Freshly updated in 2024, this timeline project includes several new discoveries & additional context on the ever-changing ag industry

Since the dawn of time, man has continually used his ingenuity to develop and perfect the tools needed to feed and clothe himself and those around him.

From soil-scratching sticks to the mechanization era in the mid-1800s to the chemistry era after World War II to today’s precision age that automatically guides high-powered tractors and combines, farm equipment has evolved through the ages to meet the food, fuel and clothing needs of the earth’s ever-growing population.

And as mankind advanced technologically, farmers and machine makers were among the first to adapt the breakthroughs to the implements and machinery of their trade. For those who call their life’s work farming, each innovation in agricultural equipment represents another step forward in meeting their only goal — producing more food to feed more people.

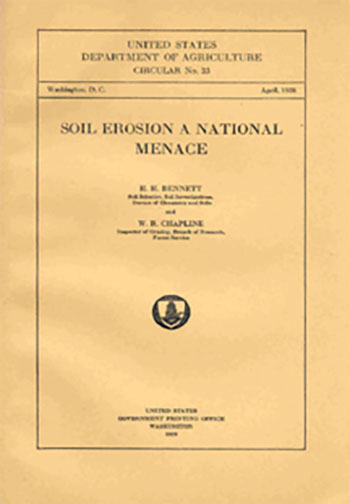

At the same time, no one has a more abiding respect for the land than those involved in agriculture — though it didn’t always seem that way. While poor farming practices and drought led to the Dust Bowl of the 1930s and devastated millions of acres of fertile land, it taught us many lessons. Today, crop rotation, conservation tillage, cover crops, soil health and new equipment aimed at minimizing soil and wind erosion ensure that agriculture will not repeat the mistakes of the past.

“Imagine how different things would have been for agriculture had John Deere been a chemist instead of a blacksmith? And instead of inventing the self-scouring steel plow, he’d invented Roundup…” – Randall Reeder, Retired Extension Agricultural Engineer, Ohio State Univ.

Through it all, the tools of farming continued to evolve, a process marked by temporary setbacks and enormous leaps forward.

It was the genius and creative thinking from individual entrepreneurs that provided many of the greatest breakthroughs in agricultural history and spurred the organization of many of today’s full-line manufacturers.

This “Timeline of Ag Equipment Firsts” is a work in progress over the last 15 years. It spans 5500 B.C. to the present, a period in which an entire generation of farmers did not know production-level agriculture without the use of GPS.

We’re aware that with each proclaimed “first” comes with debate, and you’re welcome to engage in that debate. For comments, questions or discoveries, email mlessiter@lessitermedia.com. Special thanks to our “seasoned veterans” who reviewed the 2024 document, including retirees Paul Wallem, Randall Reeder and Lars Paulsson and B&G Equipment’s Tim Brannon and Exactrix’s Guy Swanson.

5500 BC

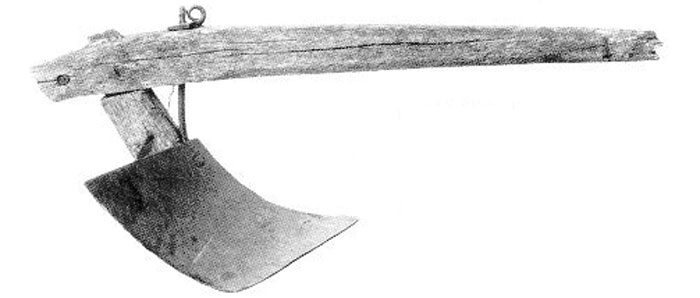

The first plows were forked sticks that Sumerian farmers would drag through the dirt to form a trench in which to plant their seeds.

5200 BC

The earliest known Egyptian farm implement is a stone sickle bar point. An early scythe, completely intact with stone points attached, was found in 2008 in excavations in the Faiyum depression, a fertile oasis about 50 miles west of Cairo, Egypt.

1500 BC

Excavations at the Egyptian town of Guft show trench silos for the storage of grain used to produce bread and beer.

Wooden plows, pulled by domesticated animals, became the accepted tool to prepare the ground for planting.

475 BC

China's agriculture flourishes in the Hunan states with the development of an iron plow. It was a simple hammered iron sweep that penetrated the ground and rolled the soil in two directions to develop a furrow for planting.

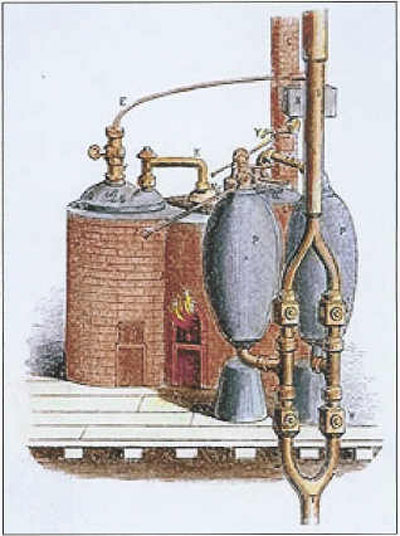

1698

Thomas Savery invents a crude steam engine which initiates a chain reaction of events that leads to the development of the steam traction engine.

1702

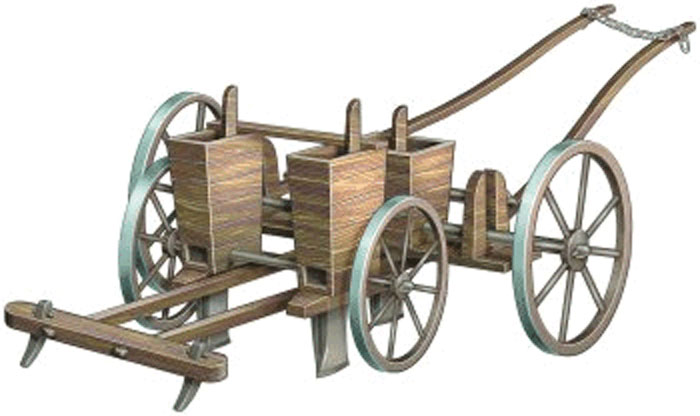

Jethro Tull of Great Britain invents the seed drill and is perhaps the best-known inventor of a mechanical planter. Built around the foot pedals of a church organ, the seed drill consisted of a box for grain seeds pulled by a horse. Because the seeds are planted in rows rather than randomly, it is much easier for a horse-drawn cart to later remove weeds that formed around the crop.

1784

British inventor Andrew Meikle devises a stationary machine to thresh grain, but it was not commercially successful.

Thomas Jefferson, U.S. president, statesman and inventor, develops the first plow designed with the use of a mathematical formula to reduce soil resistance.

1785

A plow that features a cast iron moldboard is developed in Scotland by James Small.

1794

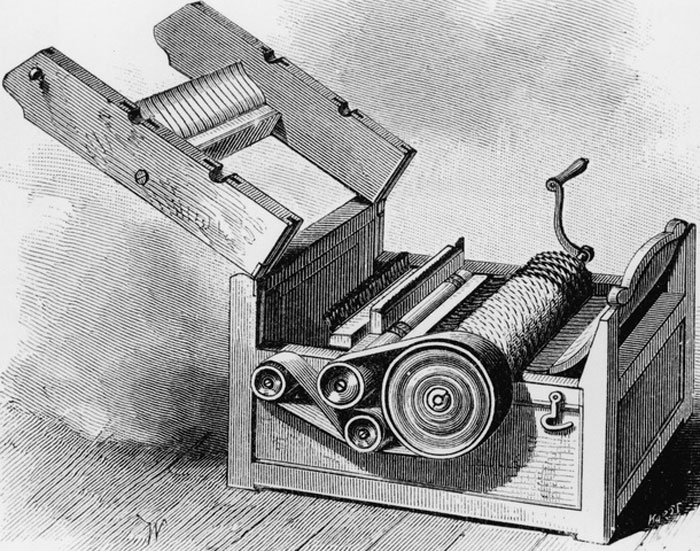

Eli Whitney develops the first hand-powered cotton gin on the General Nathaniel Greene plantation near Savannah, Ga. The gin separates seeds, hulls and other unwanted materials from cotton after it is picked, and is credited to helping cotton survive in the South.

1797

Charles Newbold patents the first cast iron plow in America.

1814

Jethro Woods, a blacksmith in Scipio, N.Y., patents a cast iron plow with three replaceable parts.

1822

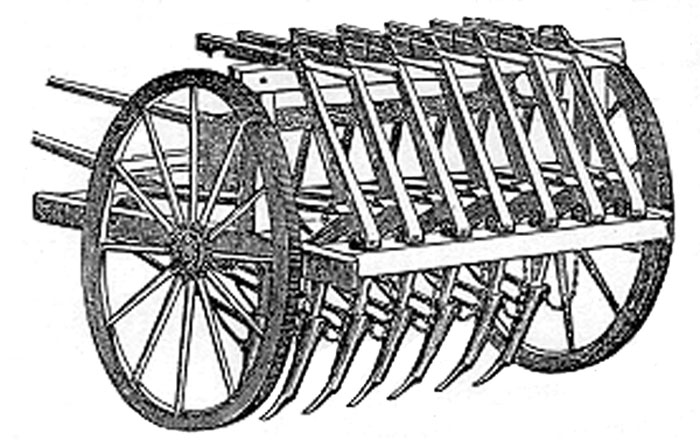

Jeremiah Bailey of Chester County, Pa., patents a horse-drawn machine with a revolving wheel with six knives for cutting hay.

1825

The “whoa-back” horse-drawn hay rake is developed. The whoa-back was named for the way in which the operator had to stop the rake and back up the horse in order to dump hay to form a windrow.

1827

Hiram and John Pitts are awarded a patent for their landmark invention of the endless-apron threshing machine, speeding up the process of separating grain from the straw.

1830

250-300 labor hours are required to produce 5 acres of wheat with a walking plow, harrow, hand broadcast of seed, sickle and flail for harvesting.

1831

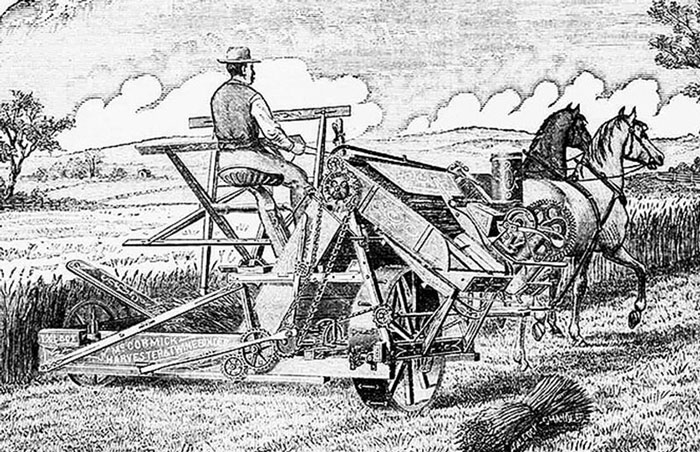

Cyrus Hall McCormick invents the mechanical reaper at the age of 22, creating the first grain harvesting machine in the U.S. and allowing farmers to harvest large fields in one day.

1833

Walter A. Wood introduces the spring-tooth dump rake (also called the sulky rake) to meet the growing needs of farmers working with hay mowers.

Obed Hussey patents the first successful reaper for small grains. It consists of an oscillating sickle bar and a platform to catch the cut stalks.

1834

Cyrus Hall McCormick develops the horse-drawn mechanical reaper at Staunton, Va., which laid the foundation for the farm equipment industry of today. McCormick’s reaper allowed one man to cut 40 acres of grain a day compared with what 5 men could do by hand., His unmatched product development, marketing and manufacturing innovations created a model that other manufacturers would follow for the next century.

Joab Center, Hudson, N.Y., patents a machine for turning and spreading hay.

1836

Hiram Moore and John Hascall, Kalamazoo, Mich., develop a combine harvester for cutting, threshing and winnowing grain that was pulled by 20 horses.

1837

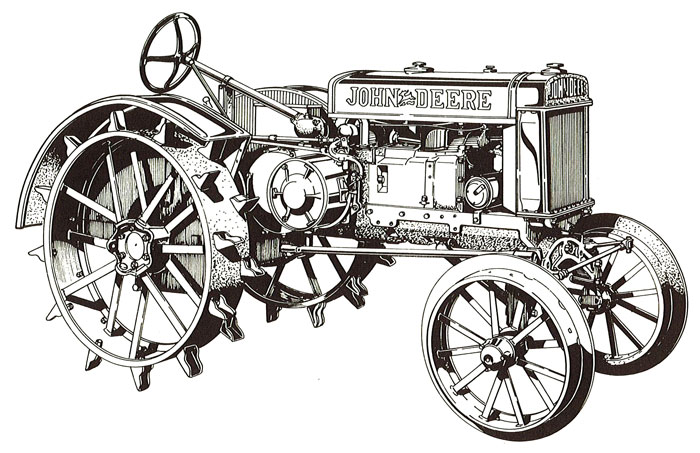

John Deere develops the self-scouring steel moldboard plow in his Grand Detour, Ill., shop. He learned to polish steel as a result of his boyhood job of polishing his mother’s sewing needles so they would easily penetrate cloth.

Wheat threshers Hiram and John Pitts follow up on their stationary Groundhog Threshers innovation with a patent for the continuous apron threshing machine, or “Pitts Thresher.” The Pitts license their patent to several manufacturers, including J.I. Case.

1838

Tile drainage is introduced to the U.S. when John Johnston used the practice from his native Scotland on his new farm in Seneca County, N.Y. Johnston laid 72 miles of clay tile on 320 acres, which increased his yield of wheat from 12 bushels per acre to 60.

1841

The first practical grain drill is patented by Moses and Samuel Pennock of Chester County, Pa.

Robert Ransomes of Ipswich, England, introduces the first steam-powered traction engine and began producing it commercially a year later.

1842

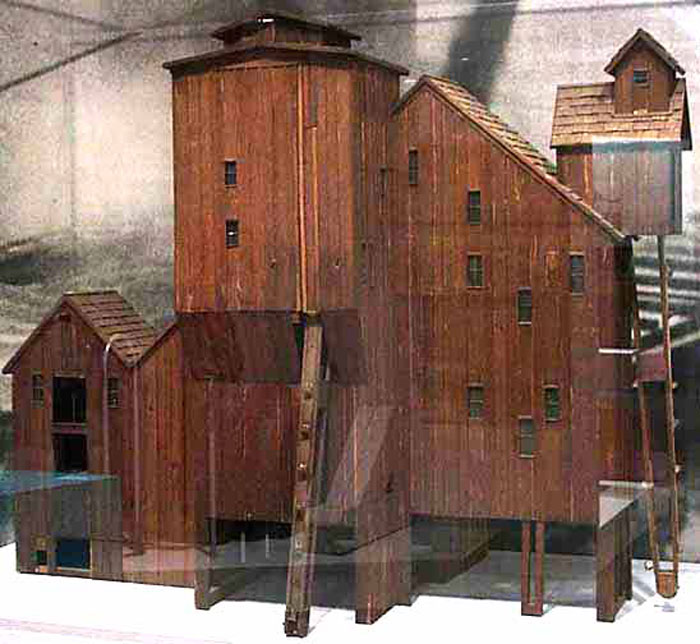

The first grain elevator is built by Joseph Dart of Buffalo, N.Y. Powered by steam, Dart’s bucket elevator raised grain from lake boats to storage bins, where it remained until being shipped or milled. The elevator had a storage capacity of 55,000 bushels.

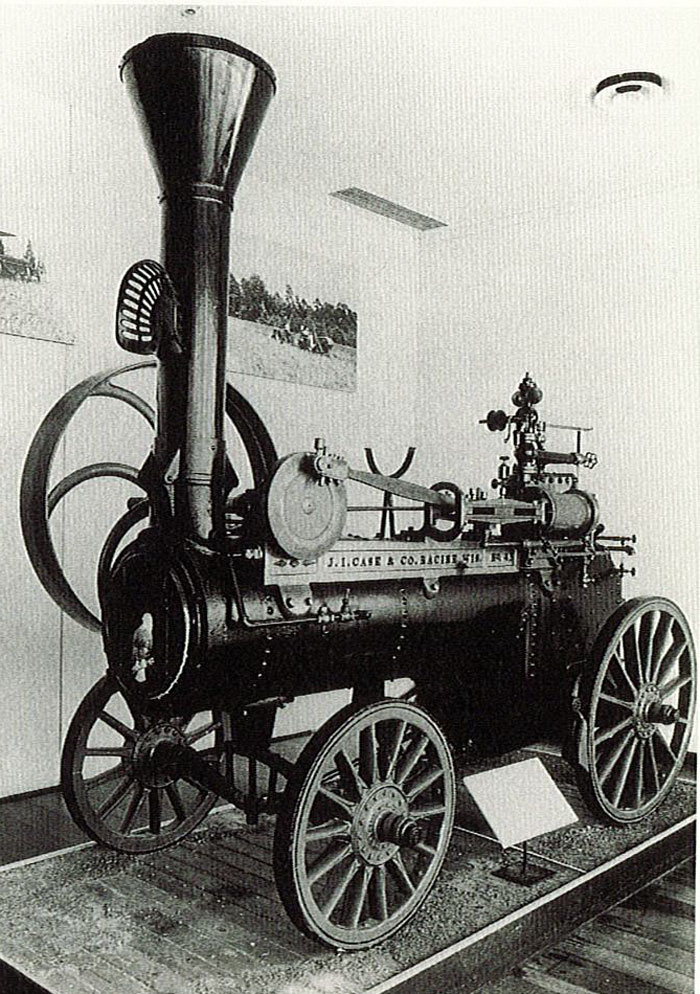

J.I. Case establishes the Racine Threshing Machine Works in Racine, Wis.

1844

William Ketchum of Buffalo, N.Y., patents the first machine designed strictly for cutting hay.

1849

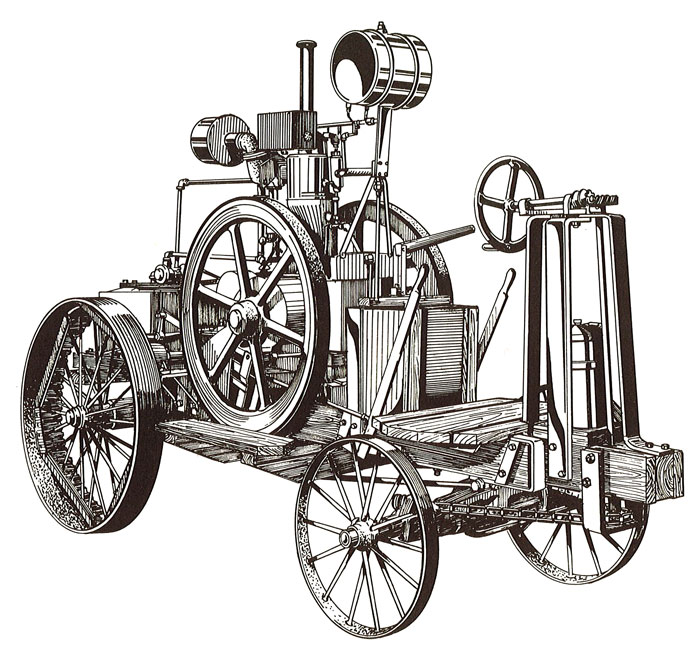

The first steam traction engines appear in the U.S., in use with threshing machines, removing the limitations of horses and oxen.

These portable models are pulled by horses. One of the first portable steam engines, the “Forty Niner,” was built by A.L. Archanbault in Philadelphia, Pa. The engine was offered in 4-, 10- and 30-horsepower sizes.

1850

The first commercially successful “hay press,” the forerunner to the modern baler, is introduced. Popularly known as “The Mormon Press,” this stationary machine processed bales of hay for transportation by barge on the nation’s rivers.

Edmund Quincy invents the corn picker.

Samuel S. Rembert and Jedidiah Prescott patent a cotton-harvesting machine in Memphis, Tenn. The original patent notes that, “Our cotton-picking machine can be duplicated and extended to such a width as to embrace several rows of cotton at once.”

1853

The first patent for a practical corn planter was issued to George W. Brown of Illinois.

1855

The first self-propelled steam-powered tractor in the U.S. is invented by Obed Hussey specifically for plowing.

1857

The Oliver chilled cast-iron plow is developed by James Oliver. The foundry process patent provides a means of chilling the wear face of cast-iron moldboard plows. By 1878, more than 170,000 Oliver chilled plows were in use worldwide. One of the world’s largest plow manufacturing facilities, Oliver’s South Bend, Ind., plant would produce tillage implements from 1876-1985.

1858

Lewis Miller of Canton, Ohio, patents an improved hay mowing machine.

1860

Wisconsin’s Daniel Van Brunt invents the disc opener and the metering unit for grain drills that prepared the seedbed and covered it before birds could devour the freshly placed seeds. By the end of the Civil War, Van Brunt Manufacturing was a successful manufacturer. By 1910, it became a major supplier of grain seeding machinery in the upper Midwest and the Plains states.

1862

Dissatisfied with portable steam engines used to power farm machinery that had to be moved from site to site by a team of horses, British farmer Thomas Aveling develops a self-moving steam engine. He manufactures his engines in partnership with Richard Thomas Porter to form Aveling & Porter.

The industry begins to switch from primarily hand work to horses, marking the first agricultural revolution.

1863

John Deere develops the Hawkeye Riding Cultivator, the first implement designed to ride instead of walk behind. Because so many men lost limbs during the Civil War, the cultivator was marketed as easily operated by “one-armed or one-legged men.”

1864

John Deere receives his first patent for the mold required in the casting of steel plows.

Civil War Brings Retail Farm Equipment Trade to Main Street

“An old-time implement dealer, writing for the Implement Irade Journal of Kansas City in 1906, told of experiences during his first 15 years in the trade. This reveals much about the early harvesting machines.

"In 1865 we sold the first Champion mowers ever sold in our county. They were made by Whitely, Fassler & Kelly of Springfield, Of. Mowers cost about $85 and sold at $125. These prices were time prices with 10 percent interest. In 1868, we sold the hand-rake Champion harvester (reaper), cost $175 and sold at $210. In 1870, we handled Smith's Pekin wagon and D. B. Buford's plows (of Rock Island); also the P. & O. stalk cutter, a very roughly constructed one, which cost $41.50 and sold for $52.50.

"In 1878, we sold the first McCormick wire binders ever sold here. We paid $300 for them and sold them at $375. The wealthy farmers were the only ones who could give such prices, and still they were wild after them. Our wheat yield was enormous that year, and we could not get them fast enough to fill demand, and all were very much pleased with them, although they gave us considerable trouble.

Other machines we sold were Selby corn planters, old wooden style; wheat drills; Nichols & Shepard horsepower thresher and steam rigs. We made a good deal of money on these machines although we had to carry the notes so long.

"In 1880, we changed our binders and sold the Deering twine binders, the first ones out using twine. We paid $280 for them and sold for $335.

Farmers were very skeptical in regard to their working, but they got over it and were well pleased. Many bundles were thrown off without being bound, but they overlooked that as they had the impression that wire wound in the straw would injure their livestock.”

— From the 1991 book, The Story of the North American Dealers Association, by Earl J. Becker1869

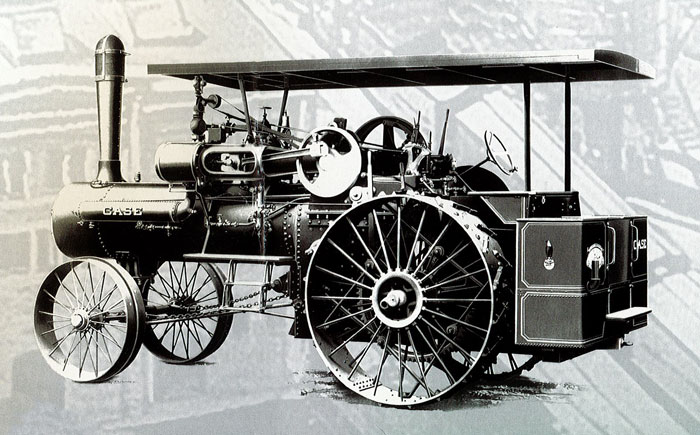

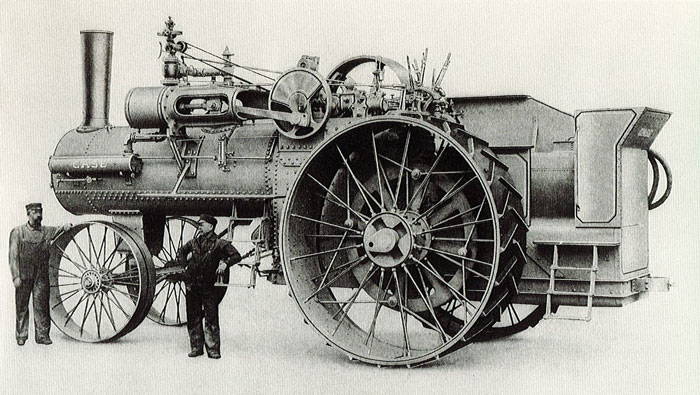

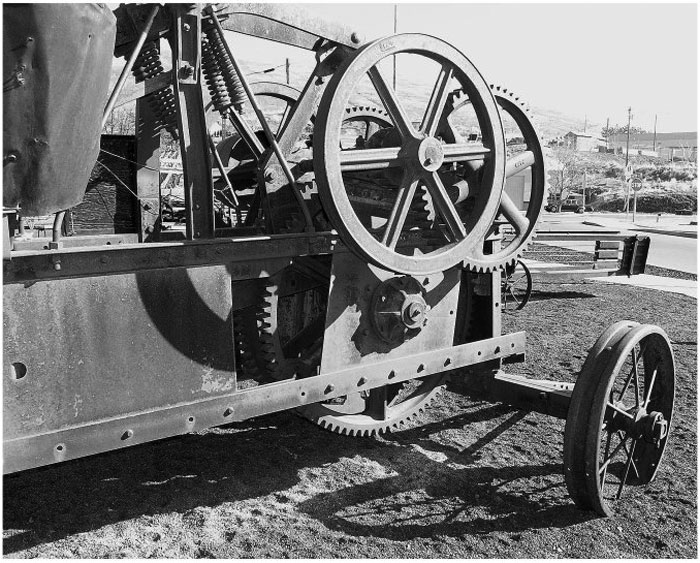

The J.I. Case Co. produces “Old #1,” the first steam-powered traction engine used primarily to replace horses in farming operations.

Gilpin Moore, John Deere superintendent, designs the Gilpin Sulky Plow, which takes farmers off their feet and into a seat as they plow.

1870

J.I. Case designs a steam engine specifically for farming. Built on a wagon and pulled by horses, it transferred power through a belt to threshers and other machines.

1872

Charles Withington designs the first “knotter” used on early grain reapers. This knotter replaces the two men required to hand wrap bundles of grain.

1873

Lewis Hatch, along with his son, Fred Hatch, erect the first tower silo on their farm near Spring Grove, lll.

1876

George Lambert patents the first mechanical corn planter.

Case produces its first traction engine, which provided power to the rear wheel and the belt pulley, while being the first to address the problems of boiler explosions and sparks.

1878

J.I. Case introduces a steam traction engine that delivers power to a rear wheel as well as the belt pulley.

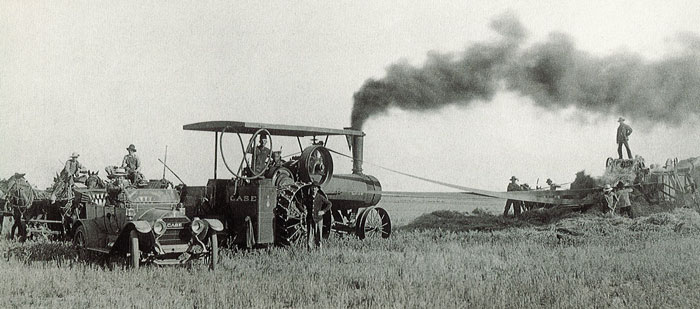

This photo shows a Case automobile, steam traction engine and threshing machine.

This photo shows a Case automobile, steam traction engine and threshing machine.

1879

John Appleby designs a knotter mechanism to bind grain bundles with twine. William Deering & Co. enter into an agreement to market the Appleby knotter on their grain harvesters.

1880

Louis Lucas and M. Silberzahn develop the Hexelbank Ensilage Cutter, a predecessor to the modern forage harvester. John W. Gehl acquires the business in 1902.

1882

Cyrus McCormick builds the first McCormick Daisy Reaper.

Missouri’s Joseph Dain receives a patent for hay handling equipment for which he receives his first patent in 1882. Within 10 years Dain becomes the largest manufacturer of hay stackers and also manufactures corn binders, tillers, harrows, and cultivators. Dain Manufacturing is acquired by John Deere in 1910.

1885

Patrick J. Lawler demonstrates the first successful horse-drawn corn picker.

1886

The world’s first self-propelled combine is developed by George Stockton Berry of Lindsay, Calif.

Benjamin Holt and Daniel Best develop early combine harvesters. By 1915, 6,000 Holt combines are harvesting nearly all of the grain on the West Coast.

William Deering & Co. is the first manufacturer to build a factory to produce “binder twine.”

Case becomes the largest worldwide manufacturer of steam engines.

1887

In Sterling, Ill., the Charter Gasoline Engine Co.’s creation of a gasoline-fueled engine led to early gasoline traction engines, years before the term “tractor” was coined by others in the industry.

1889

Charter Gasoline Engine Co. adapts its engine to a Rumely steam-traction-engine chassis and its first production run is for 6 “traction engines.”

1891

Joseph Oppenheim and Henry Synck of Ohio develop the first successful mechanical manure spreader.

1892

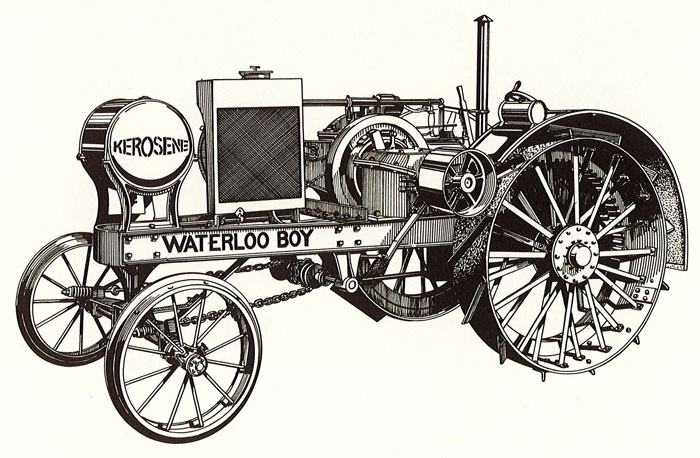

Northeastern Iowa’s John Froelich invents the first successful gasoline-powered engine that can be driven both backward and forward. The Froelich tractor, forerunner of the Waterloo Boy tractor, is considered by many to be the first successful gasoline-powered tractor. Froelich’s machine fathered a long line of stationary gasoline engines and, eventually, the famous John Deere 2-cylinder tractor.

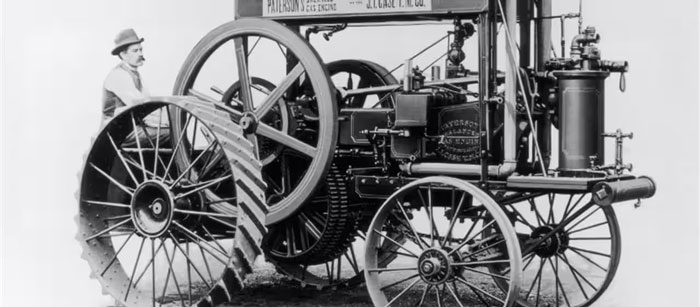

Case is the first of the old-line harvester companies to build a gas tractor. The “Paterson Tractor” was not successful and the company did not build another gas tractor until 1911.

Rudolph Diesel patents the compression ignition engine that became known as the diesel engine. Herbert Akroyd-Stuart, Halifax, Nova Scotia, files the first patent for the diesel engine in 1890, but never produces one.

Iowan Charles C. Fenno patents the first in-the-field corn silage harvester.

1893

Charles and Elwood Williamson of Union City, Ind., invent “new and useful” improvements to land rollers for farming, roads and other purposes.

1894

James B. Hill, Bowling Green, Ohio, patents the first steam traction ditching machine. It produced accurately sloped ditches for installing agricultural drain tiles.

J.I. Case begins engineering a gas traction engine when William Paterson of Stockton, Calif., came to Racine, Wis., to begin work on the experimental engine.

Recognizing the need for a practical way to place underground drain tile in the field, James B. Hill builds the world’s first ditching machine. His steam-driven ditching system led to the founding of the Buckeye Steam Ditcher Co., which patented his machine in 1894.

The side-delivery rake is developed to produce more appropriately sized windrows for hay loaders.

1897

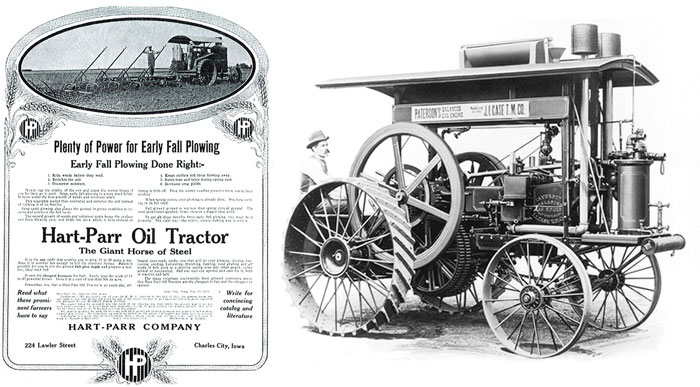

Charles Hart and Charles Parr form the Hart-Parr Gasoline Engine Co. in Madison, Wis. They move manufacturing operations to Charles City, Iowa, in 1900. The pair will adapt the Otto gas-powered internal combustion engine to propel a piece of mobile farm equipment. The pair are the first to call their product a “tractor” in 1906 favoring the shorter term over the gasoline-traction engine.

1899

New Idea introduces the first practical manure spreader. Joseph Oppenheim designed and sold the machine as his “new idea of spreading waste” as fertilizer.

1902

Minneapolis Steel & Machinery Co., Minneapolis, Minn., contracts with the Joy-Wilson Co., Chicago, Ill., to design a farm tractor. This evolves into the popular Twin City “40.”

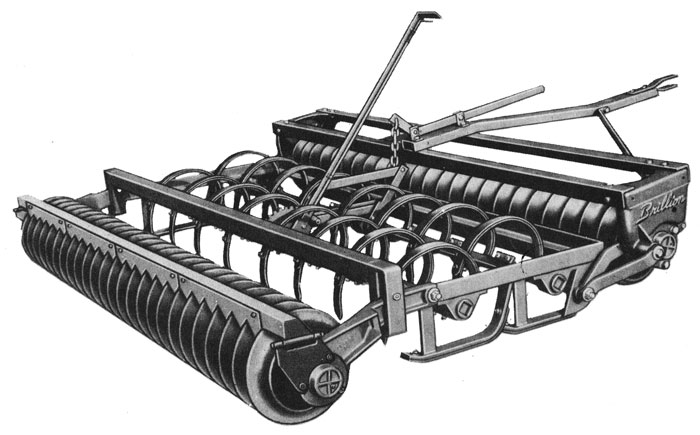

Brillion Iron Works, Brillion, Wis., produces the first soil pulverizer to produce smooth seedbeds for planting.

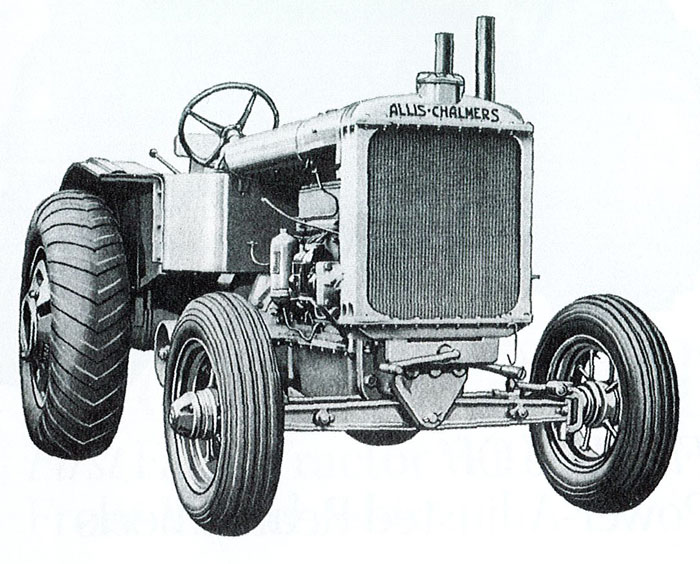

C.W. Hart and C.H. Parr produce and sell the first Hart-Parr tractor featuring an internal combustion engine. By 1940, tractors with internal combustion engines largely replace horse and steam engines.

McCormick, Deering Harvester Co., Plano Manufacturing, Champion Line and Milwaukee Harvester Co. join forces to create International Harvester.

1903

Kansas-based F. Wyatt Mfg. Co. (later evolving into the Hesston Corp.) releases the Jayhawk Hay Stacker. It was powered and driven by a team of 4 horses and was capable of lifting 700 lbs. of hay.

1904

Case’s “Road Locomotive” – the largest ever built – begins production, but will cease after 3 years.

Benjamin Holt, a California manufacturer of agricultural equipment, develops the first successful crawler tractor. It’s equipped with tracks rather than wheels to keep heavy tractors from sinking into soft soils. Best and Yuma were close behind in offering tractors on tracks. It would be called a “Caterpillar” by which his company would also be named. Moran than 10,000 Holt crawlers were provided for the allies during World War I.

1905

International Harvester develops the first friction-drive tractor by utilizing the IH stationary gas engine with a Morton chassis.

USDA sends planter Frank Meyer to China to look for interesting seeds. He sends back thousands of seeds, cuttings and whole plants which include 44 varieties of soybeans. It will take decades, but the U.S. emerges as a major soybean producer and passes Japan in 1931 and Korea in 1934.

1907

Along with chief engineer Joseph Galamb, Henry Ford begins work on an experimental gasoline-powered tractor. It is referred to as the “automobile plow” and was never called a “tractor” during development.

1908

Henry Ford’s invention of the Model T automobile leads the way for the first steam and gas-powered farm wagons that help farmers move around the farm, as well as transport livestock and equipment.

1910

Ummo Leubens develops the first round hay baler.

1911

Case produces its first gas-powered tractor.

Lilliston Corp. introduces a mule-powered peanut harvester.

1912

Australian farmer and inventor Arthur Clifford Howard develops the first powered rotary tiller.

1913

Waterloo Gasoline Engine Co. produces its first Waterloo Boy tractor engine.

New Zealand’s Norman Daysh conceived of the idea that would become the first commercial milker with master pulsation control for uniform milking. He joined DeLaval, which had produced several milking innovations since the late 1870s.

1915

Minnesota farmers Andrean and Adolph Ronning patent the horse-drawn Ronning Harvester, a corn silage harvester that improved on a harvester developed 3 years earlier by South Dakotan Joseph Weigel.

1916

Harry Krause designs and builds the first one-way disk plow in his Western Kansas farm shop, regarded as one of the first conservation tillage tools.

Ford Motor Co. starts commercial production of the Fordson tractor. The first low-cost, lightweight and mass-produced tractor using an internal combustion engine, it would achieve a 75% market share by 1925.

1917

The endless rubber V-belt is developed by Charles C. Gates of the Gates Rubber Co., leading to standard V belts for tractors and autos.

1918

American Harvester Co. of Minneapolis begins manufacturing the horse-drawn Ronning Harvester for corn silage operations.

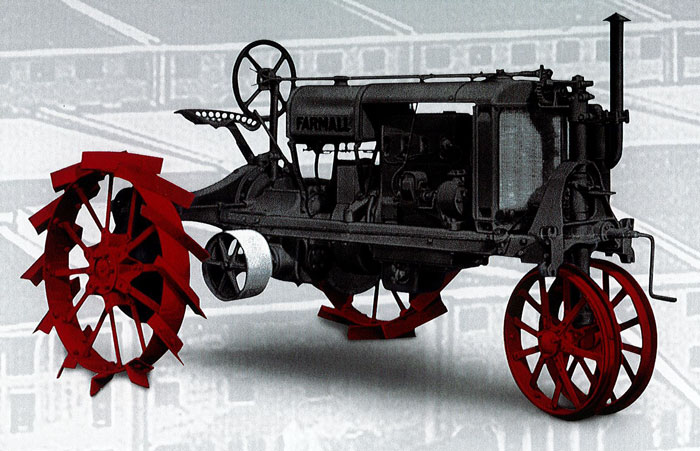

Bert Benjamin, supervisor of McCormick Harvesting Machine’ Experimental Dept., introduces the first commercial power takeoff, which transfers engine power to the implement. Two years later, he goes on record as saying that the Farmall tractor will eliminate the horse entirely.

1919

The Gilson Manufacturing Co. became the first company to attach a gasoline engine to a multi-purpose gardening implement, ultimately manufacturing about 7,000 tractors for the Beeman Tractor Co. of Minneapolis, Minn. Gilson began making garden tractors under its own name in the early 1920s. The company was renamed Gilson Bolens Co. in 1928 and Bolens Manufacturing Co. in 1939.

H.W. Bolens Manufacturing Co., Port Washington, Wis., introduces the first power-driven garden tractor.

1920

The first Nebraska Tractor Tests (Univ. of Nebraska-Lincoln) are conducted to serve as a “consumer watchdog” for farm tractors.

Massey Harris purchased Wallis Tractors to create the first 4WD tractor. Wallis Tractors was founded by Henry Wallis, the son-in-law of J.I. Case. Wallis built tractors for his stepfather until Massey Harris bought his company to build the first four-wheel drive tractor. The first Massey Harris 4WD was the GP 15/22 built from 1930 to 1936.

1921

Aerial dusting of crops emerges as a farm practice after C.R. Nellie uses a military plane to dust catalpa trees near Troy, Ohio.

1923

The Baldwin Brothers of Nickerson, Kan., develop the self-propelled “Gleaner” combine, mounted on a Fordson tractor.

Deere & Co. launches the Model “D” tractor. It will remain in the line for nearly 30 years.

Bert Benjamin builds the International Harvester Farmall tractor, the first successful row-crop tractor. With the rear wheels set wide apart and narrow front wheels, the tractor was ideally suited for cultivating row crops.

The all-purpose or tricycle type tractor is tested as the first successful row-crop tractor in Burr Ridge, Ill., by IH and marketed as the McCormick-Deering Farmall. The tricycle design allowed a variety of farm chores requiring power which was not possible with prior 4-wheel tractors. Within 6 years, IH produced 40,000 tractors out of 229,000 from a total of 47 tractor manufacturers.

1924

Babson Bros. introduces vacuum and pulsation in a high-performance milking machine under the name Surge that is developed by farmer Herbert McCormick. The Surge bucket was used by 85% of North American dairymen until the pipeline system replaced it.

1925

Deere & Co. begins work on the “GP” (General Purpose) series tractor as the answer to International Harvester’s Farmall. Introduced in 1929, the first model incorporates a narrow front wheel arrangement and rear wheels that straddle two rows, making it ideal for row-crop operations.

A multiple-V-belt drive is developed by Walter Geist of the Allis-Chalmers Corp., who was inspired to replace rope and flat belt drives with multiple V-belts, allowing efficient high horsepower transfer from engines to application.

1926

After producing 36,000 steam traction engines (with peak production in 1911), Case ceases production in favor of the gas-powered technology.

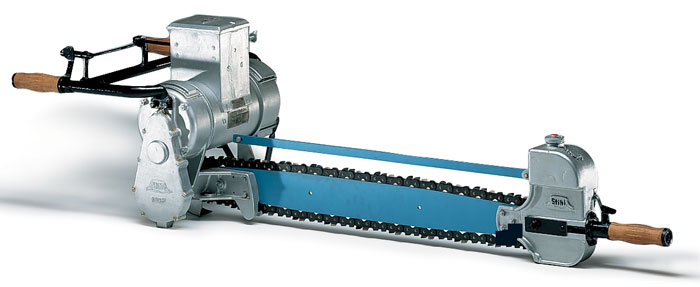

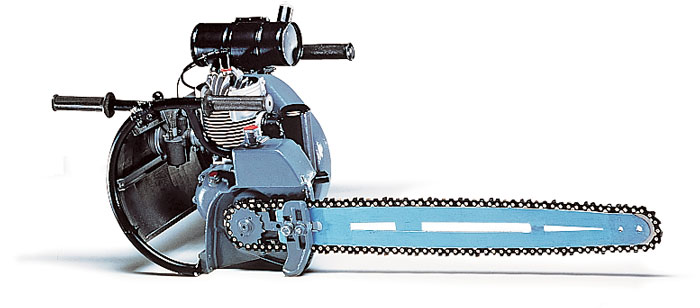

Stihl introduces the first electric-powered chain saw — a 140-pound electric “cross-cutting chain saw.” The saw’s bulk required it to be operated by two people, and its reliance on an electric motor limited its portability to areas where a power source was available, such as in lumber milling yards.

Helmer and Ellert Hanson of Lajord, Saskatchewan, introduce the hay swather. Having observed the operation of the Hanson brothers’ swather, engineers at International Harvester develop their own unit.

Irish mechanic Harry Ferguson patents the three-point linkage hitch for tractors in Great Britain. The hydraulically operated and controlled 3-point hitch utilized the draft of the mounted tool to adjust implement depth and the load on the tractor.

1927

International Harvester becomes the first company to offer hay and grain swathers for sale. These early machines were powered by a ground wheel while subsequent models were PTO-driven. With the introduction of these implements, farmers were able to windrow hay and then process it during the appropriate season.

Deere & Co. offers combines in two sizes: the John Deere No. 1 and John Deere No. 2. The No. 1 was a smaller unit for smaller acreage farms.

1928

Italian tractor manufacturer SAME is credited with producing the first diesel-powered agricultural tractor.

New Idea markets a two-row pull-type PTO-driven corn picker, significantly increasing the number of acres a single operator could farm (from 5.5 man hours in hand-husking to 3.88 hours via mechanical harvesting).

Deere & Co. is the first manufacturer to offer a mechanical power-lift mechanism, producing users with 4 forms of power: drawbar, belt, power takeoff and power lift.

H.H. Bennett and William Ridgely Chapline release the USDA bulletin, Soil Erosion: A National Menace. Bennett will go on to be recognized as the “father of soil conservation.”

1929

The Ann Arbor Baler is developed by Ray Moore McDonald in Shelbyville, Ill., and is recognized as the world’s first pickup baler.

1930

15% of farmers have adopted the tractor.

Henry W. Jeffers conceives the rotary dairy parlor that would become the Rotolactor, but it was tabled due to World War I. With the backing of Borden Company in 1930, its introduction would allow 50 cows to be washed and milked in 12.5 minutes.

With the merger of the Oliver Chilled Plow Works and the Hart-Parr Tractor Company, the Oliver Hart-Parr Row Crop tractor is introduced. It is a single-front wheel machine having holes drilled in the frame for pipe-mount implements.

1931

Caterpillar manufactures the first diesel-powered track-type tractor, Diesel 65, which offers more power, reliability and fuel efficiency than those using low-octane gasoline.

1932

Anhydrous ammonia as a nitrogen fertilizer was first seriously considered in California.

The first commercially successful pickup forage harvester is developed by Erwin W. Saiberlich and sold by Fox River Tractor Co. of Appleton, Wis.

Shell Chemical pioneers the use of ammonia as a fertilizer, first in irrigation water and in 1939 for direct soil applications.

In a breakthrough for harvesting low-growing, fragile crops, the Hume-Love floating cutter bar and pickup reel is developed and patented by James E. Love and Horace D. Hume near Garfield, Wash. The mechanisms reduce dry pea harvesting costs by 28% and crop loss from 50% to 10%.

Allis Chalmers is the first to introduce tractors with low-pressure pneumatic tires as standard equipment, speeding up the work of farming. Tests by the Univ. of Nebraska Tractor Test Laboratory find these rubber tires result in a 25% improvement in fuel economy when compared to steel and solid rubber tires. To address farmers’ skepticism, Wisconsin farmer Albert Schroeder, who buys the prototype Allis Chalmers Model U on rubber tires, goes on the road giving talks and demonstrations. A-C went on to promote rubber tires by sponsoring a special high-speed tractor that was driven by race car driver Ab Jenkins at 67.87 MPH at the Utah salt flats. By 1940, rubber tires will be available on nearly all tractors.

“Of all the major advances in farm tractors since their inception, the substitution of air tires for steel-lugged wheels is no doubt the most profound,” says AGCO’s Norm Swinford.

In response to the extreme soil drifting in Western Canada, Charles Noble develops a system to shear stubble and weeds below the ground and leave the residue on top of the soil to reduce evaporation and prevent erosion. Patented in 1937, more than 10,000 will be used around the globe by 1979.

1933

Harry Ferguson’s 3-point hitch is attached to a David Brown tractor in England, creating the Ferguson-Brown model A. By 1937, sales dropped and relations between Brown and Ferguson became hostile. Ferguson shopped his system to Henry Ford in 1939 and together they release the Ford model 9N, the first tractor to combine the Ferguson hydraulic systems with the 3-point hitch. This partnership later dissolves, resulting in a lawsuit over royalties. By 1960, Ferguson’s patent expires and the 3-point hitch becomes the industry standard.

For the Servis Equipment Co., J.B. Jarmin patents a motor grader with a single, large-diameter pipe frame.

Orton Englehardt invents the impact sprinkler head in Glendora, Calif., contributing to the expansion of sprinkler irrigation.

Horace D. Hume demonstrates the floating cutter and reel for soybean producers The H.D. Hume Co. is part of HCC today.

Fred Hoeme of Hooker, Okla., develops a heavy-duty chisel plow designed to control wind erosion on the Great Plains, and sells 2000 units. W.T. Graham, Amarillo, Texas, purchases the manufacturing and distribution rights in 1938 and brands it as the Graham-Hoeme chisel plow.

1934

Servis Equipment Co. produces the first tractor-mounted grader blade.

1935

International Harvester introduces its first diesel engine for wheeled tractors.

Allis Chalmers introduces the All-Crop Harvester, a PTO-driven, one-man combine mounted on pneumatic tires and cutting a swath 5-6 feet wide. Use of the machine spreads rapidly to small Midwest farms in harvesting a variety of crops.

Massey Ferguson introduces the small “clipper” combine. By 1949, small combines would achieve 100,000 unit each year.

1936

President Roosevelt’s Rural Electrification Act greatly improves the quality of rural life. According to EMI (AEM), “The availability of electricity as a source of constant, cost-effective power did for farmstead mechanization what tractors did for field work.”

Ed Nolt, a Pennsylvania farmer, purchases a knotter mechanism to bale the straw produced by his combine. This was the first twine tie hay/straw baler.

Stihl unveils a centrifugal clutch for chain saws that ensures the saw chain is automatically advanced as the engine speed increases.

1938

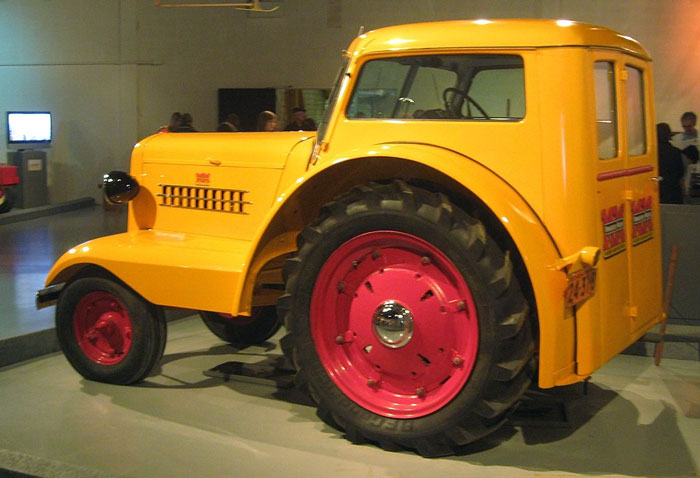

Minneapolis-Moline pioneers the closed-cab tractor with its UDLX Comfortractor (also known as the Model U Deluxe). The rear-entry cabin included a passenger seat for the wife to ride in comfort and auto-like features: a safety glass windscreen and wipers, electric-start and speedometer, clock, sun visor, rear view mirror. Other industry-firsts included a heater, cigarette lighter, ashtray and radio. Priced twice more than a Deere and Farmall ($2,155), production ceased after only 125 units.

1940

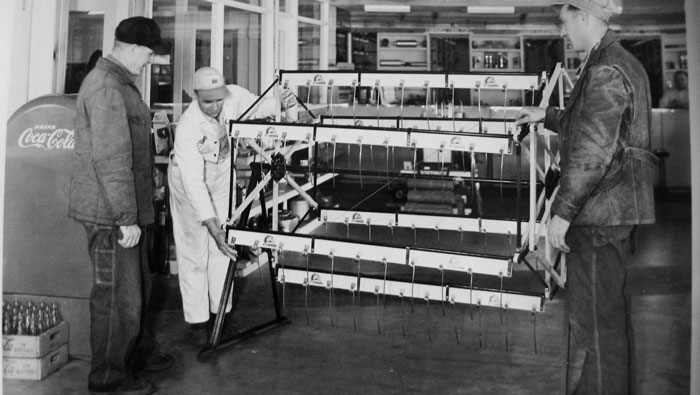

New Holland Machine Co., New Holland, Pa., markets the first commercially successful automatic pickup, self-tying hay and straw baler that uses twine instead of wire. It was invented by Edwin Nolt. The Model 73 took a 3-person baling operation and reduced it to 1 person needing to operate it.

1941

Farmhand markets Joe Schwan’s 1936 innovation of utilizing a pump and hydraulic cylinder to raise and lower a front-end mechanism, which revolutionized the stacking of hay. It would be the forerunner of the modern front-end loader.

Minneapolis-Moline offers the world’s first factory-produced liquefied petroleum gas (LPG) tractor as part of its U range. The U range had several variants, including wide-front, tricycle, high-clearance, industrial, gas-powered and diesel-powered, so the LPG version was another string of new products from this very innovative company. It claimed the tractor provided 10% more power, was cheaper to run than other tractors and its engine had a longer lifespan than other tractors.

Servis Equipment Co., Dallas, Texas, introduces the Whirlwind Terracer. International Harvester recommends its dealers become Whirlwind dealers, resulting in a rush of orders to meet new state and federal government soil conservation efforts.

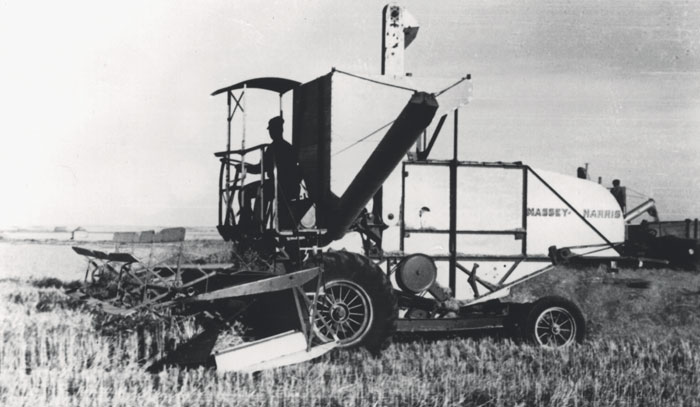

Massey Harris (now Massey Ferguson) produces the first successful self-propelled combine with the Massey-Harris 21SP combine, developed by Thomas Carroll.

Raymond Hanson invents the first self-leveling controls for hillside combine. The first self-leveling mechanism units are built in 1945. Automatic leveling saved an estimated 3% of harvested grain on hillside fields, representing millions of dollars of grain each year.

Spurred by a wartime need for domestic sources of fats, oils and meals, the U.S. doubles soybean production from 1941 to 1942, passing both Manchuria and China to become the world's leading soybean-producing nation, a lead the U.S. has maintained ever since.

1942

The Gehl Co. is the first to mass-produce forage harvesters and introduces multiple heads for hay and corn forage harvesters a year later.

International Harvester builds “Old Red,” the first commercially successful cotton picker, but scientists must modify the cotton plant to eliminate foliage and ensure uniform ripening. With its 1943 introduction in California, the spindle picker soon dramatically changes cotton harvesting and is considered the biggest change in cotton production since the introduction of the cotton gin.

1944

Leonard T. Fleischer develops the equipment for ridge-tilling and establishes Fleischer Manufacturing Co. in Grand Island, Neb.

1945

The amount of tractor power overtakes horsepower for the first time on U.S. farms

Following the end of World War II, the “Ag Chemistry” era arrives in U.S. agriculture. Dow releases 2,4-D to control broadleaf weeds, presenting the first real possibility of cultivating crops without tillage.

Glen Jones designs and sells the first tractor-powered posthole digger.

Swisher Mower and Machine Co. develops the first zero-turn lawn mower.

Saskatchewan farmer Peter Anderson builds a "stone picking machine" that will be patented in 1957 and begins to address the back-breaking work of stone removal. Within 7 years, Rosaire Bussiere, also from Saskatchewan, patents an improved rock picker and eventually establishes Rock-O-Matic

Peter Pakosh, designs and builds the first prototype grain auger and, 8 years later, starts selling thousands under the “Versatile” name, making it the standard for modern grain augers.

1946

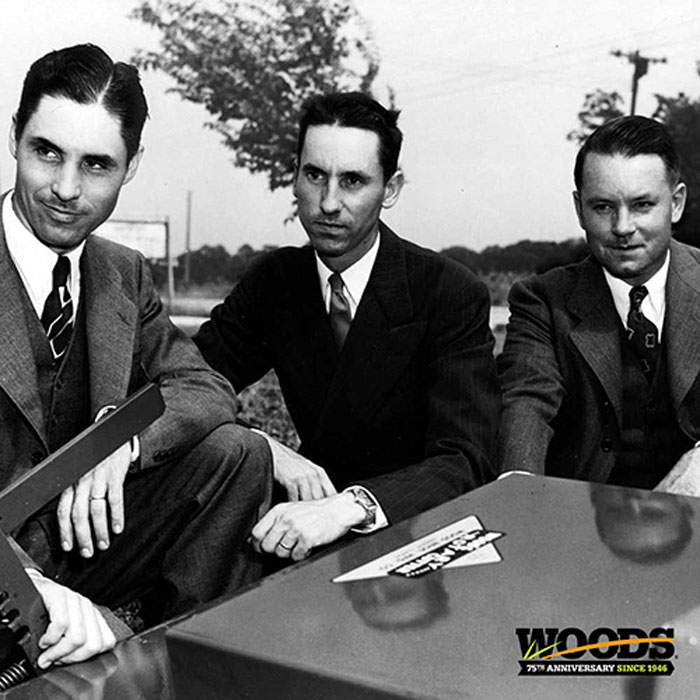

Woods Brothers Equipment Co., Oregon, Ill., develops the first tractor-mounted rotary cutter mower, invented by Keith Leonard and Mervel Wood. This advanced cutting method permits the tractor driver to control cutting lengths and effectively work on contours.

Massey-Harris stimulates demand for self-propelled combines when combine fleets known as the Harvest Brigade rolled each year from the Mexican border to the wheat fields of Canada.

1947

B. Servis Equipment Co. engineers Clyde Robinson and Hoy West develop the first front-mounted stalk shredder to shred cotton and corn stalks.

Allis Chalmers introduces the “Rotobaler” which produces round bales that are 16 inches in diameter and 48 inches wide.

Karl-Ragnar Åström builds the first front-end loader in Sweden and establishes AB Ålö-Maskiner as the manufacturer of Alo/Quicke loaders.

Edward Gideon (E.G.) Melroe forms Melroe Manufacturing Co. to produce the Melroe Pickup combine attachment.

John Eyestone, Upper Sandusky, Ohio, builds the first self-propelled, 4-row corn picker-sheller. He builds the machine around a surplus WWII 6-WD power unit, installing two Minneapolis-Moline pull-type corn heads together and adding a new Minneapolis-Moline sheller to the frame. He adds a 320-bushel bin to collect the shelled grain.

Lyle Yost, develops the first grain unloading auger that allows a combine to continue traveling during the unloading process and launches Hesston Machine and Manufacturing Co.

Ray Hagie, founder of Hagie Manufacturing Co., Clarion, Iowa, invents the first self-propelled sprayer for agricultural applications.

Washington’s Clayton Merry designs the first chain-drive front tine tiller, which was named the Merry Tiller. MacKissic acquired the Merry Tiller in 1991.

Brandt Machine Works of Carlisle, Ark., manufactures its first grain cart, designed to help a local farmer haul rice from the combine in the field to the truck.The firm followed with a round hopper grain cart in the 1950s.

The Oliver 88 tractor is credited as the first mass-produced U.S. tractor with an independent, or “live” PTO.

Wisconsin-based H.W. Bolens Manufacturing Co. introduces the first compact tractor

1948

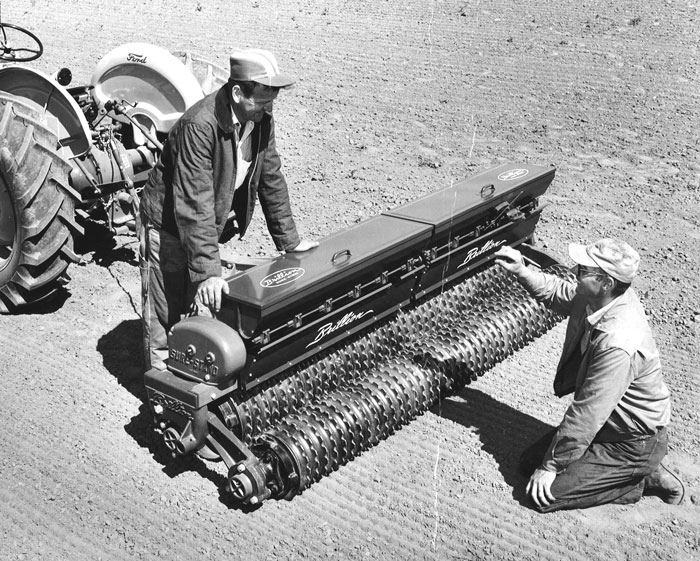

Brillion Iron Works introduces the “Sure Stand” grass seeder.

Colorado farmer Frank Zybach invents the center pivot irrigation machine, which revolutionizes irrigation technology. The system consists of sprinklers attached to arms that radiate from a water-filled hub out to motorized wheeled towers. Zybach is awarded a patent in 1952 for the “Self-Propelled Sprinkling Irrigating Apparatus,” which was purchased by Valmont Industries in 1953.

Allis Chalmers introduces the use of power-adjusted rear wheels on its WD tractor model.

1949

Univ. of California-Davis agricultural engineers Coby Lorenzen and Jack Hanna develop a successful tomato harvester that is built by Blackwelder Manufacturing Co. of Rio Vista, Calif.

Seeing a need to increase flotation in wet field conditions and make better use of available tractor horsepower, Richard and L.G. Unverferth develop the first bolt-on dual tractor wheels. This innovation uses a cast “hat-style” extension to attach the dual wheels to the drive wheel’s weight holes.

Owatonna Manufacturing Co. purchases the rights to Jullues Ommodt’s self-propelled windrower that mowed, conditioned and windowed forage crops in one operation.

1950

The self-propelled windrower is produced by Killbery Industries and marketed under the “Grain-Saver” brand name. The Canadian company is later renamed MacDon.

The Stihl BL is unveiled as the first one-man, gasoline-powered chain saw. It weighs 35 pounds and is equipped with a manually-adjusted swivel carburetor that allows the saw to be used for both bucking and felling trees.

The “Pulvi-Mulcher” implement that tills and compacts a seedbed in one pass is introduced by Brillion Iron Works.

Lilliston Corp. revolutionizes peanut harvesting with its peanut combine that removed 80% of the labor cost from the operation.

1951

The Ferguson Co. develops a side-stroke reel rake that uses only two spiders and six bars. Around the same period, a no-reel rake was invented. Called a finger-wheel type rake, it uses raking wheels with tooth-like projections. The side-delivery type continues to develop and soon becomes the most widely used type of hay rake.

Bush Hog demonstrates a new tractor-pulled implement near Selma, Ala. “That things eats bushes like a hog,” said an elderly farmer, and the Bush Hog brand was born.

1953

IH produces the first commercial no-till planter, the McCormick M-21 (2 rows on 40-inch spacing) at its Richmond, Ind., plant. The lack of weed control products at the time thwarts its success, and IH ceases production after 2 years. Only 23 of the 50 units produced were sold.

1954

The number of tractors on farms exceeds the number of horses and mules for the first time.

Valmont Industries develops the first commercially successful irrigation system for Great Plains farmers.

1955

Hesston Machine and Manufacturing Co., Hesston, Kan., introduces the first self-propelled swather that would window hay in one pass. Hesston would turn haymaking into a 1-man operation with numerous products introduced from 1955-1973.

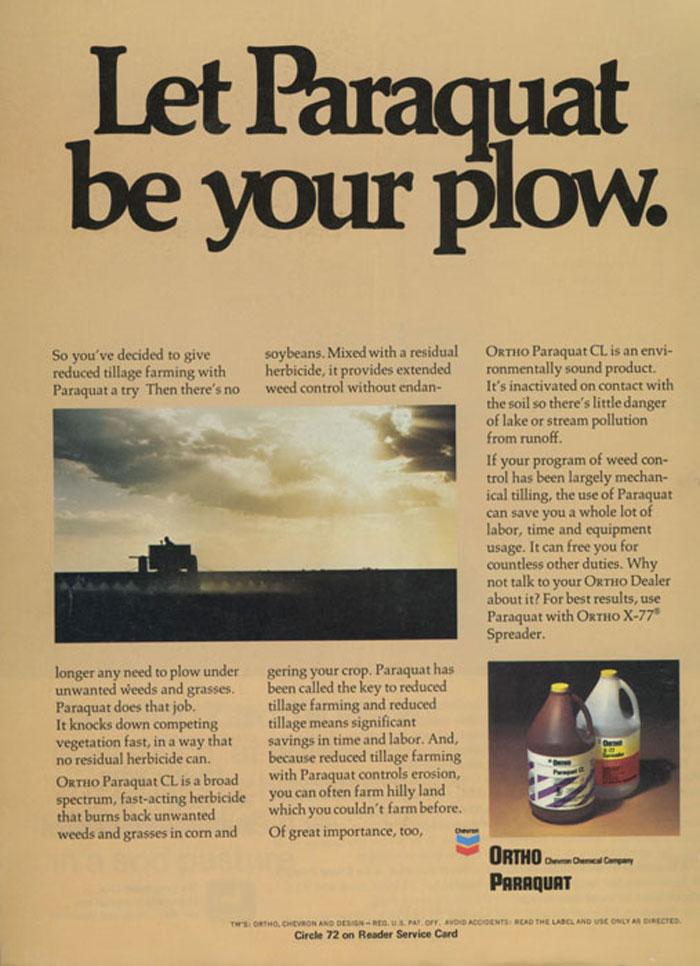

The invention of the herbicide paraquat in the U.K. prompts the Imperial Chemical Co. to initiate research into farming without tillage.

1956

With 3 models built for the 1956 model year, Wagner Tractor, Inc., Portland, Oregon, becomes the first manufacturer to build 4WD agricultural tractors with articulated frame steering.

Anhydrous ammonia is increasingly used as a cheap source of nitrogen, boosting yields.

The Roll-Over Protection System (ROPS) for tractors is developed by Lloyd H. Lamouria, Ralph R. Parks and Coby Lorenzen at the Univ. of California-Davis. In 1959, Warren Hansen equipped tractors with ROPS for North Dakota’s Highway Dept. In 1966, Deere & Co. introduced the Roll-Guard, the first widely accepted roll-over protective structure.

South Australian company Gyral, founded by Albert Fuss, introduces an air seeder in the 1950s in response to farmers who were unable to plant in more compacted soil environments. The seeder was light in weight and mounted on a Graham Holme chisel plow.

1957

Deere & Co. signals a significant change in row-crop planting with the introduction of a 6-row planter and cultivator designed for corn and cotton producers.

Cyril and Louis Keller, Rothsay, Minn., design and build a small, lightweight, 3-wheel front-end loader capable of turning 360 degrees within its own length. Melroe Manufacturing will form a partnership a year later to create the Melroe self-propelled skid-steer loader.

1958

Sweden’s AB Ålö-Maskiner develops the first “drive-in” front end loader.

Linde’s launch of the first hydrostatic transmission marked a milestone in the history of forklift design.

John Steiger, along with sons Douglas and Maurice, build the first Steiger tractor in their barn at Red Lake Falls, Minn. Steiger #1 was built from truck components and powered by a 238-horsepower Detroit Diesel engine.

Atrazine is registered in 1958 by Ciba-Geigy for weed control in corn. It will be used extensively in the U.S. by the early 1960s.

1959

The Wagner TR is the first articulated tractor in production with 4-wheel drive and 4-wheel steering. It is powered by a Cummins 8.1-liter, 90-horsepower or 12.2-liter 155-horsepower engine

Allis-Chalmers produces the first electric fuel cell tractor. Fuel cells produce electrical power directly through a chemical reaction, without heat, smoke or noise. Although the tractor is never produced, the technology allowed NASA to “put a man on the moon.”

1960

The first all-terrain vehicles (ATVs) are built by Jiger Corp. and appear as 6-wheel vehicles with yellow fiberglass tubs that allow them to float in rivers and lakes.

JI Case introduces the first cab with integral ROPS and acoustically designed to reduce noise.

International Harvester launches the Cub Cadet as the first lawn and garden tractors produced by a major tractor manufacturer.

Melroe Manufacturing Co. introduces the M-400, the first 4-wheeled, all-wheel drive “skid-steer” loader.

MacKissic introduces interchangeable grinding screens for use in stalk shredders.

1961

Lilliston introduces the rolling cultivator (developed by C.L. Lehman) to cultivate large acres of cotton, without the problems with regular, more aggressive cultivation tools. Within 4 years, Lilliston introduced a toolbar and adapted the unit to an array of other crops.

The first irrigation drip tape in the U.S., called Dew Hose, was developed by Richard Chapin of Chapin Watermatics in the early 1960s.The practice would eventually introduce a new set of implements and changed farm practices in arid climates.

John and Jake Kirschman build the original SpraCoupe sprayer in their North Dakota workshop, with features that outperform tractor-mounted spray booms in numerous ways. Rights are later purchased by Melroe, Clark Equipment, Ingersoll Rand and then AGCO.

To increase the capacity of its engines, Allis-Chalmers introduces the D-19, the world’s first mass-produced tractor with a turbocharged diesel engine that increased power by 10%. The 85 engine hp tractor was a technological victory for Allis-Chalmers, preparing the way for turbocharged diesel engines to provide more power and reduce carbon dioxide emissions.

1962

Harry Young is the first in the U.S. to use no-till on commercial farmland. He modifies a mule-drawn 2-row planter to no-till corn on a highly visible 0.7-acre plot in Herndon, Ky. John Kirkpatrick, a Haywood County, N.C., dairy farmer, also plants a no-till corn crop into old fescue sod.

The SMV (Slow Moving Vehicle) emblem was developed at Ohio State University by ag engineer Ken Harkness.

Eugene Sukup of Sheffield, Iowa, builds the first grain dryer for use in on-farm grain bins.

With West Tennessee farmers losing 40 tons of soil per acre annually, the Univ. of Tennessee AgResearch and Education Center at Milan opens.

Dicamba (first described in 1958 and patent acquired by Versicol Chemical) is approved for use in the U.S.

Oliver’s 1800 Series BFWA diesel is credited as the first farm tractor with front-wheel assist.

1963

The Steiger 4WD tractor is introduced with an enclosed cab.

John Deere enters the consumer market with the 110 lawn tractor, which sells nearly 23,000 units in 1966.

Eugene Keeton demonstrates the finger pick-up seed meter for planters and then sells the design to Deere & Co.

Iowa farmer Eugene Sukup forms Sukup Manufacturing with the introduction of the Stirway stirring machine for on-farm grain bins. The unit aerates and mixes anywhere from 6-21% moisture corn into a consistent 15% moisture for safe grain bin unit throughout the year.

John Deere surpasses IH to become the world’s largest producer and seller of farm and industrial tractors and equipment.

1964

New Holland introduces the industry’s first mower-conditioner (Haybine 460), which was the first to consolidate cutting and stem-crushing into a 1-pass operation. A total of 3,000 units were produced in its first year. The company also introduced its first self-propelled windrower, the industry’s first self-propelled forage harvester and the industry’s first automatic bale wagon.

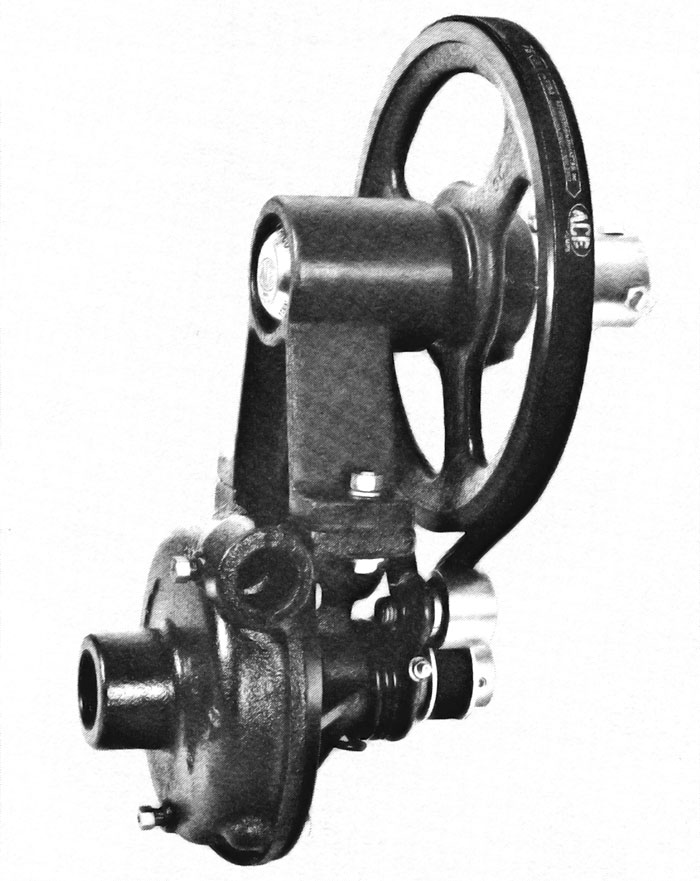

Ace Pump Corp. of Memphis, Tenn., develops the first PTO-driven centrifugal pump for applying newly developed wettable chemicals.

Stan Knight, a Wisconsin dairy farmer turned manure spreader manufacturer (Knight Manufacturing Co.) introduces the “Auggie” and enters the feed mixer market. The 3-auger design enabled producers to produce a total mixed ration for their livestock.

Banvel herbicide (containing dicamba) is registered by the USDA.

1965

The first laser-grade leveling control is developed by ag engineers James Fouss and Norman Fausey of USDA’s Ag Research Service at Ohio State Univ.

An unknown Japanese tractor manufacturer by the name of Kubota selects McCulloch (known for its chainsaws) as its importer into the U.S. McCulloch orders 100 G-12 and 100 D-20 Kubota tractors (yellow and branded under McCulloch) to be sold in the U.S.

IH introduces the Farmall and International 1206, the industry’s first row-crop tractors with more than 100 hp.

Enclosed cabs are a popular addition and many companies started building them. Minnesota farmer Merton Anderson designs and builds a cab for himself before forming Year-Around Cab Co.

1966

DICKEY-john Manufacturing Co. introduces electronic monitoring devices to allow farmers to plant crops more efficiently. Attached to mechanical planters and air seeders, the devices monitor the plant population per acre and the spacing of seeds being planted.

A farmer and rancher from North Dakota notices the need for an affordable and moderate-sized tub grinder to feed his livestock. He starts a company to produce the Haybuster C-Series. It was the first product for the company now known as DuraTech Industries International, Inc., which is headquartered in Jamestown, N.D.

European farm machinery manufacturer Amazone introduces the world’s first combination till and drill equipment.

Arthur Luscombe launches Art’s Way Mfg. after building a portable PTO-driven feed mixer in 1954 and hammer mill in 1958

While Massey-Harris created a prototype in 1932, Versatile becomes the first to mass-produce 4WD tractors and prices the units at roughly the same price as competitors smaller 2WD tractors.Their success in the new category marks the commercialization of the 4WD tractor.

Chevron Chemical releases paraquat in the U.S. for use as a burndown herbicide and to eliminate weedy plants in wheat fields.

Electronic monitors introduced by Bob Dickey and Jack Littlejohn (DICKEY-John) lead to a mechanical seed sensor device (with Sangamo Electric) that monitors the passage of seed corn through the planter’s seed tube.

1967

No-till soybeans start to be double-cropped after wheat. Soybeans lend themselves easily to no-till planting, especially for beginners.

Development of two-wheel grain carts by several shortline manufacturers lead to expanded use during harvest with on-the-go grain unloading from combines. These carts proved much more maneuverable than the more cumbersome four-wheel grain carts.

Allis-Chalmers introduces the first fluted coulter no-till (“No-Til”) planter, the first commercially sold unit to find success in the no-tillage market.

International Harvester introduces the first hydrostatic-drive combine.

Kinze Manufacturing of Williamsburg, Iowa, builds the first auger-unloading grain wagon, which allows large loads of grain to be moved under difficult field conditions.

Unverferth Manufacturing introduces the step-up wheel lug that allows farmers to adapt older tractors to the larger 38-inch diameter wheels and tires manufacturers are installing on new tractor models. The larger tires improved drawbar horsepower and speed.

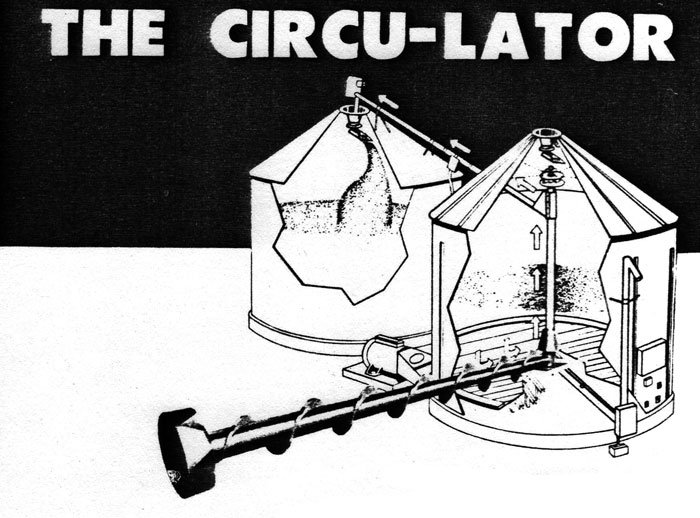

Charles Shivvers invents and patents the tapered sweep auger, the Shivvers Circu-Lator, which is the first in-bin continuous flow grain drying system.

European farm equipment manufacturer Amazone introduces tramline controls.

Hesston introduces the first hydrostatic self propelled windrower.

1968

Smith-Roles Ltd. produces the combine grain-loss monitor, developed by William B. Reed at the Univ. of Saskatchewan in 1960. It enables farmers to monitor grain losses in real time to make adjustments.

96% of cotton is harvested mechanically.

The commercialization of Monsanto's Lasso herbicide is credited with beginning a trend toward reduced-tillage farming.

International Harvester introduces the first tractor with a hydrostatic transmission, the Farmall 544.

1969

Kubota Corp. introduces its first tractor to the U.S. (L200 21-hp subcompact) to near-overnight success. Kubota Tractor Corp. is formed in 1972 to expand its penetration of the U.S. market.

Rekord Sales of Atherstone, England, develops the first commercially successful straw chopper attachment for combines.

Servis-Rhino patents the first 4-gearbox, flex-wing rotary cutter. The Flex 15 enables the wings to be raised without damaging the drivelines.

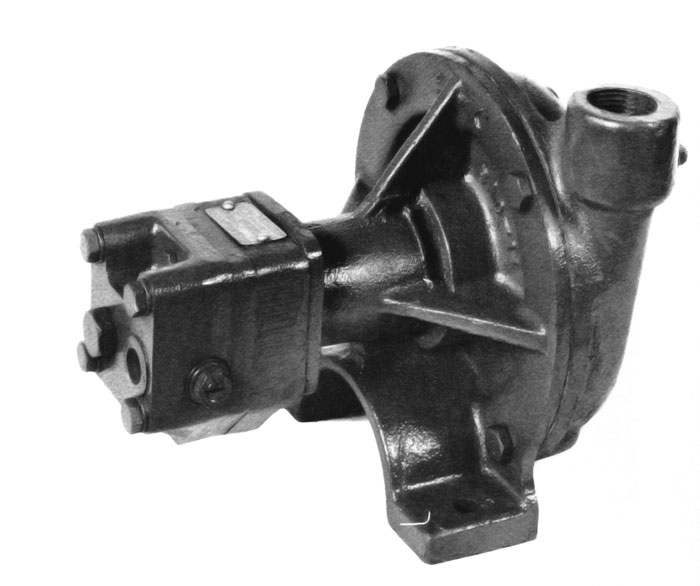

Ace Pump Corp., Memphis, Tenn., introduces the first close-coupled hydraulic motor-driven spray pump.

Oliver, Minneapolis-Moline and Cockshutt merge to form White Farm Equipment. In 1975, the 3 brands will be folded into the White brand.

Avery Weigh-Tronix invents a weigh bar for the Art’s-Way grinder mixer. Patented in 1972, it revolutionized grinder technology, allowing a farmer to accurately weigh and dispense feed rations to different groups of livestock.

The Loesch brothers of Kimball, Minn., develop a new approach to accurately plant any crop, regardless of seed size without having to change plates on each seed hopper. The air-assisted seed metering and central distribution design revolutionized planting and led to the introduction of the International Harvester (IH) Cyclo planter in 1971.

Don Landoll, Landoll Corp., invents the first traveling axle trailer.

1970

Melroe Manufacturing introduces the quick-attach system known as the “Bob-Tach” implement system.

French-based Nodet introduces a vacuum planter that allows planting of virtually any crop with precision seed depth and spacing accuracy at speeds up to 8 mph.

Specialized manufacturers like Hiniker and Year-A-Round build aftermarket cabs for all colors.

At the request of Monsanto's Dr. Phil Hamm who was excited about two compounds studied in water softeners, recently transferred chemist John E. Franz studies herbicidal use and discovers the weed-killing properties of glyphosate, an application that had not been recognized by Stauffer Chemicals a decade earlier when it was patented as a metal chelator. The third compound Franz synthesized (glyphosate) would become the active ingredient in the original Roundup formulation that would change the face of farming.

1972

HDA Design and Chuck Pelly develop the Sound Gard cab, used in John Deere tractors from 1973 to 1994.

Gleaner introduces the first electric-over-hydraulic controls for combines.

The first plastic bag silage storage system is released in the U.S. by Ag-Bag Corp. Inventors Larry Inman, Ronald Garvin, Patrick Welch and Michael Koskela will receive a patent in 1995.

Kuhn develops the disc mower hay cutting technology.

Gary Vermeer designs and introduces a modern baler to produce “big” round hay bales. The first model formed a 6-foot wide by 7-foot diameter bale that weighed more than 2,000 pounds and would spur a manufacturing company in his name. By 1982, more than 57,000 balers were assembled.

A SCS agronomist says it will take 118 years at the present rate of adoption to install all of the needed terraces on Indiana farms. The same amount of land conservation could be accomplished in a 1-year period via the adoption of no-tillage, he adds. No-till acreage is estimated at 3.3 million acres.

Kubota begins to move east from its initial West Coast presence. By the end of the decade, Kubota will become a major competitor in the small tractor market while pressuring Ford for the top spot.

DICKEY-John introduces the first automatic and fully portable hand-held moisture tester.

1973

Ag-Chem Equipment Co. introduces the first 3-wheel applicator for fertilizer and other crop protection products. The TerraGator features high-flotation tires to minimize compaction.

Telehandlers for use on farms are developed by Matbro in Horley, England, based on articulated cross-country forestry forklifts.

Allis-Chalmers is the first tractor manufacturer to adopt load-sensitive hydraulics on a farm tractor with its 7030 and 7050 tractors.

Preston Davey and Art Ross build an air seeder in Saskatchewan. Manufacturing begins 3 years later and 17 Pride Seeders sold into North Dakota and Western Canada

1974

2,314,000 farms exist in the U.S., with an average size of 440 acres.

John Deere introduces its MaxEmerge plateless planter with finger-pickup seed metering, Tru-Vee openers and angled closing wheels.

A.O. Smith Harvestore introduces the SlurryStore, an above-ground glass-fused-to-steel liquid manure tank containing pumps and agitation equipment. As the cost of chemical fertilizers rose, the nutrients in manure become even more valuable to the farmer.

According to Charlie Glass, the U.S. has about 15,000 farm equipment dealers, each with an average customer base of 154 farmers. It is not uncommon to enter a county seat town and find 4 or 5 farm equipment dealers.

Mort and Guy Swanson of Washington build a 29,000-pound no-till drill known as “Old Yeller.” A patent would be filed in 1975. Later, the Swansons team with Mike Johnson and Pete Thomason to build the Comfort King, the first successful no-till drill for the deep Palouse soils of Idaho, Oregon and Washington.

5.4 million acres of no-till crops are planted in the U.S.

Western Canadian growers raise a new variety of rapeseed developed by Univ. of Manitoba researchers Keith Downey and Baldur Stefansson that eliminates anti-nutritional components and ensures its safety for human and animal use. The new crop, later known as “canola” (Canada oil), will become the largest source of edible oil in the world and the 3rd largest crop in Canada after wheat and barley.

BASF introduces Basagran to the U.S. and the no-till soybean acreage expands. Later used in combination with other herbicides, it plays an important role in no-till farming systems in the U.S. and Brazil.

1975

Ohio no-tiller David Brandt imports a Moore seeder from Ireland, the first known no-till drill in the U.S.

Valmont Industries develops center pivot irrigation equipment designed to cover corners, square and irregular-shaped fields.

Dealers in the Red River Valley of Minnesota and the Dakotas report a shop rate of $17.50/hour with a reluctance to raise it. By 2023, most shop rates are in excess of $140/hour.

New Holland is the first OEM to release a rotary combine (twin rotors) with its TR70.

Kinze Mfg. introduces its folding planter technology, leading the way to wider planters that farmers can move down narrow fields and bridges.

1976

Kinze introduces its 24-row, rear-fold planter frames, allowing no-tillers like Ohio’s Bill Richards to double planting capacity in one pass. “John Deere was selling planters by the unit at the time, so farmers could put their own planting systems together,” he says. The efficiency achieved from no-tilling with a 60-foot planter would allow Richards to expand up to 8,000 acres in the ’80s.

SprayTarget Co., Rosemount, Minn., develops the wet lime spreader.

EPA approves Roundup, providing farmers with new non-soil disturbing options for weed control.

Ag-Chem introduces a 5-wheel self-propelled ag chemical and fertilizer applicator, nearly twice the size of the original model to meet the needs of growers with larger acreages.

DICKEY-John creates new market for speed sensing on mobile vehicles via its radar ground speed sensor, which measured true ground speed independent of wheel slip or rolling radius.

1977

IH introduces its Axial-Flow (rotary) combine, which handles threshing and separation via a rotor and at significant productivity gains vs. the drum and straw-walker models. It is the first to be mass-produced.

Valmont produces the first linear center pivot irrigation system.

MacDon introduces the Hydro Mac self-propelled hydrostatic transmission windrower.

Versatile introduces the Versatile 150, the world’s first bi-directional tractor. The first “push-pull” tractor is marketed as a “number of self-propelled machines in one.” The seat and console of the tractor swivels 180 degrees within the cab, while offering full-time hydrostatic drive to all four wheels and articulated steering.

Howard and Brian Dahl introduce small grain air seeding equipment with their Concord air drill, the first company to feature row-by-row packing and precision depth control. It’s the first air seeder to place fertilizer below the seed while planting, along with changing seeding and fertilizer rates on the go.

1978

Hesston introduces the industry’s first “large square” baler, offering significant efficiencies over smaller bale sizes.

John Deere introduces its first commercially successful no-till planter, the 7000 series.

Cummins introduces the Constant Power Concept for 4WD tractors, giving farmers more tractive force under field conditions that run the engine below its rated operating speed.

JCB introduces the Loadall telehandler.

Orthman designs the disc stabilizer, a rigid disc with hydraulics that will pivot on command. This leads to the introduction of the Tracker, which was the industry’s first ground-engaging implement steering system.

Raven introduces the Sidekick Pro, the first speed-compensated, automatic rate control system. Its direct-injection system sets a new standard for chemical applications with unprecedented precision, savings, and safety while eliminating tank mixing and misapplication.

1979

Claas develops the first row-sensing, auto-pilot technology for combines produced for Ford. Fingers mounted on the header are directly connected to the combine steering system. The manufacturer also develops folding combine grain tank doors on equipment built for Ford.

Raven’s sprayer controller developments bring precision to pesticide application. It accurately measures the flow of pesticides with the ability to shut off individual sprayer nozzles.

Gleaner introduces the first 12 row 30-inch corn head.

1980

A “perfect storm” commences for equipment dealers, with 21% interest rates, a huge drop in farmland values and the grain embargo, recalls Paul Wallem. Sales of North American farm equipment fall 50% from 1979 as a result of the economic downturn, leading to a plummeting of dealership numbers over the next 6 years.

Monosem (formerly Advanced Technical Implement) introduces vacuum planters, a new method to accurately place seeds at a higher, more uniform plant population than with mechanical or air pressure systems.

Hydro Engineering is the first company to apply manure with a pumping unit to propel manure through a hose system for injection into the soil.

John Deere produces a 4-row cotton picker, the first in the industry. The unit increases operator productivity by 85-95%.

Washington’s Mort and Guy Swanson launch the Yielder No-Till drill, the first fertilizer placement drill with a paired row designed for no-till in the Palouse and Great Plains.

The Alfa Laval Rationmaster Feeding System (with use of a transponder for automatic data identification) allows dairymen to house cows as a group, yet feed them as individuals based on production, stage of lactation and body condition.

Haybuster introduces the balebuster that allows operators to grind and more efficiently distribute hay bales. It automates range feeding, bunk feeding, bedding, erosion control and odor control in wastewater lagoons.

Loral (AgChem) introduces Air Spread and AirMax boom-type, truck-mounted fertilizer spreaders with air-boom delivery as an option to spinner-type spreaders. The Air Spread was patented in 1984.

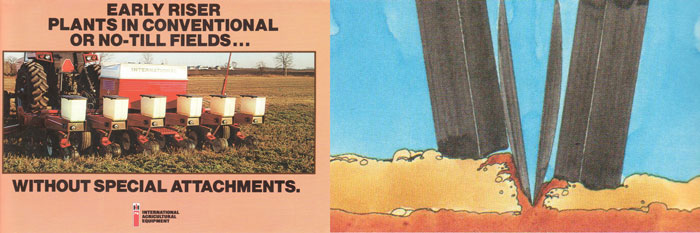

IH unveils the Early Riser 800 series planter, marketed as an “as-is” planter for minimum- or no-till, without requiring special attachments.

1981

Kinze introduces its double-frame planter for seeding corn or soybeans in 15-inch rows. By positioning planter tires between two toolbars, the front toolbar can be used for fertilizer while mounting side-by-side row units on the rear bar.

1982

John Deere’s annual revenues reach $3 billion under the leadership of William A. Hewitt, who took over in 1955 when the firms’ sales were $300 million.

KZCO introduces the Electra-Halt for anhydrous sprayer on-off control that uses a 12-volt DC electric “motorized full-flow ball valve” rather than electric solenoid valves.

1983

Kinze introduces its “push-type” planter row unit mounted to the front of its double frame toolbar. Allowing growers to “split the rows,” the Interplant system offers a precision alternative to seeding soybeans with grain drills for narrower row soybeans. Growers can plant corn in 30-38-inch rows with this planter, then quickly switch to 15-19-inch soybean rows by engaging the “push” units.

1984

North Dakota farmer Ardon Herman develops the Diamond disc blade to reduce breakage due to rocks. The diamond shape allows the unit to “float easily over rocks.” Summers Manufacturing, Maddock, N.D., manufactures the blade.

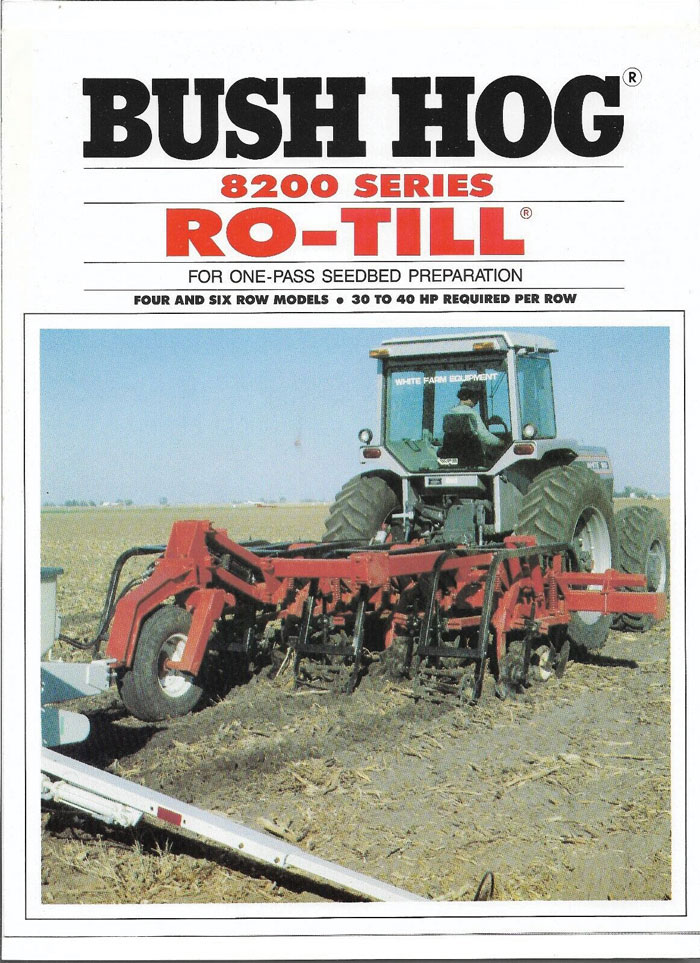

The Bush Hog Ro-Till (developed by Leo and Jerril Hardin in the mid-1970s and marketed in the South under the name of Brown-Hardin) hits the market. Marketed as “Precision Applied Tillage (PAT), it will be considered the forerunner of strip-till rigs. The row-till unit deployed a coulter, a parabolic ripper with heavy limiters to hold down the big chunks of soil, followed by discs and rolling baskets to form the ridge.

Tenneco purchases IH’s agricultural equipment division.

1985

Claas develops net wrap as an alternative to twine for round hay bales. It decreases hay losses and aids in retaining hay nutrition during storage.

The prototype of the Willmar AirRide self-propelled sprayer is unveiled. The new model fits the need for a North American-built, high-capacity, self-propelled, high-clearance sprayer. The unit featured a 100-foot boom, 118-horsepower engine, 4-wheel hydrostatic drive, and a convertible chassis to accept a liquid or granular applicator.

Case and IH merge to form Case IH.

The Kinze Twin-Line planter allows raising and rotating of the planter frame into a lengthwise transport configuration as narrow as 11 feet, 2 inches from the tractor seat.

Dealer business software becomes common and replaces the manually-intensive visi-record cards and similar practices. “Prior to then, parts managers worked late every night posting parts sales and stock order receipts on manual cards,” recalls Titan’s David Meyer.

Burndown herbicide options experience market expansion.

1986

Massey Ferguson introduces the first electronic lift control 3-point hitch as standard equipment on its tractors. It offers fast and precise control of height, draft sensing, rate of drop, as well as depth control to automatically maintain any pre-selected depth.

Ford buys New Holland and forms Ford-New Holland Inc.

Farm Equipment contributing editor Harold Halter notes that multiple-location dealerships in the U.S total about 2,750, and many are 3-5 dealer “chains.”

1987

Caterpillar introduces the “Mobil-Trac” rubber track system with its Challenger tractor line, the first tractor to use rubber tracks. It allowed travel of up to 18 mph without road damage and significantly reduced soil compaction.

Howard Martin, Elkton, Ky., files a patent for the first ground-driven row cleaner for no-till.

1988

Crary Air Reels are developed to evenly distribute grain at the combine head and improve harvesting efficiencies.

Case IH introduces the Magnum tractor, the first new machine from the combined engineering of IH and Case. By 2003, 100,000 of these tractors will roll off the assembly line in Racine, Wis.

Hesston introduces the first fully automatic round baler.

1989

Richard Follmer, owner of Progressive Farm Products in Hudson, Ill., invents the mid-mount, dual-placement strip-till toolbar, the first manufacturer to find commercial success in the strip-till sector.

Larry and Bill Matlack release the Stinger Self-Propelled Bale Stacker, which changes how farmers handle large bales and eliminates the need for multiple machines and labor to handle baled hay and straw.

1990

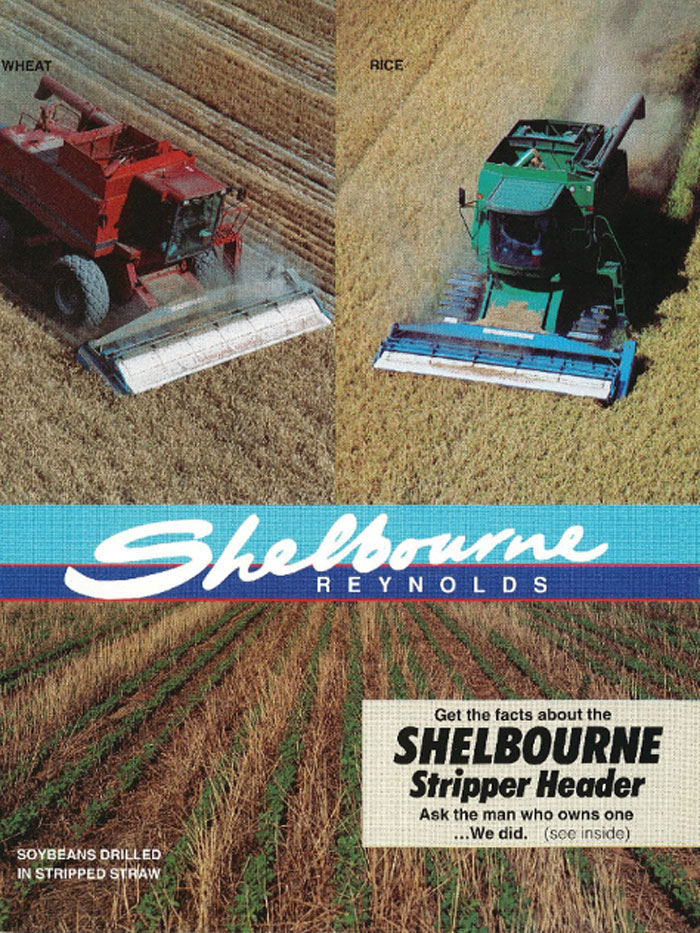

Two years after the SRI stripper-header was developed in the U.K., Shelbourne-Reynolds sells its first U.S. unit to farmers in Kentucky. Within 5 years, adoption surges as Western wheat belt growers see the benefits of stripped straw in their no-till systems.

AGCO is formed in the management buyout of Deutz-Allis from KHD, returning the manufacturing and distributing to the U.S. and offering equipment under the AGCO Allis and Gleaner brand names in North America. Dozens of manufacturers will be acquired as AGCO becomes the third largest producer of ag equipment.

Eugene Keeton, Jon Kinzenbaw and Harry Deckler develop the simple brush meter innovation that holds seeds in place and brushes away excess seed. With 90% accuracy, it allows soybean growers to use planters instead of drills.

1991

JCB introduces its high road speed equal-size tire tractor named Fastrac in Great Britain. The world’s first tractor with a full suspension system, it handles road speeds up to 35 mph.

Initial optical sensing research at Oklahoma State Univ. focuses on detecting and spraying weeds. At the same time, James Beck, a Northern California electronics engineer, develops the Patchen technology and in 1992 founds Patchen, a subsidiary of NTech. He then designs a spraying system integrating the technology. This integrated optical sensing becomes the basis for GreenSeeker variable rate fertilizer application system and WeedSeeker, which uses similar technology to selectively spot spray weeds.

1992

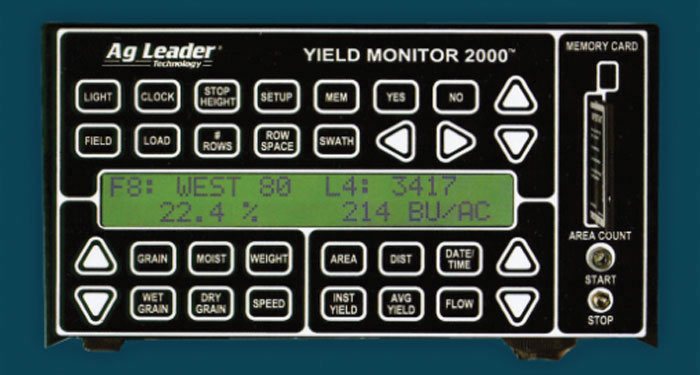

Ag Leader founder Al Myers releases the Yield Monitor 2000, the first accurate combine yield monitor, which was a significant achievement in what would become known as precision farming.

Satloc Inc. introduces the first GPS lightbar, initially designed for guidance in aerial applications. As the reliability of GPS receivers improved, the technology was adapted to ground-based applications.

Trimble develops real-time kinematic (RTK) technology. By adding a correction signal to the signals coming from GPS satellites, RTK allows extremely accurate moment-by-moment location updates while on the move and becomes invaluable for high-accuracy guidance of construction and ag equipment.

Yetter Manufacturing releases the Residue Manager in Coulter Combination, one of several iterations in the market as residue management needs were becoming understood.

1993

Howard Martin invents and patents the first spiked closing wheel for planters. The following year, he introduces the floating row cleaner.

Sunflower purchases the Best Grain Drill line from Best Mfg. of Jonesboro, Ark., bringing the company into the no-till segment.

AGCO purchases White-New Idea planters, hay tools and spreaders and its Coldwater, Ohio, manufacturing facility.

1994

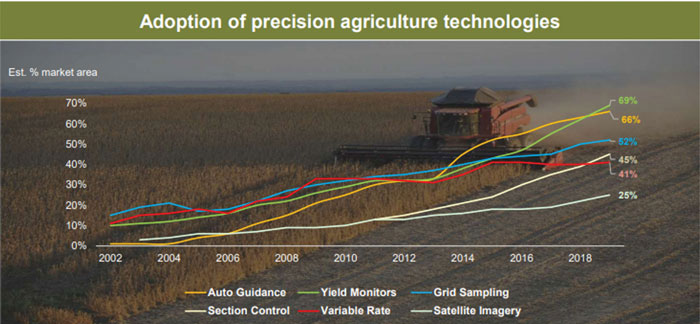

The precision age begins as farmers use GPS receivers to determine which areas need specific quantities of water, fertilizer and pesticides. Farmers synthesize this data with yield information, weather forecasts and soil analysis in spreadsheets. “Precision farming is said to have moved ag mechanization forward more than prior advances,” says Paul Wallem, “and merged new technology of the information age within a mature industry.”

Satellite technology is used in tracking and planning farming practices.

Tenneco exits the farm and construction equipment businesses with a public offering of shares in the newly-named Case Corp., which switched from branding its machines as Case International to Case IH.

Eugene Keeton files a patent for the Keeton Seed Firmer, an attachment to maintain effective seed-to-soil contact in no-till situations.

Hesston introduces the first self-propelled windrower using disc mower-cutting technology.

Pennsylvania no-tiller Steve Groff is the first North American farmer to build a cover-crop roller, emulating techniques learned from Brazilian no-tillers to reduce herbicide needs while using covers for weed control.

Patent is granted for Mattricks rubber track conversion system, the first to be released with a built-in suspension system.

1995

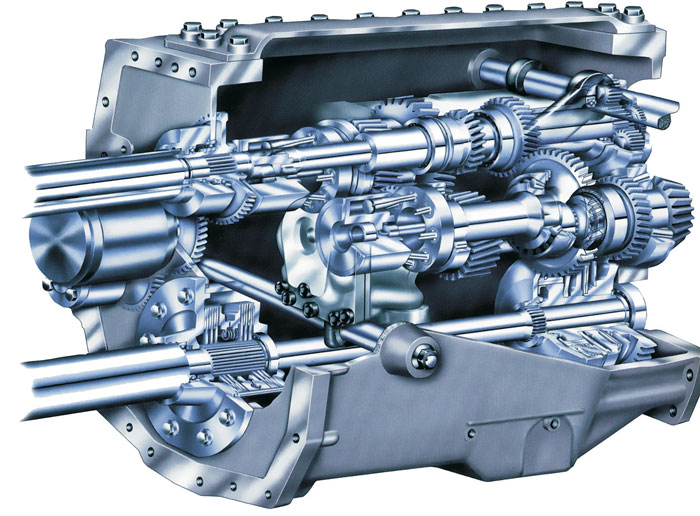

Fendt introduces the first continuously variable transmission, or CVT, tractor with its Vario launch. Developed by Fendt and Sauer-Sundstrand, the technology combines the infinite speeds of a hydrostatic transmission with the efficiency of a powershift by using a planetary gear set to split the engine output into a hydrostatic section and a mechanical section, eliminating traditional transmission gears.

Marion Calmer of Calmer Corn Heads in Alpha, Ill., develops the first 15-inch narrow-row corn head.

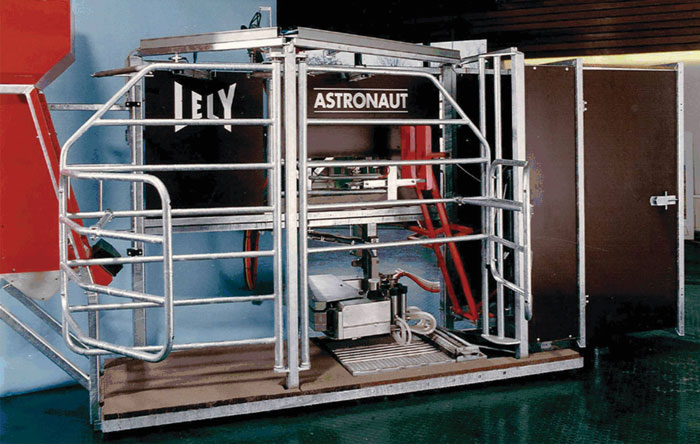

Lely introduces the first version of the Lely Astronaut milking robot. It would be regarded by some as the most important invention of the 20th century for dairy farmers.

Salford Farm Machinery Ltd., Ontario, Canada, introduces the “Wing Plow” to aid in introducing the popularity of soil conservation tillage.

GMO seeds begin to be commercially introduced into U.S. agriculture, increasing yields, lowering inputs and providing better profits.

1996

Monosem releases the first twin-row vacuum planter for peanuts. When it produced yield increases of 12-15% in Georgia, the company also develops twin-row cotton, corn and soybean planters. The twin-row configuration gives plants more room to grow, increasing yields and reducing inputs. The final design of the twin-row planter was patented in 2003.

John Deere launches its first production-grade GPS receiver, known as the GreenStar Precision Farming System. Their brochure predicted, “Information is your new crop!" Nicknamed "green eggs and ham," the receiver brought satellite control to farmers’ tractor cabs.

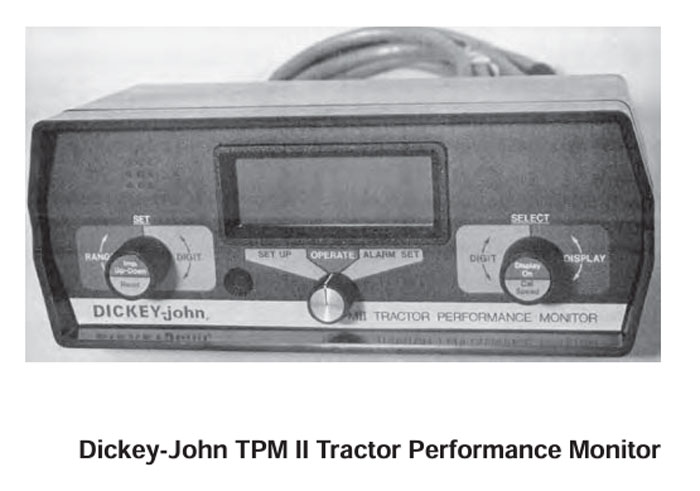

DICKEY-John couples its “radar-ground speed as true ground speed” technology with a drive-shaft sensor and to display to the farmer, true wheel slip functionality. Patented in 1988, the Dickey John TPM II tractor performance monitor is soon adopted by tractor OEMs.

1997

Equipment Technologies introduces its mechanically-driven Apache self-propelled sprayer.

Yamaha’s Rmax drone, a single-rotor helicopter with 4 gallons of spray tank capacity, is the first drone to be used for spraying, taking place in Japan.

1998

Developed by New Zealand ag engineers at Massey University, the Cross Slot planting system is introduced to the international market. Its no-till opener sows seeds into horizontal “inverted T” self-closing seed slots through virtually any amount of surface residue while avoiding hairpinning of residue and allowing the banding of fertilizer without seed burn.

Krone introduces the BiG M self-propelled mower conditioner in the U.S. It’s capable of cutting 30 feet of hay in one pass with a capacity of 40 acres per hour and merges the 30 feet into one windrow.

Brillion Iron Works in Brillion, Wis., tests a vertical tillage implement. It began selling the “Zone Commander” in 2000, considered the “first” vertical tillage tool.

Oxbo builds the first prototype double merger that led to “Hay-in-a-Day” and higher forage quality. Five years later, in 2003, Oxbo commercializes the first triple merger, branded as a MillerPro 310, that changed how alfalfa was windrowed for forage harvesting.

1999

The AutoFarm Agricultural Division of Novariant launches the first commercially available automated steering system for farm equipment using GPS.

CNH Global N.V. is formed following the merger of Case and New Holland. Following the divestiture of factories and product lines to gain approval from government authorities, a common platform manufacturing approach is followed with the brands retaining their own identities and features.

2000

Ingersoll becomes the first company to manufacture and market boron alloy steel disc blades in North America. The steel provides longer life, less wear and improved performance in tillage equipment.

2001

AutoFarm/Novariant announces the first successful implementation of sub-inch steering for a tractor with a front-mounted implement.

Salford develops the Residue Tillage Specialist system for high-speed, no-till farming.

2002

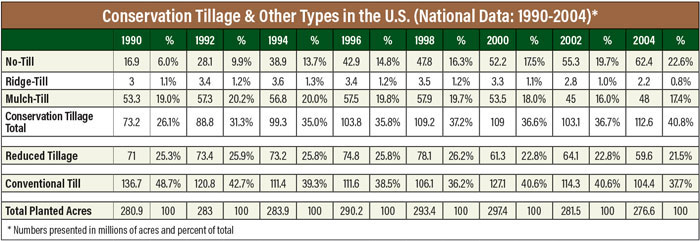

With 55.3 million acres in the U.S., no-till surpasses mulch-till to become the predominant “conservation tillage” method, according to the Consenuation Technology Information Center. No-till and conservation tillage practices grow from 26.1% of planted acres to 40.7%, while conventional tillage falls from 48.7% to 37.7%.

Jeff Moyer of the Rodale Institute designs the U.S.’ first U.S.-built cover crop roller-crimper. Several shortline manufacturers will release them to the market in the soil health trend.

2003

Canada-based Montgomery Industries develops AutoBoom boom height control system to accurately control spray booms during high-speed spraying. Raven acquires Montgomery in 2005.

2004

Claas introduces a 40-foot grain header for combines.

Fendt introduces the Tractor Management System, an electronic software interface between the engine and transmission to control engine speed relative to ground speed. It maximizes power to the ground and fuel efficiency.

Claas introduces its first self-propelled, large-scale mower for cutting a 45-foot swath in one pass.

2005

Arizona’s John A. McClure is granted a patent for a guidance system for directing a towed implement behind a tractor using Differential Global Positioning Systems. Rights are assigned to CSI Wireless Inc. of Alberta, Canada.

MacDon introduces the first flexible draper header, increasing combine productivity when harvesting soybeans.

2006

In partnership with Orthman Manufacturing, AutoFarm introduces AFTracker, the first implement steering system based on RTK GPS.

Richiger introduces the “Flexi-Grain Storage System” for loading and unloading grain stored in polyethylene bags.

Case IH launches the Module Express 625, the first commercial cotton picker with the ability to build modules while harvesting for significant time, labor and capital savings.