In 2014, the Hale Group conducted research for Iowa, including a lot of information on row-crop agriculture. In a survey of 400 Iowa farmers, one question stood out to dealers: Who do you go to when you want to learn about new products and services?

Equipment dealers were at the bottom of the list.

Most dealers, whether they realize it or not, have a marketable niche and it is a key part of growing business. For any dealer, the first step is knowing who is in your market and how you are targeting them.

According to dealers participating in a panel at the 2019 Precision Farming Dealer Summit, dealers who are most successful with their marketable niche are so because they are working to show the customer the value in the product or service. This is accomplished through conducting research, creating personalized solutions and showing ROI.

Matt Miller | Product Specialist

Butler Ag Equipment, an 18-store Challenger and AGCO dealership across North Dakota, South Dakota and Nebraska

www.ButlerAg.com

Jason Leary | Ag Technology Manager

Crystal Valley Co-op, a 14-location farm cooperative serving south central Minnesota and northern Iowa

www.CrystalValley.coop

P.J. McCullough | Precision Ag Sales Specialist

McCullough Implement, a single store Kubota dealership in Watseka, Ill.

www.McAgPlus.com

Butler Ag Equipment’s AGCO Crop Tour

Butler Ag Equipment wanted to expand on its new planter sales and one of their value points was in White planters, which have precision planting components. In 2016, Butler Ag Equipment joined up with AGCO to do a crop tour centered around those planters.

AGCO would get a plot, bring customers out and show the value the planter has to the customer. At the end of the field events, customers get real, personalized data that includes planter ROI and plot results.

“We do in-season field events and we’re spot on as far as what we saw as bringing value to our customers,” says Miller.

To show the value of the different planter components Butler offers, they decided to work with farmers in the area. “We said, ‘If you give us 10-20 acres of ground that we can do a plot on, we’ll let you plant all of your corn with our planter at no cost,’” he says.

This agreement gave Butler 20 acres of land to show the value in the planters they offered. They did so by setting a field day and bringing customers out to see the plots, what the yields were and the ROI.

Crystal Valley’s ROI-Based Field Research

In 2016, Crystal Valley Co-Op set up a 100-acre research farm with two-thirds on a corn/soybean rotation while the rest is corn-on-corn trials. This meant the co-op could go to harvest knowing the previous crop and the soil fertility, giving them the ability to capture accurate data to take to harvest, explains Jason Leary, Ag Technology Manager.

“We found that when we were relying on farmers to put on trials or on a 20-acre block somewhere, we were actually only getting about 25% of the data at the end of the year,” he says. “Between planting date splits, hybrid splits and crop rotations, there’s a lot of factors that came into plat that didn’t allow us to get all the data.”

The research farm started as a way of testing agronomy products but, due to customer demand, it expanded into a number of other areas including planter components, starters and planter closing wheels. Customers are able to drive through research plots to see results in the field. Crystal Valley also holds a meeting to present its year-end data, ROI numbers and where they found value.

For Leary and the rest of the Crystal Valley team, the field tests and local research are not about seeing which customers are taking notes; it is about letting customers know the company is doing the work. The point of the research is so that when the customer needs to make a decision on something, they go to the dealership to get that information.

“What we’re trying to do is provide data that the sales agronomist and customer can sit down with and make decisions on without us necessarily giving them a recommendation,” says Leary.

Being an unbiased middleman is the role Crystal Valley wants to play for customers. They want customers to see value in the research and that comes from it being done locally in the customer’s backyard and using their soil types, he says.

Butler Ag Equipment’s VRS Network

To better work with their niche market, Butler Ag Equipment decided to work on its RTK base network because it had limitations. “We wanted to bring in an affordable, reliable and flexible RTK correction source with benefits and growth for our customers,” says Miller.

Miller and the rest of the team at Butler sought a solution with an acceptable ROI, better data management capabilities and the ability to adapt/integrate it into other technologies. The solution also needed to be something the dealership could growth with, expanding into other revenue streams.

The solution came from Midstates VRS (Virtual Reference System), a network of stations that provide RTK quality corrections via cellular connection. Butler partnered with Frontier Precision to build the network, which allowed them to put base stations into their territories and use software to network them together. Doing this provided full coverage to customers and allowed them to use it for RTK.

Referring to a 2014 Hale Group survey, Matt Miller, product specialist with Butler Ag Equipment says dealers have to do a better job being customers’ trusted advisor.

“Anyone with RTK correction needs that has sufficient cell coverage simply connects via a cell modem or Wi-Fi hot spot for a personalized signal, specific to their location without the hassle of setting up a base station or radio,” says Miller.

VRS is subscription based and Butler has seen improvements year after year. The bonus about it being subscription based is the service brings in recurring revenue and new customers. According to Miller, other benefits in the system the dealership has seen include having full accuracy within the VRS network and the ability to scale it based on the

customer’s needs.

Crystal Valley’s N-Sight & Crystal Vue Platform

Crystal N-Sight was launched in 2017. With this platform, Crystal Valley flies a drone over fields to provide a NDVI image to the farmer. Then they overlay organic matter, elevation and yield histories on the image and sit with the farmer and agronomist to create a personalized prescription for side-dress application, Leary says.

“At the end of the day, they’re the ones writing the check and they have to be comfortable,” he says. “They are the ones making that decision on that farm. We’re just trying to help them make the best decision possible.”

Point was to find a balanced, personalized service. Many computer-generated Nitrogen and seed prescriptions are fast and easy but lack personalization, according to Leary.

The Crystal Vue platform has a MSP3 unit used to map EC organic matter and soil pH on the go. This gives them a soil map with an accurate pH, allowing them to correlate factors directly to yield.

“There’s a lot of intangibles with precision ag services that you can’t measure,” says Leary. “It’s important in some portion of your precision program that you have a way you can put a value to what you’re bringing to the table.”

The dealers on the panel offered up some of their best tips for mastering a marketable niche.

These included:

- Have touchpoints. Texts, calls and visits are important in connecting with your market and creating a relationship that has value.

- Know your target market and what your options are in that market. It is important to think about what products can be sold that go beyond the mainstay ones of the dealership.

- Take reasonable risks.

- Be consistent. Sharing the same message can be impactful.

- Make allies. This means forming relationships with agronomists, seed dealers, extension people, etc., because it helps round things out to create more of an impact with customers.

Doing these things and sharing the results help to tell the customer that there is value and that the dealer is someone they can turn to.

How McCullough Implement Determines ROI for the Customer

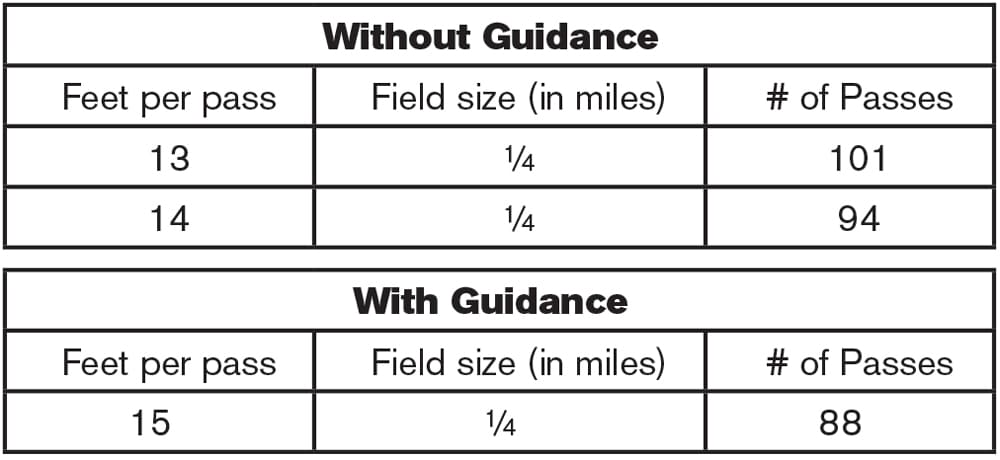

To figure out return on investment, P.J. McCullough, McCullough Implement, Watseka. Ill., looked at small acreage farmers and the ways they could get greater ROI with the use of guidance systems. “We were going to see if we could try to pay for that guidance system and how fast we can ROI pay for it,” says McCullough.

Cost of Equipment

Outback Guidance Rebel Display $2,495

Outback E-Drive XD $3,495

Total Cost of System $6,990

McCullough used the Outback Guidance system in this experiment because McCullough Implement is an Outback dealer. With the cost of the system in mind, McCullough worked to see how long it would take to pay for that system.

To answer this, he set up an 80-acre field and ran a 15-foot no-till drill on it with and without guidance.

Seed Savings in the Field

101 vs. 88 = 13% savings

94 vs. 88 = 7% savings

Split down the middle = 10% savings

Seed Savings (in acres) = 50 acres

McCullough also crunched the numbers on planting 500 acres of soybeans and then seed a cover crop. The numbers he used to determine cost were based on Iowa State University

rental data.

Drill Cash Crop $18.50 per acre

Cash Crop Seed $75.00 per unit

$18.50 x 50 = $925

$75.00 x 50 = $3,750

Cash Crop Savings $4,675

Drill Cover Crop $18.50 per acre

Cover Crop Seed $27.00 per unit

$18.50 x 50 = $925

$27.00 x 50 = $1,375

Cover Crop Savings $2,300

Total Savings for Year $6,975