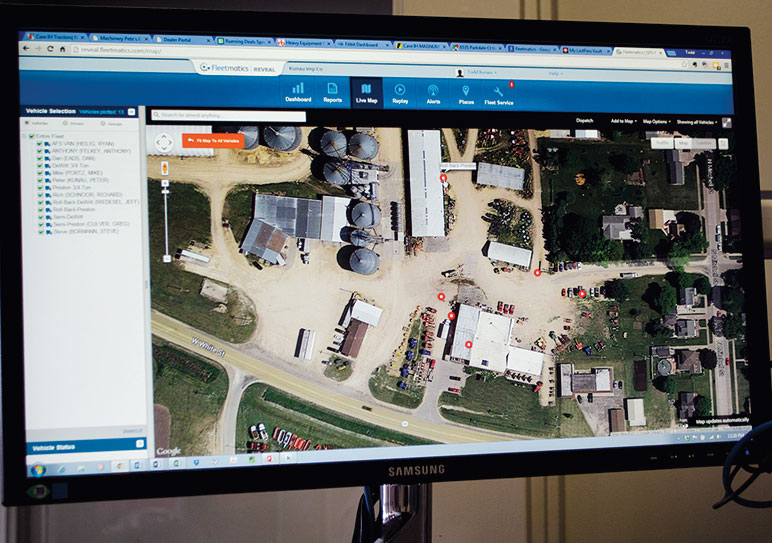

Pictured Above: Fleet management software allows dealers to track and manager both their rolling stock as well as their rental fleet. Programs like HBS Systems’ Net View ECO allow dealers to monitoring the work and location of service techs and their vehicles. HBS’s Greg Bennett says dealers are also realizing they can “grow their businesses by capturing real-time data to boost sales, parts management and expansion into rental fleets.”

For years farm equipment dealers have been streamlining their service departments with digital systems for monitoring work orders and service fleets, but with today’s move to increasingly-integrated software, many dealerships are seeing similar efficiencies emerging at the parts counter and in the sales department.

“It’s all about ‘speed to information,’” says Greg Bennett, director of sales for HBS Systems. “Many of our customers are not only realizing the benefits of monitoring the work and location of service technicians and their vehicles, but are growing their businesses by capturing real-time data to boost sales, parts management and expansion into rental fleets.”

HBS provides integrated software for roughly 1,500 businesses including farm equipment dealerships and those in equipment rental, construction, mining, material handling and industrial settings across the country. Those firms have real-time access to the status of company vehicles and rental equipment, up-to-date depreciated values of their equipment, internal communication between sales, service and parts staffs, and the ability to tap into cooperating OEM warranty, financing and parts information.

“It’s all about ‘speed to information.’ Our salespeople can download a wealth of information on customers to help them tailor their sales calls to the buyer’s potential needs…” – Greg Bennett, HBS Systems

HBS Vice President of Operations, Michael Prengler, says the system, known as NetViewECO, operates much like a smartphone app with choices for financial management, productivity and efficiency, and information on profit centers within a business.

“The program has been around since 2001, and ran on the web through a browser with pull-down menu items,” he explains. “About 4 years ago we decided to integrate all the programs we were using into the integrated system that is the data eco-system we call NetViewECO today.”

Prengler and Bennett say their farm equipment dealers are seeing benefits in time management for shop service technicians as well as those doing field repairs since service calls and appointments can be monitored by laptop or smart phone at all times — eliminating scheduling confusion. The system’s Service Connect feature, also allows a technician to record explanations as part of the service call’s record by verbally recording information on a smart phone.

With the use of telematics, dealerships can track the location, condition, performance and fuel and lubricant information of their own vehicle fleets as well as that of rental equipment, or machinery they monitor for customers.

The software allows managers to set geo-fencing around any piece of equipment or location to monitor the movement of specific pieces of machinery — in or out — which helps deter theft, plus it ensures a digital trail of rental and return or other use of specific machinery.

Bennett says the system has also been expanded, in the case of dealers and service organizations affiliated with Kubota, to allow access to warranty information and bulletins, sales incentives and programs, and other information specific to the OEM.

“Also, when our dealer partners have access to current customer information through NetViewECO, salespeople can download a wealth of information to help them tailor their sales calls to the actual needs and interests of the customers,” he explains.

Kunau Implement, a Case IH dealer in Preston, Iowa, uses Fleetmatics to help track its service trucks for about 8 years. The GPS program has improved their efficiencies on the road and allows the dispatcher to give customers more accurate times for when a tech will arrive. The communication between dispatcher and tech is done by text via the Fleetmatics software and appears on the tech’s GPS unit in the truck, explains Todd Kunau, president of Kunau Implement.

In North Dakota, Terry Tolbert says RDO Equipment Co. has a fleet of about 1,600 vehicles of its own, 1,000 of which are equipped with telematic tracking, while at the same time the company monitors more than 30,000 pieces of rental and customer equipment. Tolbert is the dealership’s vice president of internal aftermarket sales.

“We’re now integrating Bluetooth devices with telematics on various trailers we manage, and we can tell when they are attached, how much they are towing, and, of course their location,” he explains.

In addition to the economics of fleet management, he says the information on location and load is very important, particularly when equipment is used on heavily-regulated mining or petroleum-

producing sites.

RDO, a John Deere dealership headquartered in Fargo, N.D., with more than 70 locations across the central Northern U.S., uses a local firm’s program called Pedigree to integrate into one system all the data their system collects.

“Dealer groups such as ourselves which sell multiple brands and have large vehicle fleets are looking for single-source systems where all the equipment and vehicular data is housed in one site,” Tolbert explains. “This includes machine-monitoring as well as information on our staff which is working in numerous remote sites.

“Having all that information in one place is just more efficient,” he says.

Tolbert says Pedigree’s engineers are migrating GPS/telematics information on equipment into the company’s business system, which promises better financial productivity and accounting. Still, the backbone of the system is efficiency in fleet management.

“With Pedigree a manager can open a work order and be notified if the equipment has telematics on it and the location and capabilities of the machine. The system also will show the manager the location of our service vehicles, trucks and salespeople in the area, to ensure an efficient response for the service call.

“This has really helped management to assign the quickest and most efficient response,” he explains.

“Having all the information in one place is just more efficient…” – Terry Tolbert, RDO Equipment Co.

While Tolberg says RDO has never put pencil to paper on the time efficiency gained through the system, he knows the benefits are there.

“Our commercial fleet of service vehicles have to have electronic location devices anyway, so it’s been a very inexpensive way for us to use that information to boost productivity,” he says.

Todd Kunau, president of Kunau Implement in Preston, Iowa, has been using Fleetmatics software with data collected by Garmin GPS units for about 8 years to improve the efficiency of his Case IH stores’ service departments.

“We adopted the program to keep track of our assets and do it efficiently with minimum intrusion on the technician’s work and with maximum benefit to the customer,” he explains. “We really haven’t changed the system a great deal over the years, because it’s worked very well for us.”

Currently he is looking forward to adding a fuel use component to the tracking data provided through Fleetmatics.

The system allows communication between him and his service department and technicians on the road making service calls. It allows the dispatcher to see the location of which trucks are on the road at a given time so the job can be assigned to the closest tech regardless of which store they call home base, he says.

“Communication between the dispatcher and the technicians is done by text through the Fleetmatics software and appears on the tech’s GPS unit in the truck,” Kunau explains. “This eliminates time-consuming telephone calls and interruptions which inevitably make the service call longer.”

Kunau says the system has been a customer-pleaser because the dealership can now give them precise answers to where the technician is and when they can expect their problem to be addressed.

“The system has also made billing more accurate,” Kunau says. “With it we can create a precise on-location time and can record exactly how many hours and minutes the technician was on location. It gives us a time-stamp for the job, which helps us with billing warranty work with the manufacturer.”

Kunau says the system has been a positive tool for all parties involved — including the technicians, customers, the accounting department and management.

Does Your Dealership Have the Right Technology Tools in its Arsenal?Finding the Parts Inventory System That’s Right for YouIncreased Cyber Threats Require Dealers to Be Proactive, Not ReactiveAssess Risk, Value to Avoid Costly Consequences of Cyber AttacksTaking CRM to the Next Level Fleet Management Data Offers Bottom-Line Boosting Opportunities4 Changes Dealerships Must Make to Stay Connected to Customers

Post a comment

Report Abusive Comment