Columbia Station, OH – Even Mix announces the launch of its IBC Mixer, a low-weight, revolutionary design for IBC tote mixers that’s changing the way plastic tote contents are handled.

If you or your business uses IBC containers and have frequent issues with the product consistency and efficacy, this powerful new technology was designed to be tough enough to handle even the most challenging mixing scenarios while maintaining a lightweight operation that’s simple for just one person to complete the job.

Even Mix, with their revolutionary IBC tote mixer technology, are innovating the IBC tote industry. Their latest product is set to solve these common IBC tote problems:

● Product separation over time

● Solids that settle to the bottom of the tote

● Products that solidify or gel overtime

The company believes that products held in IBC containers should maintain consistent quality over time, experience high-quality mixing and blending, and achieve delivery that’s consistent with the formulation. It’s Even Mix’s goal to help their customers maintain their produce mix quality over time, reduce their raw material inputs and ultimately save money.

The Even Mix Tote Mixer isn’t just highly effective for several applications, it’s a patented technology. Even Mix received a U.S. patent on its proprietary mixing technology in late 2017.

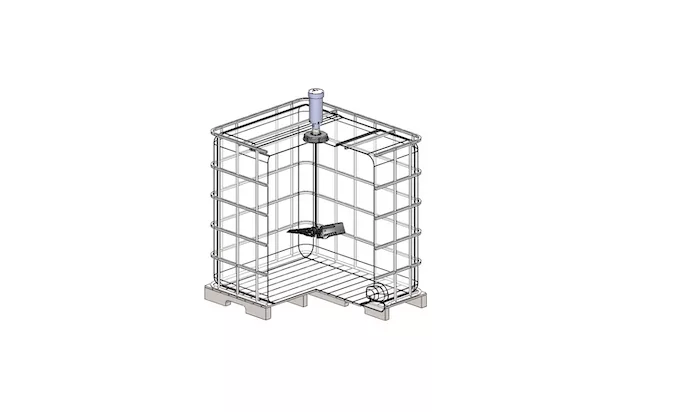

The IBC Tote Mixer is designed to provide a consistent, even distribution of materials throughout an IBC container. They incorporated NASA designed Mixed Flow Blades that are highly unique in both their design and their shape.

The blade itself folds to allow easy insertion through the 6 inch opening of the IBC tote. Once inside, the blade unfolds to 16 inches to perfectly mix the contents evenly throughout the IBC tote — even the bottom.

The light-weight tote mixing blade from Even Mix is the first of its kind, thanks in part to the aerospace engineering that allows for the superior mixing technology. The blade itself is extremely low weight, weighing in at only two pounds compared to the industry average of four pounds. A 50% reduction in mixer weight. Add in the drive system and often it’s 20% of the weight of other complete systems. A significant reduction.

The lightweight nature of the product allows for a simple, one-person installation. Installing the Tote Mixer onto an IBC is as simple as inserting it into the IBC and screwing it securely onto the top. This technology has made the IBC tote mixing process easier and more convenient than it ever has been before.

Although the blade is significantly lighter than other options, it’s very sturdy. The heavy-duty blade is built for 800-inch pounds of force and is capable of mixing liquids over 50,000 centipoise, which is about the thickness of peanut butter.

There are two different drive motor options available, air drive or electric. Both options provide heavy-duty performance and feature the lowest weight on the market. The electric model weighs in at 12 pounds and the air drive motor is just 9 pounds — both just a fraction of the weight of their competitors.

The IBC Tote Mixers are made from hardened steel and are engineered to withstand immense force. The powder-coated steel and nylon fitting help to add to the strength and durability of this product.