While aerial application of pesticides is still utilized extensively, on-the-ground sprayers continue to gain favor for applying crop chemicals. In all likelihood, their use will continue to expand, especially with the introduction of newer precision technologies with the capability to reduce chemical usage through site-specific application methods.

Despite these possibilities, many experts in the field contend that even the best of the new developments for applying chemicals can’t overcome poor sprayer practices. Count Erdal Ozkan, professor and pesticide application technology specialist at the Ohio State University, as one who stresses doing the basics correctly before jumping on the precision spraying bandwagon.

He says there’s more to it than simply filling the tank. “Spray application requires more managerial decisions than any other farm operation because a lot of things could go wrong with a sprayer that you don’t know are going on. For example, a nozzle could be clogged and the only way you can find out is by calibrating your sprayer.”

With growing emphasis on reducing input costs, Ozkan says focusing on things like prepping the sprayer prior to use really is a matter of economics. “If a farmer is spraying more pesticides than he needs, he’s wasting his money. If he isn’t applying enough, he may have to go back and re-spray the entire field.”

For accurate spraying, operators need to check nozzle flow rate, boom height, spray angle and droplet size. Source: Ohio State University

And he believes dealers can aid their customers to hold down input costs by developing their own expertise in sprayer operations and stressing proper service and preparation. He suggests that dealers could provide their farm customers with a checklist similar to the one he’s developed to ensure that their sprayer will be operating at top efficiency when they get into the field.

1. Calibrate Often. “Not calibrating a sprayer frequently is like driving your car with a speedometer that doesn’t work. You assume you know what speed you’re traveling through habit, but you’re not really sure,” says Ozkan of Ohio State University.

“The problem with a sprayer is nozzles wear out with use, application rates change with different field conditions, and traveling speeds also change. Many growers don’t take these factors into account.”

Data from Ohio and other states indicates that only one out of every three or four applicators apply chemicals at rates that are within ±5% of the intended rates, according to the OSU professor. Application rates within ±5% represent the accuracy level recommended by USDA and EPA.

He adds that surveys also indicate that 67% of applicators who calibrated their equipment before every spray application had application errors below 5%. Conversely, only 5% of applicators who calibrated their equipment less than once a year achieved the same degree of accuracy.

“Frequent calibration is even more important with liquid applications because nozzles wear out with use, and that increasing the flow rate and leading to overuse of chemicals, which impact growers’ budgets and can lead to crop damage and contamination of groundwater and the environment,” Ozkan explains.

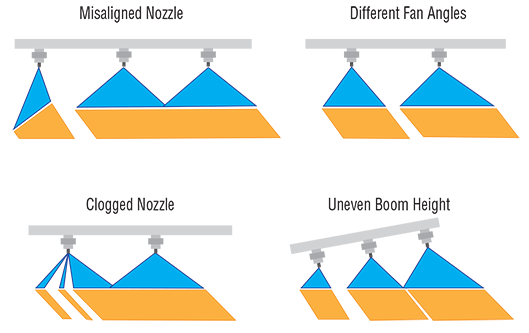

2. Use the Correct Nozzle for the Specific Job. “How the chemical is deposited on the target is as important as the amount applied,” says Ozkan. He suggests that dealers know what kind of nozzles are on their customers’ sprayers and whether or not their patterns need to be overlapped for complete coverage. Make sure the nozzles are not partially clogged. Clogging will not only change the flow rate, it also changes the spray pattern. Never use a pin, knife or any other metal object to unclog nozzles.

In addition to clogging, other things such as nozzle tips with different fan angles on the boom and uneven boom height are the most common causes of non-uniform spray patterns. These can all cause streaks of untreated areas that result in insufficient pest control, as well as yield and economic loss. (For more information on the newest nozzle developments, see pages 36-42 of this report.)

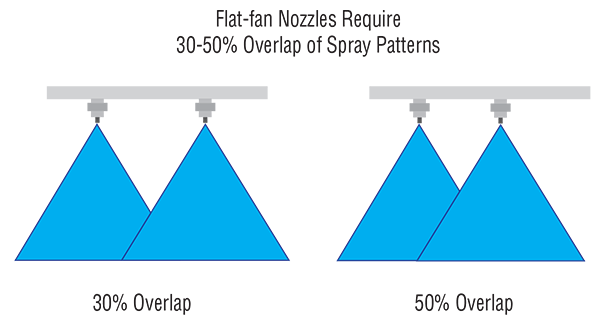

3. Set Proper Boom Height. Setting the proper boom height for a given nozzle spacing is extremely important in achieving proper overlapping, according to Ozkan. Conventional flat-fan nozzles require 30-50% overlapping of adjacent spray patterns. The easiest way to achieve this level of overlap is to adjust the boom height. Check boom height recommendations given by the nozzle manufacturers for specific for different nozzles.

4. Travel Speed is Critical. Ozkan recommends dealers remind their customers that it is imperative that they pay attention to the actual travel speed and keep it as steady as possible. “Increasing the speed by 20% may let you cover the field quicker, but it also cuts the application rate by 20%. Similarly, a reduction of speed by 20% causes an over application of pesticide by 20%, which is an unnecessary waste of pesticides and money.”

5. Pay Attention to Spray Pressure. Variations in pressure will cause changes in application rate, droplet size and spray pattern,” says Ozkan. “At very low pressures, the spray angle will be noticeably narrowed, causing insufficient overlap between nozzle patterns and streaks of untreated areas. High pressure will increase the number of drift-prone droplets.”

6. Spray Drift Wastes Money. In addition to possible environmental impacts, spray drift is expensive, according to the OSU spray technology specialist. “Don’t waste your chemical. After all, you have paid for it. Spray drift wastes more chemicals than anything else. Don’t spray when the wind speed is likely to cause drift. Don’t take the risk of getting sued by your neighbors because of the drift damage to their fields.

Keep the spray pressure low if it is practical to do so, or replace conventional nozzles with low-drift nozzles,” he advises. He also urges the use of other drift reduction strategies. These include keeping the boom close to the target, using drift retardant adjuvants, and spray in early morning and late afternoon when wind speeds are low and drift potential is less.

Other practical tips Ozkan recommends that dealers share with their sprayer customers include carrying extra nozzles, washers, other spare parts and tools to repair simple problems quickly in the field. And, above all, “Be safe. Read the chemical and equipment instructions and follow them. Wear protective clothing, rubber gloves and respirators when calibrating the sprayer, while doing the actual spraying and cleaning of the equipment.

Be well informed about the specific recommendations for a given pesticide, and follow the laws and regulations on pesticide application. Carefully read the product label to find out the specific recommendations,” he says.

Special Report Table of Contents

Can Application Technologies Reduce Ag Input Costs?

Three years of low grain prices are forcing farmers to minimize production costs. Developments in how they apply inputs will be an important part of growers’ cost cutting.

Making a Case for Curbing Spending on Inputs

Few signs point to a recovery in crop prices in the near term, which is making it imperative growers find ways to hold down costs.

What’s Trending in Ag Application Technology?

Developments in applying crop nutrients and pesticides have come fast and furious during the last decade. Many of the newest breakthroughs are aimed at ‘site-specific’ management of inputs, nozzles and individual nozzle control, and soil applications.