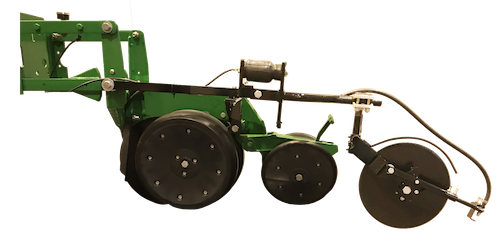

Steerable Track Kits from Gramlow Ltd.

Steerable track kits from Gramlow Ltd. will minimize pinch rows and keep your planter tracking straight. Complete bolt-on kits are simple to install right on the farm by the farmer. Tracks offer more than double the footprint of your 4 tires and only leave two tracks through the field. They will sometimes make up 4 times the surface area of the 4 tires on your planter. Use the steerable axle with GPS guided implement steering to keep your planter directly on top of strip-till strips, or keep guest rows perfect for post-emerge chemical or fertilizer application without driving on the rows. Axle spacing and track width options available to get you the kit that fits your needs.

Click here for more information.

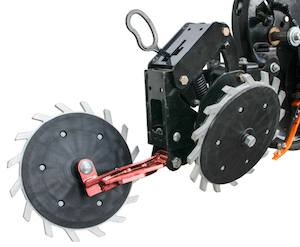

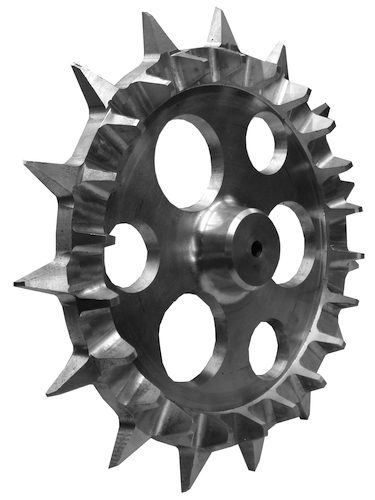

Yetter 6200 Closing Wheels and Chains

Yetter Farm Equipment’s Cast Spike Closing Wheel, Paddle Closing Wheel™, and Twister Closing Wheel ensure seed-to-soil contact by fracturing sidewall compaction, promoting even emergence after planting. The twisted-link Drag Chain and Drag Chain Shield are options that work with closing wheels, enhancing performance.

Click here for more information.

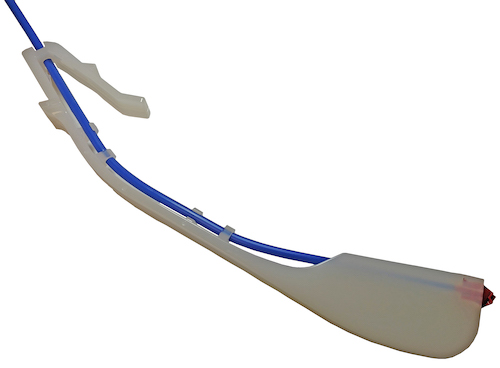

Yetter 2968 Row-Unit Mount In-Between Fertilizer Opener

The 2968 Row-Unit Mount In-Between Fertilizer Opener from Yetter Farm Equipment achieves consistent 2 or 3 inches off-the-row placement of starter, nitrogen and other fertilizers. This attachment now fits Case IH 1200 and 2000 Series row units. The 2968 mounts between the planter gauge wheel and planter firming wheels, allowing use of other attachments on the front of the row unit. The 2968 is available in single- and dual-wheel models. Also new for 2019 is the optional spring-loaded knife, which runs behind the 10-inch blade and is available on all models in place of the standard injector nozzle.

For more information, contact Yetter Manufacturing at 800-447-5777 or www.yetterco.com.

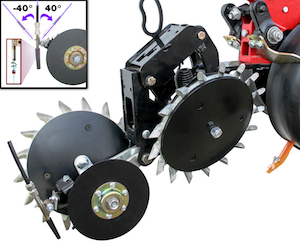

Pro-Stitch Closing Wheels

Pro-Stitch closing wheels were designed by no-tillers like yourself who needed to solve problems closing the slot and getting consistent seed-to-soil contact. Pro-Stitch closing wheels use a unique stitching effect to close the seed trench. They tuck soil firmly against the seed by stitching a seam and operate with minimum down pressure for any field condition to reduce sidewall compaction. Models are available for Deere, Case IH, Kinze and White planters; John Deere 50, 60 and 90 series drills; and Case IH PD500 and SDX series seeders.

Learn more at ProStitchAg.com.

Ag Express Electronics®

Find cost-effective solutions for precise, more profitable planting at Ag Express Electronics®. We offer rugged, reliable, maintenance-free flexible cable drive and clutch products from Elliott Manufacturing®. The systems fit a variety of planters and provide mechanical advantages without the need for additional power sources. Contact us for more information!

FlexSeeder™ is an easy replacement for Kinze® and John Deere® chain and sprocket drives.

Row Control™ provides individual row shutoff for John Deere planters with Pro-Shaft™ drives.

Surface Drive™ adds a mechanical drive system to Precision Planting vSet® seed meters.

GroundControl™ is a simple and improved replacement for John Deere RowCommand™.

Visit AgExpress.com for more information.

Schaffert Mfg. G2™ Notched Liquid Fertilizer Disc

The G2 applies larger quantities of nitrogen fertilizer behind the planter, 2-4 inches to the side of the row. The 9-inch smooth single disc opener adds only 11 pounds per row, and can be replaced with the NEW fine-tooth notched disc to cut through heavy cover crop residue better. The G2’s patented walking-beam design places balanced pressure on both press wheels, and even depth of fertilizer in uneven terrains. The low/high pressure fertilizer bracket and boot pivots so you can control where the fertilizer is injected and help eliminate fertilizer on the row unit. The G2 fits most planters.

Click here for more information call 800-382-2607.

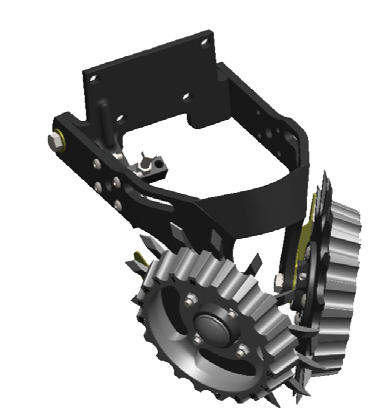

Schaffert Mfg. 4 Link Closer™ Closing Systems

Standard swing arm tail sections allow only 4 inches of travel up and down. Schaffert’s 4 Link Closer offers up to 9 inches of travel, keeps the closing wheels parallel to the seed trench at all times, eliminates planter bounce in the field, lets you run less down pressure, enables faster planting speeds, gives more even depth control and better seed-to-soil contact for even emergence. The 4LC fits most double disc opener planters and comes with ground attachments for V closing wheels, the G2™ fertilizer disc and the NEW G3™ walking beam arm. The walking action of the G2/G3 arms closes the seed furrow better and helps eliminate air pockets.

Click here for more information or call 800-382-2607.

Ace Pump Gemini™ Dual Pump Kit

The Gemini dual pump kit allows a user to operate two Ace Pumps independently from a single hydraulic supply and control them manually or with a PWM (pulse width modulated) control signal. The Gemini kit is designed to control any combination of Ace’s popular FMC-HYD Series pumps powered by our 204 and 206 motors. Once installed on a planter or sprayer, it allows operators to quickly and easily dial-in separate application rates for liquid fertilizers, herbicides, pesticides and other crop inputs.

The Gemini dual pump kit is designed for use on tractors with either load-sensing, closed-center (LS closed) or pressure-compensated, closed-center (PC closed) hydraulic systems. Oil may be supplied from one selective control valve (SCV) or the power beyond hydraulic supply. The kit includes everything needed for manual operation including a switch box, wiring harness, hydraulic valve manifold and fittings. The system may also be controlled automatically using PWM control signals from the customer’s controller to the included proportional valves.

Click here for more information.

Cruiser Closing Wheels from Copperhead Ag

The Furrow Cruiser and Cruiser Xtreme closing wheels from Copperhead Ag products offer farmers an option for absolutely every planting condition. The wheels have angular teeth that will break up sidewall compaction and close the furrow. The width of the wheel will help with firming of the soil around the seed and will prohibit the wheel from flipping out any seed, even with shallower planting depths. This combination of aggressiveness and control, combined with a unique ability among closing wheels to resist mud and plugging, make these tools the go-to option for all corn and bean growers. Visit www.CopperheadAg.com today to learn more.

Click here for more information.

Copperhead RK Products Line of Planter Repair Parts

The proven RK Products line of planter repair parts is now backed by the full sales and manufacturing team of Copperhead Ag Products! The gauge wheel arm and closing wheel arm repair kits not only fix any amount of wear on a row unit, but they stop the wear in its tracks, allowing for years of dependable service from your RKP Kits. If you are tired of wear parts that need constant replacing, fix your row units for good by visiting www.CopperheadAg.com today!

Click here for more information.

Compact Clean Ride™ Row Unit from Martin-Till®

When it comes to row cleaner performance, the patent-pending Martin-Till® Compact Clean Ride™ (CCR) unit proves you can pack a lot into a little space. As the most compact floating row cleaner on the market (measuring less than 14 inches from the face mount plate to the front of the unit), the CCR delivers superior performance when coupled with the Martin-Till® Smart Clean™ bi-directional air cylinder adjustment system. Its compact design allows for fitting on planters with nitrogen coulters or where full-size row cleaners can’t be used due to planter folding and unfolding issues. Parallel linkage delivers easy floating action, especially when paired with Smart Clean™ cylinders. Plus, its factory pre-assembled chassis saves time and makes it a cinch to install.

To learn more about the Martin-Till® Compact Clean Ride™ row cleaner and how it can fit into your planting program, visit www.MartinTill.com or call 800-366-5817.

Planter Upgrades from Moeller Ag Service, Inc.

David Moeller enters his 30th year as the No. 1 planter setup and maintenance supplier, having helped thousands of farmers with no-till planter and attachment repairs and upgrades through quality Martin-Till products. We can custom-build, maintain and repair your no-till planter based on your operational needs with Martin-Till row cleaners, liquid fertilizer knives, reduced-inner-diameter gauge wheels, closing wheels and drag chains. We also offer the Precision Planting 20/20 touchscreen display and data management system. Call us at (319) 698-4005 to discuss upgrades to your no-till planter before the 2019 production season.

Click here for more information.

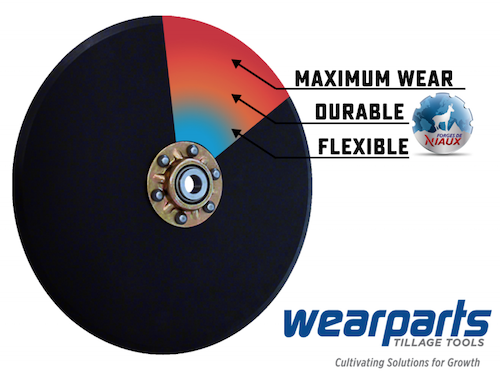

Wearparts’ Seed Openers

Longer Wear, Leading Performance. Having undergone a patented heat-treating process to harden steel, Wearparts’ Seed Opener achieves 30-40% longer wear than competing openers. Its high-hardness along the blade allows this opener to retain a sharp cutting edge and maintain accurate seed placement. Its high-performance and ability to outlast leading competitor products, lowers user’s cost-per-acre. Wearparts’ Seed Openers are assembled with a Forges de Niaux 200 Blade. Created with high-grade, quality steel, this opener fits nearly all brands of planter and drill applications and is protected with a lifetime warranty on breakage.

Click here for more information.

Sabre Tooth Disc Opener Maximizes Seed-to-Soil Contact

The PTT Sabre Tooth Planter Disc Opener is designed to cut, rotate and flow moist, granulated soil on top of seed placement for maximizing seed-to-soil contact, regardless of soil type or weather conditions. This can speed up early even-emergence, root development and enhanced soil-to-seed contact while lessening sidewall and sub-furrow compaction.

The design of this planter disc opener creates a leading blade effect for better penetration and residue-cutting. The Sabre Tooth disc opener lifts and fractures sidewalls, aiding easier closing of the seed furrow with standard OEM equipment. The Sabre Tooth eliminates the need for a leading no-till coulter assembly.

Call S.I. Distributing at 800-368-7773 or click here for more information.

Finger-Till Closing Wheel Earns Beck’s 2018 ‘PFR Proven’ Status

Closing wheels are important in establishing a seedbed as they crumble sidewalls and close the furrow for optimum seed-to-soil contact.

Beck’s 2018 PFR indicated that aggressive closing wheels, like the Finger-Till Closing Wheels, increased yields and emergence. The Finger-Till earned the status of Beck’s “PFR Proven.”

Regarding corn, the Finger-Till Closing Wheels ranked #1, with a +4.8 bushels per acre difference, in the closing wheel study at the Iowa, Indiana and Central Illinois PFRs.

Regarding soybeans, the Finger-Till ranked #1, with a +2.2 bushels per acre difference, in the closing wheel study at the Kentucky and South Illinois PFRs.

Call S.I. Distributing at 800-368-7773 or click here for more information.

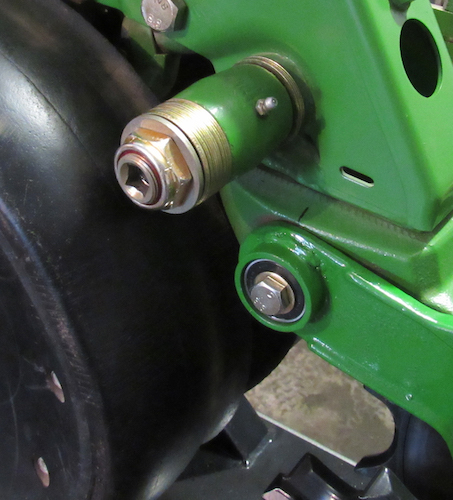

Parallel Linkage Flanged Bushing Rebuild Kits are Better than New

Precision Planter Solutions offers a solution that will make old and worn parallel linkage arms and bushings better than new.

With these new flange bushings, there is no longer any wear on parallel linkage arms. This is accomplished by installing a hardened flange bushing in the arm that can be replaced. A threaded hex bushing and a special shoulder bolt fixes the flaws of the OEM design by eliminating any wear on the parallel linkage arms.

Everything is replaceable, and your row unit will be better than it was when new. It keeps the bushings and parallel linkage arms tight.

Call S.I. Distributing at 800-368-7773 or click here for more information.

Keeton Seed Firmers Have a Proven Average of 6-Bushels Increase in Corn Yield

Uneven seed germination and uneven plant emergence sap yields. Plants coming up even a little late can’t compete with their neighbors for resources and they’re vulnerable to heat stress and insects. Keeton Seed Firmers set the seed at the right depth and create consistent seed-to-soil contact. That leads to uniform germination and uniform emergence. Studies have shown that leads to an average increase of 1,000 more ears of corn or six bushels per acre in corn yield.

Keeton Seed Firmers offers money-making advantages for your drill too. Field trials show that Firmers make you money with reduced seed costs.

Call S.I. Distributing at 800-368-7773 or click here for more information.

Soucy S-TECH 012P

Soucy S-TECH 012P tracks can easily be fitted on John Deere 1770NT and 1775NT planters from 12 to 24 rows without any modification. By using Soucy tracks, John Deere planters benefit from a better soil contact surface — a surface five times as large as that for tires. In addition, reduced ground pressure allows users to increase greatly their productivity while loading their equipment up to the maximum load capacity. Tracks for corn planters increase flotation, reduce soil compaction and preserve soil structure. As a result, with more aerated soil, crops benefit from better rooting and growing conditions.

Click here for more information.

Hawkins Planter ‘NForcer

The Hawkins Planter ‘NForcer allows for accurate position and precise placement of key starter and pop-up fertilizer. Pneumatic down pressure and a 14 inch beveled blade allow operation in all field conditions including no-till and the position adjustments to fit strip-till needs. Horizontal adjustments of up to 8 inches allow a setting to fit various field terrains and farming practices. Left and right row unit mounting options compensate for multiple planter configurations in all primary models. Rearward mounting of the fertilizer disc allows proper planter operation and residue flow, resulting in precise fertilizer placement out of the residue path and “In the Clear.” Accuracy is key for fertilizer placement and the Hawkins ‘NForcer™ hits the mark.

Click here for more information.