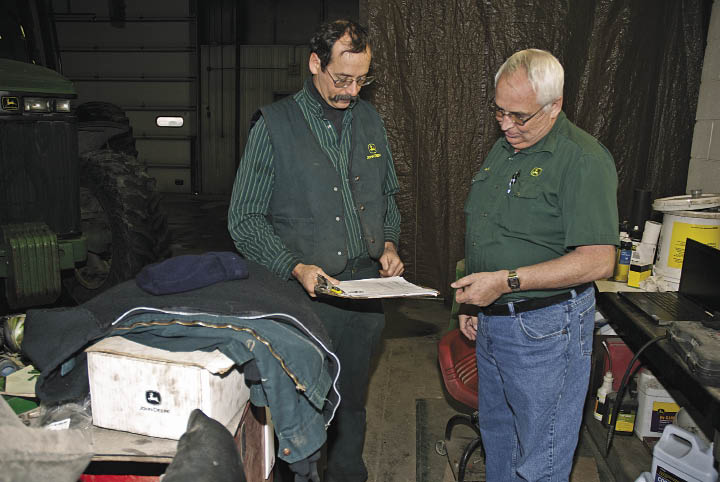

Store Service Manager: Alan Byerly

Years with Organization: 38

Role: "The service department keeps the dealership afloat. The salespeople can make the sale, but the service department has to keep the equipment running and get equipment ready for delivery. Regardless of color, every piece of equipment is made to wear out, and parts and service keeps a dealership in business."

Alan Byerly is convinced most dealer-principals fully understand the importance of service when it comes to looking at and understanding the big picture.

“Since every piece of equipment is built to wear out, the service department is what keeps the dealership afloat,” maintains the service manager at the Precision Equipment location in Washington, Iowa. “The salesman can make the sale, but the service department has to keep the equipment running and get equipment ready for delivery.”

While admitting the sales team may have a different take, Byerly believes a dealership must be strong in parts and service to have an outstanding financial sheet.

Byerly spent 18 years working as a shop technician before becoming a service manager 20 years ago. He grew up in Ainsworth, Iowa, 7 miles from the Washington store.

He finds the 10 service technicians he supervises like the variety of challenges that come from working both in the shop and the field. Service work is priced at $75 per hour in the shop, $80 in the field and $65 for lawn and garden service work at the dealership.

The shop contains a half-dozen work stations for tractors and lawn and garden equipment, along with room for four combines on the opposite side of the shop area. In good weather, equipment setup is often done outside.

Besides regular weekday work hours, the service department is open from 7:30 a.m. until noon on Saturdays. Half the crew works one Saturday and the other half works the next Saturday.

Family Comes First

During harvest, techs may go 2 months without having a Saturday off and the hours may be extended to 5 p.m. But if someone absolutely needs to have a Saturday off, it’s not a problem and they will be accommodated.

“You’ve got to keep everyone happy,” says Byerly. “It’s a give-and-take situation, but you’ll be rewarded in the end because the techs appreciate the fact that you gave them time off when they needed it.

“If a tech needs a couple of hours off during the week to watch his kids in a school play, it’s not a concern. We’ve got to keep the shop doors open, but family comes first.”

Byerly starts each morning by checking the John Deere Pathways web site to review the latest product information in the “What’s New?” section. This section is where product improvement programs are announced along with comments regarding various equipment problems.

Next, Byerly moves to the warranty area on the site. He reviews how warranty work he’s dealing with is progressing through the system.

The rest of the day is taken up with phone calls, scheduling shop and field work, assigning jobs to technicians and checking on their progress.

In early November, the service schedule included a number of tractors in for service, setup of several new tractors, post-season work on combines and putting several new planters together.

“We never seem to ever get caught up on tractor service work,” he says. “And customers who bought new planters want them put together in November and December so they can be stored out of the weather for the winter.”

When a customer calls with a service concern, Byerly fields the call.

“With my shop background, I’ve developed a bad habit of trying to fix the concern over the phone,” he says. “I usually find out what’s wrong, write up the order and assign the job to a technician.”

One of the dealership’s biggest service concerns deals with air conditioners. “This is always a big thing, especially as fall harvest gets underway,” says Byerly.

“At our annual combine clinic, I remind everyone to start their combine a few weeks before harvest to see if the air conditioner works. I want them to understand that once harvesting begins, we’re going to fix a combine that’s broken down before we’ll go out to recharge an air conditioner.”

Building Customer Relations

Byerly says the price of service can often be a concern to customers. If service is needed during planting or harvesting season, customers simply want to get the equipment rolling again.

“Some customers will shop their repair work around during the off-season,” says Byerly. “But they’ll usually bring it back to us because they respect the talents of our techs. Some customers will ask for a certain tech. If that person is available, I’ll have the technician do the work, but we have to be fair to everyone.”

While a tech just starting out has to get his feet wet, there can be concerns by customers about having a new person work on their equipment. But in the end, customers tend to develop a relationship with the tech and everything works out for the best. Seldom does a customer indicate he doesn’t want a particular tech working on his equipment.

Byerly’s goal is to always have jobs sitting in the shop that don’t require a quick turn-around. It’s a lot easier to have work waiting than to try and create jobs to keep the techs busy. But sticking $10,000 in a combine to make it pretty and having it sit on the lot for months is not something he likes to do.

Building Tech Relations

Byerly says the key for service success is building a good relationship with your techs.

“You need to earn their respect,” he says. “Once you respect each other, it’s an easy thing to manage. You can’t be a dictator.”

Byerly hasn’t faced major problems in attracting technicians.

“Experience always helps, but the way electronics and precision farming has changed over the years, we need someone with that background,” says Byerly. “When I started 38 years ago, we wanted someone to get dirty and do mechanical work. While we still need this type of person, we also need them to have an understanding of how to handle electronics work.

“Technicians used to be true mechanics. When something broke, we fixed it. Now we need to diagnose the problem and replace the parts instead of rebuilding something like we used to do.”

When evaluating a tech’s performance, Byerly wants to know how many hours it takes to do each job and whether they can get all the parts ordered at once vs. multiple orders. Also important is whether a tech can get a problem diagnosed and repaired in a single try.

While he relies on several traditional programs for effective tech training, Byerly hopes the merger will allow more hands-on training in the electronics area. He feels this service training is critical as this area continues to become more important.

To keep up on the latest product developments and concerns, Byerly talks regularly with the service managers at the other locations.

“I’m hoping the merger will open up communications between all eight locations,” he says. “If we’re having a service problem, we can see if someone else has a solution. All the years of equipment knowledge that’s been accumulated by our service managers is a tremendous resource.”

One benefit of the merger is adopting the John Deere EQUIP program to measure technician efficiency that was used by other dealerships involved in the merger. The John Deere Legacy program didn’t let him effectively measure tech efficiency.

With the new system, a computerized work order will provide an estimated number of hours that a job should take.

As an example, the system may indicate it will take 8 hours to set up a new tractor and the time will be billed to the sales department.

With eight locations, Byerly says it’s going to be much easier to track down needed parts and have them delivered the same day.

“There will be $3.6 million in parts inventory in all the locations, so we should have pretty much any part in stock,” he says. “Plus, the John Deere Parts Depot is only 90 miles away.”

Educating Customers is Essential

Byerly holds an hour-long combine clinic in early August where he explains the differences between walker and rotary style combines, corn heads, grain heads and covers the need for proper adjustments.

“I do the clinics with a PowerPoint presentation,” he says. “An hour is about as long as you want a clinic to go since that’s about how much education a farmer can absorb. My philosophy for a clinic is that you can talk to a customer all day about adjustments. But unless he understands how the equipment works, he’s not going to get anything out of it.”

Making the Extra Effort

Byerly believes it’s much easier to have 100 farmers sitting in a room watching a PowerPoint than gathering around a combine. Customers like to see on a screen and visualize what is being explained.

In late February or early March, he presents a 1 hour planter clinic for about 100 farmers. He’ll stress the importance of replacing worn disc blades and the value of precision planting.

“We’re taking planting much more seriously and explain how to make planters work properly without buying numerous aftermarket attachments,” says Byerly. “Without a good job of planting, you’re not going to have a good harvest.”

Byerly says too many growers still believe the only way to solve planting concerns is to add costly attachments. And he feels much of the popularity with various attachments is due to peer pressure from neighbors.

“A few years ago, a customer wasn’t happy with his planter performance,” Byerly says. “The farmer was ready to buy a number of attachments. After I quizzed him and found out what was going on, I told him how to make that planter do exactly what he wanted without spending another penny.

“He was using the wrong seed disc. I told him that if he had a smaller seed disc at home, I’d guarantee making that change would take care of the planter problem.”

After planting was finished, the grower told Byerly the planter monitor indicated he was putting on the right amount of seed, but less seed was used than in the past. That fall, the farmer shared he got the same or a slightly better yield with less seed.

Byerly says a major concern is that neither manufacturers nor dealers have shown farmers how to properly operate their planters.

“Some of the attachment folks have made farmers aware of what they’ve been doing wrong,” he says. “But we need to better educate customers on how to plant. We can’t just sell the equipment to them; we must also educate them on how to make it work properly to get the most out of it.

“We’ve been guilty of this situation for years, and I’ll be the first to admit I‘ve been part of the problem.”

When it comes to running an efficient service operation, Byerly is convinced that respect for both customers and employees along with providing needed education will earn solid dividends and demonstrate that an effective and money-making service department is critical to dealership success.