Editor’s Note: This Q&A originally appeared in AG Tire Talk to provide answers that farm equipment dealers have about farm tire technology. This series features a trending question followed by an abridged version of the answers. For the complete answers, check out www.agtiretalk.com.

Questions: How do you recommend dealers help producers choose the best Load Speed Index, what is impact of IF/VF, and how does change from transport speed to in field affect air pressure requirements?

Harm-Hendrik Lange, Agriculture Tires Field Engineer, Continental Agriculture North America: Starting with the simplest component: Speed Symbol (SSY). The Speed Symbol is the maximum speed the tire is designed for. It correlates with Load Index as a standard tire can carry even more if the speed is lower. For Agriculture Radial Tires, the most common Speed Symbols are A8/25mph, B/31 mph, and D/40 mph. If your tractor runs faster than 25 mph, you will need the B or D rating. If your customer’s tractor is 25 mph or lower, A8 is fine.

Standard Tires

A little more complicated is the Load Index (LI): it is always related to a certain speed and to the (nominal) inflation pressure.

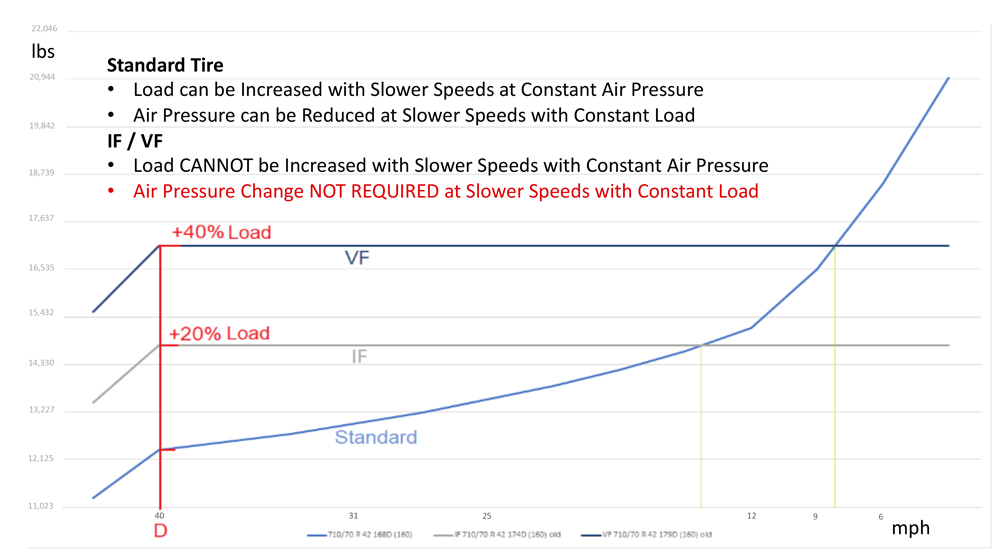

Here’s a practical example for a 710/70 R42:

The tire is rated with 173 D, so it can carry 14,330 pounds at 40 mph.

If you have a tractor with a max speed of 25 mph, the load can be increased going down three SSY (D=>C=>B=>A8).

This allows you to increase the LI three steps meaning the 173 D tire becomes a 176 A8 tire and can now carry 15,652 pounds at 25 mph.

The third influence on standard tires is the inflation pressure. Higher inflation pressure means higher load capacity. Therefore, the maximum LI and SSY are always given at the maximum allowed inflation pressure at maximum speed, called nominal pressure.

A farmer who is aware of the soil and its effect on plants, should choose a tire by its ability to be operated with low inflation pressure on the field instead of looking at the maximum LI and SSY for road conditions.

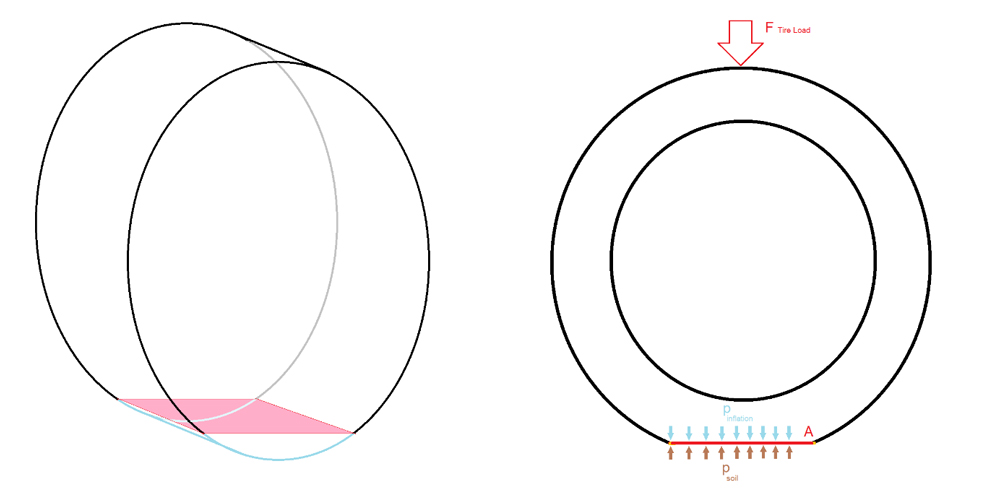

As shown above, the contact patch is directly affected by tire load and the inflation pressure. Adding load to the tire will increase the contact patch, while the pressure stays constant in this model. But also keeping the load constant and reducing the inflation pressure for in field will increase the contact patch.

In short, to run a standard tire at maximum speed with a high load on-road requires a significantly higher inflation pressure, while you can reduce the inflation pressure at on-field speeds to protect the soil. All these pressure changes require technical solutions like an air pressure kit in the field, so a new tire model was evaluated.

IF / VF

The first step was the IF, and the second evolutionary step is the VF tire, taking out the need to change air pressure between field and road speeds at constant load and ~20% more load for the maximum specified speed for IF and ~40% more load at maximum speed point for VF at the same inflation pressure compared to a standard tire.

Overall:

The higher price for VF tires can be a good investment for farmers and contractors who change between field and fast road work often, as no pressure adjustment is needed for the different speeds with constant loads. VF enables you to ride up to the highest speeds with the lowest inflation pressures.

Ken Brodbeck, VP of Technology, Precision Inflation LLC: First, be sure to have a speed rating that meets or exceeds the maximum speed of your customer’s machine. Most radial tires are at least A8 (25 mph) or B (30 mph). Newer technology tires are D (40 mph).

Next, be sure to have a load index that meets or exceeds the maximum weight requirements of your machine configured with implement you have chosen.

Your tire dealer and the major tire manufacturers list these values in their data books and online. Now let me explain each term with an example.

Load Index: is a table of maximum load values that are standardized by the tire manufacturers.

Speed Index: is a table showing the maximum speed allowed for the tire.

The speed index is usually stamped on the tire sidewall right after the Load Index number.

How do Standard (St.), (IF) and (VF) tires compare at two different axle loads?

Summary:

- Without CTIS (Central Tire Inflation System), you have to run transport psi all the time

- IF and VF tires allow lower pressures of 19 and 16 psi respectively.

- With CTIS, a standard tire can be set for 14 psi in the field and 26+ psi on the road!

- Bottom line, often a standard tire with a CTIS can outperform the higher dollar IF and VF tires without an inflation system.

Inflation system technology also improves the performance of IF and VF tires. In fact, every radial tire works better with CTIS to optimize and maximize the performance of your farm equipment.

David Graden, Operational Market Manager – Agriculture, Michelin Ag: On the sidewall you will find a load speed index expressed like this: 167B.

- The first three numbers are the load indices or weight a tire can carry.

- A8, B, or D indicates the speed rating of the tire.

Both weight carrying capacity and speed requirements must be assessed to choose the proper load speed index.

When determining speed requirements, I recommend both in field and transport maximums are determined. Knowing physics enables a standard tire to carry load with significantly less air pressure at slower speeds, this is very important if you are concerned with reducing soil compaction.

For example, an 800/70R38 MachXBib carrying Max Load of 14,330 pounds at 23 psi at 40 mph (transport) can carry same weight at 6 mph (field) with 15 psi.

Reducing pressure 8 psi over 5,000 acres equates to a significant improvement in a grower’s bottom line.

So how do you (real world) change air pressure from road transport to field quickly at crunch time? Use a CTIS system.

Do you want to take air pressure savings to another level? IF/VF tires that can do even more.

In sum, determine required weight carrying capacity, determine in field and road transport speeds, and then I recommend investing in a Central Tire Inflation system. To really maximize yield, go VF.

James Crouch, National Product Manager — Agriculture, Alliance Tire Americas: Load and speed index symbols are a little bit mysterious. The numbers—like 129, 141, 151 — look arbitrary, and the use of stars or letter/number combinations like A8 to indicate load doesn’t feel very precise. But the most important aspect of load and speed index is that you know that they exist, and you make sure to match them to your needs when you purchase new tires.

Mysterious or not, load and speed index represent vital information. If you buy a tire with too low a load/speed index to cover your needs, you could overload your tire. That can lead to premature wear, accidents and spills, or even injury or death. I can’t say this too many times: you need to match the load and speed index of your tires to the machinery they will be running on.

Be sure to calculate your need for load and speed based on the real-world weight of each axle on your machine. That means you have to look beyond the machine’s shipping weight to also account for the weight of fuel, spray solution, ballast, and load on the drawbar. If it’s got a bucket on the front, add the weight of a full load of dirt or gravel. Be real about what you’re going to be doing with that machine and you will end up with an accurate load index.

The same goes for speed. The low speeds of planting or fieldwork can be accomplished at a lower inflation pressure than higher-speed road driving. If you’re going to operate a farm tire at higher speed, check your inflation tables to match the load, speed and optimum inflation pressure. If your pressure is too low for your load and speed, your sidewalls will flex too much and build up extra heat, which can result in excessive stress on the tire carcass and ultimately could destroy your tire.

That’s where IF and VF technology come in. The special design and materials in IF and VF sidewalls allow us to operate these high-tech tires at lower inflation pressure without giving up load and speed. In fact, the load rating of an IF tire at a particular inflation pressure is 20% higher than the load rating of a standard radial at the same pressure. With VF tires, the bonus load capacity is 40%.

To get the full benefit of IF or VF technology, check the inflation tables and make sure you run at the proper pressure for the load and speed that reflect your operating conditions.

And to really stay in step with load/speed index and optimum tire performance, central tire inflation system (CTIS) is the ultimate tool. Linking a compressor to each tire on the machine for on-the-go pressure adjustments, CTIS technology — used by the U.S. military since the mid-’80s — is surprisingly affordable and allows you to increase inflation pressure to run safely on the road and decrease it for better performance and lower soil compaction in the field.

The nomenclature of load and speed index may be mysterious, but the answer to all the mysteries is right there on the inflation tables. Every tire manufacturer issues them for each of its tires, and here’s a link to standardized tables and you can find them online or in manufacturers’ literature.

Bradley J. Harris, Manager, Global Agricultural Field Engineering, Firestone Ag: The Load Speed Index is the identification system that replaces the tire Ply Rating and the Star Rating. While there are a few key differences between these rating systems, utilizing the best Load Speed Index will lead to a better purchase when choosing the right tire for your operation.

The load index on tires indicates the load of the tire at the measured inflation pressure.

Quick tip: The specific load index value is equivalent to the rated load for any tire size.

For example, a tire with a load index of 168 equates to a rated load capacity of 12,300 pounds (5,600 Kg). Customers may switch from wide tires to narrow tires depending on the season and application. If you have a tractor that uses wide tires in the spring for planting, you may use a 710/70R42 168 tires on the rear axle, leaving each tire to carry 12,300 pounds at 23 psi.

The speed rating of the tire follows the load index, for ag tires is it usually A8, B or D. A typical description would read 168 B. These values indicate the maximum speed the tires are recommended for. The speed rating for each value is:

A8 = 25 mph (40 Km/H)

B = 30 mph (50 Km/H)

D = 40 mph (65 Km/H)

It is always important to make sure to match the maximum speed of the tire to the maximum speed rating of the tractor. In North America, the B speed rated tires will be acceptable for most tractors. Currently, there are only a few tractors in the market which exceed 30 mph, but for those tractors the D speed rated tires are needed.

With the IF or VF technology in the tire, the load index value increases when comparing the same sized tires. The below tires are speed rated to 30 mph; however, the rated load increases with IF and VF technology (while maintaining a rated inflation of 35 psi):

- 480/80R50 Standard Radial 159B

- IF 480/80R50 166B

- VF 480/80R50 171B

New tire technologies help customers by increasing load capacity while maintaining the same tire size.

When setting inflation pressures in tires, the axle loads and the operating speeds are critical to ensure proper inflation. Without having a central tire inflation system (CTIS) on your tractor, the inflation pressure needed is based on the fastest travel speed and the maximum axle load. If the tractor is only being used to haul equipment, like a disc or field cultivator, there is not a weight difference between field application and road transport. Once the pressure is set, there is no need to adjust applications. If a tractor is being used with 2-point or 3-point equipment, the rear axle weight changes between field use and road travel. In this example, the inflation pressure of the rear tires would be set based on road axle weight and road travel speed. If the tractor does have a CTIS, the inflation pressure could be set for the field use and then changed for road transport.

Understanding load index and speed rating will allow you to make an educated decision when choosing your next set of ag tires.

Greg W. Gilland, Business Development & Ag Segment Manager Maxam Tire International: Each Agricultural Operation requires equipment designed to maximize the harvest of that chosen crop.

In the case of Tractor applications, the choice of machine size and horsepower selected will dictate the size of tires that will be employed to deliver the planned or expected yield of crop.

Tires are the pressured vessel that create the interface between the machinery and the soil necessary to carry out the farming operation every step of the way from land preparation to crop harvest.

Agricultural tires are designed based on their size geometry, materials, and air chamber to carry a certain amount of weight at a given ground speed and to fit a certain wheel base or equipment.

All Radial Ag tires employ the tire carcass (rubber & nylon casing construction) to carry 20% of the given tire load with the compressed air in tire chamber carrying 80% of the remaining given weight.

The primary function of an Ag Tire is three-fold: u Carry the Load, v Resist Lateral Forces & w Transmit the Torque or Machine Power:

Ag tires are therefore rated by a common index to identify their load capability or carrying capacity at a given speed.

The key objective of any given machine utilizing tires in a farming operation is to choose the optimized air pressure that can carry the maximum weight expected, while providing the least amount of soil compaction.

The yield of the crops produced is directly impacted by the amount of ground pressure caused by the weight of the ag machinery due to the topical soil pressure or soil compaction caused by the equipment working in the field.

Growers should therefore choose the tire size and corresponding air pressure that best suits the weight and horsepower of their tractor as optimized to pull their heaviest implement in their operation.

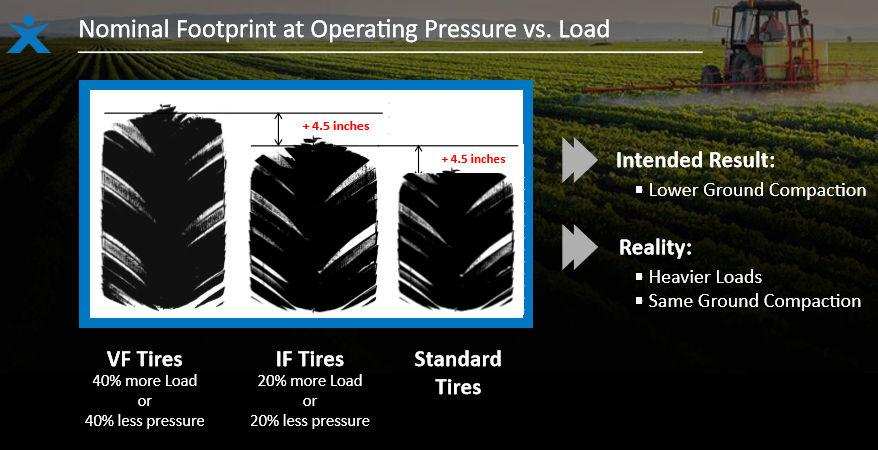

The advent of “Increased Flexion” Technology or IF & VF technology has revolutionized how the traditional tire is employed through the science of new rubbers and carcass materials able to carry additional weight at higher speeds or reduce soil compaction though decreased air pressure increasing the tire footprint for a given load.

- IF Technology Tires allows either 20% more tire load at normal pressure or 20% less air pressure for the same tire load

- VF Technology Tires allows either 40% more tire load at normal pressure or 40% less air pressure for the same tire load

- The advantage of IF & VF technology is the capability to reduce soil compaction with lower air pressure by extending the tire footprint or conversely the ability to carry more weight at the same ground pressure or standard air pressure.

To maximize the utilization of IF & VF technology tires, the grower should consider adjusting the air pressure of his tires as he modifies the weight being pulled or load being carried by his equipment. The optimal air pressure in every case will reduce the ground pressure thus increasing the yield of crops through reduced soil compaction.

Higher transport or road speeds will demand higher air pressure to sustain the weight and/or corresponding speed to move ag equipment from the barn to field operation or from field to field. Newer tractor and Ag equipment are utilizing onboard inflation equipment to quickly adjust IF or VF Tires up or down in air pressure to the optimal footprint needed to either move on the road or in the field.

The challenge to the Grower is to employ sustainable methods to adjust and maintain the air pressure of his IF or VF Tires as he moves his equipment from transport mode to field working mode by lowering the air pressure to the absolute minimum needed to float over the soil thus reducing compaction while transmitting the necessary torque or force to pull his equipment and get the job done. The right air pressure for the right load is the answer to improved ag profits.

Norberto Herbener, OE Applications Engineer, Trelleborg Wheel Systems: Let’s first clarify what Load Speed Index means. In modern tire manufacturing each tire has a specific Load Index (LI) and a Speed Symbol (SS) and both together are referred as Load Speed Index. The Load Index (LI) represents the load capacity at the nominal inflation pressure of the tire and there is a direct correlation between load capacity and inflation pressure (the higher the inflation pressure, the higher the load capacity).

These values depend on the tire size (width, ratio and rim diameter) and are all normalized by TRA (Tire and Rim Association) in the US and by ETRTO (TRA counterpart in Europe) meaning that a specific tire size, at a specific inflation pressure will have the same Load Index (LI) for all tire manufacturer (comparable apples to apples). If for the same tire size, the market offers different Load Index values, it means their nominal inflation pressure (highest inflation pressure allowed) is different. For example, for a Mitas 1250/50R32 SFT 188A8 the nominal pressure is 35 psi (2.4 bar) and for Mitas 1250/50R32 SFT 194A8 the nominal pressure is 47 psi (3.2 bar). Each manufacturer tire catalog will include the table specifying the load capacity for each Load Index (LI).

On the other hand, the Speed Symbol (SS) represent at what speed this Load Index (LI) is referred to. A large combine flotation tire will normally have a A8 Speed Symbol (SS) that represent 25 mph (40 km/h). On a sprayer specific tire, the Speed Symbol (SS) will be a D representing 40 mph (65 km/h). On conventional tires the reduction of working speed allows higher load capacities of the tire. This can be explained in the fact that at higher loads the tire temperature increases, and the temperature increases also when the speed is increased. So, when we reduce the speed (lower temperature) we compensate for the temperature increase by increasing the load. For example, a Mitas 480/80R50 159A8 inflated at 2.4 bar will be able to carry 9,650 lbs. (4,375 kg) at 25 mph (40 km/h) and 13,500 lbs. (6,125 kg) at 6 mph (10 km/h)

Standard Tires

When looking into a tire manufacturer manual, you will see that for each conventional (non-IF or VF models) tire size there is a specific data matrix with inflation pressure and speed. Each combination (inflation pressure vs. speed) will specify the max load capacity of that tire for this combination. So, when farmer wants to know what inflation pressure he needs for his tires, first he must know the load each tire has to hold and second the speed he will be using for that load. With these two values he can determine the correct inflation pressure for his tire. It is very important to use the correct inflation pressure depending upon the load applied and the speed used as this will allow to have the best performance and the largest footprint (lower compaction) of the tire. An over-inflated tire will result in a higher soil compaction.

IF / VF Technology

When talking about newer and higher tire technology, we must talk about IF (Increased Flexion) and VF (Very High Flexion) type tires. Both technologies represent reinforced tires that allow higher load capacities (20% higher for IF and 40% higher for VF) at the same inflation pressure for the same tire size, compared to conventional tires. Using this same concept, we can say that if we have the same load applied to the tire an IF tire allows to use 20% less inflation pressure and the VF 40% less inflation pressure (always comparing same tire size). For example, comparing the load capacity between the conventional Mitas 710/70R42 173D SFT vs. the VF version Mitas VF 710/70R42 179D HC2000 at 23 psi (1.6 bar), the conventional can carry 12,350 pounds (5,600 kg) and the VF can carry 17,085 pounds (7,750 kg). On the other hand, if our tire needs to carry 12,350 pounds (5,600 kg) the conventional tire would need 23 psi (1.6 bar) and the VF tire would require 14 psi (1.0 bar) for the same load. This reduction in inflation pressure will increase the total footprint and reduce the specific pressure on the soil and the soil compaction.

These higher technologies have the special characteristic that the load capacity will not change by changing the speed only by changing inflation pressure. Making it easier for the farmer to adjust the correct inflation pressure.

Dave Paulk, Manager Field Technical Services, BKT USA Inc.: Speed and load ratings on tires have become more important with the influx of tractors and equipment coming into the U.S. from Europe. When choosing a tire, weight carrying capacity for the weight of the tractor, the intended load, and the transportation speed should all be considered. Some tractors will run up to 45 mph, so the tires must be able to carry the weight required at those speeds.

The load and speed index of a tire follows the size on the sidewall of the tire. Charts are available to show the maximum load capacity of a radial tire at the maximum speed. The charts can be found in most tire manufacturers’ handbooks, as well as on the internet. An example is a tire may have a 154D/157A8 Load and Speed Index rating (BKT 600/65R38 RT 657). This means that the tire will carry 8,250 pounds (154 load index) at 40 mph (D speed rating) at 35 psi. This same tire will carry 9,090 pounds (157 load index) at 25 mph (A8 speed rating) at 35 psi. The higher the speed, the less weight carrying capacity a tire can handle.

Tires that come on original equipment tractors are selected by equipment manufacturers to carry the loads of the tractors with ballast to handle the speeds that modern tractors run. Aftermarket add-on’s (ex. saddle tanks) sometimes cause overloading on the tires, usually the fronts, and will cause the tires to fail prematurely. The rears can also be overloaded with the heavier equipment, so correct air pressures are vital to prevent premature failures.

Radial farm tires are designed to run at lower air pressures in the field, at field speeds (5-10 mph). The higher the speed, the less weight carrying capacity a tire has. 8-10 psi may be perfect at field speeds, but when the tractor is transported between fields and/or farms on the highway at 30 mph, the weight carrying capacity is greatly diminished. The tires may need more air pressure to transport equipment on the highway than they do in the fields. Sidewall damage and sidewall separations can occur when tires are run overloaded and under inflated. Realizing that time is precious in the spring and fall during planting and harvest, money can be saved by running the correct air pressures for the application and usage during these times. Air Inflation Systems are now being offered as aftermarket items, but manufacturers are looking at them as OE options to minimize tire damage and premature failures.

IF and VF technology is being used to enable a tractor to carry more weight without having to widen the tire to the point where it can’t be transported on the highway. This technology can also be used to reduce air pressure to minimize soil compaction in areas where no till and minimum till is used. An IF rated tire will carry 20% more weight at the same air pressure as a standard tire of the same size. A VF rated tire will carry 40% more weight at the same air pressure as a standard tire of the same size. If an IF/VF tire is being used, air pressure can be reduced to carry the same weight as a standard tire. This decreases ground bearing pressure, and thus reduces soil compaction. On the opposite side of the spectrum, sometimes the higher weight carrying capacity is needed. An example is radial implements (IF rated) on planters and cultivators where a bias ply implement tire will not carry the heavy weight of the implements. The VF rated tire is good for sprayers as they run at higher speeds and can handle the weight capacities.

There are still a huge number of bias ply farm tires running in the U.S. market. Bias ply farm tires are designated with ply ratings. The higher the ply rating of a bias farm tire, the more air pressure it holds and the more weight it carries. Bias ply tires, unlike radial farm tires, are not made to run at low air pressures. If bias tires are being used, the load carrying capacity should be checked to make sure they are not being overloaded.

It is important to consider many things when choosing the correct tire for your equipment, your load, and your fields. BKT technological specialists are available to help with any questions you may have.

Scott Sloan, Ag Product Manager / Global LSW Titan International Inc. (Manufacturer of Titan and Goodyear Farm Tires): Before I get started, I think it would beneficial to review the differences in tire technologies and what they offer.

- Conventional tires are just that, they have been around since the dawn of the pneumatic tire.

- IF (Increased Flexion) tires are designed to carry the same load at 20% less inflation pressure than the conventional tire of the same size.

- VF (Very High Flexion) tires are designed to carry the same load at 40% less inflation pressure than the conventional tire of the same size.

The theory behind IF_VF technology is that as the tire deflects more the footprint becomes larger and the larger footprint means less ground bearing pressure and ultimately less compaction

With so many tire options it can be a bit confusing when making decisions on what one should purchase. Tractor manufacturers offer a multitude of options. They actually do a good job of offering the appropriate load and speed index tires on the tractor coming out of the factory. If a grower is in need of replacement my quick answer is to replace it with a similar rated tire, you really can’t go wrong.

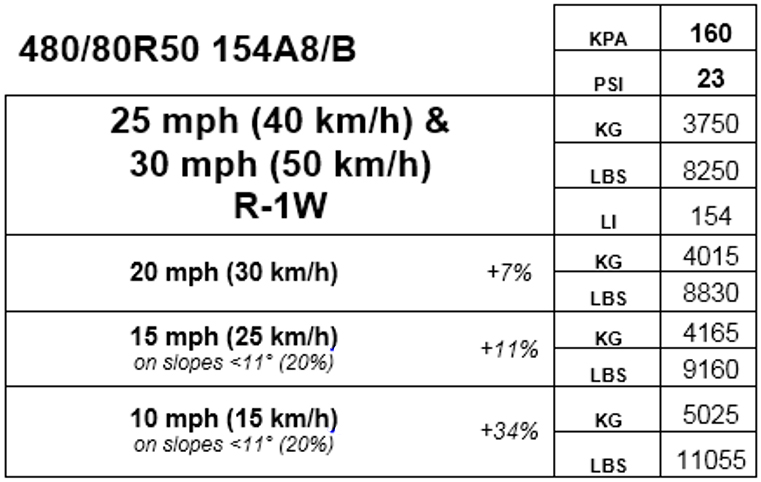

Things get a bit more complicated if that grower is attempting to make a tire technology change which requires a bit more thought. For instance if they are looking at converting a MFWD from conventional tire technology to IF_VF technology not only will they need to replace all of the tires on the tractor they will need to choose a load index that suits the tractor at its heaviest condition. Some manufacturers take into account that at slower speeds conventional tires are actually allowed a load bonus or plus up at 20 mph (+7%), 15 mph(+11%) and 10 mph(+34%) as it operates in at different speeds. See Table 1.

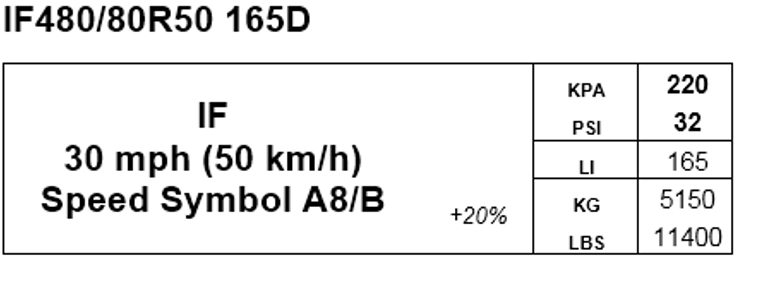

In this case a 154 load index rated at 8,250 pounds at 23 psi is capable of carrying 11,055 pounds under 10 mph. When converting to IF or VF there is no load bonus for slower non-cyclical applications. An IF or VF tire can carry the same load at 40 mph as it does at 10 mph but is not allowed a load bonus or plus ups. That means that you will need to select a load index that will cover at least as much of the load of the standard tire to meet the load requirements of the tire you are taking off. See Table 2.

In this case the tractor would need to be converted to 165 load index and that tire would need to be inflated to 32 psi in order to carry the same load. Now granted a tractor typically doesn’t see those extreme loads all the time and inflation pressures can be adjusted much lower for general farming, but it is important that you select a tire with a load index high enough to handle those times when the tractor is experiencing those conditions or you will risk damage and or failure to the tire and possibly damage the tractor.

At the end of the day the grower needs to decide what is best for their operation. Converting to new technology on an existing tractor is not cheap and they need to weigh the benefits vs the cost. But if they do decide, it is best they understand the technologies and what gets them the biggest bang for the buck In addition, doing research and understanding their loads and applications will give them the best chance of being successful with the conversion. The tire dealer or tire manufacturers would be a great resource to ask questions if they are having trouble understanding.