Omaha, Nebraska, January 3 — Claas of America Inc. has won recognition from the American Society of Agricultural and Biological Engineers (ASABE) for ag industry innovation. For the seventh consecutive year, Claas received awards showcasing its capacity to deliver product and systems technology that advance agricultural engineering.

The AE50 awards program annually honors 50 companies or products for innovative engineering in the areas of agriculture, food and biological systems. Products are judged on specific criteria; they must provide the most profound technology in their industry, improve user safety and benefit producers by saving them time, money and labor.

2011 awards were presented for the following Claas products:

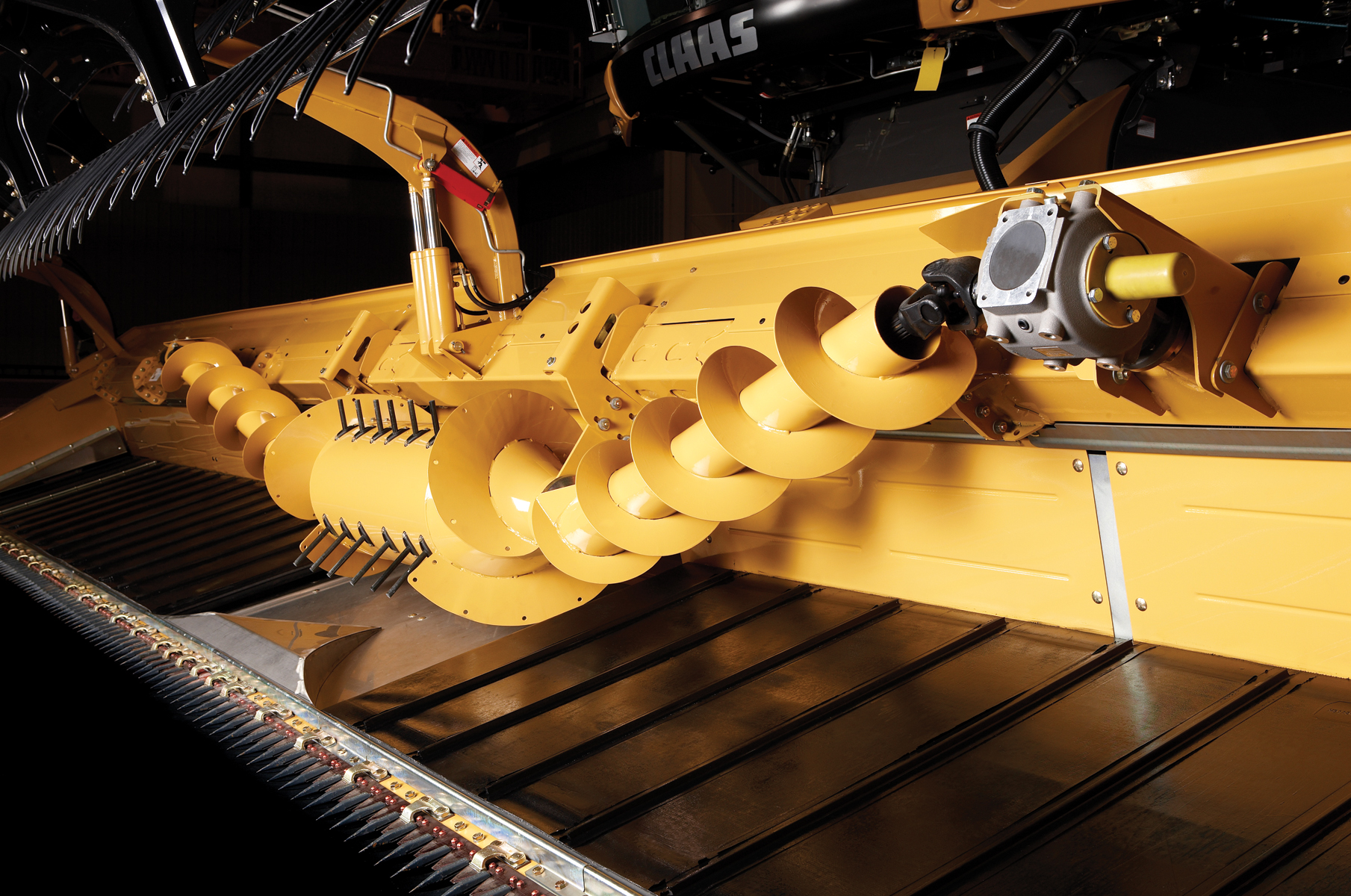

MaxFlo 1200 draper head – The MaxFlo 1200 is a 40-foot draper head equipped  with compression augers to positively feed cut material to the combine without the added complexity of a center-feed belt (draper) and adapter. With no center adapter, the header can be mounted closer to the combine improving visibility and lessening travel distance of material between the cutterbar and feederhouse intake. The compression augers hold material to the surface of the side conveyor belts to ensure continuous positive feeding into the stationary, contoured center floor section. The contour of the stationary, center floor section directs material flow into the header’s center feed drum, as supplied by the side belts (drapers) and compression augers, and on into the combine feederhouse for processing.

with compression augers to positively feed cut material to the combine without the added complexity of a center-feed belt (draper) and adapter. With no center adapter, the header can be mounted closer to the combine improving visibility and lessening travel distance of material between the cutterbar and feederhouse intake. The compression augers hold material to the surface of the side conveyor belts to ensure continuous positive feeding into the stationary, contoured center floor section. The contour of the stationary, center floor section directs material flow into the header’s center feed drum, as supplied by the side belts (drapers) and compression augers, and on into the combine feederhouse for processing.

The Terra Trac stationary center floor also acts as a catch basin to capture and collect potentially harmful foreign objects traveling within the material flow and prevent ingestion by the combine. A six-sensor digital auto-contour terrain sensing system maintains a safe and consistent cutting height in all ground conditions. Belt (draper) speed is operator controlled to optimize material flow pending conditions. Additionally, the side belts (drapers) can be reversed from the cab to assist in clean-out and/or to dislodge obstructive material or objects.

Terra Trac – Terra Trac is a suspended-track undercarriage with independently suspended rollers. A hydropneumatic suspension system of hydraulic cylinders with integrated accumulators connect to their respective roller system (rear driver, front idler, and oscillating mid-rollers) enabling them to respond independently to uneven or changing terrain in order to maximize machine ride stability and operator comfort while minimizing ground pressure and disturbance to the soil structure. An automatic (hydraulic) belt-tensioning system maintains continuous belt tension for consistent performance and durability. The stability of the new Terra Trac undercarriage supports higher road speeds, up to 40 kph (25 mph) (750 TT only), minimizing the time required for road transport and improving the ratio between engine hours and fieldwork hours for an improved return-on-investment.

The Terra Trac system replaces the generation II Mobil-Trac System (MTS), which utilizes a mechanical linkage interface between the track undercarriage and the axle and contains shock absorbers to dampen the effects of changing terrain.

Claas Telematics – The Claas Telematics system is a management tool that  collects all important operational data of a self-propelled harvester and transfers it to a web page to give the owner unlimited access using just an Internet connection. Telematics helps analyze the efficiency of the harvester, displays all settings, and offers a wide range of management tools like live remote GPS tracking, GPS tracing, direct machine comparison, live settings, yield monitoring and mapping, and checking the status of machine maintenance. For custom operations, Telematics offers an easy way to log and collect data for invoicing and cross compliance purposes. Telematics also includes the capability of remote service and diagnostics so that the service partner can remotely connect to the harvester and diagnose problems to reduce service technician travel time and machine downtime.

collects all important operational data of a self-propelled harvester and transfers it to a web page to give the owner unlimited access using just an Internet connection. Telematics helps analyze the efficiency of the harvester, displays all settings, and offers a wide range of management tools like live remote GPS tracking, GPS tracing, direct machine comparison, live settings, yield monitoring and mapping, and checking the status of machine maintenance. For custom operations, Telematics offers an easy way to log and collect data for invoicing and cross compliance purposes. Telematics also includes the capability of remote service and diagnostics so that the service partner can remotely connect to the harvester and diagnose problems to reduce service technician travel time and machine downtime.

Disco 3900 TC center pivot mower conditioner – This 12 ft. 6 in. trailed unit incorporates the new Active Float hydraulic flotation system. The Active Float provides the suspension for the mowing cutterbars to float and follow the ground contours in the field. This Active Float can be adjusted to increase or decrease the pressure to make the cutterbar lighter or heavier during operation. The heavyduty cutterbar is protected with Safety Link, which protects the cutterbar from internal damage when the cutterbar comes in contact with external objects. The Quick Knife system allows for quick removal of the knives. The full-width tine conditioner maximizes dry down, facilitating the hay in a day practice or a narrow windrow for other markets.

Orbis 635 row independent corn head – The Claas Orbis 635 is a specially designed header to harvest row distances of both 0.8-m (30 in.) and 1-m (38 in.). The header can gather seven 1-m (38-in.) or eight 0.8-m (30-in.) rows of corn, milo, or forage sorghum while allowing the forage header to run its tires in-between rows and furrows. The most innovative feature is a unique center gathering drum, allowing harvest of one 1-m (38-in.) row exactly in the center of the machine as required by the grower. The Orbis 635 allows for a smoother crop flow and consistent stubble height as most headers are designed to fit only 0.8-m (30-in.) row applications. The Orbis 635 complements the range of Orbis headers by using many common parts.

Post a comment

Report Abusive Comment