Editor’s Note: This Q&A originally appeared in AG Tire Talk to provide answers that farm equipment dealers have about farm tire technology. This series features a trending question followed by an abridged version of the answers. For the complete answers, check out www.agtiretalk.com.

Question: What are your unique proprietary naming conventions, what specific tire attributes do they identify, and what features and benefits do they offer producer?

Michelin Ag, David Graden: Operational Market Manager – Agriculture

Over the years, Michelin has invented numerous Ag tire technologies, several of which are a global standard today. These technologies were designed specifically to improve tire performance, enabling producers to increase yield and operate more efficiently at a lower total cost of tire ownership.

The Michelin “Self Cleaning Hinge” is probably the most basic concept. This “hinge” is seen on our Agribib and Agribib 2 tractor tires. The idea is to reduce mud adhesion to a tire by allowing air between the mud and the tire casing. Think of a suction cup to a table, but slip the corner of a sheet of paper under the edge of that suction cup.

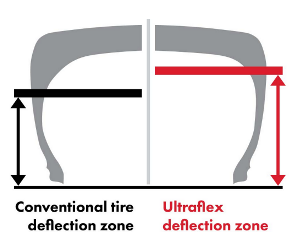

Probably the greatest Michelin Agriculture invention is UltraFlex technology, which is a global standard today. Michelin invented UltraFlex in the late 90’s/early 2000’s. Very basically, this is also known as IF (Increased Flexion) and VF (Very Increased Flexion). It changes the flex point in the sidewall of a tire that enables that tire to carry either 20% or 40% more load at the same air pressure as a standard tire or run at 20% or 40% less air pressure to carry the same load as a standard tire.

A little lesser known technology is our Stubble Shield rubber compounds. This was designed with the North American farmer in mind. As GMO products became the norm, producers needed a tire that could stand up to the new extreme stubble- Michelin Stubble Shield tires handle this extreme with ease.

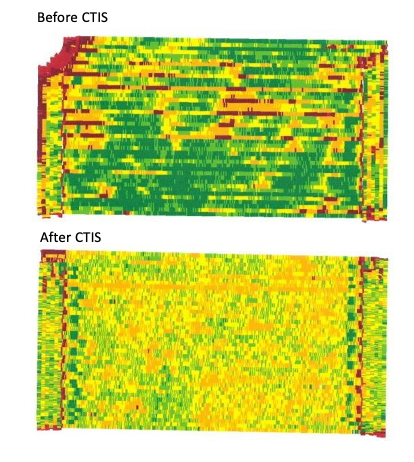

We have also recently begun stamping many of our IF/VF tires with “Air Systems Ready” on the sidewall. This all started when Michelin acquired a central tire inflation company, PTG. As we began to integrate PTG into Michelin Agriculture, we realized we needed to be sure our tires could handle the constant increase and decrease in air pressures while working, along with the ultra-low air pressures. Whereas all Michelin Ag tires will handle this abuse, we rigorously tested our IF/VF tires to be absolutely certain, as these tires give the greatest benefit when coupled with a central tire inflation system (CTIS). “Air Systems Ready” DOES NOT identify non-standard load inflation tables.

Trelleborg Wheel Systems, Norberto Herbener: OE Applications Engineer

Blue Dimension™ – Solutions for better sustainability

At Trelleborg we believe that the benefits of our solutions stretch beyond functionality and business performance. Whenever possible they should also contribute to better sustainability. This is what we call Blue Dimension™ – Solutions for Better Sustainability.

Trelleborg’s innovative tires offer low compaction with a wide footprint that distributes the weight of the tractor evenly. The tires run lightly on the earth, minimize compaction of the soil and protect its fertility, while optimizing fuel consumption – significant benefits to both the farmer and the land.

Blue Dimension™ benefits:

- Higher crop yields. Up to 18 % wider footprint than the market average.

- Lower fuel consumption: Up to 12 % less fuel and additional 860 hours life time (360 hp tractor) more than the market average.

- Reduced CO2 emissions by 6% compared to standard tires.

Inter-Lug Terracing

The inter-lug terracing is an advanced design at the base of the lug which helps with mud ejection, maximizing the self-cleaning capability of the tire.

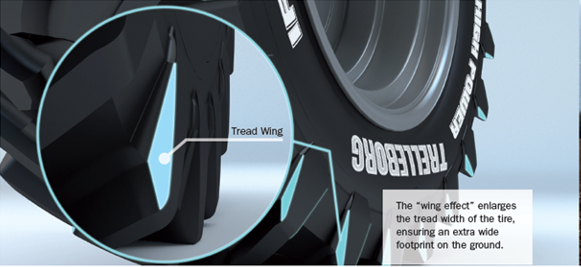

Wing-Effect

Enlarges the tread width. A wider tread means less compaction, better traction, more even wear and a smoother ride.

ProgressiveTraction®

The unbeatable performance of the Trelleborg ProgressiveTraction® is a testament to its innovative double edge lug. While its two points of anchorage boost grip, the stronger base of the lug significantly reduces vibrations, wear and fuel consumption. In addition, the double edge lug also enhances the inter-lug terraces of the Trelleborg TM tires, maximizing the self-cleaning capability of the tire.

The grip performance is enhanced by 2 anchor points. The extra lug acts as an additional terrace on the unique Trelleborg TM tread profile, enhancing its great self -cleaning capability and increasing the efficiency of the lug.

Continental Agriculture North America, Dana Berger, Ag Business Development Manager at Continental Commercial Specialty Tires

The simplicity and complexity behind Continental’s proprietary naming focuses on making the products stand out. From the various exciting technologies, to the sidewall of our allround agriculture tires, Continental tries to reach customers by describing different attributes of our products.

N.flex technology

Continental’s unique way of providing our agriculture radial tires with flexibility for impact without permanent deformation. The nylon cords are wound tightly to provide a robust structure, while also allowing extreme elongation. This advancement helps our tires adjust to the various surface and climate conditions they encounter and prevents flat spotting for the next day of work.

d.fine technology

Defining the need for farmer comfort, high traction and stability in the field and better mileage on the road, was key in the development of Continental’s agriculture radial tires. The challenge was met with the introduction of d.fine technology, which created a deep lug overlap and allowed smooth linkage between the tread block and tire base. This technology will also decrease vibration and therefore can create a quieter experience, when on the road.

Tractor85 and Tractor70

Continental allround agriculture radial tires follow a simple naming structure related to their aspect ratio. This ratio, as a percentage, is relevant to the sidewall height divided by the width of the tire. The Tractor85 has an aspect ratio of 85%, while the Tractor70 has an aspect ratio of 70%. The larger aspect ratio [85%] meaning our Tractor85 has a taller sidewall, than the Tractor70.

CombineMaster & TractorMaster

The term “Master”, in Continental’s CombineMaster and TractorMaster, expresses the pursuit to offer advanced technologies to the agriculture market. Both tire lines are part of Continental’s portfolio of radial agriculture tires, adding to the allround standard Tractor85 and Tractor70 tires. The advanced tires introduce Continental’s d.fine technology and the CombineMaster receives a single wire hexabead, for ease of mounting with a strong seal to the rim.

Maxam Tire International, Greg W. Gilland: Business Development & Ag Segment Manager

Our radial agricultural tires are designed to deliver a simple, yet effective range of tires grouped by aspect ratio (tire tread width versus sidewall height) and size to meet current as well as future equipment evolution. Provided below is the MAXAM agricultural offering or nomenclature (tire sizing) conventions:

- AGRIXTRA 85: Tires that have “80” or “85” (as well as standard sized tires: 18.4R38) in their sizing

- AGRIXTRA 70: Tires that have “70” in their sizing or have “lower aspect ratio”

- AGRIXTRA 65: Tires that have “65” in their sizing or have “super low aspect ratio”

- AGRIXTRA XL (Extra Large): Tires for high horsepower tractors or harvesters with “70 & 65” aspect ratios

- AGRIXTRA H (Harvesting): High volume tires for harvesters or floaters (spreader) applications

- AGRIXTRA N (Narrow): Narrow applications tires with “90 or 100” aspect ratios for tractors or sprayers

- FLOTXTRA (“Float-extra”): Steel constructed tires for high load or speed implement or tanker applications

MAXAM radial agricultural tires have been developed with the load and speed capacity to meet current market needs and as well with the capability to address future market applications. In addition, we are designing VF or “Very High Flexion” tires within each product group to engage current and future high load or high-speed equipment evolution.

BKT USA, Inc., Dave Paulk: Manager Field Technical Services

Listed are some unique proprietary names used by BKT:

The AGRIMAX FORCE is an IF rated tire designed for tillage, haulage, and harvesting operations. This tire is designed for high horsepower tractors (250HP and above) and harvesters. The ratings include IF and IF-CFO for heavier load carrying capacities. They can also run at lower air pressures to minimize soil compaction.

The AGRIMAX FORTIS tire is designed for soil tillage and haulage operations for the most modern tractors. This tire has excellent traction and is designed to carry heavy loads at 40 mph.

The AGRIMAX SIRIO is a high-speed tire developed for high performance tractors. This tire is designed to run at speeds up to 45 mph. Some sizes are IF rated to carry heavy loads at lower air pressures. It is designed for both transport and soil tillage.

The AGRIMAX SPARGO tire is designed with VF technology to carry heavier loads at standard air pressures for reduced soil compaction. It also has a 40-mph speed rating. This tire can be used on row crop tractors and high-speed sprayers.

The AGRIMAX TERIS tire is designed for harvesters, cotton pickers/strippers and grain carts. Most sizes are CHO or IF-CFO rated to carry heavy loads in cyclic operations and minimize soil compaction. It has special sidewall protection and reinforced shoulders to resist punctures.

The AGRIMAX V-FLECTO tire is designed as a VF rated tire to carry heavier loads than the standard and IF tires at standard air pressures. The V-FLECTO can be used in row crop applications and where soil compaction is a concern. Soil compaction is minimized by being able to carry heavier loads at lower air pressures. The V-FLECTO can reach speeds up to 40 mph. This tire also features the Narrow Rim Option (NRO) that allows it to be mounted on standard wheels.

BKT has an extensive product range of over 2,700 high-performance specialty tires.

SPECIAL FEATURE: Central Tire Inflation System Naming Conventions:

Precision Inflation LLC, Sally Brodbeck, President

Precision Inflation Unique Naming Conventions

CTIS (Central Tire Inflation System) technology has been widely used in agriculture in Europe to allow farmers to quickly and easily inflate tires up to an optimal road pressure to handle the speed, weight and heat on a hard surface. Then the tire pressures can be reduced On The Go for optimal field pressures to increase yield and reduce compaction.

Certain terms unique names used by Precision Inflation, LLC come directly from PTG in Germany. Here are just a few:

RDS – This is an abbreviation of a very long German word that means “Tire Pressure Control System.” Precision Inflation uses RDS to refer to an Inflation System where the rotary union is installed on the bar axle behind the tires so there are no overhanging lines.

Airbox – This is a name for an inflation system where the rotary union sits outside the spindle and the airlines are visible. This system works well on tractors, sprayers and implements.

Dual Line Technology – No one wants flat tires! Our Dual Line Technology uses a check valve in each wheel and two air lines to move air in and out of the tires. One small line opens the valve to allow air in and out, and the other supplies a large volume of air to the tire. Once the system is finished changing to the preset pressure, the check valve closes sealing all the air in the tire. This prevents wear on the lines and the seals and provides optimum safety and durability of our systems.