Editor’s Note: This Q&A originally appeared in AG Tire Talk to provide answers that farm equipment dealers have about farm tire technology. This series features a trending question followed by an abridged version of the answers. For the complete answers, check out www.agtiretalk.com.

Question: In the 100+ HP Tractor Segment, how does grower properly ballast a tractor, how often should process be done, and what is impact on tire traction and soil compaction?

BKT USA Inc., Dave Paulk, Manager Field Technical Services

There are several important reasons for using ballast on tractors. Tractors and combines often have to add weight to accommodate horsepower imbalances. Adding weight where required will improve traction and reduce slippage. Managing the ballast and tire inflation pressures can maximize traction, minimize compaction, increase the life of the tractor drivetrain, and increase productivity. Adding ballast to a tractor is an effective way to get the power of the tractor to the ground.

Alliance Tire Americas, James Crouch, National Product Manager — Agriculture

It takes a certain amount of weight for a tractor to transfer one horsepower of energy from the engine to the ground — figure 130-140 pounds per PTO horsepower for front-wheel assist (MFWD) tractors and 95-110 pounds per PTO horsepower for 4WD tractors. That often requires a little extra weight, which is called ballast.

More from the series…

If you have too little weight, your tractor isn’t working as efficiently as it should. Your slip increases and you just aren’t getting all the power you paid for when you bought that machine. If you have too much weight, your soil compaction increases and your fuel efficiency can be reduced. And if the weight is poorly balanced, you can lose efficiency and experience power hop.

Continental Agriculture North America, Harm-Hendrik Lange, Agriculture Tires Field Engineer

The right ballasting for tractors depends on many factors. Generally speaking though, the tractor should be as least ballasted as possible, if the ballast is not really needed. Each pound that needs to be moved forward needs energy during acceleration, creates more energy during braking, creates a longer stopping distance on average, and creates more soil compaction during operation on wet soil conditions.

However, there are certain applications and operations where ballasting is needed and reasonable. Those situations can be clustered in two main topics:

- To prevent an unbalanced situation on the tractor, e.g. when working with a heavy front loader and adding ballast in the rear hitch or on the rear axle, or when using a front ballast as a counterweight for a heavy rear hitch. With higher loads on one end, the maximum speed may be reduced for both the axle and the tires. Ballasting can help counter this unbalance to lessen the need to lower speed.

- To make the tractor heavier to transmit more force to the soil, e.g. for implements with lower working speed like a plow where the operational speed is less than 6 mph. Here, all the engine power is transformed into a high torque on the axles, which means high forces in the contact patch between tire and soil. In this instance more weight means better grip for force transmission to the ground.

Michelin Ag, David Graden, Operational Market Manager – Agriculture

Depending on the machine’s use, improper ballasting will cost more time and money than most would expect.

On the flip side, however, adding wheel and/or suitcase weights or a ballast box, you could achieve proper weight distribution for your machine and its horse power. As a direct result, you would gain better fuel economy, ideal slip, less soil compaction, a better ride, and increased yield.

We strongly encourage producers to work towards proper weight distribution of their machine. In many cases this can be costly; however, we can work with the current weights on the machine and air pressures to transfer as much torque as possible. Each Michelin field representative is equipped with a set of tractor scales and the knowledge to calculate proper weight distribution to efficiently transfer the machine’s maximum torque to the ground. This should be an all-encompassing solution to maximize traction (which reduces slippage and soil compaction), torque and fuel efficiency, minimize power hop and road loping, and overall productivity.

Maxam Tire International, Mark Turner, Senior Product Marketing Manager, Agricultural Tires

Correct ballasting for field work is entirely about ensuring that slip rates are kept in the best window that allows optimum tractive efficiency and drawbar pull.

Typical recommended rates of slip are 10-15% for 2-wheel drive tractors (2WD) and 8-12% for 4-wheel drive (4WD) or mechanically assisted 4WD tractors (MFWD).

Too much weight can, in addition to using more fuel, mean not enough slip resulting in soil structure damage and possibly over stressing of transmission components.

Too little weight results in slip rates that are too high which can mean longer time is required to finish the work and can also lead to excessive fuel consumption.

It is worth remembering that soil compaction in the top 12 – 16 inches (30-40cm) is primarily a function of the tire pressures, below this level, compaction and structural soil damage is related to total vehicle weight. It is easy to see why correct ballasting that allows efficient traction and enables good speed across the ground is a major contributor to soil health.

The best type and weight of the ballast should be assessed for each implement used and should be added to the front and / or rear to ensure optimum weight distribution between the 2 axles.

Trelleborg Wheel Systems, Norberto Herbener, OE Applications Engineer

The first point is the correct weight and weight distribution that the tractor must have to transfer power with efficiency. As a rule of thumb, a correct weight ratio begins considering that between 100-120 pounds per horsepower of the tractor is needed. Therefore, a 300 horsepower tractor should weigh approximately 30,000-36,000 pounds. This weight will allow the tire lugs to penetrate the soil deeply enough to create optimum grip and acceptable tire to soil slippage. The best way to increase a tractor’s weight is by adding solid ballast to the axles or on the tractor chassis. Adding weight by filling tires with liquid ballast is not recommended as it reduces the ability of the tire to flex, can cause corrosion of the rim and creates additional inertia on the wheel when moving.

The second point is weight distribution. Once the correct tractor weight is defined, the distribution should be 50% on the front axle and 50% on the rear axle for 4WD. For a front wheel assist tractor, the distribution should be between 40-45% on the front axle and 55-60% on the rear axle. If the design of the implement creates a high load on the rear axle (reducing the load in the front axle), the ratio on front wheel assist tractor should be closer to 45-50% in the front and 50-55% in the rear. For 2WD tractors the front axle should have between 25-35% of the total load. It is very important to measure this weight per axle with calibrated scales (individual per tire or per axle, like on a grain elevator scale). An incorrect weight distribution can create issues like “power hop” where the front axle is too “light” (losing traction) and the rear axle is overloaded creating excessive “grip.” When a customer has power hop issues, it’s a clear indication that the total tractor weight and/or weight distribution is not correct for the application. This issue can be fixed by correcting the ballasting without the need to change tire size or tire ratio.

The third point is tire inflation pressure. Each tire’s size load capacity changes with inflation pressure changes –the higher the inflation pressure (more air volume in the tire chamber) the higher the load capacity.

CEAT Specialty Tires Inc., Jim Enyart, Technical Manager

Ballasting has been utilized for equipment functionality and stability as well as transferring power to the ground. Many types of ballasting materials have been utilized including rocks, soil, cast iron, water, calcium chloride, magnesium chloride, beet juice and more. These options have advantages as well as disadvantages. Some are relatively cheap while others are expensive. Some are environmentally friendly and others not so much. Some have lots of versatility while others are not. The choice of ballasting materials includes many factors but the most critical aspect of adding ballasting is how much weight to add and where to place these materials.

The first critical factor is knowing the engine horsepower of the tractor and the axle weights. Ideally, the weight per horsepower ratio should be between 100 and 120 pounds per horsepower. The lighter weights are more desirable and efficient as long as there are no performance issues such as stability or wheel hop. Increased weight ratios may be utilized to reduce slip which increases efficiency especially in demanding applications.

The weight distribution is extremely important. For 2-wheel drive tractors the weight distribution should be 30% on the front axle and 70% on the rear. MFWD tractors should have 35% on the front and 65% on the rear axle. Four wheel drive tractors should carry 60% on the front and 40% on the rear axle. Allowances for additional weight due to attachments should also be calculated into your weight distribution adjustments.

Titan International, Inc. (Manufacturer of Titan and Goodyear Farm Tires), Scott Sloan, Ag Product Manager/Global LSW

Proper ballasting can be complex but there are many resources available online or even your tire dealer to assist with ballasting tractors. The end game is trying to minimize tire slippage when you head to the field. Between inflation pressure and ballasting you will have your tractor performing at its most efficient. Most manufacturers shoot for slip in the 8-15% range. Anything over that is extremely noticeable and not very efficient. rowers feel they are sending a lot of money with little return though the exhaust stack. Most growers I deal with do prefer to be running in the 3-9% range.

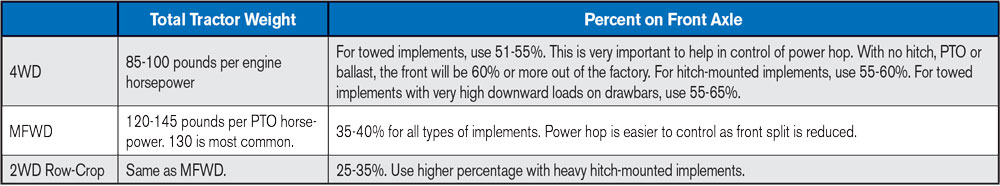

So a quick fast approach to get in the ballpark for example on a 4WD depending on the application to have anywhere from 85-125 pounds per rated horsepower. For instance, a 4WD rated at 500 horsepower should be in the 50K to 55K total weight with 55%-60% on the front and 40%-45% on the rear. Not only is the total machine weight important, the distribution of that weight is just as critical. The table below is a quick reference to proper ballasting and weight distributions.

Firestone Ag, Bradley J. Harris, Manager, Global Agricultural Field Engineering

To get the most efficiency from a tractor it’s critical to have the proper amount of ballast and the weight appropriately split between the front and rear axle. There are some general rules that tractor and tire manufacturers use when helping customers set up tractors used for fieldwork. These guidelines help make sure there is enough weight on the tractor to transmit the horsepower to the ground, while making sure the tractor is not so heavy that horsepower is wasted trying to move the tractor. To properly set up a tractor, a short five-step procedure can be used:

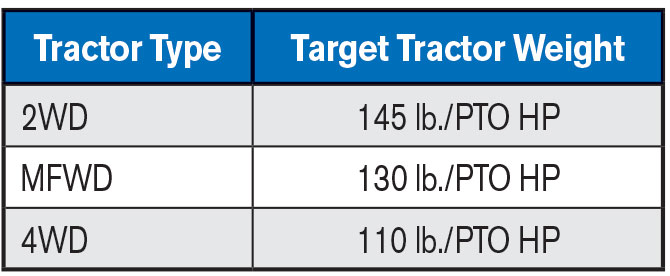

Step One: Identify the horsepower rating of the tractor. For 2WD and mechanical front wheel drive (MFWD) tractors, the rated PTO horsepower is used. For 4WD tractors, the tractor’s rated engine horsepower is used. For the following calculations, we will use a MFWD tractor with 180 PTO horsepower being used to pull drawbar implements as the example.

Step Two: Calculate the target total tractor weight. The target tractor weight is based on the driveline of the tractor. Chart 1 has the target weight per horsepower for the three types of tractor.

Example Target Tractor Weight: 180 PTO HP x 130 lb./PTO HP = 23,400 lb.

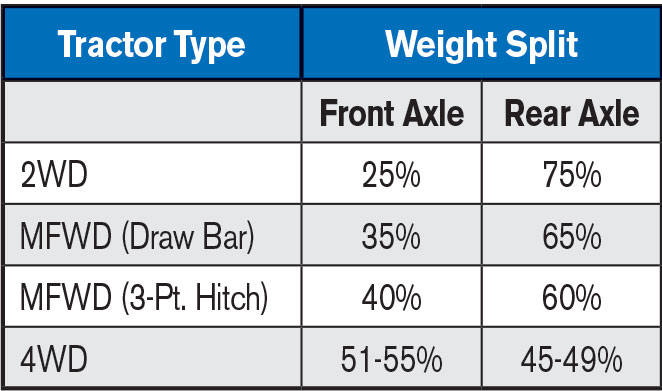

Step Three: Calculate the recommended front and rear axle weight splits. Just like determining the tractor weight, the weight split is based on the tractor type and how the tractor is being used. Chart 2 has the target weight splits, according to standard industry practices. Keep in mind these are all target weight splits with no equipment mounted to the tractor. If 3-point equipment is being used, make sure there is enough weight on the front axle to keep the front axle on the ground.

Example Tractor Weight Splits:

Front Axle 35%: 23,400 lb. x 0.35 = 8,190 lb.

Rear Axle 65%: 23,400 lb. x 0.65 = 15,210 lb.

Step Four: Weigh the tractor. The most accurate way to find the weight is to use a scale. This can be done on a platform scale or on portable scales. When weighing a tractor, make sure all the fluids are topped off, especially the fuel tank. If for some reason the tractor cannot be weighed, please consult your operator manual or your equipment dealership. With most newer tractors, the manufacturer has a procedure to calculate the tractor weight based on the base tractor and the weight package on the tractor. If aftermarket items (Saddle tanks, loaders, etc.) are added to the tractor, I recommend using a scale.

Example Tractor weighed with portable scales:

Front axle: 10,150 lb.

Rear axle: 15,500 lb.

Step Five: Add or remove weight. In most cases a tractor cannot be ballasted to the exact target weight outlined in Chart 2. In the example, the target front axle weight is 8,190 pounds, but it weighed 10,150 pounds. Let’s assume the example tractor has 6 front suitcase weights. Since the front axle weight is heavier than the target weight, we would remove the suitcase weight and re-weigh the front axle. Even though the suitcase weights are 100 pounds, they add 130 pounds to the front axle because the weights are in front of the axle. When the weights are removed, the tractor is weighed and the new front axle weight is 9,370 pounds.

Step Six: Set the inflation pressure of the front and rear tires. Now that the front axle and rear axle weights are known, we can use the tire inflation tables to look up the minimum inflation pressure required to carry the load. To help customers with setting correct pressures, most tire manufactures have free tire inflation pressure calculators on their websites or as an app. On FirestoneAg.com, there is a new inflation pressure calculator to help determine the recommended inflation pressure. With these calculators, all the customer needs to do is select the type of equipment being used, select the tire setup (singles, duals, triples), enter the tire size, and input the axle load. The calculator will determine the minimum inflation pressure required to carry the load. In this example, the front tires were 420/90R30 used as singles. The minimum inflation pressure to carry the 9,370 pounds is 17 psi. The rear tires were 480/80R46 used as duals. The minimum inflation pressure to carry the 15,500 pounds is 12 psi.

Future Topics

- Rubber Tracks vs. Tires

- How to Reduce Road Lope in Sprayer Application

- Tire features to improve traction, reduce operator fatigue, and improve yield

- What to look for in a Radial AG warranty

- How to Choose Best Load Speed Index