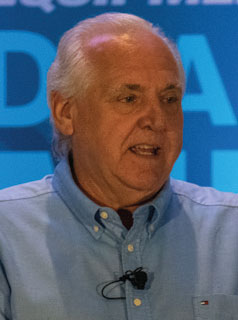

While all aspects of a dealership are crucial to its success, one area impacts each of the others more significantly, according to Bob Clements.

“There’s nothing that happens in a dealership that the parts department doesn’t touch,” says Clements, president of Bob Clements International.

“The service department is the backbone, but the parts department is the blood that flows through the body,” says Clements.

“If I don’t have a good parts department, I’ve got a problem in my service department. My sales department flows through the parts department, too.

“The parts department is an integral part of everything that goes on in a dealership.”

One reason the strength of a parts department is so meaningful to the success of the entire dealership is the role it plays in customer relations.

“The parts department is the most highly visible, customer interactive part of a dealership,” says Clements.

He frequently reminds dealers that new customers who stop by the dealership visit the parts counter first — making the culture and processes of the parts department pivotal when it comes to turning new customers into returning customers.

Width Matters More than Depth

One customer retention strategy Clements advises dealers to embrace is focusing on width over depth in their parts department.

“The goal in a parts department is not to have a lot of volume, but to have a lot of width,” he says. “Shallow and wide is what we’re looking for in a parts department. I don’t need dozens of parts.

“If you can get parts in 3-4 weeks, do you need enough to keep going for 6 months? Not at all.”

“The service department is the backbone, but the parts department is the blood that flows through the body…”

Along with that, Clements wants parts department managers to worry more about their fill rate than their turns.

“We used to focus on turns,” he says. “This was the old way of looking at inventory. What’s more important today is not your turns — it’s your fill rate. You’ve got to know your fill rate of stocking inventory in your parts department. This is what keeps people from going someplace else.”

Clements tells dealers to strive for a turn rate of 1.5-2 per part, while their fill rate should be much higher than was previously thought necessary.

“If you’re an owner, go back and look at your fill rate,” he says. “If it’s less than 85%, I would look at selling down some of my parts volume because I don’t want to add any more dollars of parts to my inventory.”

It’s important to reduce item counts on parts that dealers have too many of for a 3-4 month period, according to Clements. That money can then be invested in SKUs that don’t get sold as often, resulting in an improved fill rate out of stocking inventory.

“I can have a better fill rate and not expand my inventory if I sell down some of my volume, take that money and spread out my SKUs,” Clements says. “If you spread out your SKUs, you’re going to have a lower turn rate, but I’m going to accept that because I’m getting a higher fill rate.”

Unique Demands Inform Stocking Decisions

None of that is to say that turn rate isn’t still important to the success of a parts department, Clements says. In fact, understanding each part’s turn rate is key to knowing when to phase a part in or out of the inventory.

“Three unique demands would tell me I should bring that part in as a stocking part,” he says. “Not selling the part 3 times on the same piece of equipment — 3 unique demands over a season.”

Properly checking in parts and having a defined process for the task is critical to the parts department’s success, according to Bob Clements. Photo: Lauren Harrigan

Part of understanding those unique demands, Clements says, is keeping track of lost sales.

“If you’re not keeping track of lost sales, how do you know what your demands are?” he says. “Even though I couldn’t fill it, it’s still a demand. Pretty soon you’re going to get to a point where you don’t have what people need, and you’re going to become the place that used to have everything but not anymore.”

On the other hand, if a part is only sold once a year, it’s probably time to consider phasing it out, Clements says.

“If it only sells once a year, most likely your shop uses it,” he says.

If that’s the case, it’s worth liaising with the service manager to determine whether or not to phase that part out of the inventory. However, if the service manager opts to keep it in stock, Clements says an important change must be made.

“When a part turns less, you have to move the margin up on it to offset the lack of turns,” he says. “We’re in business to make money. I can’t charge you 35% on the part and hold it for a year. I’m going to have to move that part to 50% to be able to justify holding it.”

It’s possible that price increase will ruffle the service manager’s feathers, causing them to opt to send the part back after all.

“That’s great,” Clements says. “We flex our margins on parts based upon turns. The more it turns, the less I need to make on it because I’m selling more of it. The less it turns, the more I need to make on it.”

Parts Support Specialist: Crucial Hire

Not only is it necessary that a parts department has a system for determining when to phase a part in or out, but that department also must have a process for checking in and stocking new parts, according to Clements.

In a lot of parts departments, he says, workers get slammed with a shop full of customers and forget to unpack and record the contents of a newly arrived box of parts. Then, when someone in the service department needs one of those parts, they’re likely to grab the part and take it back to the shop without remembering to make a note of it or tell the parts manager — leading to confusion when workers in the parts department start looking for a part they were sure they ordered but can’t locate anywhere.

“This is critical,” Clements says. “If you’re a parts manager, this daily stocking order has to be checked in and put away ASAP. The last thing you want is a service manager coming in and opening up your parts box and taking something out. Because as much as he wants to remember to tell you he took that out, a million other things happened after the time he took it out.

“It creates a breakdown in your process, and then it starts to escalate. So the process is critical.”

Define Your Process for Special & Emergency Order Parts

According to Bob Clements, these 5 questions need to be answered when determining what your process will be for special order parts and emergency orders:

- How is it paid for?

- How is it ordered?

- Where is it stored?

- How is freight collected?

- How is the customer notified?

To avoid this issue, Clements advises each parts department to hire a parts support specialist whose main job is to move the parts that have come to the shop.

“The first thing they do is look at all the parts that are backordered for the shop,” he says. “They go through that list and get them to you as soon as they possibly can. Next, they pull all the special order parts and call the customer to let them know their part is in. Then they can take all the other parts and put them away.”

A great candidate for this kind of job, Clements says, is a person with school-aged kids who wants to be at home when the kids go to school as well as when they come home at the end of the day.

“I like to find somebody who can work from either 9-1 or 10-2,” he says. “We find a lot of moms who love it because it fits their schedule. It gives them a ton of flexibility.”

Minimize Access to Parts

Not only can a parts support specialist help the parts department log and put away parts that have been delivered, but that person can also assist the department in other pivotal ways.

“They do cycle counts on your inventory once they’ve got all the parts checked in,” Clements says. “They’re doing cycle counting all the time, so I’m never stopping my parts department ever.”

Assigning a parts support specialist to unpack new parts before a member of the service department walks off with them is an important part of ensuring that parts are properly tracked, but it’s not the only necessary adjustment to the flow of a parts department.

“I am very restrictive on who gets to go back into the parts department,” he says. “It’s a pretty limited group. A manager can always go back — whether you’re a service manager, parts manager, sales manager, general manager, you have the right to go in the parts department because I know you’re going to keep track of stuff and do it the right way.”

However, when it comes to service technicians, Clements says it’s necessary to keep them from wandering into the parts department looking for items they might need.

“I can’t just have people walking back in the parts department, because ultimately what’s going to happen to my parts inventory?” Clements says. “It’s not people stealing parts, they just forget to write it down. Pretty soon it’s $15,000 of net profit you lost.”

Another simple change to the parts department that can prevent profits from diminishing is to restrict who can give discounts.

“Nobody at a parts counter should be able to approve a discount unless it’s the parts manager,” Clements says.

Otherwise it’s too easy for employees to offer discounts with a frequency that significantly impacts the dealership’s bottom line, he says.

Post a comment

Report Abusive Comment