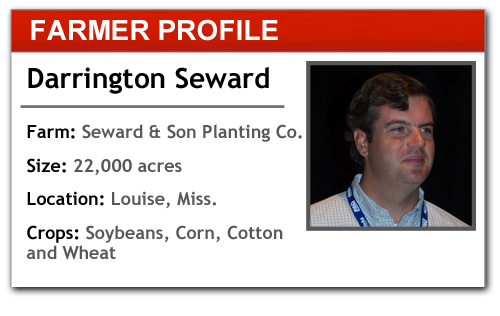

Darrington Seward, managing partner at Seward & Son Planting Co. and Seward & Harris Planting Co., knows all too well the importance of staying on top of work in progress on the 22,000 acres they farm in a 4-county radius near Louise, Miss.

“We go through $50,000 of inputs per hour in the spring and we harvest $50,000 worth of crops per hour in the fall. We need real-time data access to be most efficient,” he says.

The heart of the farms’ precision farming system are John Deere 2630 monitors and StarFire receivers on each piece of equipment. “We rely on the dealer’s RTK signal. In the past, we had 900 mHz base stations that we mounted to posts in the field, but over time, the posts would settle and we’d lose accuracy,” Seward says.

“We went to base stations mounted on grain legs, but needed a more consistent signal. The dealer’s 450 mHz signal is far more accurate than the 900 mHz signal we were using.”

Points of Pain: Signal Loss and Software Compatibility

While the dealer’s RTK signal is more accurate, it can go down from time to time. This can be a major problem for Seward and his expansive farming operation, especially at peak times of the year.

“We sometimes have to call our dealer and alert them, or they might catch it if their field techs notice it went down,” he says.

The operation needs a highly accurate signal because they run very wide equipment — 45 foot wide cotton hippers and 60 foot wide planters. They plant corn in 30 inch rows and cotton is planted in 30 inch rows with a 2-and-1 row skip to help control boll rot.

“The accuracy is good enough to allow the planter to plant on top of the row across a pass and a half of the hipper and we don’t end up with any guess rows either,” he says.

The Orthman Tracker 4 guidance system on the hipper has active and passive GPS control, Seward says. The hipper has 4 big coulters with a wheel angle sensor that takes readings from a StarFire receiver mounted on the hipper and talks with the passive guidance system on the tractor also to maintain sub-inch accuracy, Seward says.

In addition to maintaining a strong RTK signal, machine compatibility is another critical part of Seward’s operation. But transferring data isn’t as seamless as Seward would like at this point.

“The 2630 monitors are a beautiful product, but they don’t readily talk with other systems,” he says. “We have more than 300 fields, and using John Deere’s APEX software to transfer that data is too cumbersome.”

To move data between equipment, they use Ally Precision’s FieldLynx to tap into the 2630 monitors’ information and move it to a separate system, which transfers it to Seward’s farm online database. Field data then gets matched via GPS coordinates.

“Often, two planters will work the same field and the only way operators have been able to successfully transfer A-B lines between planters is to have one operator set up the A-B line, then take a picture of the screen and send it to the other planter operator via smart phone so they can set it up on their system,” Seward says. “I am pushing for easier data transfer between machines.”

The operation runs 17 tractors, 5 combines, 4 cotton pickers, a self-propelled fertilizer spreader, a self-propelled sprayer and a fuel truck.

“We need to be able to query any piece of equipment at any time and know how fast it’s going, how much work it has done and its working vs. non-working time,” Seward says. “It’s important to have that level of information to stay on top of the work.”