The pursuit of higher crop yields and healthier soils is pointing farmers in the direction of cover crops. The 2015-16 Cover Crop Survey conducted by the Conservation Technology Information Center and Sustainable Agriculture Research & Education revealed that average acres of cover crops per farm have more than doubled over the previous 5 years. Additionally, cover crops increased corn yields by an average of 3.4 bushels per acre, while soybeans increased by approximately 1.5 bushels per acre.

Results of the 3rd Annual Strip-Till Operational Practices Benchmark Study conducted by Strip-Till Farmer in 2016 showed that more than half of strip-tillers responding to the study are planting cover crops to conserve moisture and reduce erosion. It showed 53.3% of respondents were using cover crops, up from 48.4% in 2014 and 44.1% in 2013. “Nearly 65% of those reporting using cover crops, say they are planting cereal rye,” says Jack Zemlicka, managing editor of Strip-Till Farmer. “That’s up more than 4 percentage points over 2014 figures.” Other popular cover crops with strip-tillers were tillage radishes (50.2%) and rapeseed (21.8%).

USDA is also supporting its use by incentivizing farmers to plant cover crops. From 2005-13, agency funding for cover crops through the Natural Resources Conservation Service’s Environmental Quality Incentives Program (EQIP) increased ten-fold — from about $5 million to more than $50 million in nominal terms.

Cover Crop Challenges

The biggest problem for farmers wanting to utilize cover crops is getting started. According to the Cover Crop Survey, cover crop establishment was the No. 1 “Major” challenge reported among cover crop users, at 32%. Time and labor required for seeding and managing the cover crop came in third at 31%.

Also, in some areas of the U.S., particularly in northern states, there may not be enough time to get cover crops seeded after harvest to achieve decent cover crop growth before winter.

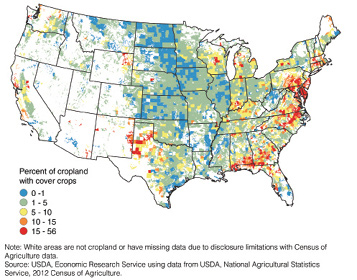

Distribution of Cover Crops in the U.S.

A practice that farmers and ranchers are adopting to build or restore soil health is cover cropping. Farmers plant cover crops or cover-crop mixes between plantings of cash crops, usually in the winter. Reasons for planting cover crops include reducing erosion, preserving soil moisture and increasing organic matter. Common cover crops include cereal rye, clover and annual ryegrass.

Cover crops are not harvested and so do not provide revenue for a farmer, although sometimes farms get direct value out of a cover crop through grazing their livestock on it. The use of cover cropping is concentrated in the southern and eastern U.S. Regional differences in the adoption of cover cropping are related to differences in climate, regional agricultural markets and state incentive programs. For example, Maryland has relatively high rates of adoption because of a program that pays farmers to grow cover crops in order to improve water quality in the Chesapeake Bay.

Depending on a farmer’s goals, climate, row widths, cover-crop species and even herbicide programs, interseeding covers — the practice of seeding them with a drill, spinner spreader, toolbar or sprayer into an established and growing cash crop — is often the solution.

As the use of cover crops continues to expand, so will the demand for specialized equipment needed to seed them at a time that’s most advantageous to achieve their intended purpose. This trend could represent a solid equipment sales opportunity for dealers ready to take on the challenge.

Evolving Equipment Needs

In many cases, growers have had to figure out what would work for them by experimenting with various interseeding techniques and equipment set ups.

The need for predictability is what led Loran Steinlage to interseeding covers on his no-till and strip-till farm in West Union, Iowa. “Airplanes are too unpredictable,” he says, “and the drill after harvest is too late.”

Six years ago he took a spinner box and seeded his covers by hand, down 6 corn rows while the corn was still small and growing. Since then he’s gone through 6 different toolbars he’s modified for interseeding. Now he’s using DawnBiologic’s DuoSeed Cover Crop Inter-Seeder row units on a rig he built to interseed annual ryegrass and clovers into corn at the V4-V6 stage, which he says is the ideal time for his area.

Despite the changes in equipment and associated costs, Steinlage says the cover crops are paying their way. He reports an average 15 bushel increase in the current corn crop and soil organic matter levels average 3-5%, with some field areas climbing up to 6% and 7%.

“Growers have had to figure out what works for them by experimenting with various interseeding techniques…”

Allen Dean of Bryan, Ohio, had a similar experience to Steinlage. He first tried interseeding cover crops with a helicopter later in the summer, thinking it would do a decent job of distributing the seed. When he found that wasn’t the case, he decided to have an airplane fly on his seed and did that for several years. But he still wasn’t happy with the results.

“In our area there are a lot of homes, odd-shaped fields and trees,” he says. “And we just knew that if we had a ground rig, we’d do a better job of distributing and getting the seed exactly where we wanted it.”

Today, Dean and his family run a custom interseeding business with a Miller Nitro cab and chassis with a front-mounted boom modified into an inter-row air seeder, and he says the seeding rates and establishment from it are near perfect.

Mildmay, Ontario, no-tiller Gerard Grubb is in his third year of interseeding cover crops and has noticed an increase in soil tilth and improved soil structure. For his northern location, interseeding is the only way he can get a cover crop established. He tried seeding annual ryegrass after soybean harvest one year, but says it was too late.

Matching Equipment to Needs

Once a grower determines interseeding timing and cover crop species, choosing equipment for application is the next step, but at this point, choices are somewhat limited.

After his third year of interseeding, Ontario no-tiller Gerard Grubb has noticed an increase in soil tilth and improved soil structure from the annual ryegrass he’s interseeding into his corn. For his location, interseeding is the only way he can get covers established on time.

If the option is available, hiring someone with an interseeder to custom seed cover crops may be an option. Mike Werling, a no-tiller in Decatur, Ind., says his custom applicator uses a Hagie sprayer with a Valmar air seeder and drop-down tubes to seed the covers in between the corn rows.

Grubb is also using a Valmar 3255 air seeder, which he mounts to his AGCO Spra-Coupe 4455 sprayer. He says he’s modified the unit so he can take the tank off and mount the Valmar on in a few hours.

Originally he was using a Flexi-Coil air cart on the back of his sprayer to experiment with interseeding, but he didn’t have any control on the seeding rate, prompting him to invest in the Valmar seeder.

“The other thing is I was driving a big tractor and air cart through the field and we have to be primarily concerned with the crop in the field,” Grubb says. “If you hit cornstalks and run some plants over, it’s going to hurt your yield.

“With the Valmar unit on my three-wheel sprayer, I’m seeding a lot more rows more accurately and more evenly.”

Dean and his family modified the Miller sprayer so it could variable-rate seed their cover crops, allowing them to bump up their seeding rate on slopes and areas more susceptible to erosion.

The seeder also has a scale, Dean says, which allows them to double check that the Miller Nitro is seeding the cover crops at an accurate rate.

Ontario no-tiller Gerard Grubb used an AGCO Spra-Coupe 4455 sprayer with a Valmar 3255 air seeder to interseed his cover crops. Originally he was using a Flexi-Coil air cart, but he didn’t have any control on the seeding rate. He says the Valmar seeder lets him seed more rows accurately and evenly.

Steinlage has been modifying and experimenting with different seeding equipment every year since he started interseeding, including a Hiniker drill that he adapted for twin-rows and using drop tubes on his toolbar.

Last year Steinlage modified DawnBiologic’s DuoSeed Cover Crop Inter-Seeder on a Dalton toolbar that he ran with a Hiniker box to drill soybeans, then switched the Hiniker for a Montag to interseed covers and sidedress nitrogen.

“It’s working phenomenally,” he says. “We drilled soybeans and urea with it, and did all of our sidedressing with it. We then switched right over to interseeding cover crops.”

Steinlage is planning on running the DuoSeed Cover Crop Inter-Seeder again next year but hopes to add a Montag Gen II nutrient metering system on the machine so he can seed cover crops and apply urea at the same time.

“I’m trying to eliminate passes, but I’m also trying to get the most out of one piece of equipment,” he says.

Dealer Developments

Gary Fennig is a farmer and a shortline-only equipment dealer in Coldwater, Ohio. His company developed the FE4R system for fertilizer application and cover crop seeding using a Hagie highboy sprayer. He says the system was designed to do just that — allow growers to utilize their sprayer for more than just spraying. Adding the system to the Hagie high-clearance sprayers allows growers to interseed their cover crops and apply dry fertilizer.

“There are a lot of companies trying to come up with the best way to do interseeding,” he says. “This is just one way a farmer can utilize what he has already.”

Iowa no-tiller and strip-tiller Loran Steinlage went through several different iterations of interseeding equipment and now says his DawnBiologic DuoSeed Cover Crop Inter-Seeder (right) is working “phenomenally,” noting he used it last year to drill soybeans (left) and urea, sidedress nitrogen and then interseed covers. He typically sees a 15 bushel increase in that year’s corn yields where he interseeded annual ryegrass with clovers into them at the V4-V7 stage. The yield increase alone is making the cover crops pay for themselves, Steinlage says.

He says Fennig Equipment has tried seeding cover crops both around sidedress time and toward the end of the growing season, and both methods get the job done. “That’s the whole background of the interseeding process — getting the cover crop established before harvest so you have something there over the winter,” he says.

According to Adam Fennig, Gary’s son, the unit is “basically a high clearance seeder” that’s made to attach to various sprayer models and is capable of 120 foot application widths.

He says dealers handling interseeding equipment need to dig some to determine what the farmer needs for his specific operation. “It has everything to do with their goals.” For example, Adam explains, if the grower intends to use annual ryegrass, it has to be established early. “The only way to do that is with a high clearance machine and by interseeding. You can’t try to get it started post harvest.”

Wes Liebrecht, a sales representative for Fennig Equipment, adds, “Inter-seeding with our highboy machines gives growers a longer cover crop growing season. This exponentially increases the benefits of cover crops such as deeper roots, nutrient retention, more water infiltration, and more growth, providing more winter hardy cover crops for the northern states.”

Customer Goals & Experience

Both Adam Fennig and Liebrecht agree that the choice of equipment is completely dependent on what the grower wants to achieve with cover crops. And this shows in the various ways farmers are seeding it, when they seed and the types of covers they’re using. “There are so many ways guys are doing it, there’s no one catchall that will fit every grower’s needs. Our equipment fits with what a lot of guys want to do, but it’s not right for everyone. We plan to introduce a combine seeder at the National Farm Machinery Show. The dealer needs to know his customer’s goals before suggesting a seeder. ”

In many cases, the dealer may have to spend time educating farmers who have not worked with cover crops or had a poor experience getting them established previously. “There’s a learning curve. Some just blew it on the ground and didn’t get a very consistent stand that first year, so it might take more than that to do a good job,” says Liebrecht. “They’ll also have to understand they need to watch for herbicide issues.”

He explains that if they’ve applied an herbicide to their cash crop and it was still active, it could prevent the cover from getting established. In these cases, they may have to modify the timing to interseed or the amount of the herbicide to accommodate establishment of the cover crop.

If Adam Fennig were to offer advice to other dealers considering offering interseeding equipment to his customers, he says, “Be open to all these new ideas. You’ll probably have to come up with the some new ideas as well. Think outside of the box to tackle your customers’ unique situations.”

In other words, as the use of cover crops continues to expand, there’s still much to learn, and interseeding cover crops is one of those practices that is evolving and changing the more that’s come to be known about their effective use. But one thing does seem certain; As farmers look to get the most out of the acres while reducing passes through the field, interseeding will be one of applications they’re going to use.

October/November 2016 Issue Contents