Sprayer vs Tractor Tire Difference

- What is the difference between a Row Crop Sprayer Tire vs Tractor Tire (Void Ratio / Tread Depth / Tread Design / Standard vs VF / Load Speed Index) and why is it important for producer to match the correct tire for the application?

- AG TIRE TALK KEY TAKEAWAYS YOKOHAMA: “Like so many segments in the tire industry, sprayer tires have become very specialized—it’s really the opposite of a one-size-fits-all market…we’ve seen amazing response to the unique hybrid tread pattern—industrial-style tread blocks arrayed in an R- 1-style curved pattern to enhance traction and self-cleaning…”

- MICHELIN: “Compared to a tractor tire, the stability of a sprayer tire is of utmost importance. Sprayer tires are specifically designed to handle the constant pitch and sway of a machine loaded with liquid, in addition to the dynamic loads, with a very high center of gravity.”

- TRELLEBORG: “A major difference between a tractor tire and a sprayer tire is tread depth…the term tractor is derived from the Latin word “trahere”, which means “to pull.” Consequently, a tractor tire needs to pull whereas a sprayer tire needs to float on the ground and provide some traction, but flotation and stability are its main contributors.”

- BKT: “Standard tires for tractors and tires for sprayers can be the same sizes, which can lead to some confusion…farmers should be careful to make sure that the tires used can carry the weight of the load and are rated for the speed.”

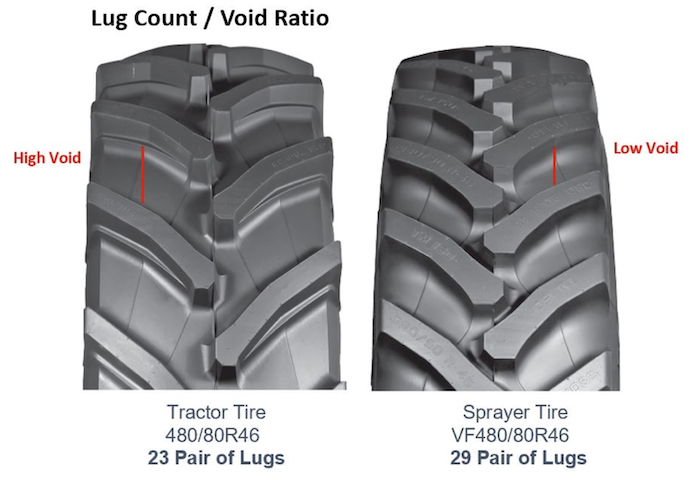

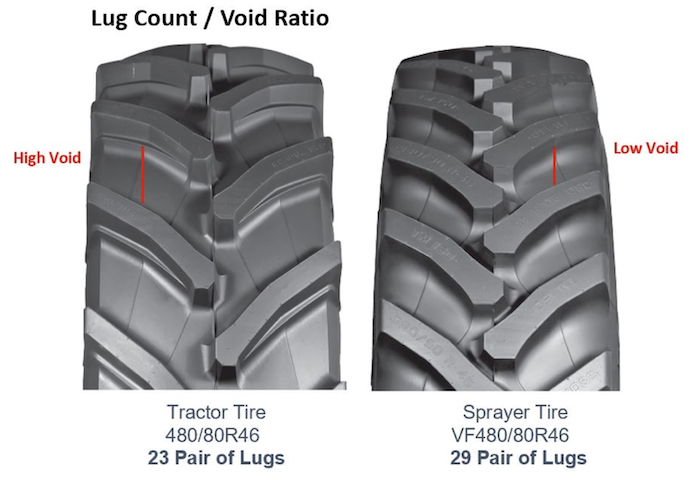

- CONTINENTAL: “A high void ratio means there is more gap in the tread than rubber contacting the driving surface…This is a benefit for self-cleaning efforts and soil compaction, common to tractor tires. A lower void ratio provides good traction, a smoother/more comfortable ride and provides better stability, common to sprayer tires.

- PRECISION INFLATION: “Which is better, Standard, IF or VF? If soil compaction, flotation and soil health is important, then IF or VF are the best choice for sprayer and tractor high load requirements.”

- MAXAM: “In sum, as a general rule the following sets a sprayer tire apart from a tractor tire: lower void ratio, higher weight carrying capacity, shallower tread, and higher speed rating.”

-

Trelleborg Wheel Systems

Norberto Herbener: OE Applications Engineer

Let’s start this AG Tire Talk with some basic definitions:

A tractor is a vehicle designed to provide a high tractive effort (pulling force) at slow speeds in order to haul a trailer or machinery used in agriculture or construction. The term tractor is derived from the Latin “trahere”, which means “to pull.”

Agriculture sprayers are complete spray systems engineered for generating pressure to drive spray fluid from a tank out to the sprayer’s nozzle(s) to crop or soil. Sprayers are most often used for the administration of water, insecticides, pesticides, herbicides, and fertilizer. Sprayer tires need to pass over the soil and crops consequently high traction is not necessarily needed. High speed is also a necessity. Obviously these two definitions are very different, consequently they will need very different tires.

WORKING SPEED The need for higher productivity in the world’s agricultural industry drives the professional and extensive use of modern sprayers. New generations of fertilizers and self-propelled high-powered sprayers require a significant upgrade in tire technology to cope with new, high demand applications, through high load, stability, and reduced fuel consumption. Current sprayers and spreaders normal working speed is between 25 and 30 mph. Transport speeds are up to 45 mph. Sprayer specific tires must at least have a speed symbol of “D” (40 mph). TREAD DEPTH Another major difference between a tractor tire and a sprayer tire is tread depth. Sprayer tires normally have an R-1 tread design, where as a tractor tire normally has an R1-W tread design. The main difference is an R1-W lug design is 20% taller than an R-1 and assures a higher traction transfer from the tractor to the ground. Below details the difference: The advantages:- Tractor tire is designed with the deeper tread. It will provide more traction and pulling power.

- Sprayer tire is designed with the shallower tread. It will provide more stability, less heat build-up and a smoother ride on the road.

Blaine Cox National Product Manager–Agriculture, Golf & Turf Yokohama Off-Highway Tires America, Inc. Like so many segments in the tire industry, sprayer tires have become very specialized—it’s really the opposite of a one-size-fits-all market. There are some common denominators. For instance, applicators need to protect crops, whether it’s by running between the rows of standing crops or by minimizing soil compaction, especially if they are running on wet, compaction- prone soils. They need precise, reliable steering, without the squirrely wobble that many older-style tires can create. Good roadability is an absolute must to cover as many acres as possible in a day—that’s critical to maximize income or ROI, and also to react with protection when the crops need it. And applicators and managers have come to recognize the value of a smooth ride to help maximize productivity. We've seen amazing response to the unique hybrid tread pattern—industrial-style tread blocks arrayed in an R-1-style curved pattern to enhance traction and self-cleaning. Applicators comment on the steady, stable ride of the 363 in the field and over the road, which is a benefit the low rubber-to-void ratio. Meanwhile, the large number of biting edges from all those tread blocks provides outstanding stability on slopes. Choosing the best sprayer tire takes a little consideration, but it’s time well-spent. The right tire can help maximize the productivity and impact of an application rig at times when the stakes are high and the crop—or an applicator’s bottom line—are at stake. BKT USA, Inc. Dave Paulk: Manager Field Technical Services Although tractor tires and sprayer tires are used interchangeably at times, there are major differences concerning the two applications. Standard tires for tractors and tires for sprayers can be the same sizes, which can lead to some confusion. An example is a 380/90R46, a popular size used on both tractors and sprayers. The 380/90R46 is made in a standard tire for tractors, and IF and VF versions for sprayers. A standard BKT tractor tire, the RT945 380/90R46 159A8/B is rated to carry 9,640 lbs at 58 psi at 30 mph. A BKT sprayer tire VF 380/90R46 AGRIMAX SPARGO is rated to carry 13,760 lbs. at 61 psi at 40 mph. There is quite a bit of difference between the standard and VF in speed and load carrying capacity. Most modern self-propelled sprayers are heavy and run 40 mph carrying a lot of liquid weight. They are driven on the highway to get to the fields. The tires used for this application must be able to handle the speeds, loads, and the highway with some stability. There are smaller self-propelled sprayers on the market that require smaller tires. These smaller sprayers don’t have the heavy weight and run the high speed of the larger sprayers. Again, farmers should be careful to make sure that the tires used can carry the weight of the load and are rated for the speed. Some sprayers are made as pull behind sprayers. Generally, the tanks on these sprayers are smaller and carry less fluid. Tires are not as critical on these as self-propelled sprayers. There are a variety of different sizes and tread designs used (R-1, R-1W, and R-3). The sprayer will only travel as fast as the tractor is pulling it. There is no torque applied to the tires, as they are free rolling. The tires must be rated heavy enough to carry the load. IF and VF tires are used for general farming as well as being used on sprayers. In this application, less air pressure can be used to create a larger footprint and minimize soil compaction. In a sprayer application, the weight carrying capability and higher air pressures are needed. Maxam Tire International Greg W. Gilland: Business Development & Ag Segment Manager If you compare tractor or harvester designed tires to sprayer tires, there are specific items to consider that are uniquely inherent to each farming application: Self-propelled sprayers will operate both at a slow 5 to 10 mph average in the field and at an average 40 mph when roading from field to field requiring a D rubber compounding. Due to heavy tank Loads in cyclic spraying operations, tires must be rated for heavy axle loads in terms of load index or load per tire. As sprayers operate when crops are in full bloom and therefore require high crop clearance, the resulting tire sidewall or tire air chamber is smaller which demands stronger structural casing materials and rubber compound designed for high air pressures equal to the load at hand. In addition, due to the constant roading of sprayer from field to field, tires designed for this application will have more lugs per tire to reduce the lug to void ratio increasing the amount of rubber contacting the surface ensuring improved stability under load and speed.

Choosing the best sprayer tire takes a little consideration, but it’s time well-spent. The right tire can help maximize the productivity and impact of an application rig at times when the stakes are high and the crop—or an applicator’s bottom line—are at stake. BKT USA, Inc. Dave Paulk: Manager Field Technical Services Although tractor tires and sprayer tires are used interchangeably at times, there are major differences concerning the two applications. Standard tires for tractors and tires for sprayers can be the same sizes, which can lead to some confusion. An example is a 380/90R46, a popular size used on both tractors and sprayers. The 380/90R46 is made in a standard tire for tractors, and IF and VF versions for sprayers. A standard BKT tractor tire, the RT945 380/90R46 159A8/B is rated to carry 9,640 lbs at 58 psi at 30 mph. A BKT sprayer tire VF 380/90R46 AGRIMAX SPARGO is rated to carry 13,760 lbs. at 61 psi at 40 mph. There is quite a bit of difference between the standard and VF in speed and load carrying capacity. Most modern self-propelled sprayers are heavy and run 40 mph carrying a lot of liquid weight. They are driven on the highway to get to the fields. The tires used for this application must be able to handle the speeds, loads, and the highway with some stability. There are smaller self-propelled sprayers on the market that require smaller tires. These smaller sprayers don’t have the heavy weight and run the high speed of the larger sprayers. Again, farmers should be careful to make sure that the tires used can carry the weight of the load and are rated for the speed. Some sprayers are made as pull behind sprayers. Generally, the tanks on these sprayers are smaller and carry less fluid. Tires are not as critical on these as self-propelled sprayers. There are a variety of different sizes and tread designs used (R-1, R-1W, and R-3). The sprayer will only travel as fast as the tractor is pulling it. There is no torque applied to the tires, as they are free rolling. The tires must be rated heavy enough to carry the load. IF and VF tires are used for general farming as well as being used on sprayers. In this application, less air pressure can be used to create a larger footprint and minimize soil compaction. In a sprayer application, the weight carrying capability and higher air pressures are needed. Maxam Tire International Greg W. Gilland: Business Development & Ag Segment Manager If you compare tractor or harvester designed tires to sprayer tires, there are specific items to consider that are uniquely inherent to each farming application: Self-propelled sprayers will operate both at a slow 5 to 10 mph average in the field and at an average 40 mph when roading from field to field requiring a D rubber compounding. Due to heavy tank Loads in cyclic spraying operations, tires must be rated for heavy axle loads in terms of load index or load per tire. As sprayers operate when crops are in full bloom and therefore require high crop clearance, the resulting tire sidewall or tire air chamber is smaller which demands stronger structural casing materials and rubber compound designed for high air pressures equal to the load at hand. In addition, due to the constant roading of sprayer from field to field, tires designed for this application will have more lugs per tire to reduce the lug to void ratio increasing the amount of rubber contacting the surface ensuring improved stability under load and speed.

In sum, as a general rule the following sets a sprayer tire apart from a tractor tire: lower void ratio, higher weight carrying capacity, shallower tread, and higher speed rating.

David Graden: Operational Market Manager – Agriculture When considering tires for a high clearance self-propelled sprayer, it is vitally important that you understand your needs and the limitations of the tires you choose. Your top two considerations should be safety and efficiency. Compared to a tractor tire, the stability of a sprayer tire is of utmost importance. Sprayer tires are specifically designed to handle the constant pitch and sway of a machine loaded with liquid, in addition to the dynamic loads, with a very high center of gravity. As these machines continue to get larger and carry heavier loads, the tires also must meet or exceed these demands. Unfortunately, the width of these tires is not able to grow unless our row spacing widens. This, in turn, has forced the industry to move towards IF/VF tires. These tires can carry an additional 20% to 40% more load, while maintaining the necessary widths to fit down a row without damaging crops on either side. In short, unless recommended by your tire dealer for very specific circumstances (i.e. reducing harmonic vibration by fitting sprayer tire with higher lug count to tractor), I highly recommend sticking with the manufacturer’s intent and using sprayer tires for sprayers and tractor tires for tractors, ensuring safe trouble free optimum performance. Precision Inflation, LLC Ken Brodbeck, VP of Technology 1. Speed rating: i. Sprayers should be D speed rated since sprayers’ top speed is 30+ mph. ii. Most tractors top speed is 30 mph or less, B rating covers to 30 mph. 2. Tread pattern: i. Sprayers have heavier and more tread bars than tractors to handle high pressures during road transport. ii. Tractors can have fewer, but deeper tread depth for better soil penetration. 3. Load Rating: i. Sprayers have load ratings equal or greater than tractors but are usually narrow tires. This requires high pressures and a heavy tire body. ii. Tractors use wider tires and run at lower pressures; this makes a more flexible tire body. Inflation system technology also improves the performance of IF and VF tires. In fact, every radial tire works better with inflation system technology to optimize the maximum performance of your farm. PrecisionInflation.com

Michelin Ag

Related Content:

Choosing Best Tire Construction for Application, Improving Carbon Sequestration with Tire Selection and Air Pressure, Operator Tips to Reduce Soil Compaction