Cummins engines power agricultural equipment from some of the world's finest manufacturers. For over 60 years, Cummins has been at the forefront of the industry, delivering the most durable and dependable powertrain solutions from 60 hp to more than 800 hp. From irrigation systems and sprayers to combines, harvesters and more, there's a Cummins engine perfectly suited to help you get the job done, even in the most challenging environments. Visit cumminsengines.com or tweet us @cumminsengines for more information.

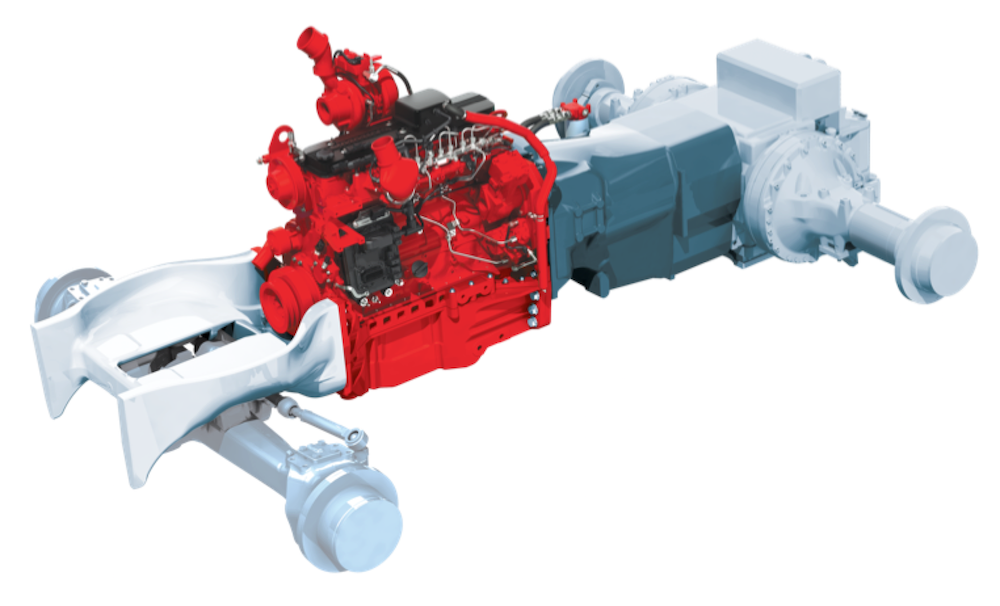

One of the biggest surprises at Agritechnica 2017 was Cummins unveiling of its new B6.7 engine — fully integrated into a structural driveline designed for agricultural tractor use.

Eric Neal, Cummins Executive Director – Off-Highway Business, said: “Cummins has been a successful supplier to the agricultural industry for many years, with approximately one million engines in operation around the world. Structural capability has now been designed into the B6.7 engine, the latest version of the renowned Cummins B Series, and it is the first of its type in the company’s portfolio for some time.”

The launch of the B6.7 structural engine has been aligned with that of the company’s Performance Series, which brings key product benefits to agricultural customers in both structural and non-structural applications.

“Designed for flexibility, with configurations available to suit a variety of tractor installations, the B6.7 structural engine minimizes weight while maintaining structural strength. Its adaptable design has already attracted the attention of a number of agricultural equipment OEMs, particularly as it uses only a structural oil pan rather than the more common structural pan and block configuration. In addition, the structural concept can be applied to a variety of Cummins engine sizes based on customer requirements,” added Neal.

Like the whole Performance Series, Cummins structural B6.7 engine integrates key in-house technologies to deliver operational benefits, including exceptional power density, responsiveness and fuel-efficient performance achieved through a Holset VGT Turbocharger. Cummins electronic controls expertise has enabled the company to tailor engine performance for on-farm conditions, with the power bulge and torque back up needed for agricultural tractor operation.

In addition, the B6.7 engine utilizes Cummins latest Single Module aftertreatment technology, which offers a space envelope savings of up to 50% and is up to 30% lighter than its Tier 4 Final predecessor. The higher NOx conversion efficiency enables the required level to be met without the use of Exhaust Gas Recirculation (EGR) while also removing 99.9% of all Particulate Matter (PM) by weight and count.

“Engine envelope differences between the latest Performance Series and Tier 4 Final products are minimized in our design. This reduces complexity for OEMs in their manufacturing processes. With no EGR, the high sulfur fuel tolerance of up to 5,000 parts per million (ppm) adds to this global capability,” concluded Neal.