 HP Swing Auger.

FARM KING showed off its first line of galvanized augers, which are designed to compete in markets on the east and west coast where moisture eats away at paint and metal. “This will prolong product life and prevent corrosion,” says Jordan Parmer. The augers come in the conventional 1036 and 1061 models, or “back saver” 1070 and 1370 models with a scissor lift.

KSI CONVEYORS’ Seed Pac modular seed storage system can be used on the farm for remote seed storage, saving farmers from unnecessary trips between the field and the elevators. “It’s a way to store seed at a location for timely planting,” says Paul Kaeb. The Seed Pac has 35-degree hoppers to ensure cleanout, 180-degree flip-open lids for ease of filling, and it can be used with a semi trailer and discharged out the back. KSI also had its Model 161272UP Swing Away Conveyor on display.

SUDENGA INDUSTRIES unveiled a new line of 12-in., high-efficiency portable augers. Available in 92-122-ft. lengths, the auger features Sudenga’s overhead truss system for smoother and more stable operation, and a scissors-style lift for lowerprofile storage, says Larry Stubbe. The auger can process up to 7,000 bu. per hour and includes a wide, low profile, twin-screw hopper.

ALLIANCE exhibited its Parker 1038 and 1338 grain carts, featuring a low-profile design for easy filling and excellent stability. The exclusive in-line auger is located up front and has a low-maintenance belt drive with manual disengagement, says Blake Rule. The model 1038 unloads over 8 bu. per second, and the model 1338 more than 12 bu. per second.

PLANTING & SEEDING

SALFORD showcased its 520 Double Disk Air Drill. Designed for maximum versatility in all soil types and operations. Jim Boak says it combines the speed and depth control of the disk opener with the added capacity of an air system and allows growers to truly customize their machine to match farming practices.

KINZE introduced its 660 TS Two-Section Twin- Line Planter at the show. Among the standard features are Cobalt monitoring system with color touch-screen display, Air Seed Delivery (ASD) system, which features two centrally-mounted 55-bu. hoppers that distribute seed to individual row units using air pressure; and a 3-section frame that allows for 13 degrees up and down movement. Other new products included the 3700 front-folding planter and 3800 forward-folding planter.

GREAT PLAINS highlighted its new Air-Pro seed metering system. Key features include auto air pressure, positive air vs. vacuum, precise spacing, clear-shot seed tube and simple, two adjustment use.

The new Twin Disc Drill from AMITY features opposing single discs, the first totally new seeding concept in generations, says Eugene Breker. The no-till and conventional drills come in 30-, 40- and 50-ft. lengths, and have 6 in./9 in. paired rows, compared to the industry average of 7.5 in. It also feature on-the-go depth control and downpressure control from the cab. The drill eliminates sidewall compaction and hairpinning, Breker says.

HITCH DOC displayed its new Travis seed cart. According to Dan Reetz, these carts are designed to unload 2,500 lb. of seed in 4 minutes, or about 625 lb. per minute. They’re available in a variety of models ranging from 2 to 4 boxes. The gooseneck model can handle up to 6 seed boxes. All models are equipped with a 15-foot hydraulic fold, 7-in. poly-cupped flighting and a 3-stage telescoping down spout.

HARVESTING

CALMER CORN HEADS showcased its new BT Crushers According to Marion Calmer, the new crushers are a solution to farmers raising BT corn who need to break down the stalk. “It crushes the stalk vertically, serrates it horizontally and lays it on the ground to let the bacteria get in and have it decayed by spring.” Allen Berry adds, “You don’t want the residue chopped and blowing around the field. You want it to stay intact, make contact with the soil and let it decompose.”

AGCO unveiled a number of new products this year, including its new DynaFlex flex draper header. It’s available in 30-, 35- and 40-foot wide sizes for Gleaner, Massey Ferguson and Challenger combines. According to Reid Hamre, the 41-in. wide draper conveying system is designed to maximize overall combine capacity because it allows the crop heads to face in the same direction, greatly improving crop flow, feeding and threshing. An exclusive flexible cutterbar design with 8-in. range of travel and 10 degrees of tilt adjustment provides precise cutting of the crop in a wide range of conditions.

The Lexion corn head auto–pilot was featured by CLAAS this year. This row-sensing guidance system acts alone and doesn’t require the combine to be equipped with GPS. When the corn stalk touches one of the sensors, which are connected to the steering system, automatic adjustments to the combine’s direction are made to follow the corn row accurately. System operation is completed with a single zero-steering angle calibration and a single engagement switch on the joystick

OXBO introduced its new Soft Touch 50 series corn heads. According to Mike Miller, the new head is designed to “make every kernel count.” Unlike conventional corn heads, this innovative design cuts the ear off the stalk using tapered intermeshing knife rolls and remote actuated stripper plates to create gentle, precision ear removal. The 50 Series corn heads are available in sizes ranging from 6-row to 14-row with 30-in. spacing as well as in limited configurations in 20-in. spacing.

DRAGOTEC USA displayed its Hi-Tech Corn Harvesting System with Automatic Self-Adjusting Deck Plates. Each deck plate independently adjusts each row for the best setting per stalk and the automatic self-adjusting deck plates make thousands of critical decisions for users every time they cross the field. Deck plates have rolled edges to reduce leaf stripping. Plus, it allows the butt of the ear to get closer to the knife rollers reducing ear bounce, butt shelling and ear loss.

CLARKE MACHINE exhibited a 24-row, 40-ft. custom corn head with 20-in. spacing. “We’ve had customers that want to go bigger, and combines keep getting bigger and we’re ready,” says James Huls. The head has a single-point hookup, hydraulic deck plates, automatic height control, and can be adapted for any make of combine.

FANTINI NORTH AMERICA displayed its new 16-row corn header introduced this year. Peter Stark discussed how the Italian corn head manufacturer, which imports directly and not through a third-party, has increased sales since opening its North American headquarters in Le Center, Minn. Stark, says the firm currently has 26 dealers with a desire for about 40 with protected territories. He also noted that the firm’s sunflower headers are also experiencing a brisk demand, and opening sales for the corn headers as well.

CRESSONI USA highlighted its Roto-Cross Cut system. Romano Cressoni says that the system delivers a unique crossed and continuous partial cut of the stalks to allow them to better decompose over the winter months. “It uses less power and requires less maintenance while increasing harvest speed,” he says. “It’s also big for no-tillers who don’t want the chopping that blows small pieces of residue all over the place.”

MAURER MANUFACTURING exhibited its new head transporter with a suspended front axle. It has a standard telescoping tongue and new tie-down system, says Mike Sievers. The product is due out in October.

LAWN & GARDEN

Among the host of new products in the ARIENS booth was the AMP Rider electric riding lawn mower. The AMP Rider delivers as much drive and cutting power as a conventional gas mower but is 50% quieter than conventional mowers and requires no gas or oil. It has a 34-in. cutting base and has an average cut time of 75 minutes.

GRASSHOPPER’S 72-in. Power Fold Deck allows it to offer the easy-access deck on their full range of mowers. Simple switch activation rotates the deck upright, simplifying underside access for blade replacement or sharpening, mulching kit installation or removal, or deck cleaning, while creating a shorter overall length for easy transport or storage.

More from Farm Progress

Farm Equipment will provide more coverage of the newest developments from the 2009 Farm Progress Show in the annual SHOWCASE issue in January 2010.