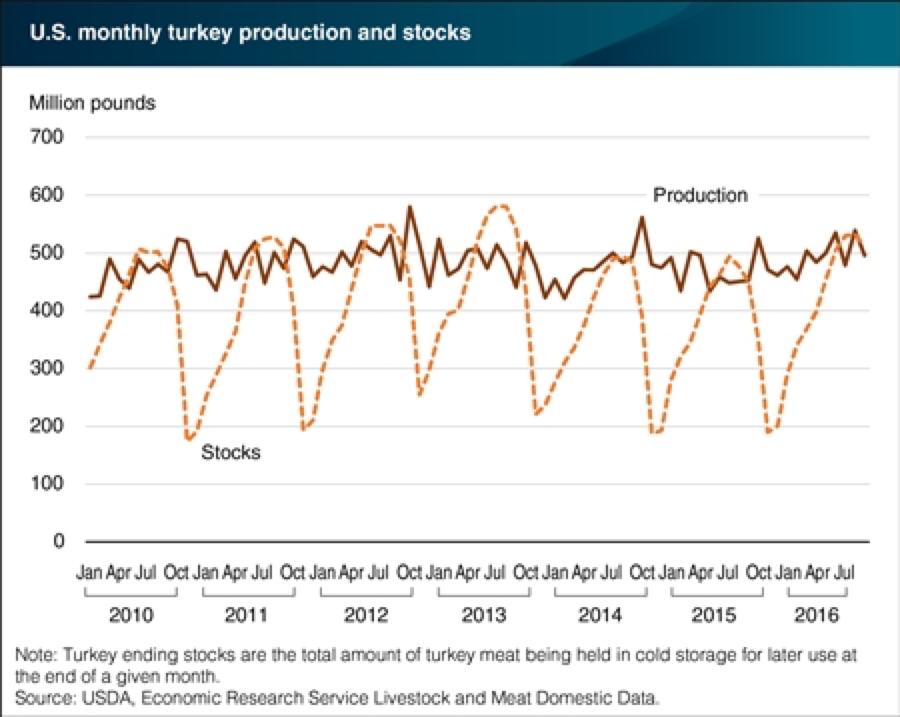

Since 2010, turkey meat production has averaged just under 500 million pounds per month. While that’s enough turkey to meet the needs of consumers during an average month, it is not enough to cover Thanksgiving demand.

In order to make up for this deficit, producers build up stocks in cold storage throughout the year in order to sell them when November comes around. Turkey stocks reach a low point each year after November and then begin building back up throughout the following year, reaching a high point around September just in time to begin the process all over again.

The process also helps explain the gap in prices between fresh and frozen turkeys at the grocery store. Since demand is met, in part, by frozen product built up throughout the year, only a limited portion can be bought fresh leading to a premium at the checkout line.