The end-user, whether it be the cow or the cattle feeder, is becoming more important to hay and forage producers, and because of that, the equipment in the hay meadow is changing.

“Forage vs. baleage is the trend I’m seeing,” says Gary Berger, sales and marketing director for Edney Distributing Co., a machinery distributor serving the upper Midwest. “I see both sides of this equation getting a lot more attention, whether you’re chopping forage and putting it in a silo or baling it.

“The newest things are ways to improve windrowing a crop. Customers are increasingly sophisticated in their demand to maintain feed value in their crop and they’re moving away from raking with wheel rakes in favor of mergers or rotary rakes and basket rakes,” he explains. “That way you can gather the crop without additional contaminants.”

Research shows rotary rakes and basket rakes rank extremely high in producing low-contaminant hay, when compared with wheel or finger rakes.

John Deere’s Mark Pavcik, Hay, Forage & Livestock production system manager says relative feed value (RFV) of alfalfa leaves can range from 500-600, while similar results for stems can easily fall below 100.

“There is very little nutritional value in the stems for a cow to make milk,” he says. “That’s why it’s so important to reduce leaf loss wherever possible, from hay harvest to feeding.”

Addressing the ‘Haymaker’s Dilemma’

Do I cut for quantity or quality? Do I cut now, or take a chance that the 20% chance of rain will jump to 40%? Once I’ve harvested hay, how do I get it dried down as quickly as possible to be able to bale it in a quality fashion and get it stored properly? Will there be enough dew tonight to bale without shattering precious leaves? How do I get all of my hay crop in, when there’s only me and maybe another hand to help? How do I have a life with my family and friends and still produce hay for a living?

Equipment makers big and small are responding to those questions every year with innovations, inventions and improvements to existing hay tool designs.

This spring we visited with several manufacturers who are introducing products that address the various questions of the Haymaker’s Dilemma because they know hay’s worth is directly tied to feed value.

This report shows some of the new products aimed at improving the flexibility of haying and maintaining the quality of hay as it is cut.

University studies in the western U.S. show dairy cattle can produce up to 4 pounds of milk per day more on optimum rations made from high RFV alfalfa hay, when compared with hay of lesser RFV.

“At John Deere we’re developing equipment for the entire production system of harvesting crops including cutting, conditioning, raking, baling and feeding. We don’t pinpoint one machine, but consider all the steps. We want to preserve as many leaves as possible, because that’s where the nutrition is. For cattle farmers, it is all about the cow, and for alfalfa — it is all about more leaves in the feed,” he explains.

Hay and forage quality begins to fall as soon as the harvester contacts the standing crop and continues to deteriorate because of mechanical damage, plant respiration and environmental conditions until the feed is consumed.

“Loss from plant respiration is relatively small when the crop is dried quickly under good field conditions, but under slow drying conditions it can add up to 7% of the crop dry matter (DM),” says C. Alan Rotz, USDA-ARS ag engineer in University Park, Md. “When rain damage occurs, the resulting losses can range from 30-90% of the crop’s DM.

“Mechanical losses increase as more machinery operations are used,” Rotz says. “For instance, a raking operation can reduce an alfalfa crop yield by 5% with some of this loss being the more nutritious leaves.”

Similarly, any field operation that causes leaf shattering is steadily eroding the worth of the hay. In many cases, the overall moisture of harvested hay when it is windrowed, fluffed or raked has a direct bearing on how well leaves are retained.

Berger also says the trend toward maximizing production for row crops is beginning to affect hay and forage producers as well. “Land and labor are expensive, so the more value you can retain and sell through the final product is very important to today’s forage producers,” he explains. “There’s so much more interest in baling high moisture hay or chopping it and putting it in the bunker because it’s just more efficient use of farm resources to produce a higher value crop.”

Moving Toward High Moisture Hay & Forage

Part of that move also can be traced to growers moving toward technology that increases the flexibility in harvest timing — namely cutting higher moisture forage when it can be harvested and retaining it in bags or wrapping.

“Hay and forage quality begins to fall as soon as the harvester contacts the standing crop…”

“With balers equipped with wrappers, forage producers are more in charge of their own destiny. The design of new balers has changed considerably and growers are taking advantage of that,” Berger says. “Where we used to sell bale wrappers and wrapping supplies mainly in Wisconsin and Minnesota, we’re now selling far into North and South Dakota, an area traditionally known for dryland hay making.”

Berger also says as more growers move to higher moisture forage products, they find the need to change balers, particularly because of the increased weight of high-moisture baleage.

“A 5 x 6 foot baler had been the standard in our country forever,” Berger says. “But now, with forage and high moisture hay, a 5 x 6 machine is just not suitable. Growers are opting for a better made 4 x 4 foot bale with a machine that is designed to handle high moisture forage.

“Some of this is also attributable to new baling and packing technology which decreases air pockets and provides a more densely-packed bale,” he explains.

Cole Carling, Hay and Forage manager at Case IH, says local traffic regulations are also affecting bale size in some areas.

“The 5 x 6 foot baler is the most popular size sold in North America,” he says. “But, in some states they don’t sell this size baler because you can’t put two bales on a trailer side-by-side because it’s too wide.”

Precision Technology for Haying Operations

Carling says another trend is the move to more precision in the hay meadow. “I see a significant move, particularly for the big commercial hay guys, to auto-guidance. Farmers want the same precision in the hay business as they have for their row-crop operations.”

“You have to drive a windrower straight for the most efficient field work. With auto-guidance you just snap an AB line and the machine drives itself,” he explains.

Carling says modern precision agriculture systems offer growers the ability to take their guidance equipment off the combine or tractor and put it on their haying equipment. “With a Class III ISOBUS, you have speed rate control and the baler can send messages to control the tractor and keep engine and baler speed at the proper levels for the most efficient operation,” he explains.

“Also, for night baling, after a few hours the operator may not be as sharp or wide-awake. With this system operating speeds and fuel efficiency are maintained by the machine. You get more productivity and more consistent bales.”

McHale’s Fusion Baler/Wrapper Combo

McHale’s Fusion 3 baler/wrapper combination, a popular European design, makes baleage a portable — easy to sell — cash crop. Also the technology is popular with growers with smaller cow herds who want to produce and store their own high quality forage. Photo Courtesy of Edney Distributing Co.

Krone Comprima Baler/Wrapper

“Hay makers never know what side of the bed Mother Nature is going to get up on,” says Brent Raines, northern region product manager for Krone North America.

“The increasing use of baleage by farmers and ranchers is a change I’m seeing. Long practiced in Europe, the use of plastic-wrapped high moisture forage is becoming increasingly popular in the U.S. as growers face increasingly unpredictable weather,” he explains.

“In late May some of our customers in Ohio faced a 60% chance of rain when they started their day, only to see forecasts drop that percentage to 20 by midday, and then saw the evening weather report put the chance of rain at 40%,” he says. “Growers throughout the country face this kind of uncertainty, and the heavy rains many faced last season forced them into dealing with baleage to feed their cows.”

As the winter show season progressed, Raines says he noticed increasing numbers of questions about baleage to skirt the uncertainties of the weather. He also noted the increasing use of cover crops — tillage radishes, clovers, rye and others — also are offering growers new opportunities to take additional forage as baleage options.

“Everyone’s trying to do more with less, and in an unpredictable window, so they want to shorten haying from a week’s work to a couple of days and they’re looking at plastic wrap as the way to do it,” he explains.

Raines says Krone’s Comprima CV150 XC baler/wrapper allows one operator with one tractor to make wrapped bales on the go. “We used this combination at a recent field day in Columbia, Mo., over a 7 day period,” Raises explains. “During that week, only 2 days were without rain and the machine ran every day.” Photo Courtesy of Krone NA

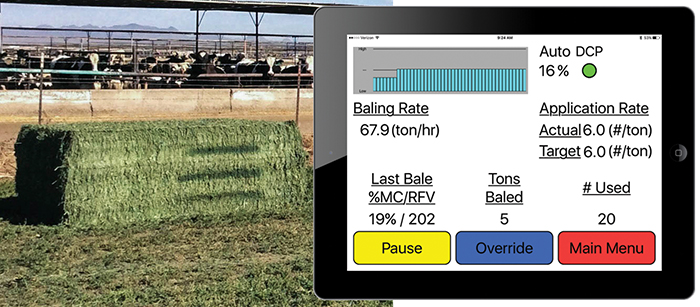

AGCO’s RFV Calculator

AGCO’s new HayBoss G2 RFV Calculator is a software package downloaded into the company’s HayBoss G2 Preservative Application System and allows a producer to calculate the relative feed value of a given bale of hay based on bale weight and moisture content, says Dean Morrell, strategic marketing manager for hay and forage.

“Hay feeders must identify hay quality to mix accurate and balanced rations,” Morrell explains. “Our RFV Calculator gives hay producers the ability to monitor and record variations in moisture and quality as they bale their forage. Tests show the Hay Boss G2 system and bale weight scale is accurate to plus-or-minus 2% for bale weight and for RFV.

“It’s not uncommon to find 30-40 points of variation in RFV from bales in one field,” he says. “With the RFV Calculator, the producer can monitor those changes and automatically mark and sort bales according to low, medium and high RFV calculations. Being able to track and record those changes is critical to knowing the value of your hay and being able to represent it to end users.”

In Utah State University studies involving 542 bales, the RFV Calculator accurately correlated with core sample analyses taken on the bales and sent to two separate laboratories, according to Morrell. “In another test of 3,000 bales from 8 farms, the RFV Calculator also correlated with lab results on a wide range of RFV samples.”

The AGCO RFV software also allows individual bales to be tagged, using a tagging system, with a radio frequency identification (RFID) tag as to field location, moisture content, bale weight and RFV calculations, to enable the producer to provide “field-to-customer” information with a simple RFID scanner, he says.

“Individualized RFV calculations and easy bale identification can help hay producers store and sort hay for themselves and customers in an efficient manner, as well as provide a way for producers to collect premiums for various hay lots that meet or exceed the needs of feeders,” Morrell adds. “From the feeder’s standpoint, knowing the RFV of hay allows much better precision in mixing rations for optimum animal performance, or for feeding lesser-performing animals less-expensive forage. Either way, producers and feeders can benefit.” Photo Courtesy of AGCO

Staheli West Dewpoint Steamer

Staheli West is marketing its DewPoint 6110/6210 system, a diesel-fired, low pressure boiler unit that adds steam to the hay windrow to reduce leaf shattering by as much as 50%. Marketed mainly through Case IH and AGCO dealers, Staheli West has sold more than 260 steamers for large square balers in the U.S. and Australia — and not just in low humidity, low moisture areas like the Western U.S.

Justin McArthur, marketing manager and communication director, says the steamers are being used mainly from Texas to southern Washington, but increasingly in the Midwest and eastern U.S. “We have a customer in Pennsylvania using one of our machines in conjunction with preservatives. He adds steam even when it’s wet,” he explains.

“Dave Staheli built the first steamer in 1995 to enable himself to bale dry alfalfa in Utah without shattering the leaves. The technique worked and he began redesigning the machine until he perfected the current 6110 design in 2009,” McArthur explains. “Today, we’re building the 6210 steamer and we’re developing similar smaller design II and III Series machines for 2 and 3 string balers.”

The DewPoint machines can add enough steam to bring the moisture percentage of a windrow up 4-5%, McArthur says. “It depends on where the hay is when you start. A lot of growers market their hay for export and start with about 8% moisture, but they don’t want to go over 11%. They use our machines to adjust that humidity to their market conditions.”

An added benefit, and one which McArthur says has begun to sell even more DewPoint machines, is growers don’t have to wait for the rising humidity of nightfall to bale.

In 2014 Staheli West staged a 72 hour round-the-clock baling marathon on a number of cooperator farms and knocked out 4,500 large square bales with one tractor, one baler and one 6110 steamer. All the bales contained consistent moisture, despite being baled throughout sunny days with winds that provided negative humidity readings, and during nights with natural dew moisture.

“People are realizing by adding moisture, they have the control of their crop now to bale in the dry afternoon, still preserve leaf contents and have their evenings with their families,” McArthur explains. “One of our customers had a machine for about 3 years. He bought a new 5,000 acre farm and three more steamers. When the hay is ready, he hays non-stop until it’s done.

“He says, ‘We don’t bale hay. We grow hay … it always has to be cut and cured, but when that’s done you can bale it when you want with the steamers.’”

McArthur says another advantage of using steam in the windrow is that bale density can be increased by 20-25% if desired, while baling at higher speeds. “Increased bale density allows more tons of hay to be stored under valuable barn space and fewer bales are needed on trucks to reach legal weight limits.” Photo Courtesy of Staheli West

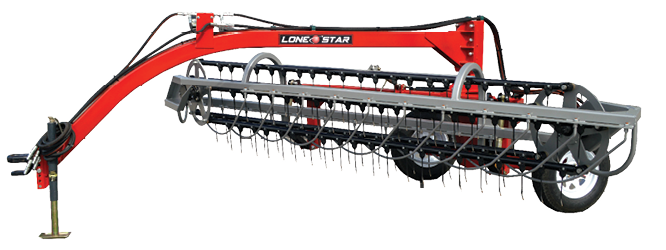

Lonestar Single Basket Rake

Northstar Attachments is introducing the single-basket Lonestar hay rake to complement its twin-basket Twinstar rakes that have provided quick hay handling and, ultimately cleaner hay bales for a number of years.

“This smaller-design basket rake is aimed at smaller acreage growers, but it incorporates the proven design Northstar has enjoyed with the larger, traditional Twinstar rakes,” says Dave Rankin with Northstar Attachments. “The Twinstar rakes provide uniform windrows and the cleanest hay on the market,” he says.

“Research shows a significant reduction in dirt, rocks and debris in hay handled with a basket rake, along with less leaf loss, when compared with hay gathered with many other types of rakes. We’re bringing that technology to growers with smaller farms.”

The new unit features hydraulically-driven rubber mounted tines to allow the operator to match the basket and ground speed to the crop conditions for consistent windrows that dry faster. Offset wheels follow ground contours and baskets can be hydraulically raised if needed to avoid obstacles. Also, the basket is wider than competing models and its angle of operation can be adjusted if necessary, Rankin explains. Photo Courtesy of Northstar Attachments

How Component Design, Materials Can Improve Hay Tool Performance

Improving the relative feed value of hay is the highest priority for producers today. This makes being able to get into and stay in the field during peak conditions critical for producing the highest quality forage. Besides weather, machine reliability can be the determining factor in making hay while the sun shines.

No one feels this pressure more than the custom operator. This means there is a need for tighter tolerances as their machines are run harder for longer periods. The demanded life cycle of these machines is also being extended.

Pequea Machine manufactures a wide range of rakes, tedders and other hay tools. As demands on its customers increase, Pequea engineers are now specifying machined castings rather than multi-piece weldments. According to Jim Westlake, Pequea’s engineering manager, the cast part represents a more dimensionally consistent component with tighter tolerances, which means more durability and precision in machine operation.

Reducing welding means tighter tolerances are possible between parts. The new design means the tolerances tightened from 0.060-0.005 inches. This precision means less wear in the field and longer component life.

One recent example of innovative component design that is demonstrating improved performance of its TT-4100 TurboTedder is the development of inner and outer pivots as a single austempered ductile iron (ADI) casting vs. a two piece steel weldment.

Austempering is a type of heat treatment that allows inexpensive, domestically sourced ductile iron to replace steel in many demanding applications where the strength and properties of steel had been required.

In the case of the outer pivot, the original design meant 25 individual pieces of steel were welded together to make the final part. In the case of the inner pivot, 23 pieces were welded. Reduction of part numbers allows for fewer opportunities for dealer stock-outs and quality problems, according to Applied Process Inc., the company that provides the austempering service.

According to Westlake, the pivot design will be used on all of Pequea’s 4, 6 and 8 rotor machines, as well as on upcoming 10 and 12 rotor machines. In addition to reducing part numbers and improving performance of the tedders, it also reduces costs, he says. Photo Courtesy of Pequea Machine

Post a comment

Report Abusive Comment