AG TIRE TALK KEY TAKEAWAYS

MAXAM: “The biggest driver of combine-harvester tire choices will be dictated by the type of crop and farming practices.”

Yokohama TWS: “Small grain crops stems are weaker reducing the possibility to damage the tires- Super Singles are the predominate choice of tires vs. a Dual Setup.”

BKT: “Super singles work well on combines in dry soil and have better flotation in moist and wet soil than duals.”

ASCENSO: “Generally speaking, if the correct field CFO air pressure is maintained with VF load tables on the largest dual fitment, then we believe Straddle Duals will make the case of the best overall option.”

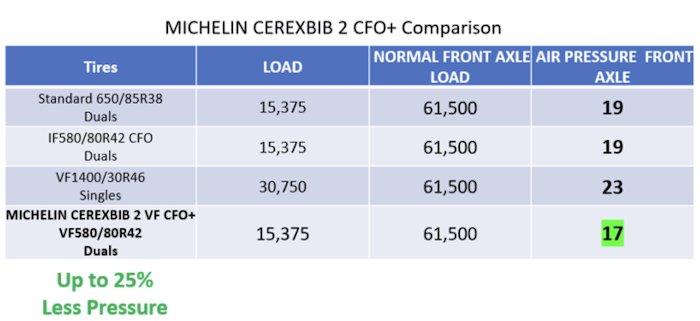

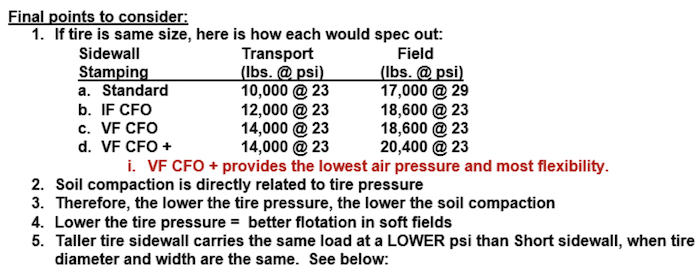

MICHELIN: “The easiest way for producers to compare tires in regard to soil compaction is evaluating Field Air Pressure, choosing the product with lowest inflation pressure able to carry the load at the speed they are traveling.”

PRECISION INFLATION: “Soil compaction is directly related to tire air pressure; therefore, the lower the tire pressure, the lower the soil compaction: VF CFO+ provides the lowest air pressure and most flexibility.”

YOKOHAMA OFF-HIGHWAY TIRES AMERICA: “In most situations except very wet soils, properly inflated tires can deliver equivalent traction and minimize soil compaction just as well as tracks, while eliminating the extra weight, maintenance and expense of the bogie wheel assemblies required for tracks.”

Maxam Tire International

Greg W. Gilland: Vice President Global Agriculture

The overall key market drivers for tires or tracks for harvester application are listed below:

- Farmers or growers own an estimated +88,000 combines from Class 6 to Class 10 harvesters in North America.

- Currently custom harvesters account for about 3000 to 5000 harvesters operating across both the US & CA.

- Ability of the tires to resist stubble or tread damage.

- Ability to operate at lower tire pressure to increase flotation and to reduce overall soil compaction.

- Utilization of a track in heavy or wet soils to avoid rutting or creating soil waves as the tire transmits the torque.

- Ability to deliver traction and grip to lower machine slip resulting in increased productivity.

The introduction of VF tire technology with the additional 40% more load-carrying capacity per tire has helped to rewrite the load-carrying rules for either singles or duals. This technical advantage, without changing the tire sizing, is allowing OEMs to move to a new larger capacity, heavier, and increased powered combine harvesters to deliver the harvest faster.

Michelin Ag

David Graden: Operational Market Manager – Agriculture

This is an excellent topic! Often, I get asked this question by producers looking to minimize their down time during the harvest season, first and foremost. Second to that, they want to reduce their machine’s impact on the soil, especially in wet conditions.

Dual Set-Up

Our answer for both of these questions, in addition to reducing fuel consumption, lowering maintenance, minimizing the total cost of ownership, and maximizing total efficiency is the Michelin CerexBib 2 VF CFO + in Dual Set Up. Using this tire specifically designed for harvester application, I have seen some of the world’s largest combines harvest through standing water and saturated soils on a set of straddle dual VF 580/85R42 CerexBib 2 tires.

VF

With regard to the impact on the soil, these tires are VF (Very High Flexion) technology, which allows them to operate at 40% less air pressure than standard tires, or up to 40% more weight at the same air pressure as standard tires. This means they have a massive tractive capacity due to a larger footprint and, in turn, more lugs on the ground. As an added bonus, this large footprint significantly improves in-field fuel efficiency. As these tires work through the ground, they are able to roll over the soil instead of push through the soil, creating less resistance.

CFO

Tires are also rated for Cyclical Field Operation, or CFO, a 33% load bonus given to specially designed and constructed VF tires while that tire is being used in a “cyclical” condition and operating at or below 10 mph. “Cyclical” means that the load applied on the tire is constantly changing during the normal operation of the machine on which the tires are fitted; the tires are engineered and built to handle the fluctuating load, including when it spikes. The best example of this application is a combine with live load during harvest!

Tires are also rated CFO +, meaning they add another 9.5% to Cyclic Load for the Field. In short, CFO + rating allows a producer operating at or below 10 mph to increase load under cyclical conditions by 42.5% over Standard VF Tire.

Duals vs Super Singles

Unfortunately, many folks think large single/floater tires always offer the best floatation. Where that may be true, in some cases, it doesn’t guarantee floatation and traction. In wet conditions, these wide tires can pack with mud and completely lose their tractive capacity. As these tires spin, they can create massive ruts, compact your soil and dig themselves into a hole, having a major negative impact on your yield for years to come.

Higher Air Pressure = More Soil Compaction

The easiest way for producers to compare tires in regard to soil compaction is evaluating Field Air Pressure, choosing the product with lowest inflation pressure able to carry the load at the speed they are traveling. Why?

Air pressure reductions equate to fewer Pounds per Square Inch transmitted to the soil. In other words, pressure to soil is a linear equation to Tire PSI, so as you reduce air pressure in the tire, you are reducing pressure to the soil and reducing soil compaction.

Below Study illustrates, comparing our CerexBib 2 VF CFO + tires to the competition:

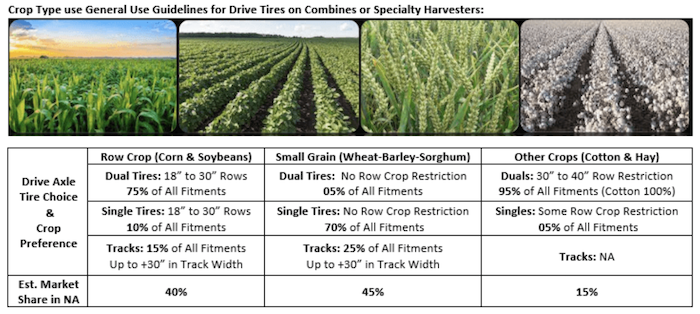

Chris Neidert: AG Marketing, Training and Development Manager – North America When looking at the US combine market needs and preference, we can divide them in two large groups based on the crop they harvest, and business model and it will explain the “why” of their choices.Winter Crops – Custom Harvesters

Many Custom Harvesters will harvest wheat and small grain. They start in Texas/Oklahoma and work their way all the way up to the border with Canada as the maturity of the crop moves north. Super singles is the predominate choice of tires vs. a dual setup. The main reason would be ease of transport from one customer’s field to the next, as most of these combines are transported on trucks and the outer duals would have to be dismounted requiring additional equipment to handle them. Small grain crops stems are weaker reducing the possibility to damage the tires. Popular sizes are 800 or 900 cross-sections that can handle the weight of most small grain headers.Midwest Farmers

They will be mainly combining corn and soybeans. In general the farmer is the owner of the combine with possibly a Custom Harvester, but in a neighborhood area. Different as with small grains, corn and soybean maturity is more concentrated in time not allowing for custom harvesters to have a long harvest run. These combines are used most often times locally and not transported on trucks. Here a dual fitment is the setup of choice. Using duals, the grower will enjoy better lateral stability in the field and when roading the combine. Many times the header stays on the machine even when roading. This dual configuration provides additional load capacity for the combine, especially when fitted with corn headers that are heavier than a soybean header. Most popular dual combine sizes vary between 520, 580 and 620 cross-sections.Stubble Damage Possibly Reduced

Running duals will have less stubble damage because the tires can possibly go in between the rows and help minimize stubble damage. Super singles will have to travel over the stubble and additional stubble damage can occur.

RUBBER TRACKS

Plus:- More Flotation in Mud

- Narrower than Tires

- $120,000 Premium Over Tires

- Can be Rough Ride on Pavement

- Heavier than Tires

- More Maintenance on Rollers & Joints

- Transport causes Significant Heat Increase

BIG SINGLE TIRES

Plus:- Only 2 Tires to Maintain

- Faster Road Speed & Runs Cooler than Tracks

- Lower Cost than Tracks

- With Tire Inflation System, tire PSI can be Lowered in Muddy Soils = More Flotation

- More Expense to Replace versus Duals

- If 1 tire Damaged, Lower Replacement Cost

- Big Duals are More Stable on Hillsides

- Wider than Super Singles

- Faster Road Speeds & Runs Cooler than Tracks

- Lower Cost than Tracks

- With Inflation System, tire PSI can be Lowered in Muddy Soils = More Flotation

- 4 Tires to Maintain versus 2

Nick Phillippi, Technical Support and Product Development, Ascenso Tires North America

Recommending a fitment for a specific harvester is difficult from a 30,000-foot level, whether being a manufacturer or wholesale distributor. Then when you talk about all the variables to consider- soil types, moisture condition, stubble issues, transport width, tracking down the row, local tire dealer support, customer preference, and others it gets even tougher. Not only duals vs super singles vs tracks but what about tread type, tread depth, availability of product, and even the ROI?

But as far as recommendations, the best person to make this decision is ultimately the producer and the local tire professional in that area. They both know the details of that farm’s use and priorities, weather history, type of crops, and other key details.

Generally speaking, if the correct field CFO air pressure is maintained with VF load tables on the largest dual fitment, then we believe Straddle Duals will make the case of the best overall option. Until we have onboard air in agricultural equipment, we really can’t truly give the farmer the best in field and on-road performance. Lowering and raising pressure manually is just not an option that is practical in the real world.

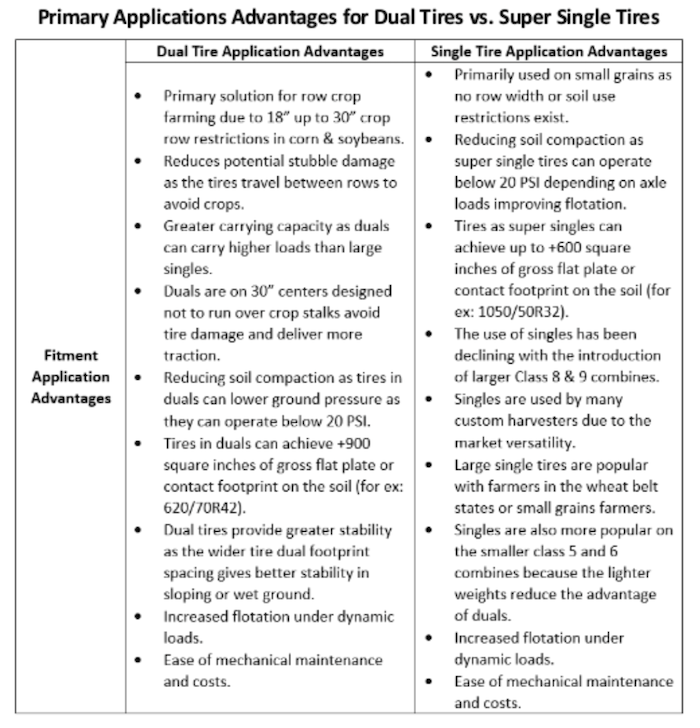

BKT USA, Inc.Dave Paulk: Manager Field Technical ServicesDualsDuals work well on combines in moist to dry conditions. Duals can help carry more load and help distribute that load over a wider area to minimize soil compaction with the correct air pressures. Combines and grain carts carry cyclic loads and can take advantage of IF-CFO and VF-CFO technologies that tires offer. This allows the tires to have more weight carrying capacity at slower speeds (field speeds) without changing air pressures. In wet conditions, duals are more likely to cause ruts and collect mud between the duals.Super Singles

Super singles work well on combines in dry soil and have better flotation in moist and wet soil than duals. In moderately dry soil, super singles have a much wider footprint to distribute the weight of the machine and load and minimize soil compaction. Some super singles are IF or VF-CFO tires and can carry larger loads at slower speeds. Super singles do not cause ruts as bad or as deep as duals in wet and muddy soil. Depending on the type of soil, super singles may not clean out as well because of the width of the tires.Tracks

In wet and muddy conditions, tracks seem to work well because of the width and length to distribute the weight of the machine and load over a much larger area. They provide good traction and good flotation. They can cause ruts in wet and muddy dirt, but generally not as extreme as duals. Since they are wider and longer, they float over the dirt better. In moist and dry dirt, all three setups work well. With the right tires and air pressures, all three can be used to minimize soil compaction and provide good traction. When compaction can be neutralized, crop yields improve.Roading

Pneumatic tires seem to wear better and smoother on the highway than tracks when moving between fields, especially with long distances. Depending on the track setup and brand of undercarriage, tracks speeds can be a little slower while roading than a combine using tires.Maintenance

On tractors with pneumatic tires, there is a tire, a wheel, and a hub. Although tires and wheels can be expensive when needing to be replaced, there isn’t much maintenance required. As long as the wheels are kept clean and the tires run at correct air pressure, they are usually problem free. Tracks have many more moving parts. They have drive wheels on positive undercarriages, or guide wheels and idlers on friction undercarriages. Tracks are somewhat more expensive to take care of but can provide good flotation in wet dirt and good traction in dry soil.Yokohama Off-Highway Tires America, Inc.

Blaine Cox: National Product Manager—Agriculture, Golf and TurfThere are a number of variables to consider when deciding between duals and large singles on combines, ranging from the size and capacity of the machine to the soil type, moisture levels, and even the width of local roads. In most situations except very wet soils, properly inflated tires can deliver equivalent traction and minimize soil compaction just as well as tracks, while eliminating the extra weight, maintenance and expense of the bogie wheel assemblies required for tracks.Tires are also more fuel efficient than tracks, and are significantly better on the road—they ride smoother and last longer when roading compared to tracks.Dual configurations can spread the load over a larger surface, which is obviously effective for reducing soil compaction force. However, if you are using the combine in gumbo, sticky mud or muck, the space between the duals can fill up with mud, reducing overall performance. Also, for many operators, the result can be a combine too wide for roading or even storage in some sheds, and, of course, more tires means more cost.As an alternative to duals, our Alliance Agriflex 372 IF (increased flexion) tire comes in a 1250/50R32 size that provides more than four feet of width on each tire for massive surface area in a single-tire configuration.High-capacity tires—in dual or single configurations—can be a high-performance, cost-efficient alternative to tracks. Since inflation pressure is such an important part of performance, it’s worth considering also investing in a central tire inflation system (CTIS), which allows the operator to adjust inflation pressure on the go. That ensures a low, compaction-minimizing inflation pressure on the field and a quick switch to a higher pressure for better roading. Optimizing inflation pressure ensures optimal performance, and can add significantly to tire life, making CTIS an investment that pays itself off very quickly.