The environment a person works in can have a big impact on their attitude and their performance. The same goes for customer experience. An outdated and crowded parts department, for instance, does little to foster a good relationship between your parts staff and customers.

“As our customer base has transitioned to be more technologically knowledgeable, more informed on products and pricing, and having higher expectations from their dealers and manufacturers, we wanted to take a step in meeting that expectation by creating a relationship driven, high-quality and professional environment for our customers,” says Clay Parris, general manager of Medlin Equipment, a Case IH dealership in Charleston and Sikeston, Mo.

In an age of consolidation, a dealer modernization and improvement project is one way to communicate to your customers that your business is here to stay. “Our remodel was done to assure the community and the customer base that Bowling Green Tractor was here to stay and to give more efficient service to those that want to do business with us,” says Bob Schuckenbrock, manager of Bowling Green Tractor, part of Quincy Tractor, a 5-store New Holland dealer in Missouri and Illinois.

Customer Experience

Medlin Equipment is in the middle of a complete makeover, including the showroom, front offices, break room and parts counter. Co-owner Renea Medlin has taken on the dealership renovation as a personal project. “She has taken our customer and office areas out of the traditional hardware-store style and into a rustic/industrial modern vibe. We’ve worked closely with Julie Crawford, the retail environment services manager for Case IH, who has played a major role in the designing and planning our new showroom,” says Parris.

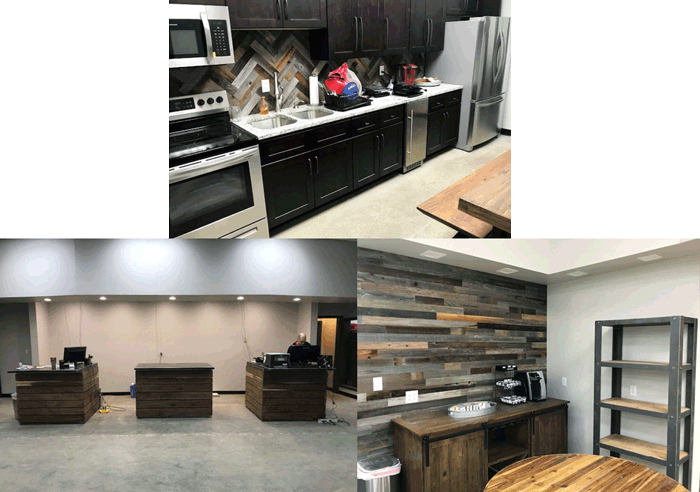

Medlin Equipment’s renovation project has taken on a modern industrial feel, and includes (l-r) a fully equipped kitchen for staff and events, new parts “islands” and a customer hospitality center with a coffee and refreshment bar.

The dealership removed the old gray, rectangle parts counter and are replacing it with three “island-style” stations that are accented with dark-stained barn wood. Parris says the new stations will be more customer friendly and provide a more open environment. A customer hospitality center with seating, coffee and a refreshment bar were also added.

“Instead of having hardware and parts displayed on our showroom floor like we previously did, we are considering featuring a small Farmall tractor or Kubota model on our floor, as well as having apparel displays with outerwear, boots and various other retail items,” Parris says.

Other updates include an new conference room for meetings and events and fully equipped and modern kitchen/break room that will serve both the employees and customer needs. All of these areas were painted and now have updated fixtures, flooring and ceilings.

“To speak more specifically to the dealership modernization, we are replacing some of our old hard-copy printed product literature with mounted flat-screen television displays that will showcase product details, point of purchase marketing, promotions and discounts, and other customer-focused topics. We are downsizing our filing and paper storage systems and replacing them with digital databases and computerized storage systems,” Parris explains. “On our parts counter islands, our computer monitors will be mounted on swivels to make it easy for parts personnel to walk customers through what parts they will need in an engaging and hands-on manner.”

Parris says there’s one recurring theme in all the improvements the dealership is making. “We want our customers to feel welcomed, comfortable and impressed by the level of excellence at which Medlin Equipment operates. We have by no means accomplished this completely, but we believe that this is a step in the right direction for creating a relationship-driven and excellence-focused environment,” he says.

Better Work Environment

In 2015, Quincy Tractor began a 3-stage renovation of its Bowling Green store. The first stage was building a new 11,900 square foot service shop, including a 20 x 40 foot hanger door and an 18 x 24 foot roll-up door, says Schuckenbrock, who describes the new shop as “a mechanic’s dream.”

The shop also features a mounted lift for lawnmowers, two overhead cranes with hoists, three 15 foot Big Ass Fans, a dedicated tool room, a lunch room and a new office for the service manager. The changes have helped the shop to become more efficient. “The shop is now able to handle enough equipment that when one tractor is waiting for parts the mechanic can tear down the next one. There is Wi-Fi in the building now so mechanics can access the internet at their work stations,” he says.

In 2015, Quincy Tractor renovated its Bowling Green, Mo., location. The New Holland dealership added a 11,900 square foot service shop with a 20 x 40 foot hanger door and an 18 x 24 foot roll-up door. The showroom and parts department were updated in stage 3 of the project.

Stage 2 connected the new shop to the old building with a 70 x 25 foot connection. This part of the building is used for receiving parts and storage. It also includes 2 restrooms and the electronics room, Schuckenbrock says.

Finally, stage 3 involved completely remodeling the old 6,000 square foot building. With the renovations service, parts, sales and bookkeeping are all located close to each other. “This part involved replacing all the tin and insulation, tearing out old offices and building new ones, moving all parts and bins to their new location and running new wires for the phone and computers, We did all this while keeping the doors open for customers,” Schuckenbrock says.

He adds that the improvements have made the dealership a clean, bright place to work with plenty of room. “This overhaul has greatly improved the attitude of the employees and their perception of where they work. This alone helps bring in more business when they talk to the customer with an up beat attitude,” he says.

“The showroom and parts counter is now a welcoming sight for customers when they walk in. The sales offices are bigger and more organized, the bookkeepers have no more steps to climb, the conference room is enormous compared to what was here before and with the inferred heaters, spray foam insulation, new tin and windows the utility bills have lowered substantially.”

Schuckenbrock says customers have taken notice of the improvements as well. “Not a day goes by when someone isn’t commenting on how nice the place looks and what a change it is from what was here before. There is more business coming through the door. Everyday people see that the investment has been made and it is here to stay and they are more willing to do business here,” he says.

Improving the working environment was one of the main reasons Monroe Tractor, a 12-store Case IH and Claas dealership in New York and New England, renovated its Adams Center, N.Y., store. In 2017, the dealership invested in a $1 million improvement project that added 8,000 square feet of service bays and 2,400 square feet in the parts department and showroom, says Adams Center store manager Jim Munroe.

Monroe Tractor updated its Adams Center, N.Y., store in 2017. The $1 million project included an additional 8,000 square feet of service bays in the shop and a 2,400 square foot addition to the parts department and showroom.

“Our original shop was designed when equipment was smaller, and we needed more efficient flow on the floor. The facility now has two large overhead doors instead of one,” he says. “We are in ‘snow country’ so most of our 10 technicians are indoors for the winter months and the old space was cramped for space.”

Part of the renovation included updating the lighting to include more natural light. “Happier workers have better morale,” Munroe says.

During the excavation, they had to hammer out a lot of rock. Monroe Tractor carries a line of rock crushers, so they handled a lot of the stone crushing themselves and expanded the equipment yard and parking areas. Munroe says this was important for two reasons. “First, in the winter we need room to push and store snow. And second, we eliminated much of the grass on the display yard, which tended to be inconvenient due to the amount of care necessary to keep the yard looking presentable,” he says.

Changing with Your Customers

Originally built in 1973, Hillsboro Equipment in Hillsboro, Wis., has seen some additions over the years with minor improvements, throughout the building. But in 2017, the dealership took on a complete overhaul of its sales, parts, accounting and showroom areas. Jacob Olson, sales and advertising for the 3 store John Deere dealership, says they moved the location of the offices and improved the parts counter and showroom area. The project also involved relocating the main entrance to the center of the building and reconstructing the exterior of the building.

In 2017, Hillsboro Equipment updated its nearly 45-year-old facility. The project included relocating the main entrance to the center of the building and restructuring the exterior of the building.

“We felt that our customer base had changed so we needed to do that as well. The old building restricted us some in making changes. For example, ceiling height was limited and we were able to raise the ceiling over portions of our showroom and not others,” he says. “We opened up the sales and accounting offices with more windows. We improved lighting throughout with all LED. All the old paneling went out!”

Hillsboro Equipment also added exterior buildings for additional storage for large equipment, and a larger show was built to better handle repairs on the larger equipment.

Hillsboro Equipment’s renovations also included a complete overhaul of its parts, sales, accounting and showroom areas. The offices were relocated and the parts department and showroom were upgraded with a modern design.

Whether it is just small updates or a complete renovation, most facilities need some level of work every several years, dealers say. “We feel that every 2-3 decades most infrastructure tends to need modernization. We want customers to know that we are willing to invest in ourselves in order to serve them better today and in the future,” Munroe concludes.